Robot-based intelligent warehouse management method and device and storage medium

A warehouse management and robot technology, applied in computer-readable storage media, in the field of intelligent warehouse management based on robots, can solve the problems of unsatisfactory, imperfect system structure, high labor cost, etc., and achieve the effect of intelligent automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a robot-based intelligent warehouse management method.

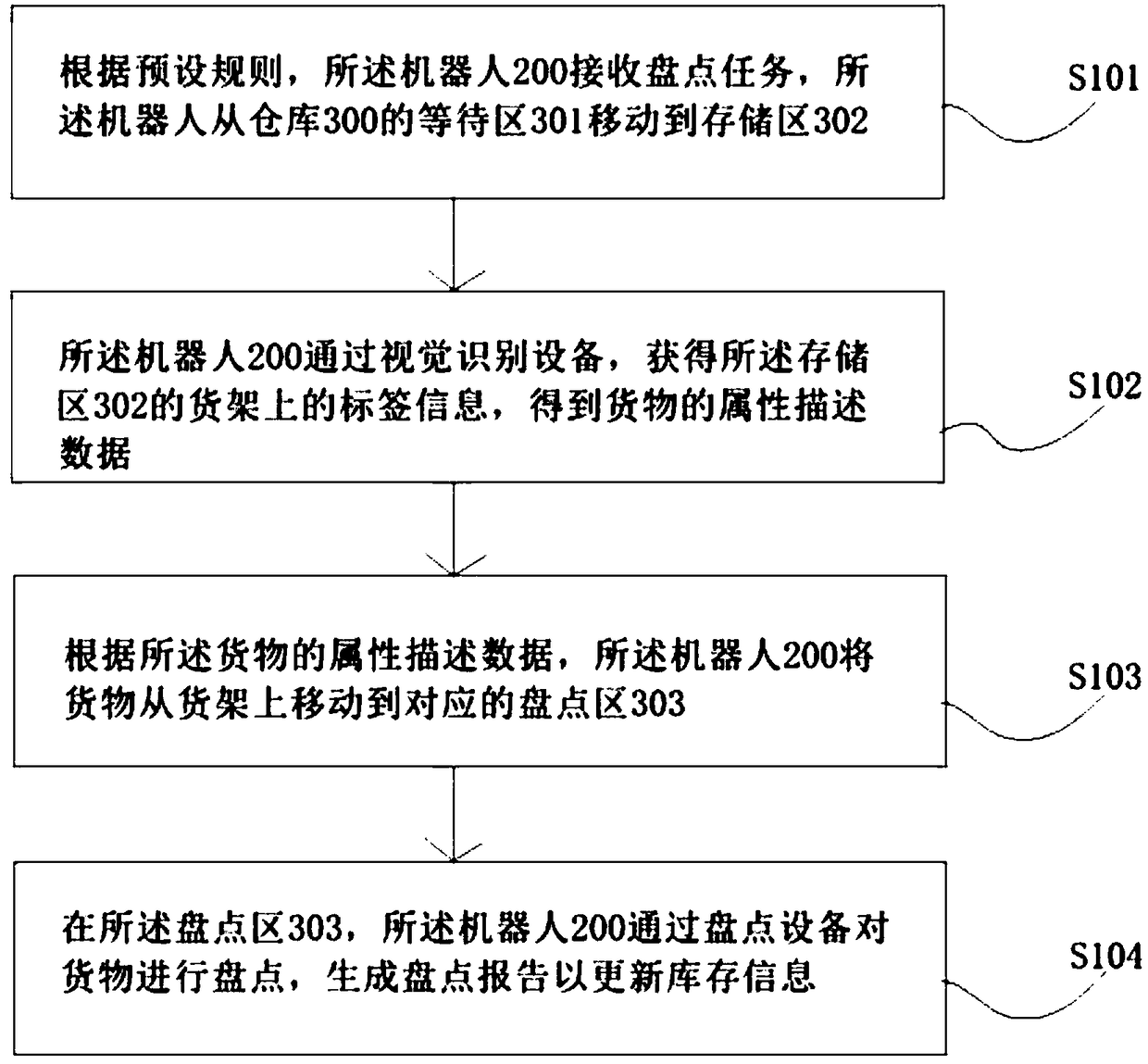

[0029] Please see figure 1 , figure 2 as well as image 3 , the robot-based intelligent warehouse management method includes:

