Powder feeder

A powder feeder and powder tank technology, used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of easy wear of the screw conveyor shaft, damage to the motor, low conveying efficiency, etc., to improve the working capacity of the equipment, The effect of eliminating equipment maintenance and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

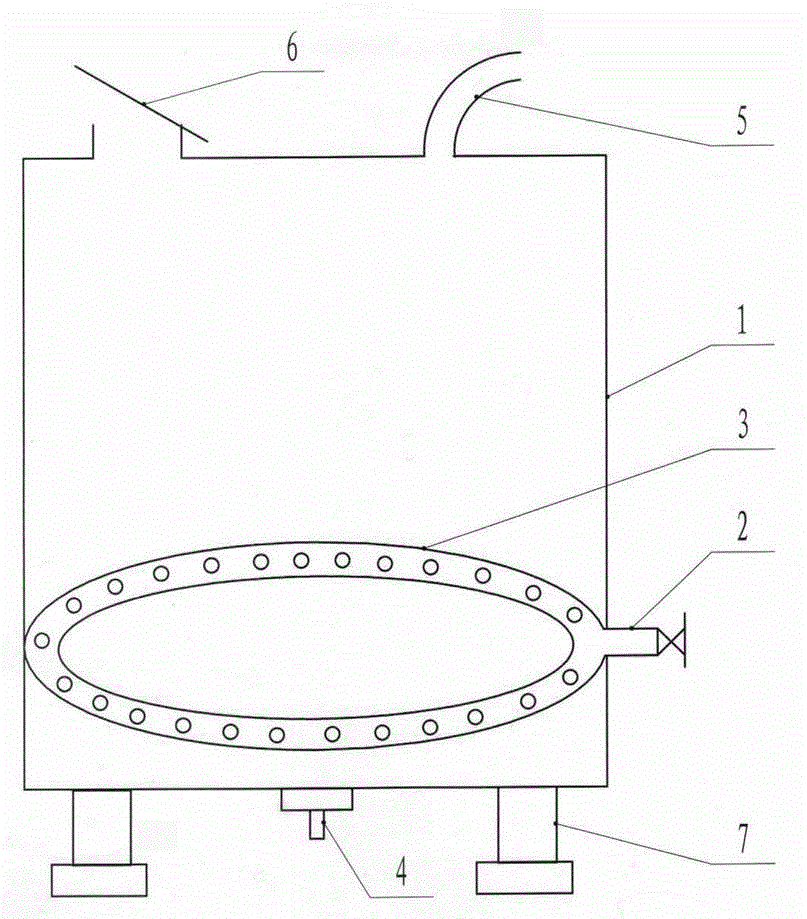

[0008] According to the accompanying drawings: the top of the powder tank body 1 is respectively provided with a charging port 6 and a discharge port 5, and a pneumatic vibrator 4 and a base 7 are respectively installed at the bottom thereof. A circular air duct 3 is mainly installed on the bottom inner wall of the powder tank body 1 cavity. Blow the powder in the direction and then spray it to the outlet 5.

[0009] When in use, when the powder is put into the back cover from the charging port 6, start the pneumatic vibrator 4 and send air from the air inlet 2, and the wind blows the powder evenly through the small holes on the circular air duct 3, and then blows the powder evenly from the discharge port. Spray from the mouth, and spray the powder evenly on the panel without interruption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com