Automatic lifting material rest

An automatic lifting and racking technology, which is applied in the direction of accumulating material equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increased impact force, increased vertical height, increased frequency of pipe transfer, etc., to improve bruises, reduce Shock force and volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

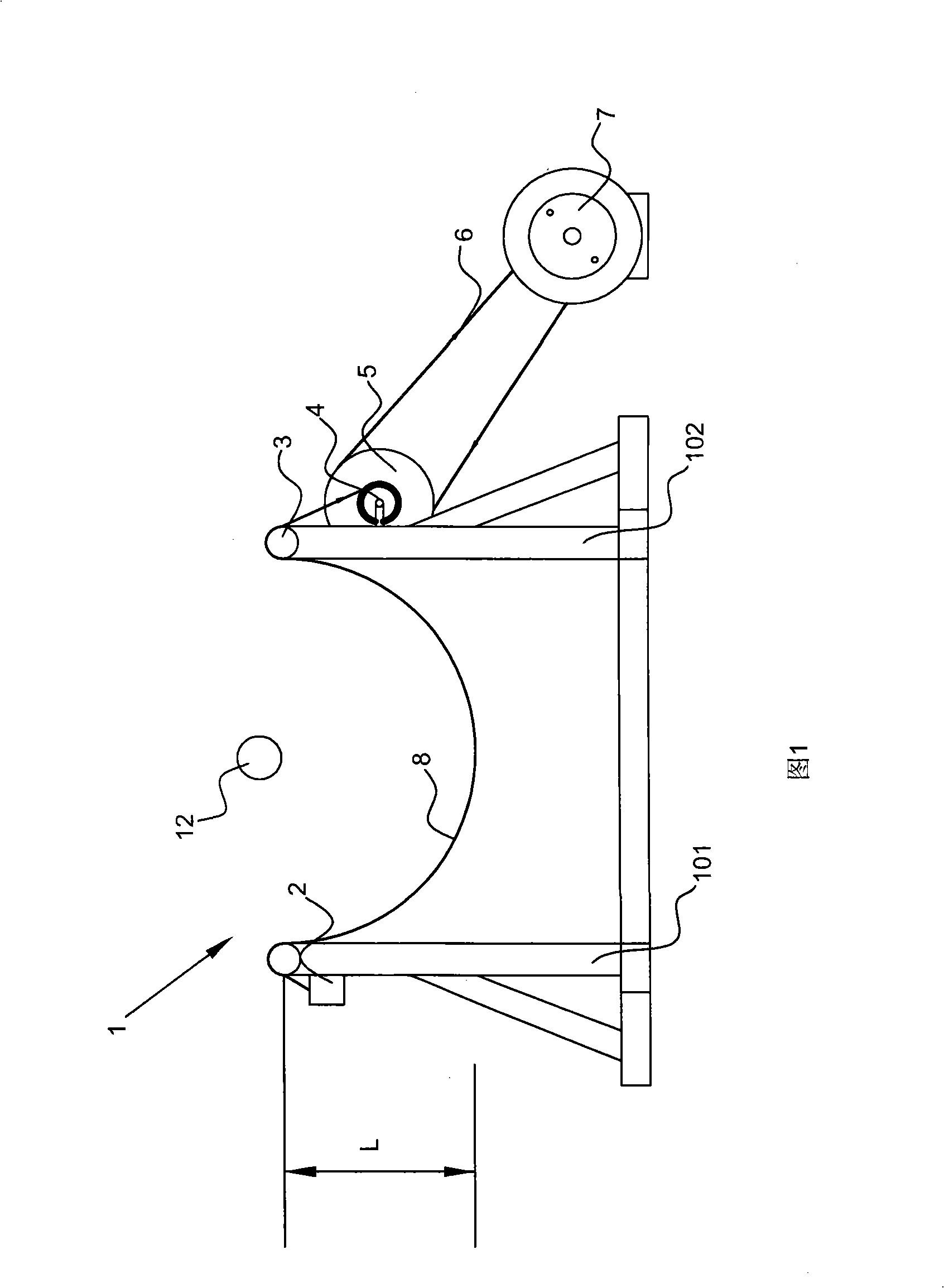

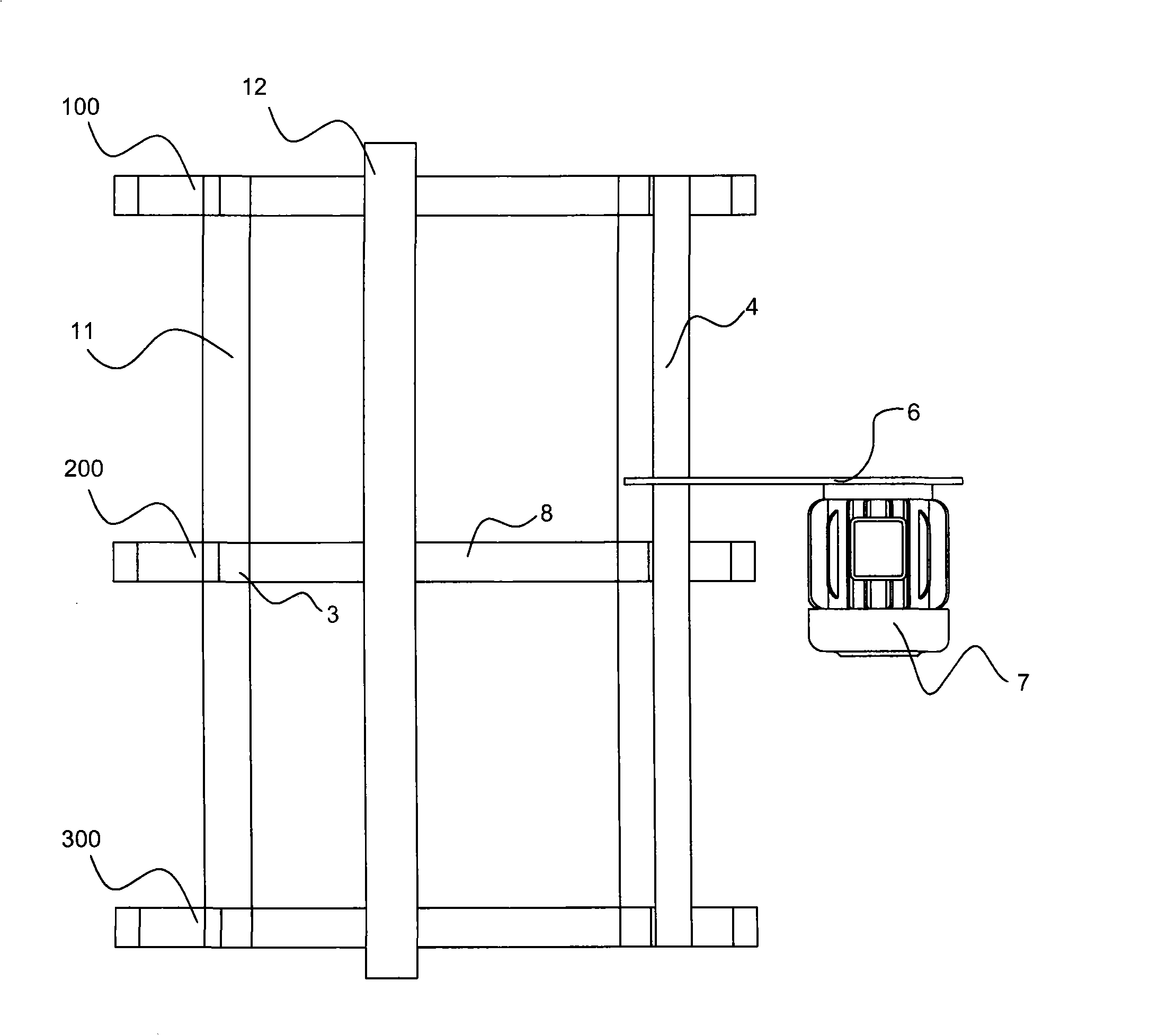

