Laser punching method of multilayer printed circuit board and system using same

A multi-layer printing and laser drilling technology, which is applied to printed circuits, laser welding equipment, manufacturing tools, etc., can solve problems such as difficult control, difficult to maintain stable quality of blind holes, and differences in thermal conductivity femtosecond laser absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

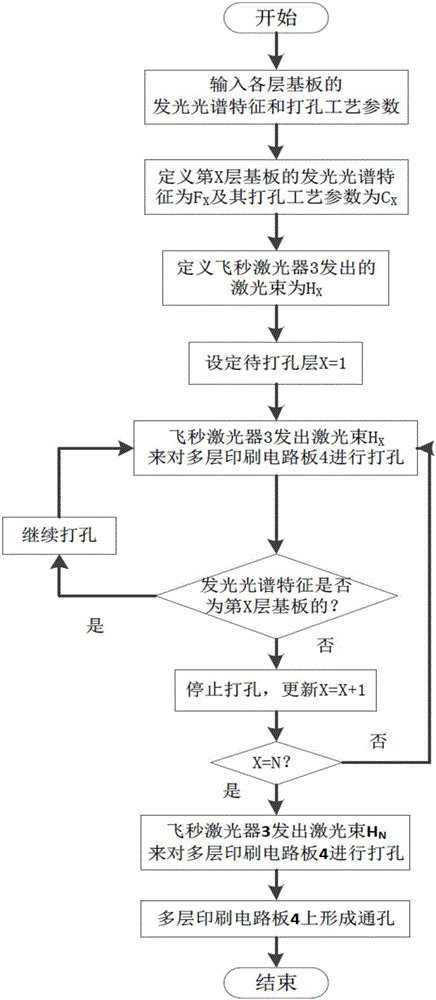

[0043] The laser drilling method of the multilayer printed circuit board of the present embodiment, as figure 1 As shown, including the process of punching holes into multilayer printed circuit boards:

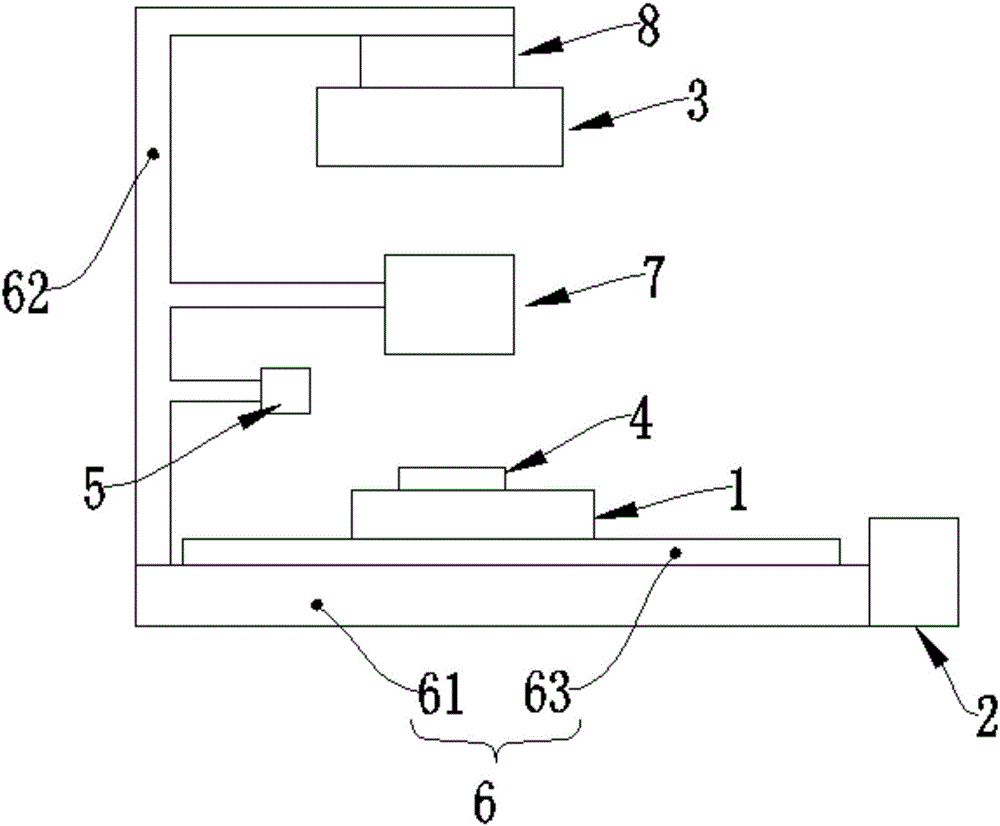

[0044] Step A1, place a multilayer printed circuit board 4 on the punching table 1, and the position to be punched of the multilayer printed circuit board 4 is aligned with the femtosecond / picosecond laser 3, and the multilayer printed circuit board 4 There are N layers of substrates with different materials from top to bottom along the thickness direction, N=2, 3, 4, ..., k, k≥2;

