Sheet metal part production process facilitating feeding

A production process and technology for sheet metal parts, which is applied in the field of sheet metal parts production process for convenient feeding, can solve the problem of laborious pulling of thin steel sheets, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

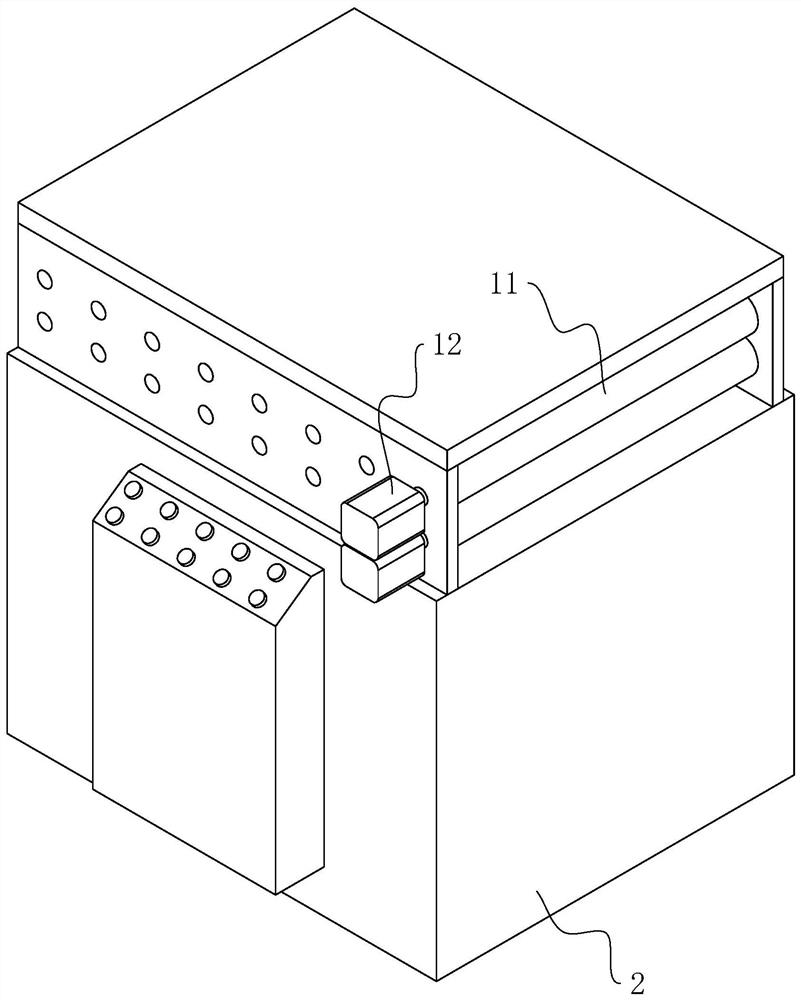

[0042] The following is attached Figure 1-12 The application is described in further detail.

