A kind of preparation method of steel biomimetic multi-scale superhydrophobic functional surface

A super-hydrophobic, multi-scale technology, which is applied in the direction of surface coating liquid devices, special surfaces, coatings, etc., to achieve the effect of simple operation process, low requirements for experimental conditions, and not easy to freeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The surface of the X70 pipeline steel sample is shot peened by an industrial shot peening machine, the particle size of the steel shot is 0.9 mm, and the shot peening time is 2 minutes.

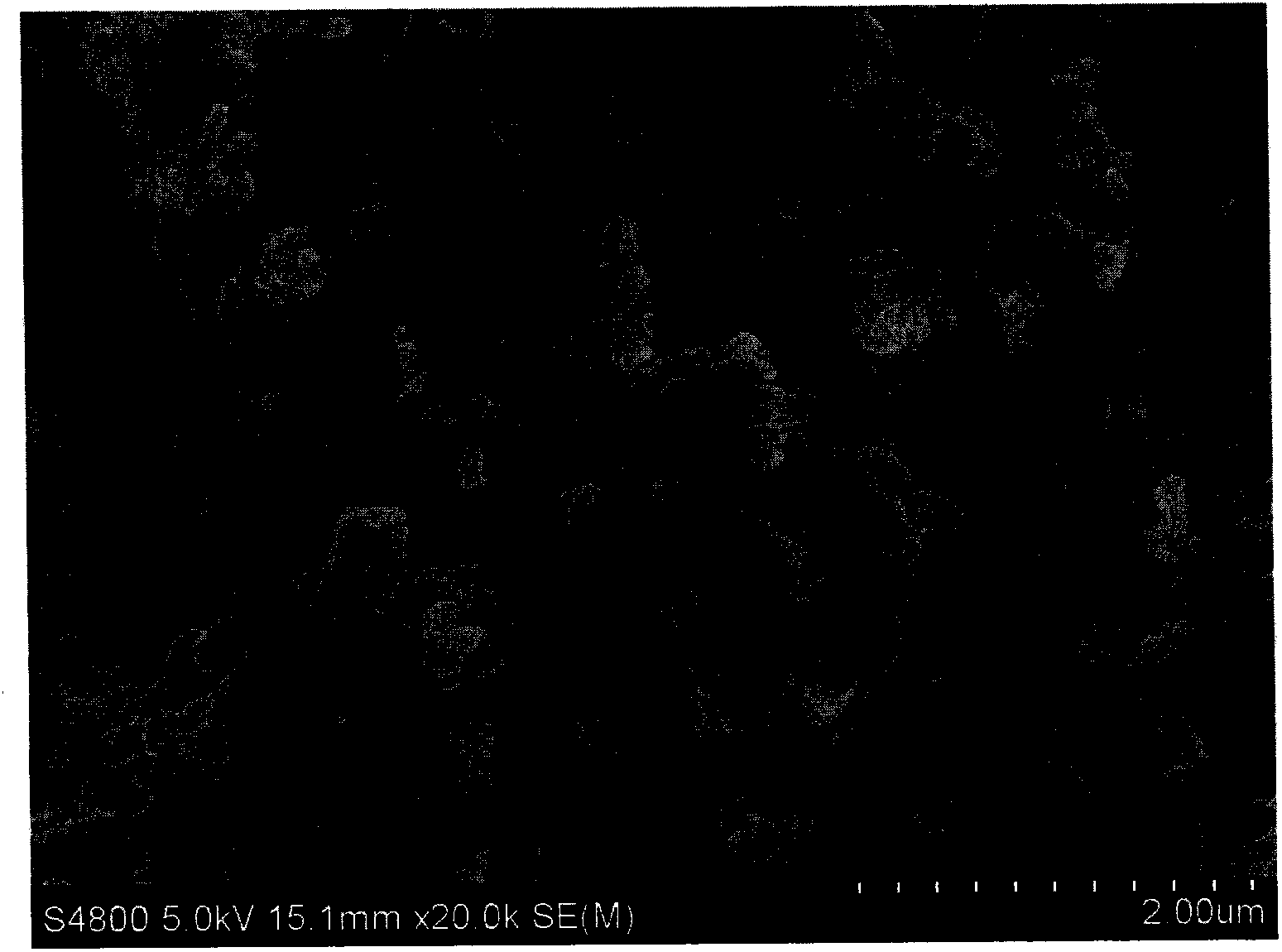

[0026] Prepare a hydrochloric acid solution with a concentration of 6mol / L, put the shot blasted X70 pipeline steel sample into the hydrochloric acid solution for chemical etching, the etching time is 320 minutes, take it out after the reaction, put it in deionized water, and clean it with ultrasonic waves Clean the instrument and dry it with a hair dryer. After the above treatment, a large number of "coral" structures with a diameter of about 1 μm were formed on the surface of the sample. On each "coral" structure, nano-scale fine layered and worm-like structures were evenly distributed. Together form a micro-nano multi-scale structure, such as figure 1 As shown, the steel surface has the micro-nano structure required to form a hydrophobic surface.

