High voltage porcelain insulating semiconductor glaze

A technology of insulating semiconductor and high-voltage porcelain, which is applied in the field of semiconductor glaze, can solve the problems of insufficient smoothness of semiconductor glaze, rough surface of semiconductor glaze, low structural stability, etc., and achieve good suspension performance of glaze slurry, good gloss, and accelerated melting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

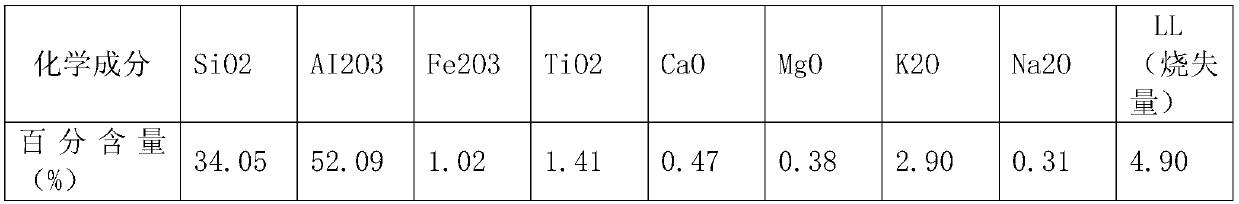

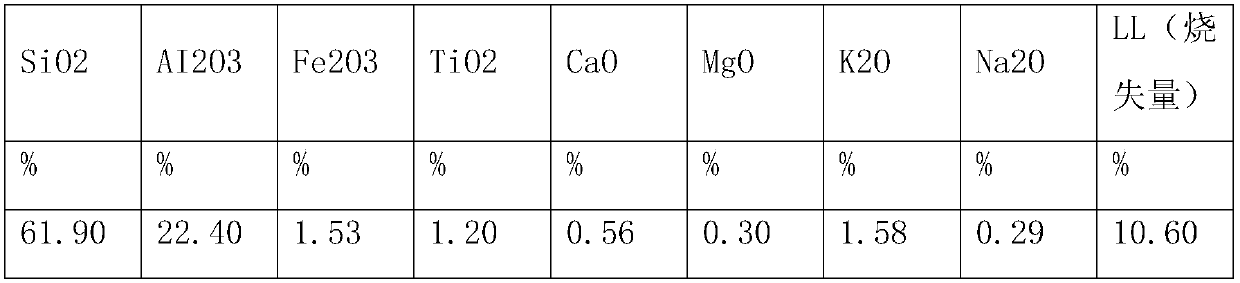

[0017] 1. Physical and chemical properties of raw materials

[0018] High-voltage ceramic insulating semiconducting glaze, made of ten kinds of raw materials including high-potassium and low-iron feldspar, quartz powder, forged talc, mud, barium carbonate, Dongsheng soil, iron oxide red, chromium oxide green, titanium dioxide and spodumene , the specific physical and chemical properties of raw materials are as follows:

[0019] 1. High-potassium and low-iron feldspar: Fujian feldspar is used, produced in Sanlian Mineral Products Processing Plant in Shaowu City, Fujian Province.

[0020] (1) Appearance quality

[0021] Before burning: yellow or light yellow powder.

[0022] After firing: It is in the shape of white frit, round and smooth, with a smooth cross-section and a small amount of black spots evenly distributed.

[0023] (2) Chemical analysis

[0024] SiO2

AI2O3

Fe2O3

TiO2

CaO

MgO

K2O

Na2O

LL

%

%

%

%

%

% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com