A same-side material loading and blanking method and an automatic material loading and blanking mechanism for realizing the above method

A technology of automatic loading and unloading, feeding mechanism, applied in the direction of conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve the problems of long solid crystal time, low efficiency of manual feeding, and insufficient crystal solid, to achieve high efficiency And the effect of high degree of automation, saving mechanical placement space, and improving the utilization rate of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

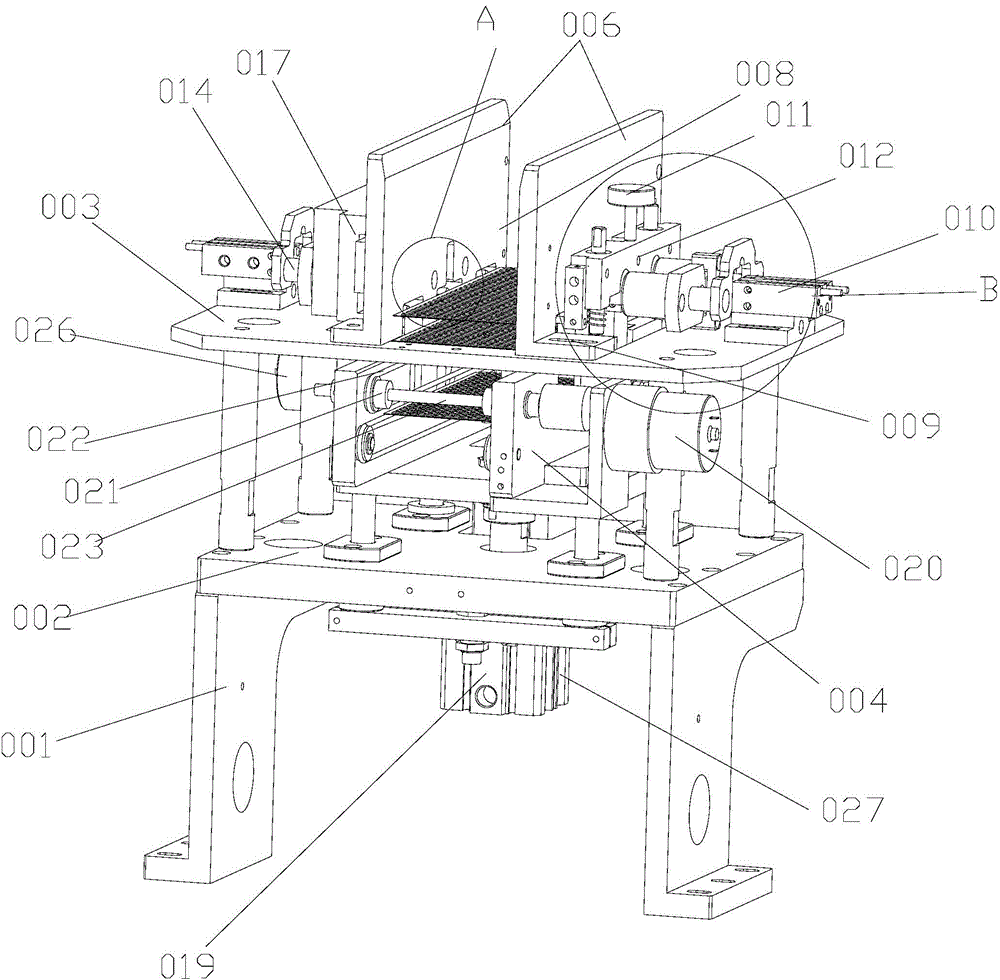

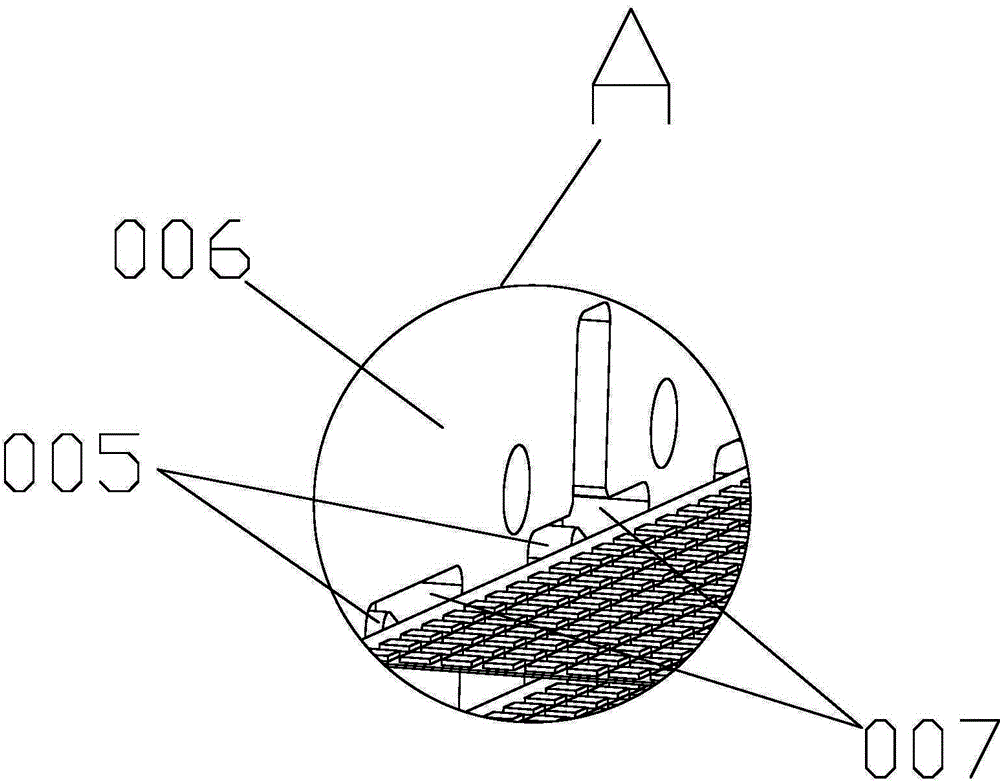

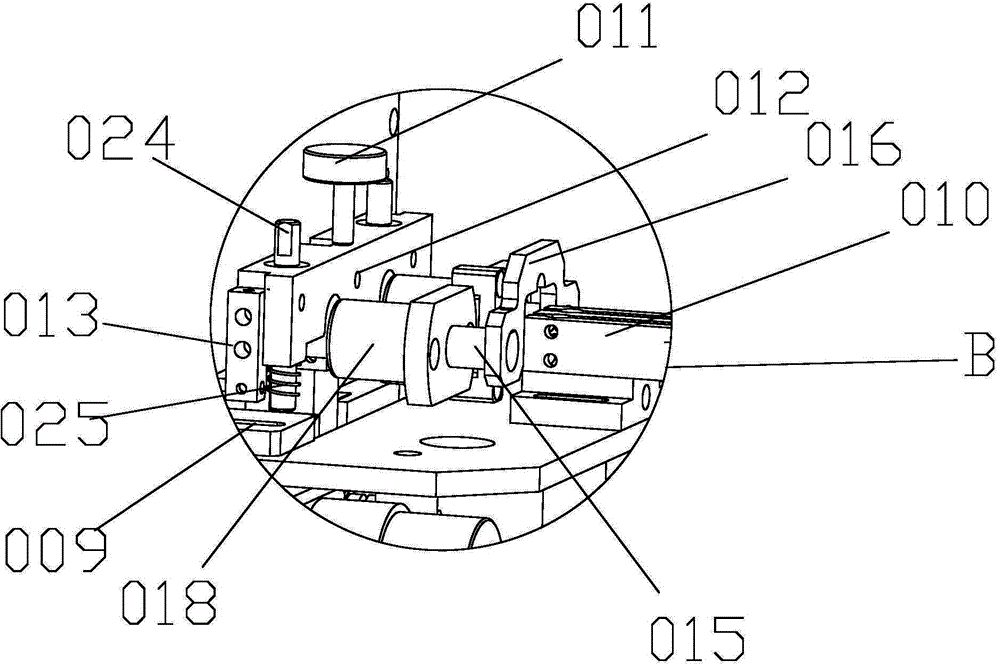

[0025] Figure 1 to Figure 4 The automatic loading and unloading mechanism according to the present invention is schematically shown.

[0026] According to one aspect of the present invention, a method for loading and unloading on the same side is provided, which includes the following steps:

[0027] A. Place the processing material in a stack of material space. At this time, the processing material is placed on the bottom of the stack space, and the penultimate processing material is lifted by the split ejector pin, and the first processing material is still in the stack In the bottom layer of the material space, after the first loading is completed, the second loading is the dropping thimble to loosen the remaining processed materials, and then the third or more processed materials are lifted up, so that the drop type is realized in a loop Loading

[0028] B. The processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com