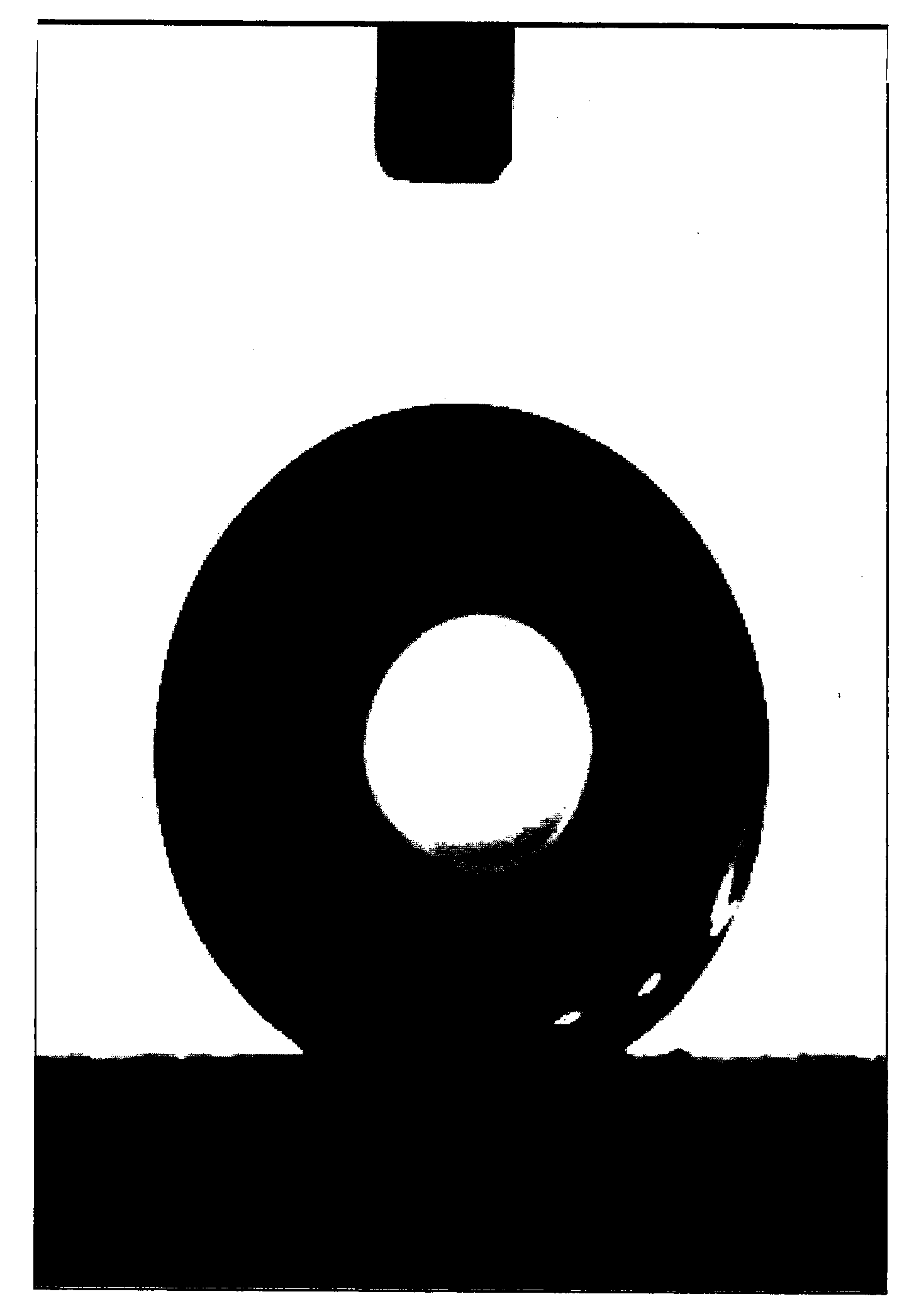

[0027] Prepare a myristic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com