Intelligent cleaning robot suitable for high-speed railway ballastless track plate molds

A ballastless track, high-speed railway technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low work efficiency, manual cleaning labor intensity, etc., to achieve the effect of improving work efficiency and realizing intelligent automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

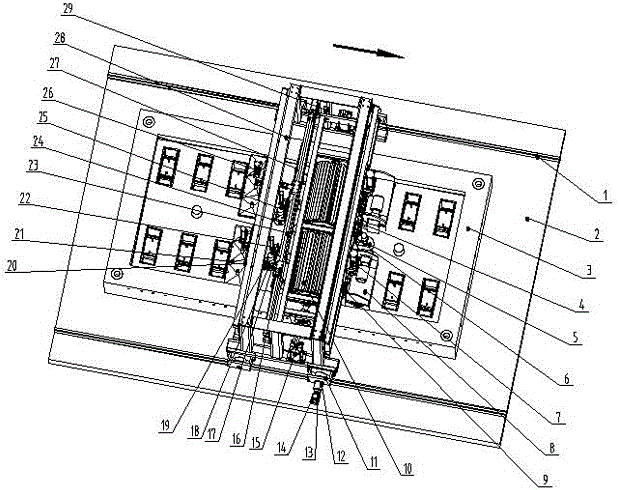

[0017] In order to better solve and implement, the following will describe in detail the intelligent cleaning robot suitable for high-speed railway ballastless track slab molds in conjunction with the attached drawings. Install I-shaped steel light rails 2 on the ground 1 of the work area for intelligent cleaning of high-speed railway ballastless track slab molds. The robot travels along the X-axis in the work area. The main structure of the robot is a frame body 28 with a truss structure, and four rail wheel assemblies 11 are arranged on its left and right sides. The power source for the operation is provided by the traveling servo motor 14. After being decelerated by the reducer 13, it is transmitted to the rail through the coupling A12. wheel assembly 11.

[0018] The big brush roller 10 is connected to the left and right sides big brush roller lifting cylinders 15 by pin shafts, and the big brush roller lifting cylinders 15 are fixed with the frame body 28 by the bolt asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com