Method for restraining boron impurities expanding in P-shaped pseudo buried layer

A pseudo-buried layer and heavy doping technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to ensure performance and suppress external expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

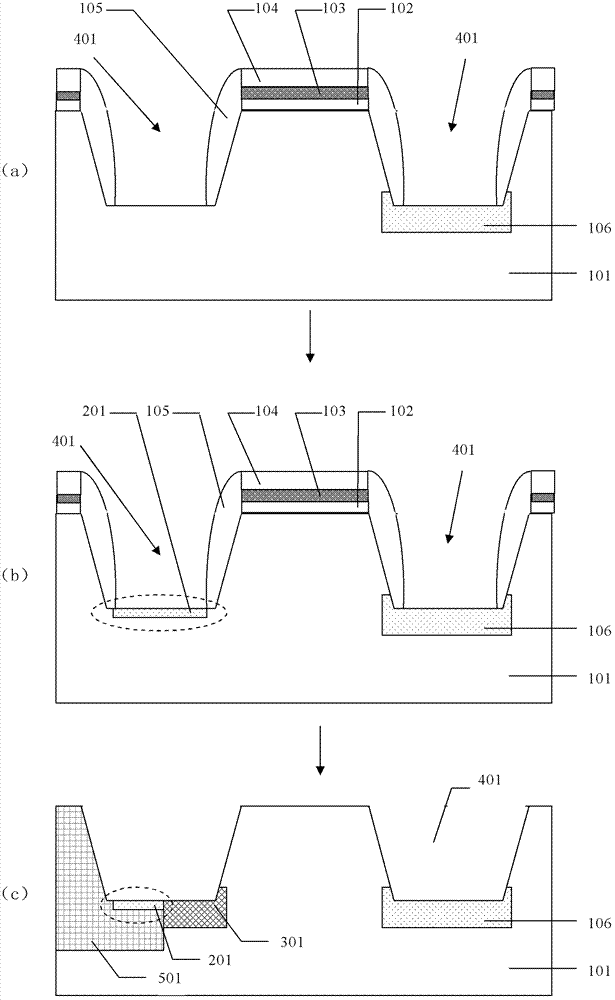

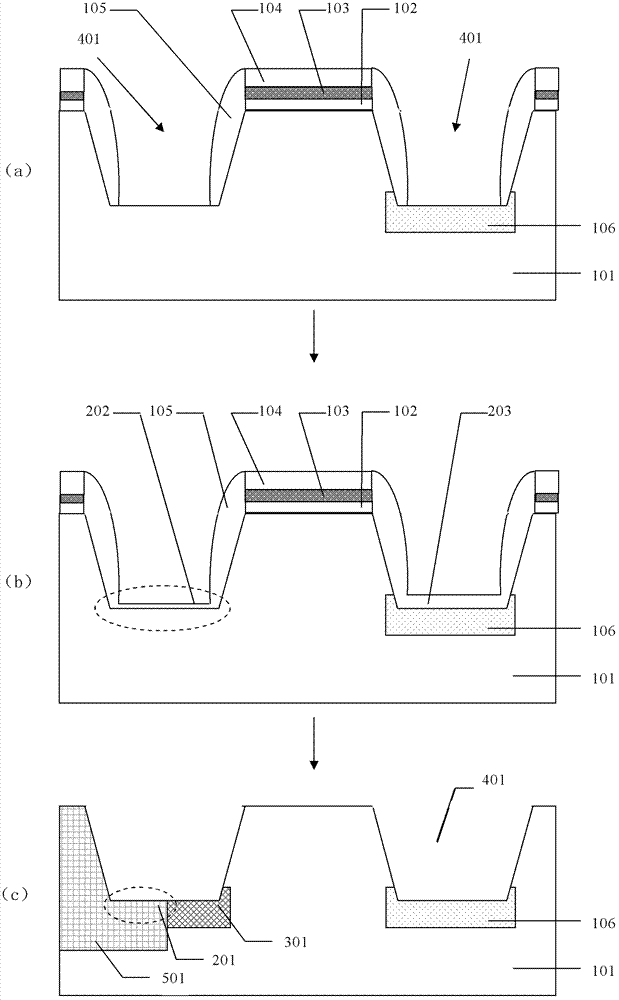

[0030] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0031] In order to suppress the external expansion of boron impurities in the P-type pseudo-buried layer, the present invention improves the process flow of the SiGe BiCMOS pseudo-buried layer, and adopts the following process steps:

[0032] 1) Deposit silicon oxide 102 and silicon nitride 103 on the surface of the P-type silicon substrate 101; then use silicon nitride 103 as a barrier layer to etch a shallow trench isolation (STI) 401 structure; then make silicon oxide 104 and silicon oxide sidewalls 105 .

[0033] Wherein, the thickness of the silicon nitride 103 is 300˜1000 angstroms. The silicon oxide sidewall 105 has a thickness of 200-1200 angstroms.

[0034] 2) A high-concentration P-type impurity boron is implanted on the surface of the STI to form a hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com