A self-priming device for waste liquid transportation and its realization method

A technology of self-priming device and waste liquid, which is applied to components of pumping device for elastic fluid, liquid fuel engine, non-variable-capacity pump, etc. problems, to achieve the effect of reducing the input of maintenance manpower, reducing the workload of maintenance, and reducing the workload of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

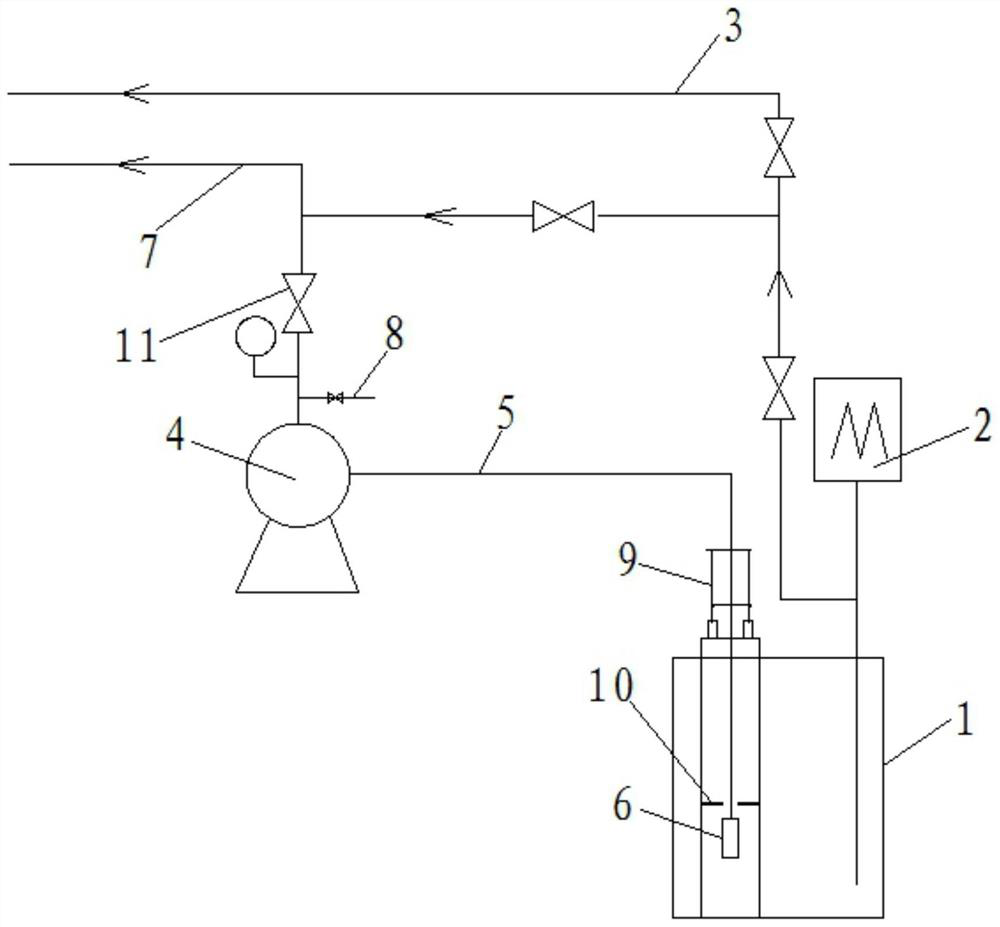

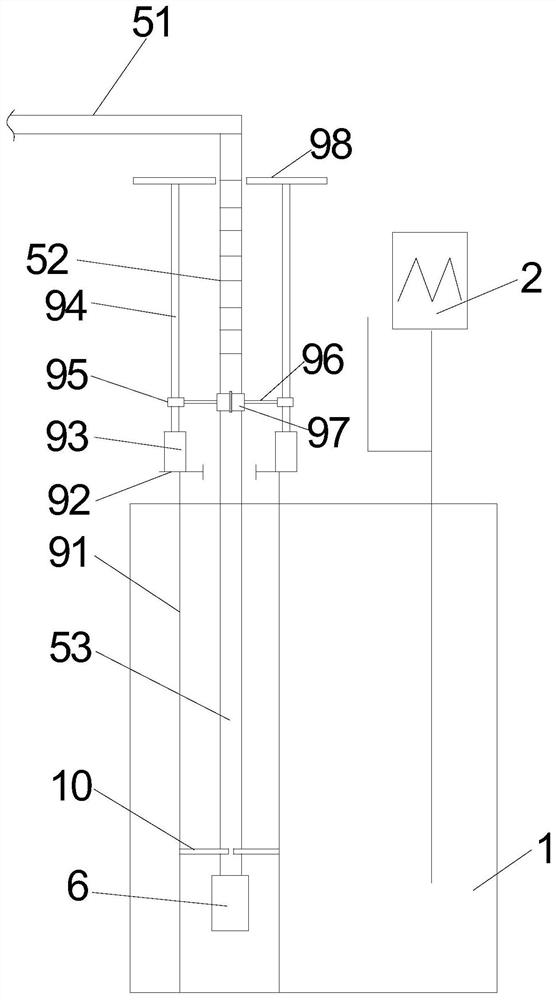

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings to be more readily understood by those skilled in the art, so as will be more clearly defined by those skilled in the art.

[0031] See Figure 1-3 As shown, the self-suction device for waste liquid delivery, including:

[0032] Waste collecting tank 1 for collecting waste liquid;

[0033] The liquid lower pump 2, inlet into the waste liquid collection tank 1, the outlet of the liquid lower pump 2 is connected to the first liquid pipe 3;

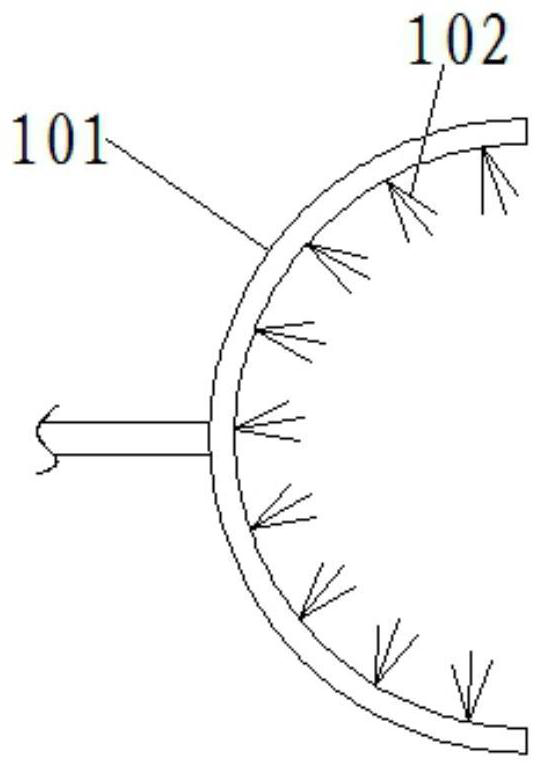

[0034] The self-suction pump 4, the inlet is connected to one end of the liquid pipe 5, and the other end of the liquid pipe 5 extends vertically into the waste liquid collecting tank 1, and the other end of the liquid pipe 5 is provided with suction. The liquid head 6; the outlet of the self-suction pump 4 is in communication with the outlet of the second liquid pipe 7 and the liquid lower pump 2, and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com