Patents

Literature

63results about How to "Increase the effective surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

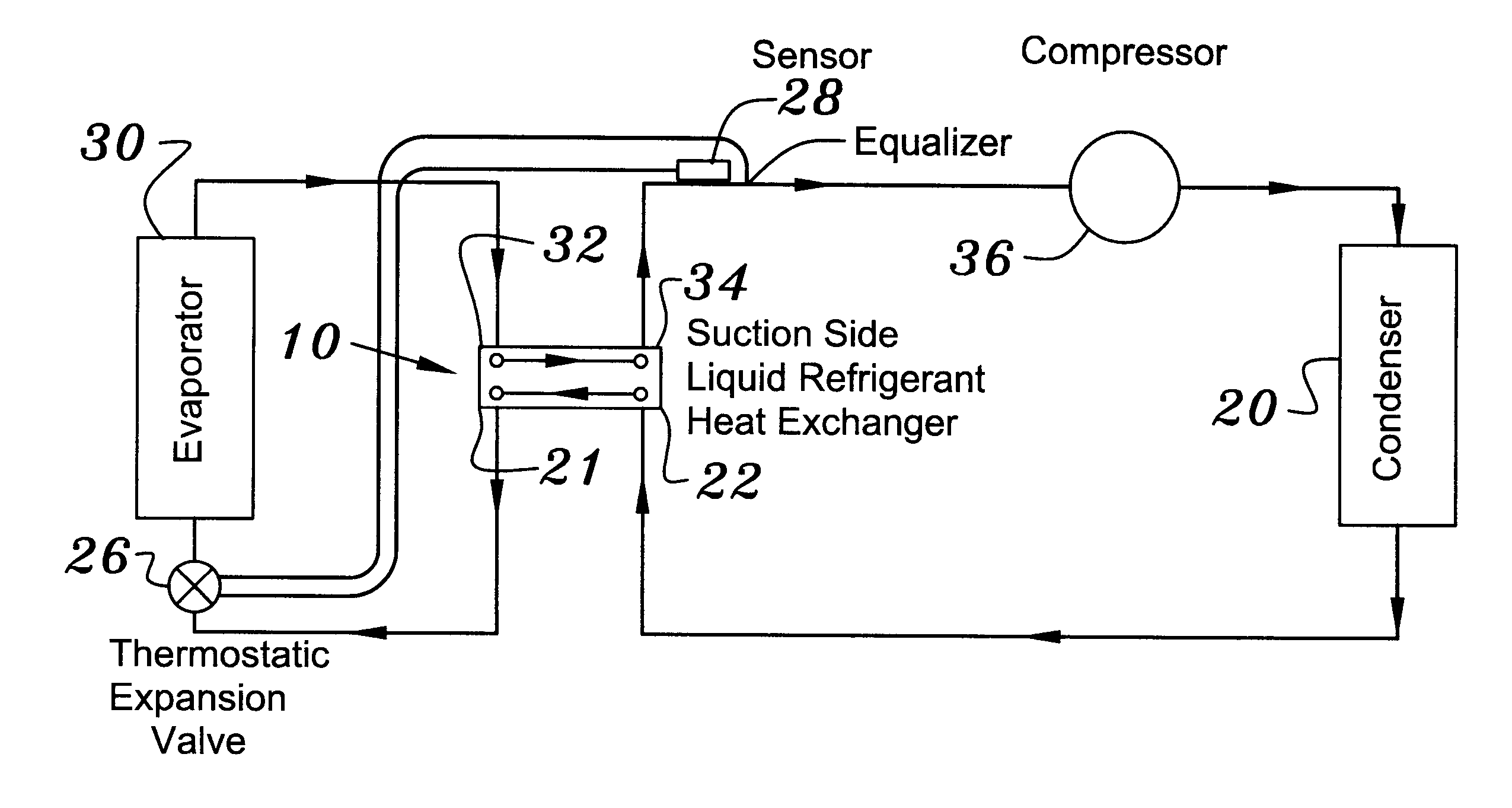

