Apparatus for and method of manufacturing a helically wound tubular structure

a technology of helically wound tubular structure and manufacturing method, which is applied in the direction of metal rolling, material accumulation devices, transportation and packaging, etc., can solve the problems of complex process and long process, and achieve the effect of facilitating continuous supply of strip material and reducing downtim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

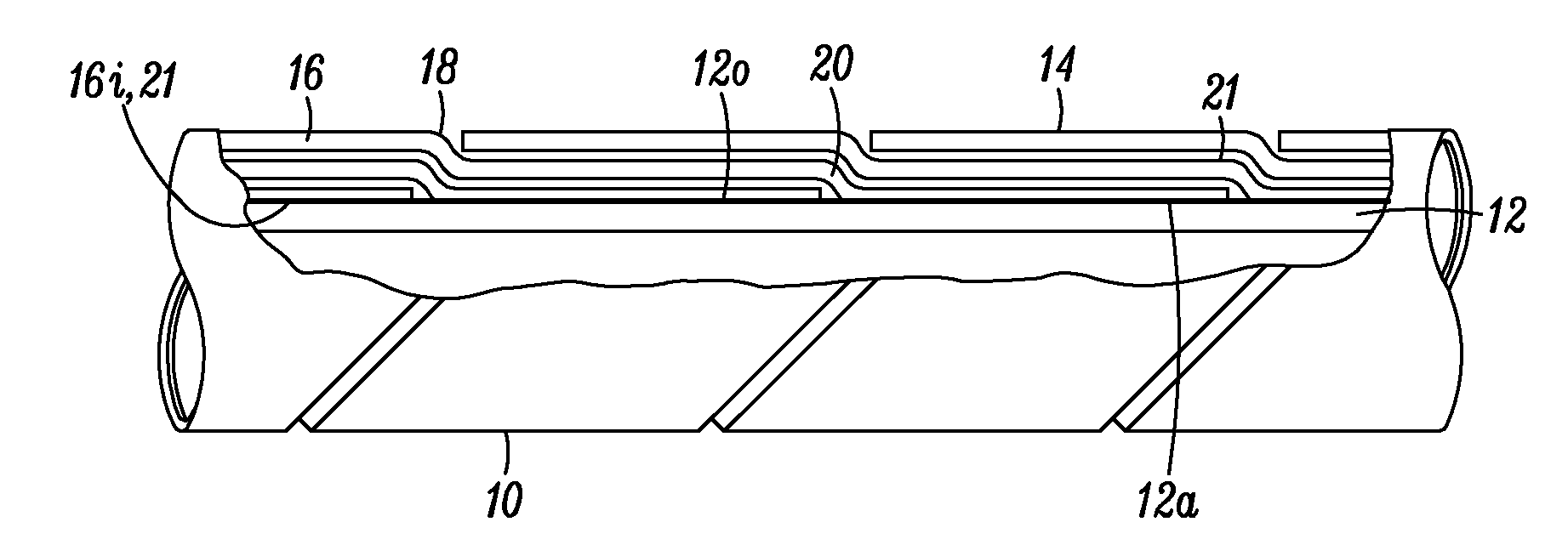

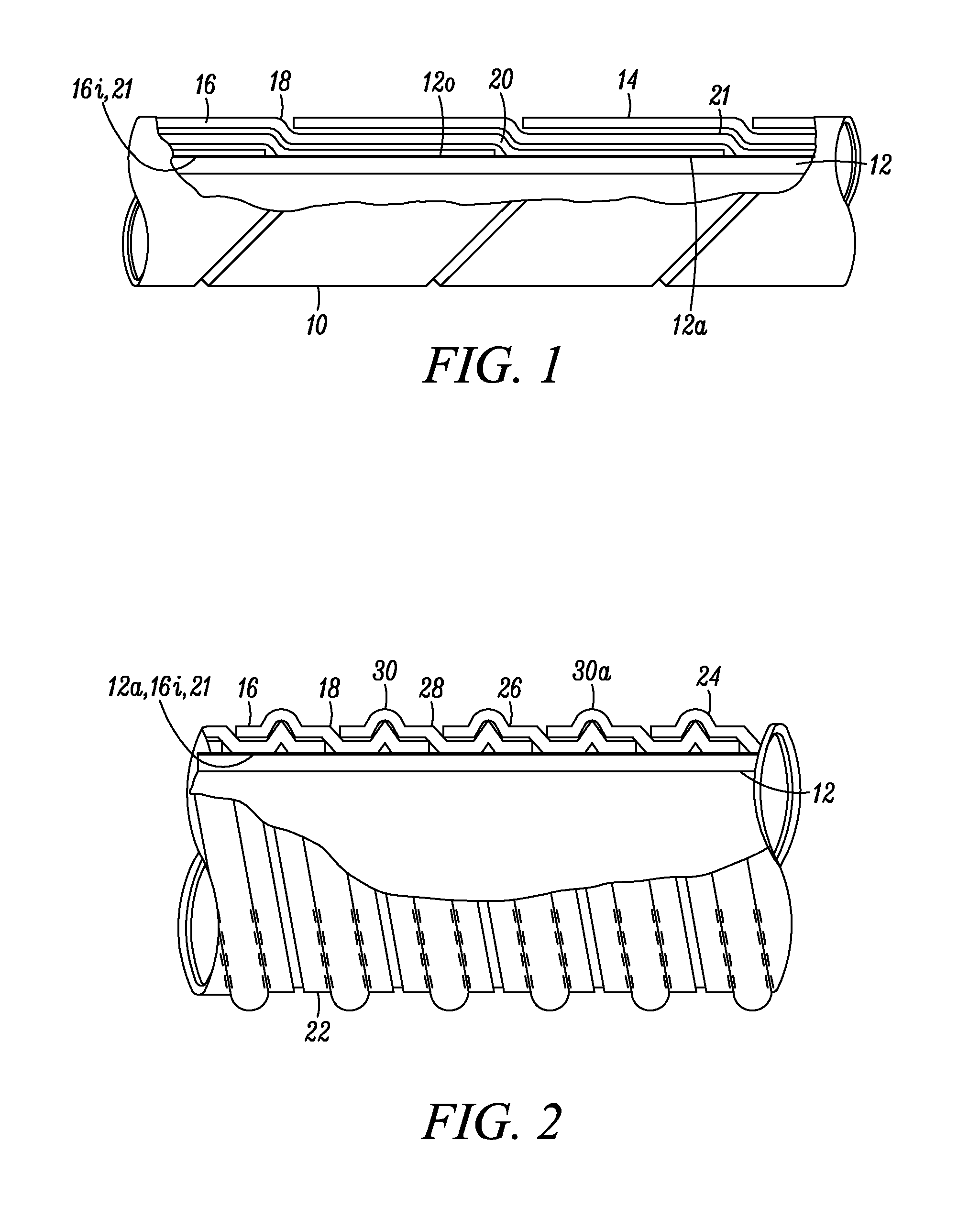