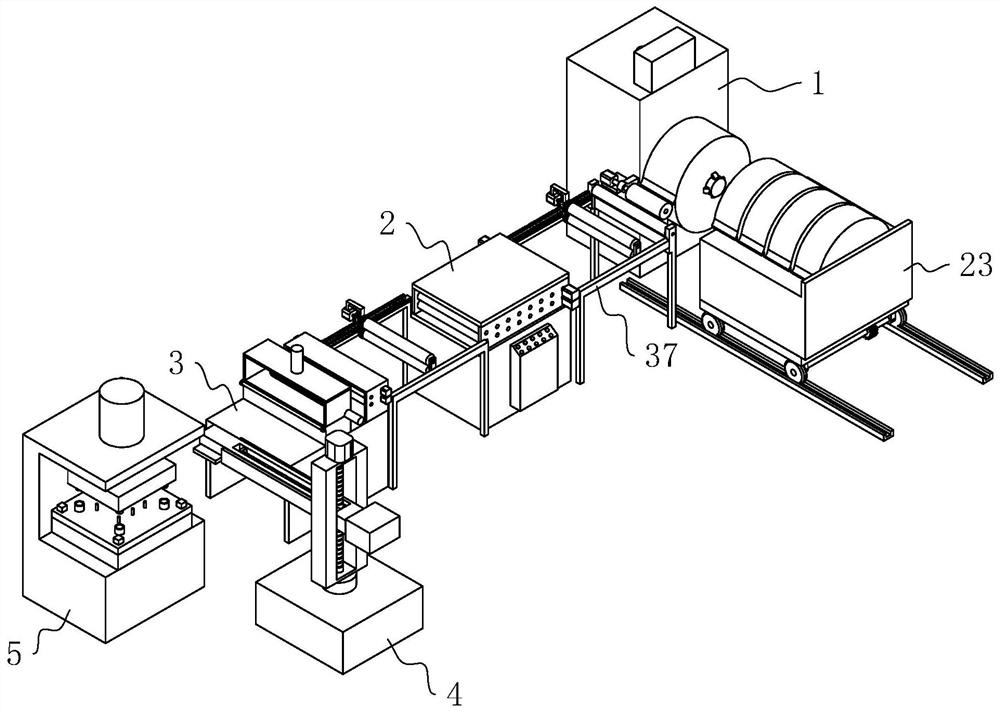

[0043] The embodiment of the present application discloses a sheet metal production process that is convenient for material loading. refer to figure 1 , the process includes the following steps:

[0044] Step 1: Leveling the thin steel sheet coil, leveling process: pull the thin steel coil on the unwinder 1 and transport it to the shaping machine 2 for leveling;

[0045] Step 2: Cut the flattened thin steel sheet, cutting process: transport the flattened thin steel sheet coil to the feeder 3 for cutting;

[0046] Step 3: Transport the cut thin steel sheet to the pneumatic punch 5 through the mechanical arm 4 for stamping;

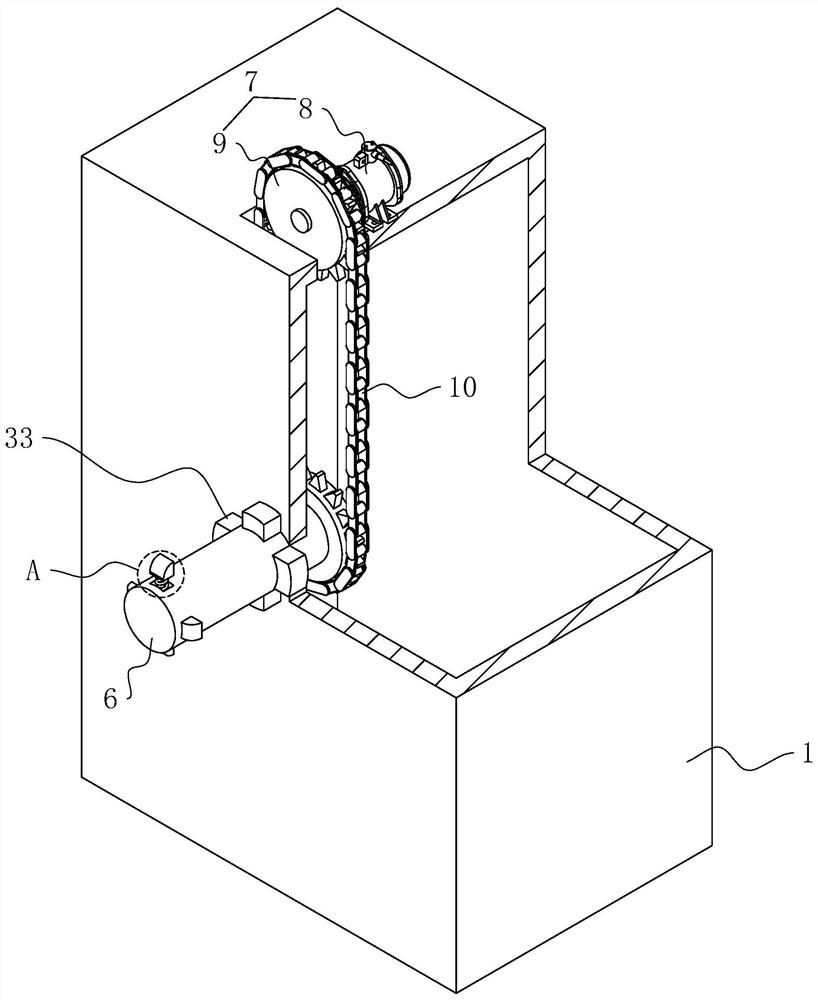

[0047] refer to figure 2 , in the above steps, the uncoiler 1 is rotatably connected with a rotating roller 6, and the thin steel sheet coil is used to be sleeved on the rotating roller 6, and the rotation axis of the rotating roller 6 is horizontally arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com