Additional material rotating worktable with circular cooling function

A rotating table and circulating cooling technology, which is applied in the direction of additive processing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of low cooling efficiency, difficulty in continuous supply of cooling water, and affecting manufacturing efficiency, so as to improve cooling Efficiency, the effect of guaranteeing process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

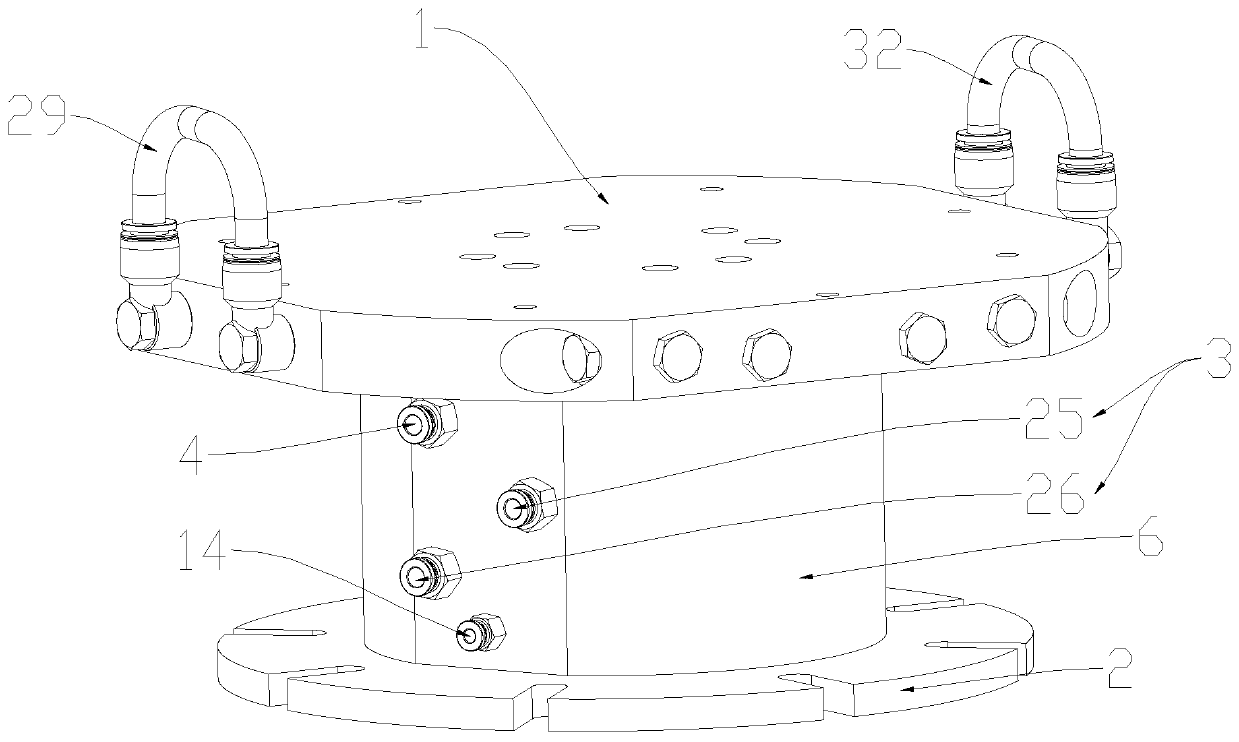

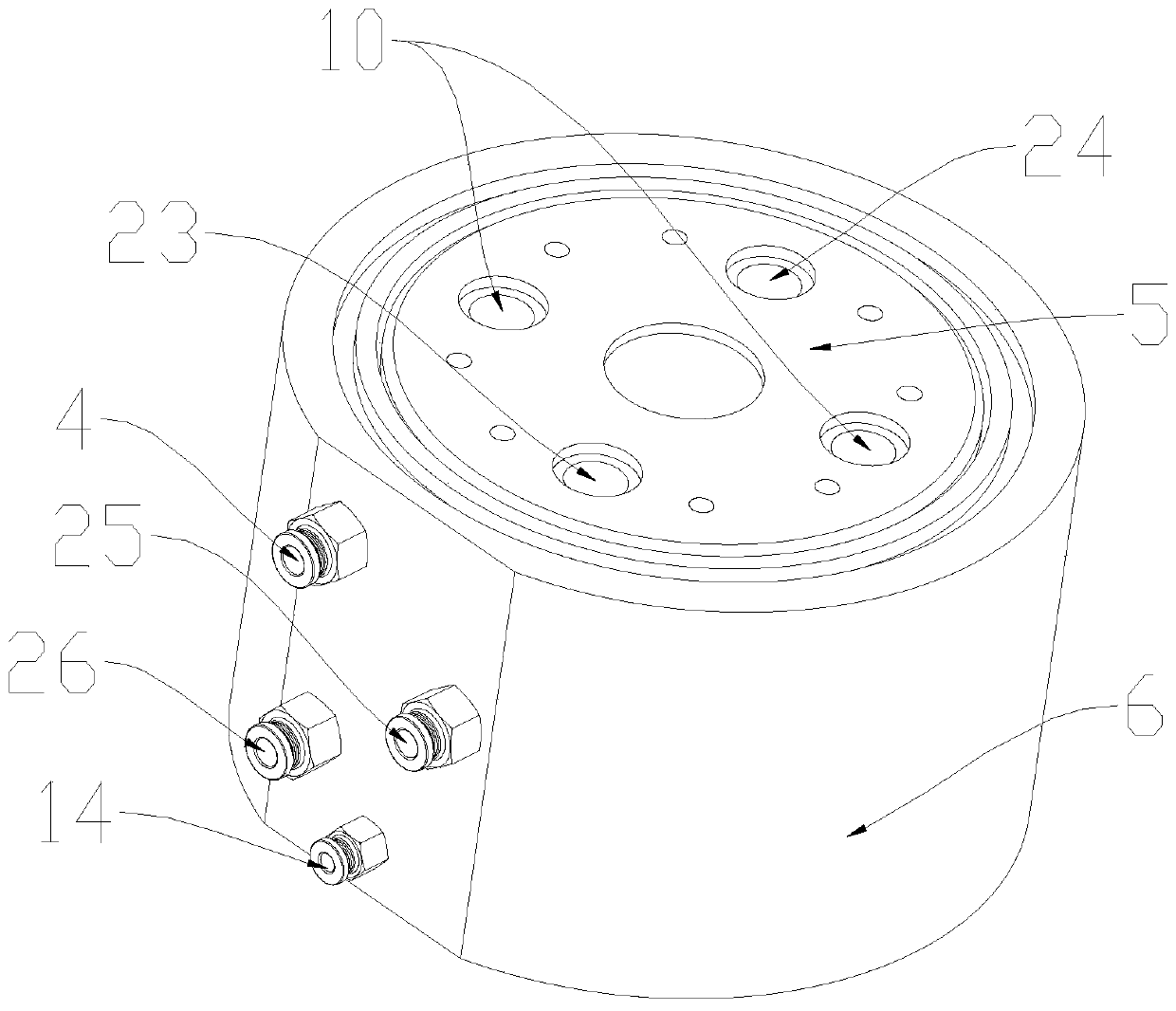

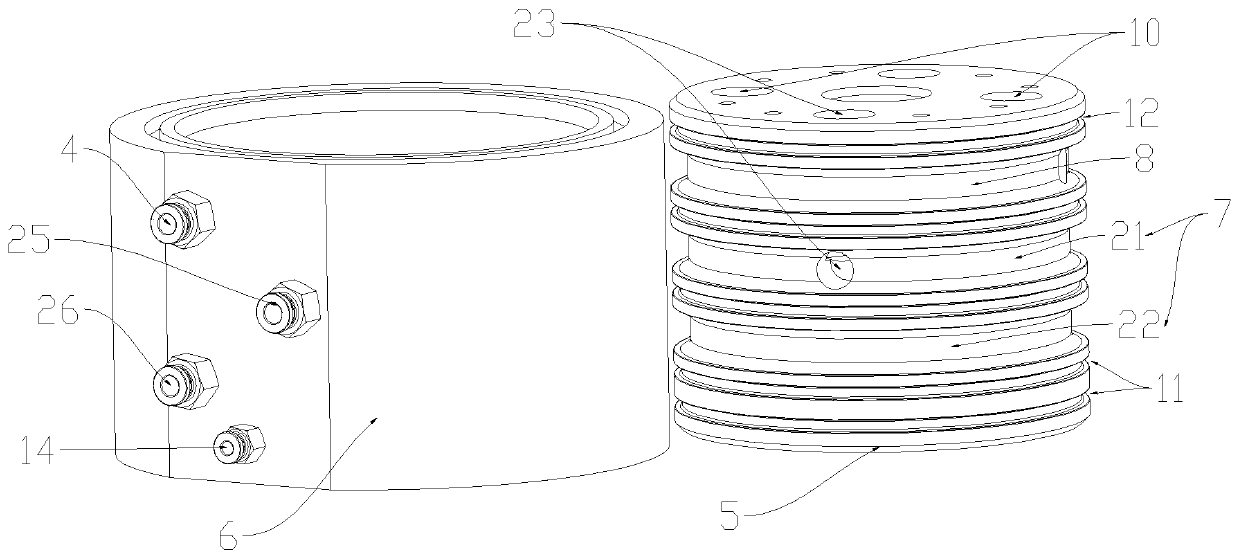

[0034] see Figure 1 to Figure 9 , an additive rotary table 1 with a circulating cooling function, including a rotary table 1, a rotary sealing shaft, and a base 2 connected to an external rotary drive device, wherein the external rotary drive device is generally a drive motor of an additive device or The power output mechanism controlled by the driving motor, such as a reduction box, etc., the top of the rotary sealing shaft is connected to the rotary table 1, the bottom of the rotary sealing shaft is connected to the base 2, and the rotary table 1 is provided with a cooling circuit for the flow of coolant, wherein the cooling circuit For the circulation channel opened by the deep hole processing technology, the cooling liquid inlet 3 and the cooling liquid outlet 4 are arranged on the rotating sealing shaft. The cooling liquid inlet 3 is connected to the cooling liquid outlet 4 through the cooling circuit. During the additive printing process, the workpiece The heat will be ...

Embodiment 2

[0046] This embodiment is the same as embodiment 1 except the following content: see Figure 10 , also includes a wall-attached cooling device, the wall-attached cooling device includes a liquid inlet pipe 33, a liquid outlet pipe 34, a thin steel strip 35, and several heat-dissipating copper blocks 36 that are close to the outer wall of the workpiece 41, and some heat-dissipating copper blocks 36 are fixed by screws Mounted on thin steel strip 35, see Figure 11 and Figure 12 , the heat dissipation copper block 36 has a cooling channel 37 for the circulation of cooling liquid, one end of the liquid inlet pipe 33 is connected to the inlet of the cooling channel 37, and the other end of the liquid inlet pipe 33 is connected to the first serial connection inlet 27 or the second serial connection inlet 30, and the outlet One end of the liquid pipe 34 is connected to the outlet of the cooling passage 37, and the other end of the liquid outlet pipe 34 is connected to the first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com