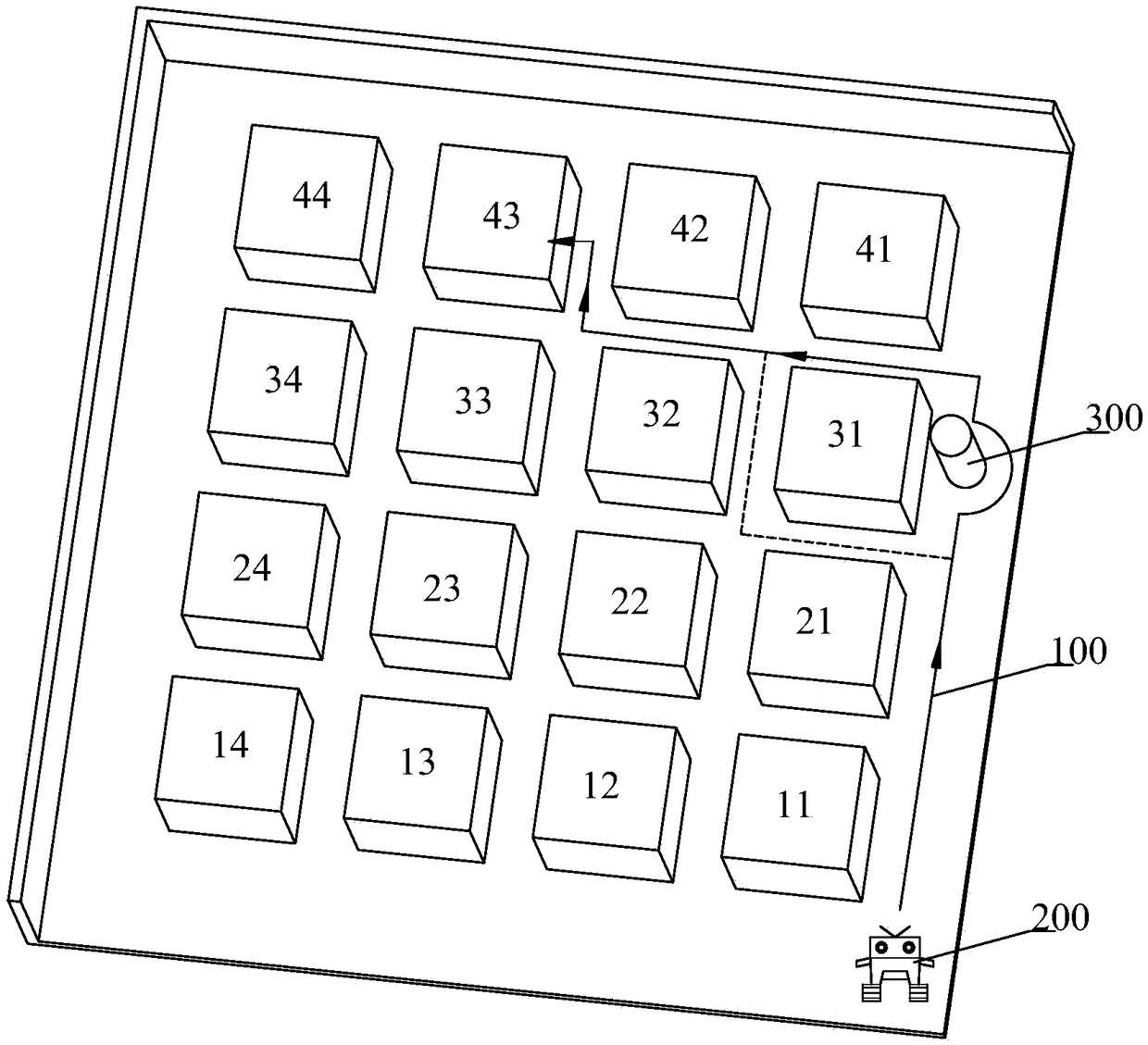

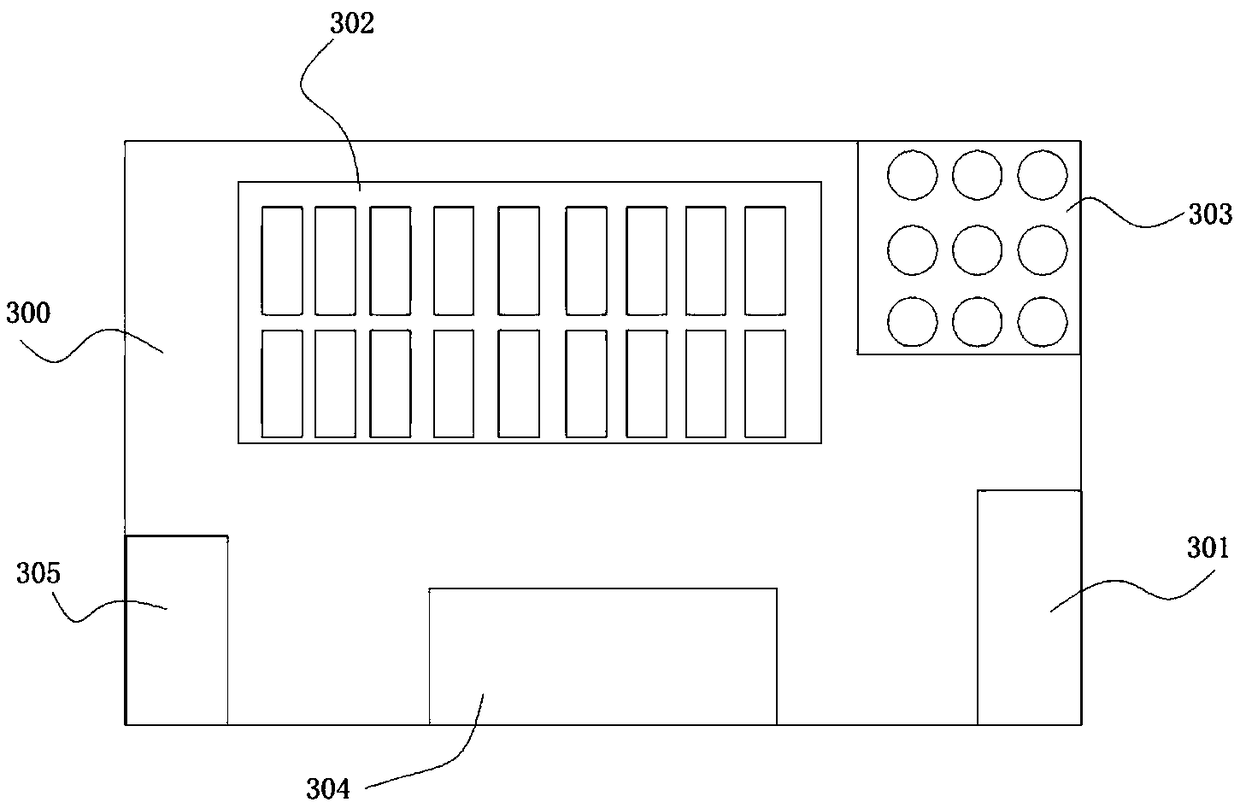

[0030] Step S101, according to preset rules, the robot 200 receives an inventory task, and the robot moves from the waiting area 301 of the warehouse 300 to the storage area 302; wherein the moving path 100 of the robot can refer to figure 2 middle;

[0031] Step S102, the robot 200 obtains the label information on the shelf in the storage area 302 through a visual recognition device, and obtains attribute description data of the goods;

[0032] Step S103, according to the attribute description data of the goods, the robot 200 moves the goods from the shelf to the corresponding inventory area 303;

[0033] Step S104, in the inventory area 303, the robot 200 performs an inventory of the goods through the inventory equipment, and generates an inventory report...

Embodiment 2

[0039] This embodiment provides a robot-based intelligent warehouse management method. This embodiment is based on the foregoing embodiments, and additionally adds a process. details as follows:

[0040] Please see Figure 4 , including the following steps before the robot receives an inventory task:

[0041] Step S201, the robot scans the barcode of the goods through the visual recognition device in the storage area of the warehouse;

[0042] Step S202, accessing the inventory database according to the barcode information of the goods, and judging whether the inventory exceeds the limit;

[0043] Step S203, if the inventory does not exceed the limit, the robot moves the goods to the corresponding storage area and places them on the corresponding shelf, and puts the goods into the warehouse, and the robot updates the inventory information;

[0044] Step S204, if the inventory exceeds the limit, an alarm indication is issued, and the robot moves the goods to the buffer ar...

Embodiment 3

[0050] This embodiment provides a robot-based intelligent warehouse management method. This embodiment is based on the foregoing embodiments, and additionally adds a process. details as follows:

[0051] Please see Figure 5 , before the robot receives the inventory task, including:

[0052] Step S301, pre-setting the types of goods that can be stored in each storage area, and at the same time, pre-setting the storage areas that can be placed for each type of goods, and making a two-way association between the goods and the shelf position. The counting tasks include: the types of goods to be counted and the location of the shelves.

[0053] Step S302, the robot plans a path according to the inventory task, so that the robot moves from the waiting area to the storage area corresponding to the inventory goods. Wherein, the system pre-stores the map information of each shelf in the warehouse, and generates the moving path 100 according to the location of the waiting area wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com