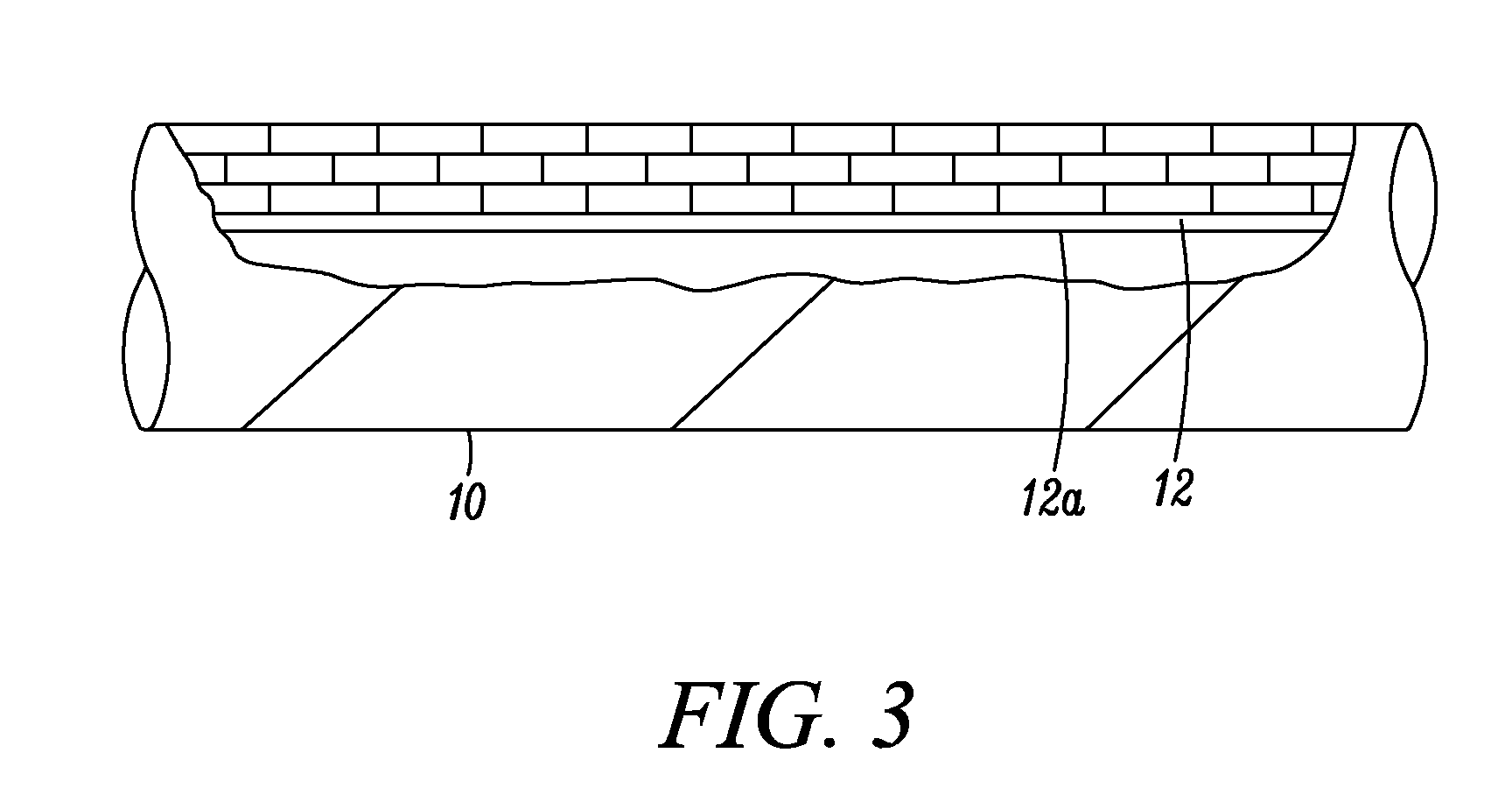

[0018]Referring now to FIG. 1 of the drawings, a tubular body indicated generally at 10 forms a pipe for use in a pipe system such as a pipeline carrying hot fluids (which may also be under pressure). The tubular body may comprise an inner portion in the form of an inner hollow core 12 which may be formed by any one of a number of forming processes known to those skilled in the art and an outer load carrying casing discussed in detail later herein. In the preferred process the inner pipe comprises a continuously formed core, as will also be discussed in detail later herein however, one may have a core made from a plurality of discrete lengths inter-engaged with each other so as to form a long length. The outer casing indicated generally at 14 is formed on the inner hollow core 12 by helically winding a strip 16 of material onto the outer surface 12a of the core 12 in an abutting or self-overlapping fashion similar to the manner which is described in detail for the formation of a pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com