Aluminium strip enwinding device

An aluminum strip and equipment technology, which is applied in the field of electric heating plate production and processing to achieve the effect of simple structure and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

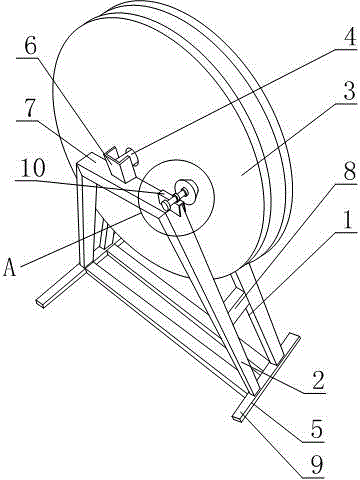

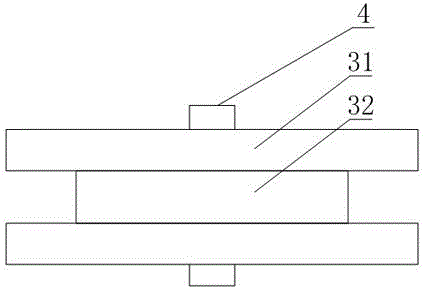

[0026] Such as Figure 1 to Figure 3 , a kind of aluminum strip winding equipment, used for the storage of the aluminum strip wrapped by the electric heating plate and feeding to the crimping machine, the aluminum strip frame wrapped by the electric heating plate includes a bracket 1 and a pulley 3 fixed on the bracket 1, the The pulley 3 comprises two side plates 31 and a central plate 32 arranged between the side plates 31, the side plates 31 and the central plate 32 are circular plates, and the axes of the three are collinear, and the diameter of the central plate 32 is less than the diameter of the side panel 31;

[0027] The pulley 3 is also fixed with a rotating shaft 4, and the bracket 1 is also provided with a shaft seat 6 for clamping the rotating shaft 4;

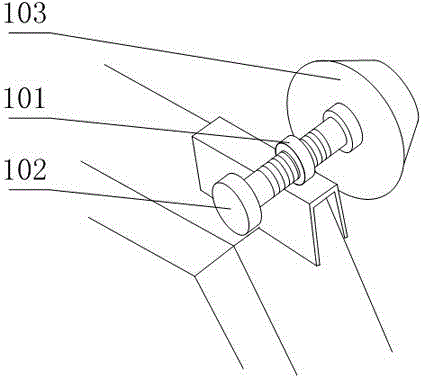

[0028] The support 1 is also fixedly connected with a pre-tightening part 10, and the pre-tightening part 10 includes a threaded seat 101 fixed on the support 1 and a pre-tightening screw 102 threaded with the th...

Embodiment 2

[0033] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 , as a form of support 1 with simple structure and good supporting capacity, the support 1 includes a bottom plate 5 and two parallel stands fixed on the bottom plate 5, the stands are arched, and each stand Shaft seats 6 are arranged on them.

[0034] As an easy-to-manufacture stand structure, the stand includes upright bars 2 at both ends and a central cross bar 7 , and the shaft seat 6 is arranged on the cross bar 7 .

[0035] As a form of support 1 that is stable relative to the ground, ground anchor holes 9 and / or suction cups are also provided on the bottom plate 5 .

[0036] As a structural form of the support 1 with good rigidity, it also includes a tie rod 8, and the two ends of the tie rod 8 are respectively fixedly connected to different stands.

[0037] As a low-cost, light-weight pulley 3 form, the pulley 3 is a polyvinyl chloride disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com