Preparation process of foaming product and foaming product

A preparation process and technology for foaming products, which is applied in the field of polymer material processing, can solve the problems of destroying the internal structure of elastomers, blurring the three-dimensional structure of the surface, and low foaming ratio, and achieves excellent performance, fine surface structure, and high foaming ratio. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

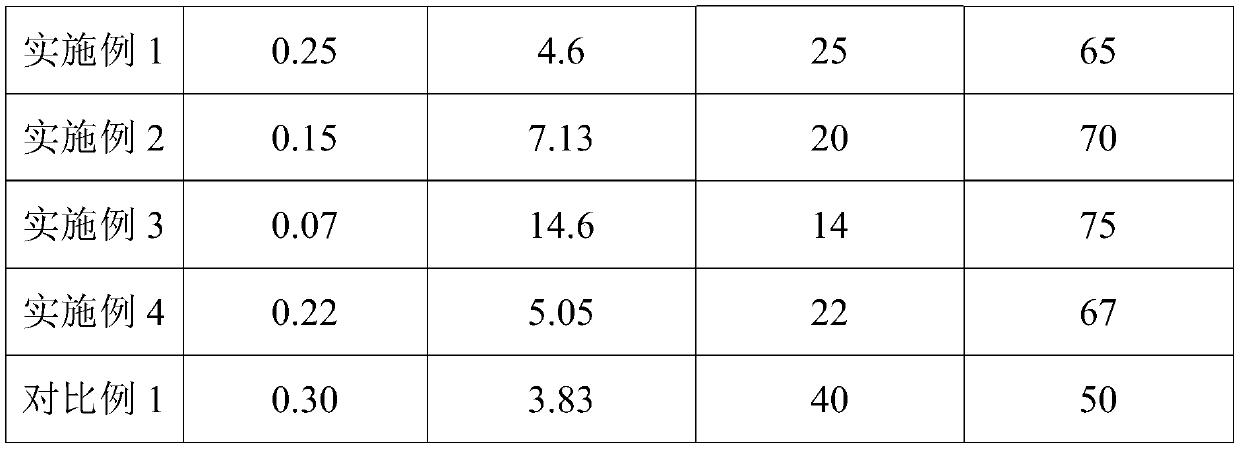

Embodiment 1

[0033] This embodiment provides a method for preparing a foamed product, specifically a sports shoe midsole with a pattern on the surface, comprising the following steps:

[0034] (1) According to the external dimensions of the midsole of the sports shoes to be prepared, use breathable steel to process and manufacture molds with the same internal cavity external dimensions and surface patterns after mirror conversion;

[0035] (2) Select hardness as 85A, melting point as 165°C and density as 1.15g / cm 3 The TPU resin is used as the material, and the solid foaming body is prepared by injection molding. The injection temperature is 200°C, the mold temperature is 80°C, and the injection speed is 20cm 3 / s.

[0036] (3) Put the solid foaming embryo into the mold, and impregnate it with supercritical fluid for 150 minutes at 160°C and 15MPa, in which the volume ratio of carbon dioxide and nitrogen is 10Mpa, and then release the pressure at a rate of 5MPa / s. The foamed embryo body ...

Embodiment 2

[0038] This embodiment provides a method for preparing a foamed product, specifically a sports shoe midsole with a pattern on the surface, comprising the following steps:

[0039] (1) According to the external dimensions of the midsole of the sports shoes to be prepared, use breathable steel to process and manufacture molds with the same internal cavity external dimensions and surface patterns after mirror conversion;

[0040] (2) Select hardness as 98A, melting point as 160°C and density as 1.07g / cm 3The TPEE resin is used as the material, and the solid foaming body is prepared by injection molding. The injection temperature is 205°C, the mold temperature is 90°C, and the injection speed is 30cm 3 / s.

[0041] (3) Put the solid foaming embryo into the mold, and impregnate it with supercritical fluid for 20 minutes at 155°C and 25MPa, in which the volume ratio of carbon dioxide and nitrogen is 4:1, and then release the pressure at a rate of 1MPa / s , the solid foaming embryo ...

Embodiment 3

[0043] This embodiment provides a method for preparing a foamed product, specifically a sports shoe midsole with a pattern on the surface, comprising the following steps:

[0044] (1) According to the external dimensions of the midsole of the sports shoes to be prepared, use breathable steel to process and manufacture molds with the same internal cavity external dimensions and surface patterns after mirror conversion;

[0045] (2) Select hardness as 94A, melting point as 170°C and density as 1.02g / cm 3 The TPAE resin is used as the material, and the solid foaming body is prepared by injection molding. The injection temperature is 210°C, the mold temperature is 70°C, and the injection speed is 30cm 3 / s;

[0046] (3) Put the solid foaming embryo body into the mold, and pass supercritical N 2 Immerse for 80 minutes, and then release the pressure at a rate of 1000MPa / s. The solid foaming body expands and foams, and forms thermal pressure when it contacts the inner wall of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com