Starter for an internal combustion engine

A technology of starter and internal combustion engine, which is applied in the direction of starting the engine, starting the motor with the engine, machine/engine, etc., and can solve the problems of diameter reduction and limitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

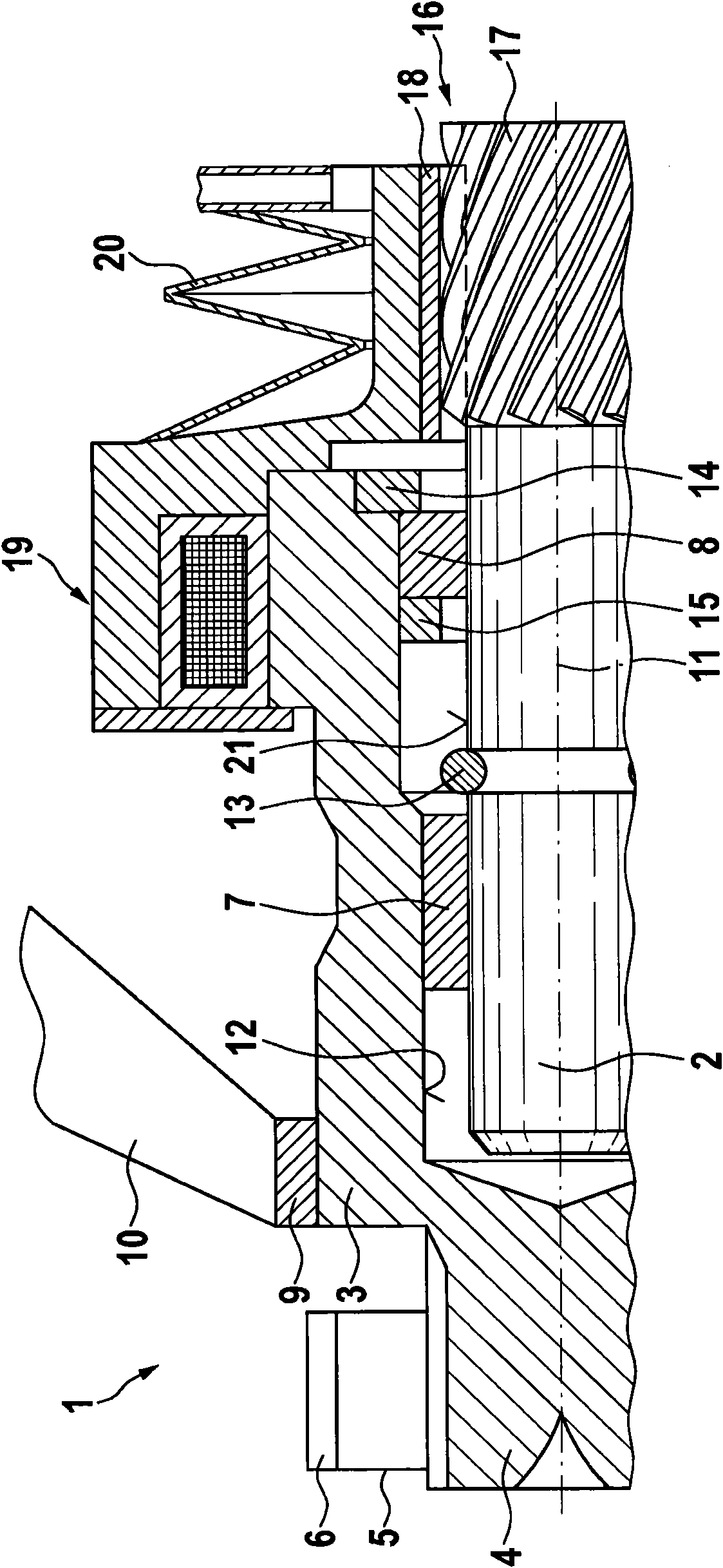

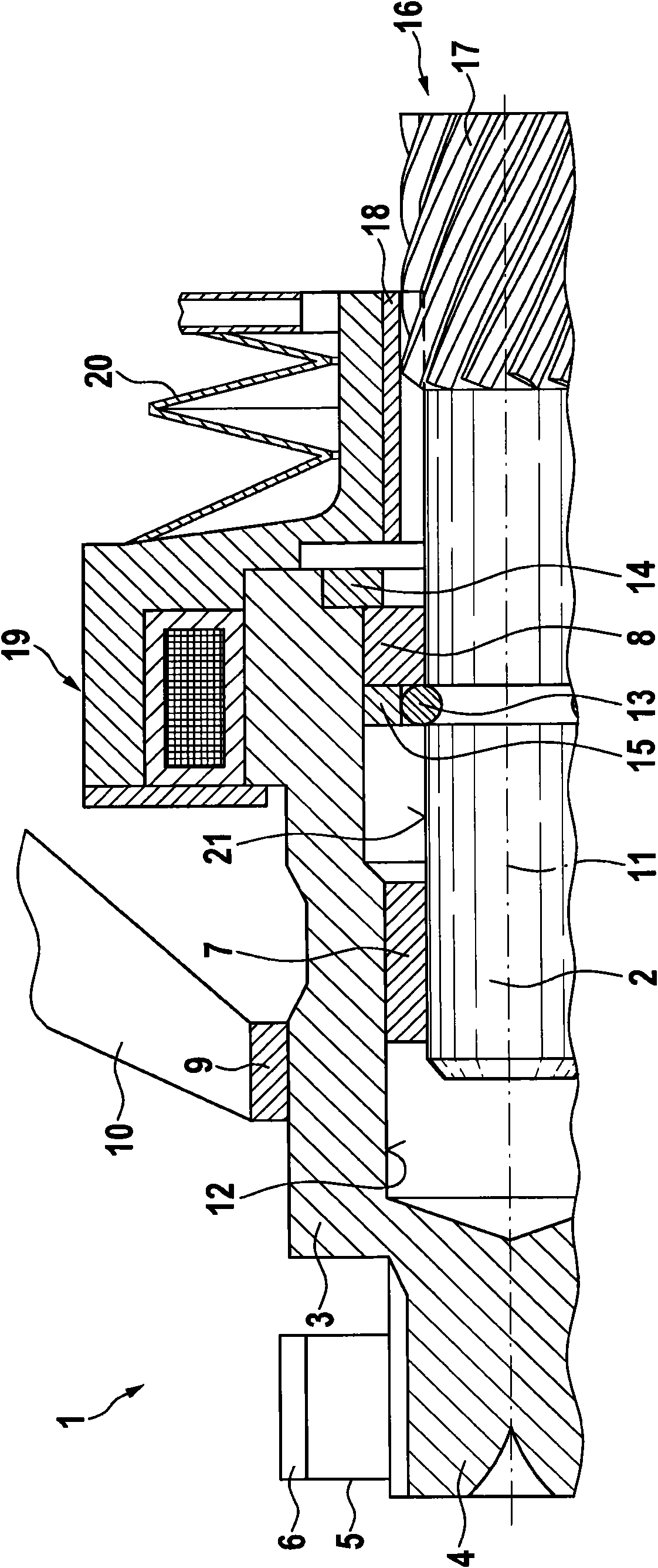

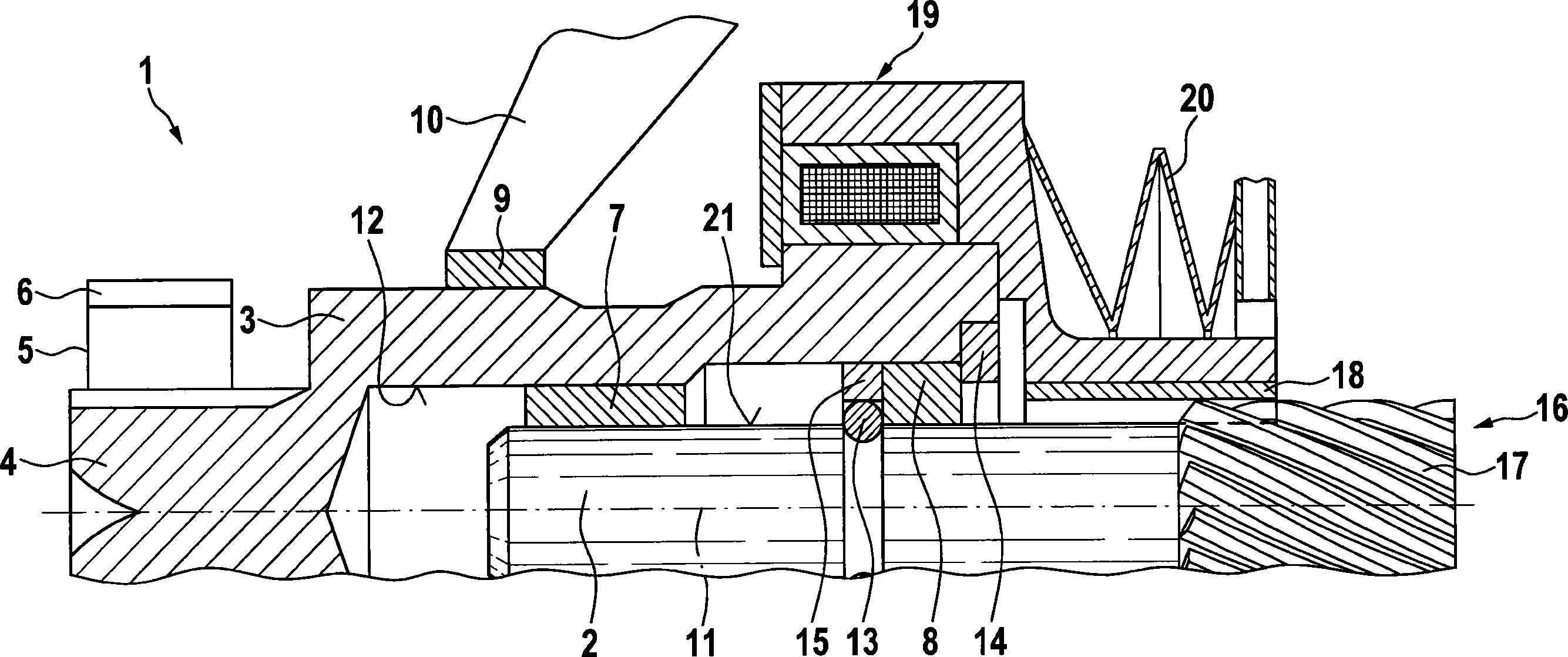

[0022] exist figure 1 and 2 The starter 1 shown in is used for starting an internal combustion engine and has a motor-driven drive shaft 2 and a pinion shaft 3 with a starter pinion 5 . The pinion shaft 3 is embodied as a hollow shaft in which the drive shaft 2 is accommodated. The pinion shaft 3 has an end-side carrier section 4 which is the carrier of the starter pinion 5 , wherein the starter pinion 5 is embodied as a separate component from the pinion shaft 3 and can be used as a socket The gear is pushed onto the end-side carrier section 4 of the pinion shaft 3 . To start the internal combustion engine, the starter pinion 5 with its outer toothing 6 engages with the ring gear of the internal combustion engine during the meshing process.

[0023] The pinion shaft 3 is supported on the drive shaft 2 in an axially displaceable and rotatable manner about a shaft longitudinal axis 11 . This support is achieved by means of two bearings 7 and 8 on the inner wall 12 of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com