Batch type medicine packaging box paper board conveying mechanism

A technology of conveying mechanism and packing box, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex structure of automatic paper feeding mechanism, poor paper feeding accuracy, inability to meet the requirements, and achieve compact structure, reduce production cost, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

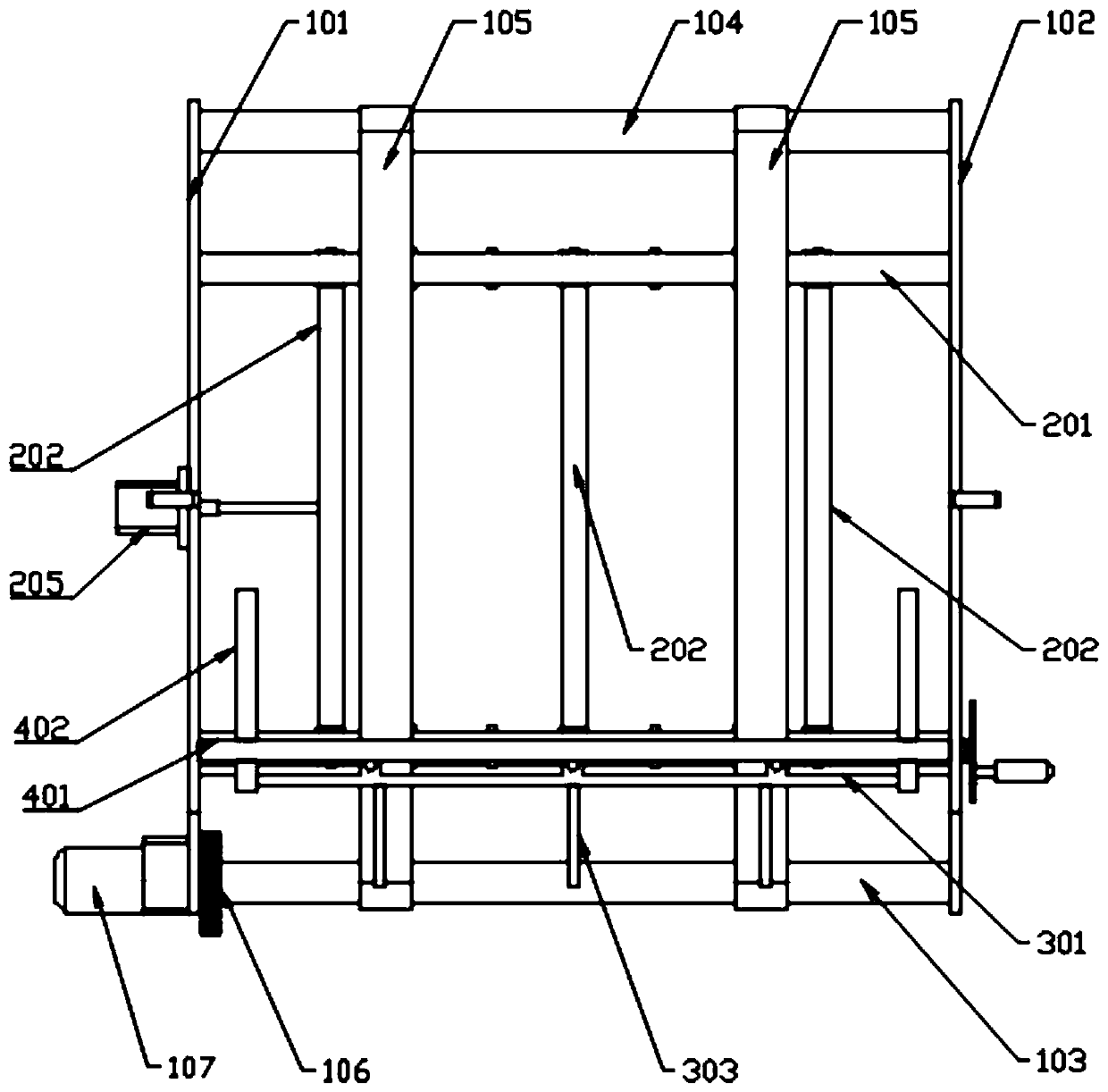

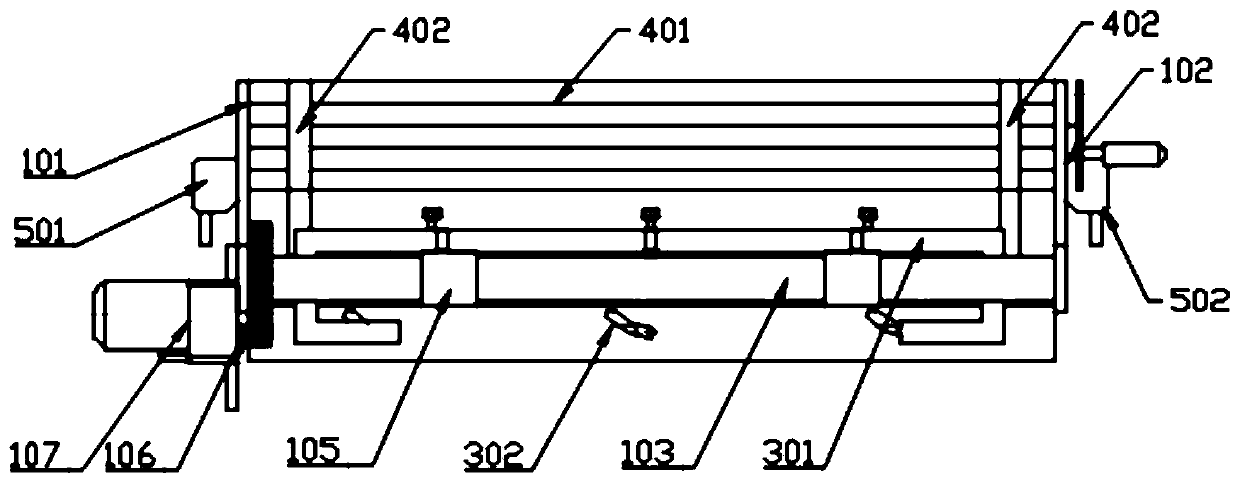

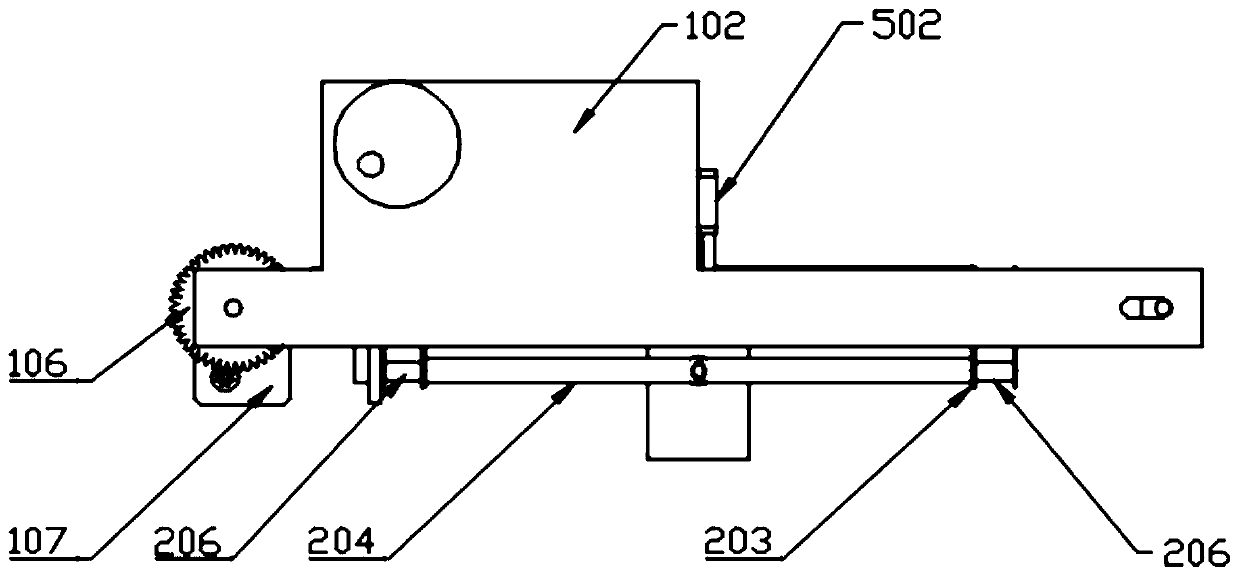

[0034] Such as Figure 1 to Figure 5 As shown, an intermittent medicine packaging box cardboard conveying mechanism of the present invention includes a cardboard transmission unit, a cardboard lifting unit and a cardboard blocking unit. The cardboard lifting unit is located in the direction of the entrance of the cardboard transmission unit, and the cardboard blocking unit is located in the direction of the exit of the cardboard transmission unit. . The cardboard conveying mechanism mainly adopts the cooperative cooperation of the cardboard conveying unit, the cardboard lifting unit and the cardboard blocking unit to automatically convey the stacked cardboard individually.

[0035]Specifically, the cardboard transmission unit includes a left side plate 101 and a right side plate 102 that are parallel to each other and arranged at intervals. The left side plate 101 and the right side plate 102 are made of 10mm thick steel plate material. A driving roller 103 and a driven rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com