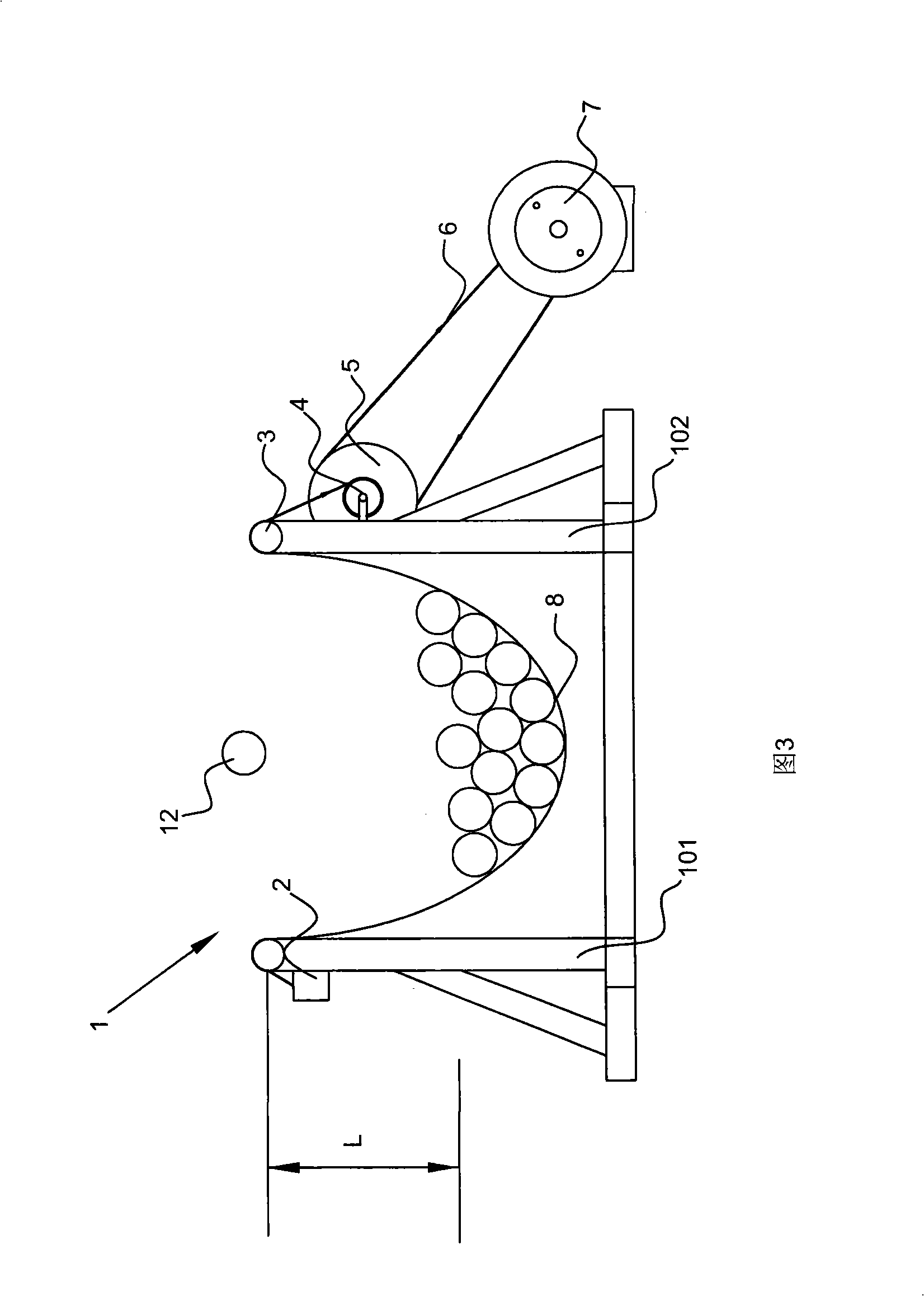

[0015] as attached figure 1 to attach image 3 As shown, the automatic lifting rack in this embodiment is composed of three "U"-shaped first units 100, second units 200 and third units 300. The above-mentioned first unit 100, second unit 200 and third unit The three units 300 are fixedly connected to each other through the bottom connecting piece 11 to increase the stability of the entire rack; two pillars 101, 102 are vertically fixed on the first unit 100, the second unit 200 and the third unit 300 respectively, Rollers 3 for reducing the friction between the carrier tape 8 and the pillars 101, 102 are respectively arranged on the tops of the pillars 101, 102, and a carrier tape fixing for fixing the carrier tape 8 is arranged on the pillar 101. The carrier 2 is provided with a carrier tape winding shaft 4 on the pillar 102. One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com