Sand leakage preventing sand injection nozzle for large-calibre core shooting mould

A technology of sand injection nozzle and sand leakage prevention, which is applied to the parts of molding machines, casting molding equipment, metal processing equipment, etc., can solve the problems of sand core molding not meeting the requirements, high production cost, quality impact, etc., and achieve the benefit of natural The effect of accumulation, simple production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

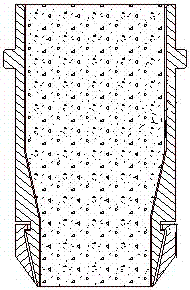

[0015] figure 1 It is a cross-sectional view of the structure of the sand shooting nozzle in the prior art, figure 2 It is a schematic diagram of the structure of the nozzle head of the prior art, refer to figure 1 with figure 2 As shown, when the sand shooting mechanism is raised, before the sand shooting is ready, the sand is very easy to fall from the sand shooting nozzle due to the large diameter of the sand shooting nozzle. Once the sand 4 falls, the sand core formed by the sand shooting will not meet the requirements. Quality suffers severely.

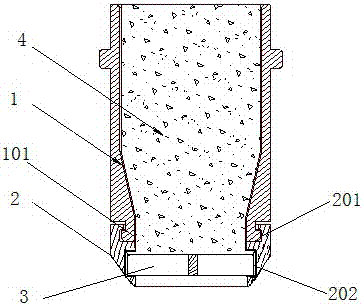

[0016] The invention proposes a leak-proof sand i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com