Production line management system

A production line management and management end technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of inability to realize timely response of production management, low production efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

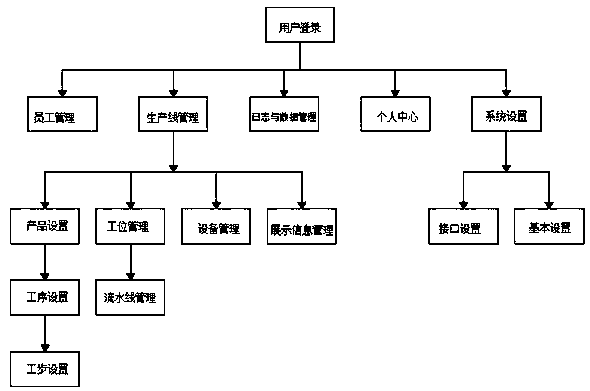

[0134] A production line management system, including a management terminal, the management terminal includes a production line management module, the production line management module includes a product setting unit, a process setting unit, and a work step setting unit; the product setting unit is used to add and delete products, Modify product information, set product coding rules; the process setting unit is used to set the process and station association, set process pictures and descriptions, export process information, process completion confirmation methods, and create, edit, and delete processes; the process step settings Units are used to set pictures and descriptions of process steps, set equipment manipulation actions, set associated components, and create, edit, and delete process steps.

[0135] The present invention realizes the management of finished products, semi-finished products or assemblies on the production line, realizes the management of products, proced...

Embodiment 2

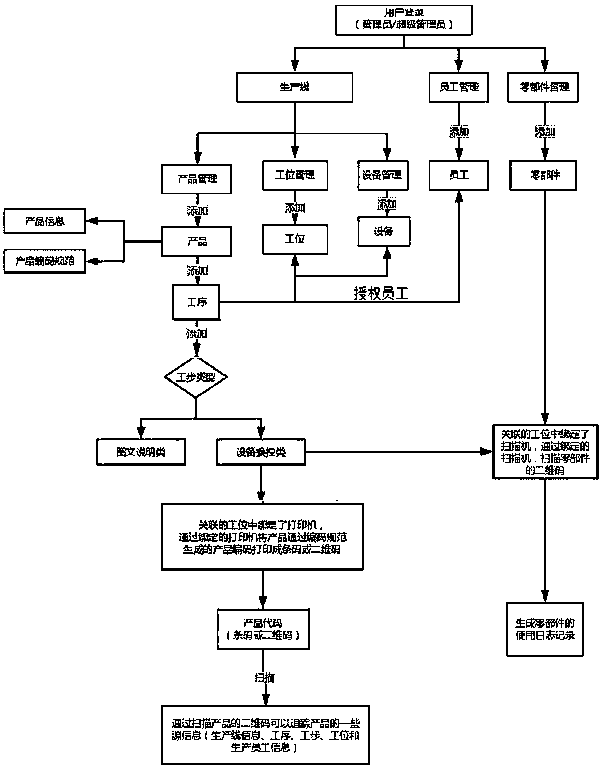

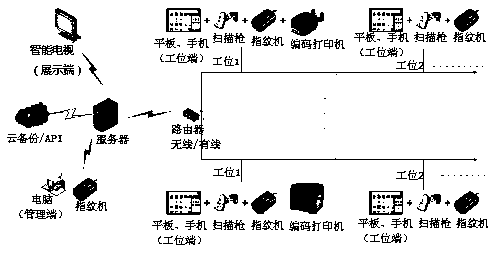

[0137] This embodiment is optimized on the basis of embodiment 1, such as figure 1 , image 3 As shown, the production line management module includes a station management unit and an assembly line setting unit, and the station management unit is used for station and equipment association setting, station and employee association setting, station and process association setting, station introduction / Describe and create, edit and delete stations; the pipeline setting unit is used to create pipelines, set pipelines, and delete pipelines.

[0138] A printer is bound to the associated station, and the product code produced by the product through the coding specification is printed into a barcode or two-dimensional code through the bound printer; the source information of the product can be traced by scanning the two-dimensional code of the product; the associated station A scanning machine is bound in the system, and the QR code of the component is scanned by the bound scanning ...

Embodiment 3

[0142] This embodiment is optimized on the basis of embodiment 2, such as figure 2 As shown, the production line management module also includes an equipment management unit and a display information management unit; the equipment management unit is used for detailed setting, equipment classification, and searching, adding, and deleting equipment. Classification of terminal equipment and production and processing equipment; the display information management unit is used for structure display, real-time status display, status statistics display, production task release, custom message release and exception prompt of the production line.

[0143] The statistical information of the production line of the display information management unit includes the utilization saturation of workstations and the saturation of employee work, and the formula is as follows:

[0144]

[0145]

[0146] The invention realizes the real-time monitoring and real-time adjustment on the workstati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com