Method for developing aluminum nitride crystal in large size through flow of plasma flame

A technology of plasma and aluminum nitride single crystal, which is applied in the field of preparation of high temperature semiconductor single crystal materials, can solve the problems of difficult control of crystal growth rate, difficulty in precise measurement and control, and crucible damage, so as to avoid the selection and use of crucible materials. life, improve crystal growth rate, and ensure the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

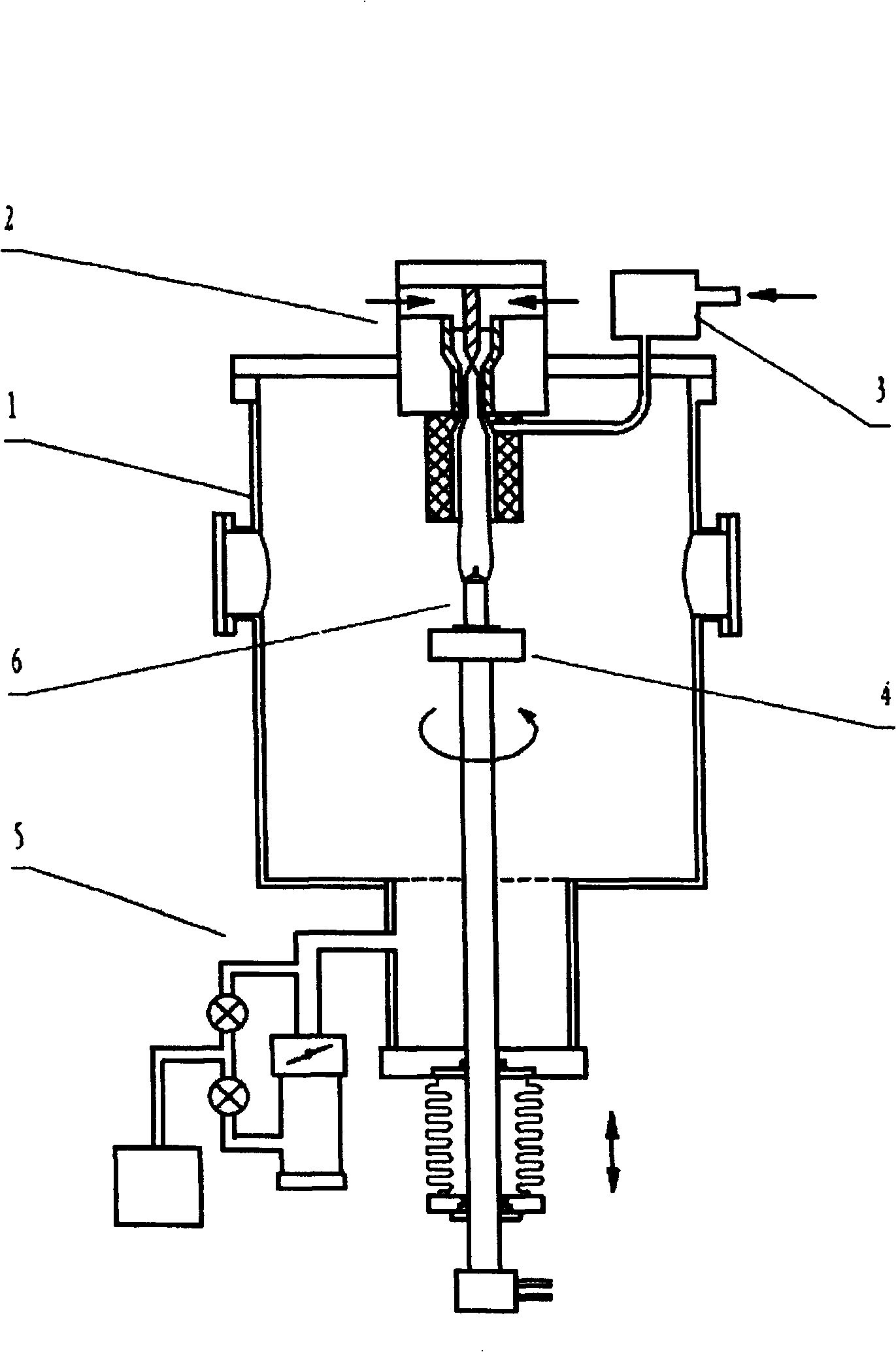

[0011] use figure 1 The schematic experimental setup is shown for the growth of AlN single crystals. The principle device includes a shell 1 made of metal materials such as stainless steel, and is equipped with a DC arc plasma flame flow device 2, a raw material powder feeding rate control device 3, a sample stage 4 with lifting and rotating functions, a vacuum device and Pressure control system 5, and seed crystal holder and substrate support table 6. The power supply, gas supply system and carrier gas supply system of the plasma plume equipment are not shown in the schematic diagram.

[0012]The DC arc plasma flame 2 is used as the heat source for heating raw materials during the crystal growth process, high-purity aluminum powder is used as the source material of aluminum atoms, the seed crystal is selected from aluminum nitride single crystal grown by other methods, and nitrogen is used as the protective gas in the growth chamber. Before crystal growth, the reaction cham...

Embodiment 2

[0014] This embodiment also uses figure 1 The schematic experimental setup is shown for the growth of AlN single crystals. The DC arc plasma flame 2 is used as the heat source for heating raw materials during the crystal growth process, the aluminum nitride micropowder with appropriate particle size is used as the source material of aluminum atoms, the seed crystal is selected from aluminum nitride single crystal grown by other methods, and nitrogen gas is used in the growth chamber as the source material. Protective gas. Before crystal growth, the reaction chamber is evacuated to remove oxygen and other impurity gases, and then filled with nitrogen. During the growth process, the pressure in the growth chamber is maintained near an appropriate value by the pressure control system 5 . When the aluminum nitride crystal growth starts, the plasma flame flow is first turned on, and the parameters of the plasma are adjusted to the appropriate parameters for the growth of the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com