[0045] The femtosecond / picosecond laser 3 can switchably output laser beams of N different wavelengths to be used for etching substrates with N layers of different materials correspondingly;

[0046] Step A2, input the luminescence spectrum characteristics and punching process parameters of each layer substrate in the multilayer printed circuit board 4 in the industrial computer 2, and define the ...

Embodiment 2

[0076] A through hole with a diameter of 60 μm was drilled in the multilayer printed circuit board 4 by using the laser drilling method for the multilayer printed circuit board described in Embodiment 1. Such as Figure 4 As shown, the number of layers of the multilayer printed circuit board 4 in this embodiment is 4 layers, and the total thickness is 1.8mm. The material of the first layer substrate 42 and the third layer substrate 43 is red copper, and the second layer substrate 44 and the fourth layer substrate The material of the layer substrate 45 is FR-4 epoxy resin; the wavelength of the femtosecond / picosecond laser 3 is 800nm, the pulse width is 50fs, the highest laser beam repetition frequency is 1KHz, and the maximum laser beam pulse energy is 3mJ.

[0077] Specific steps are as follows:

[0078] Step 1, obtaining the luminescence spectrum characteristics of the conductive material copper used in the multilayer printed circuit board 4 and the insulating material FR-4...

Embodiment 3

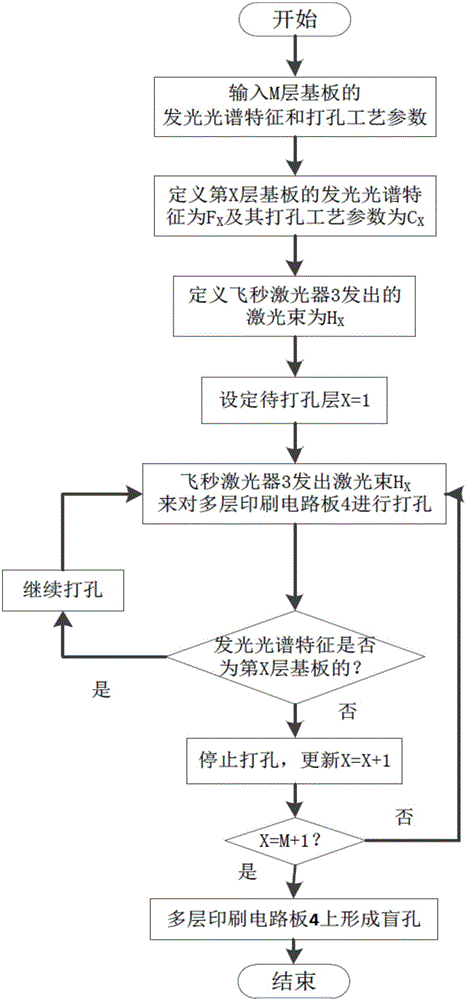

[0085] A blind hole with a diameter of 80 μm to the third layer substrate 43 is drilled on the multilayer printed circuit board 4 by using the laser drilling method for the multilayer printed circuit board described in Embodiment 1. In this embodiment, the number of layers of the multilayer printed circuit board 4 is 4 layers, and the total thickness is 1.8 mm. The materials of the first layer substrate 42 and the third layer substrate 43 are red copper, and the second layer substrate 44 and the fourth layer substrate 45 The material is FR-4 epoxy resin; the femtosecond / picosecond laser 3 has a wavelength of 800nm, a pulse width of 50fs, a maximum laser beam repetition frequency of 1KHz, and a maximum laser beam pulse energy of 3mJ.

[0086] Specific steps are as follows:

[0087]Step 1, obtaining the luminescence spectrum characteristics of the conductive material copper used in the multilayer printed circuit board 4 and the insulating material FR-4 epoxy resin under the acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com