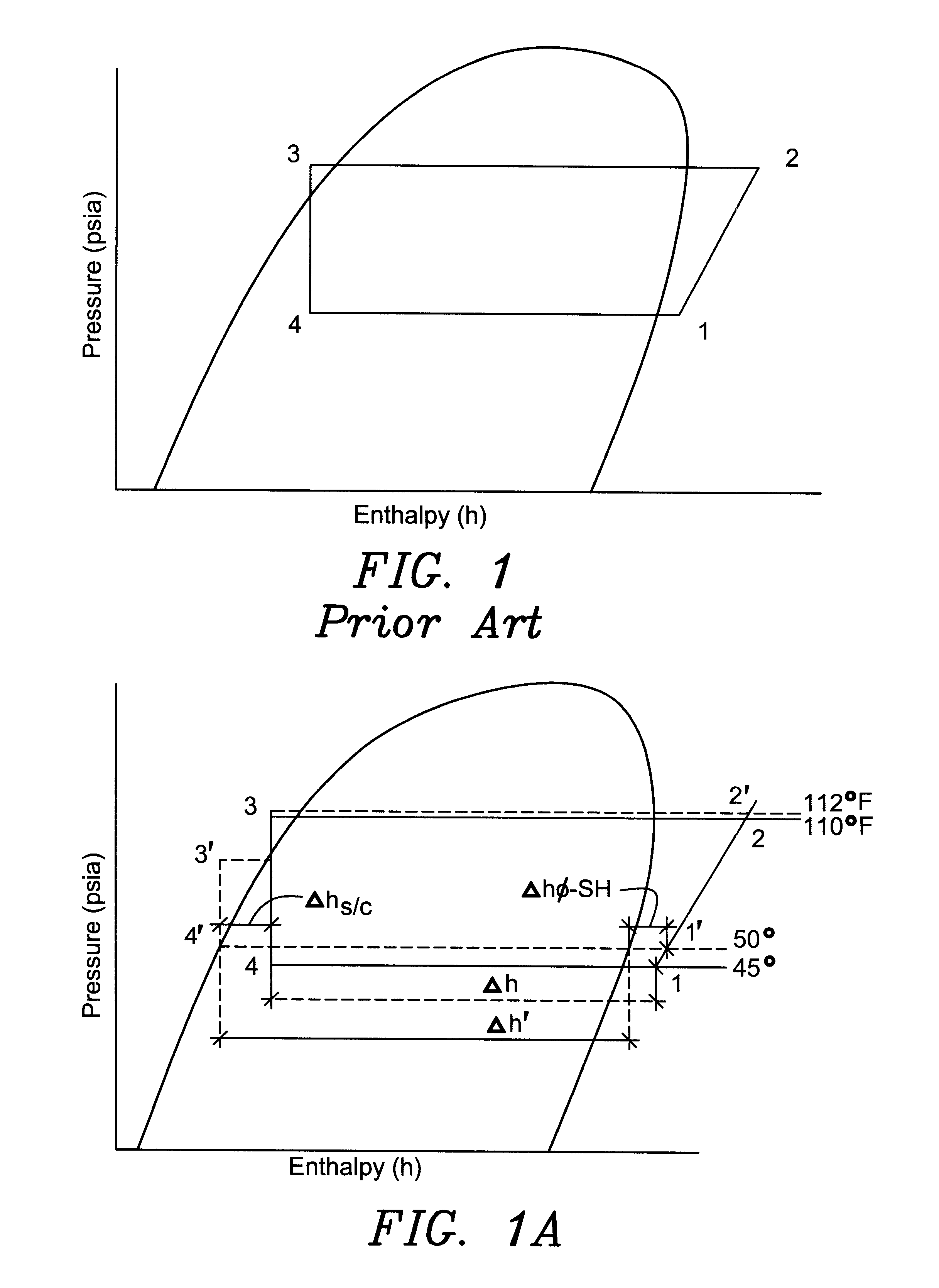

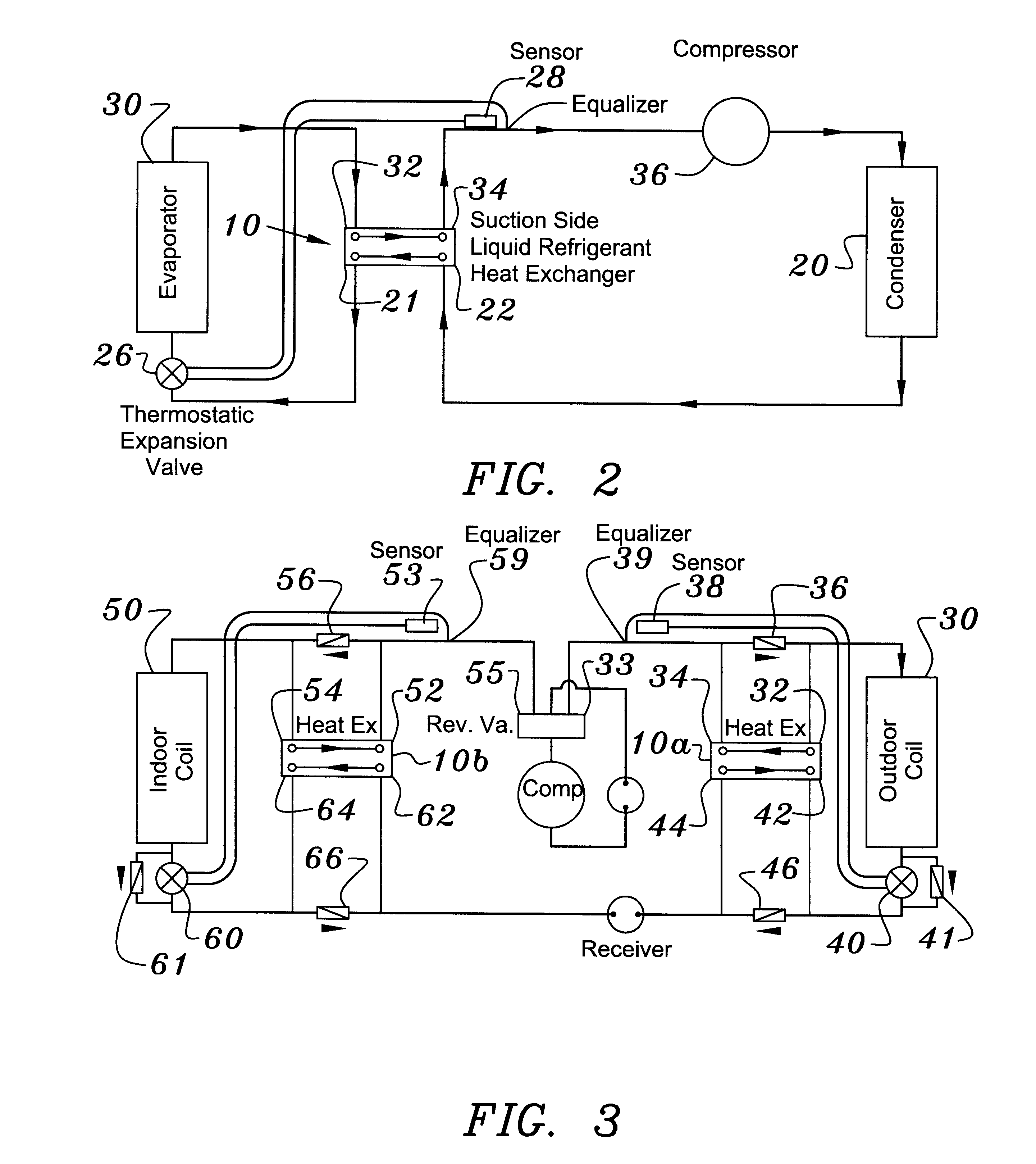

Flash gas and superheat eliminator for evaporators and method therefor

InactiveUS6460358B1Comprehensive understandingImprove cooling effectMechanical apparatusFluid circulation arrangementHeat rejectionFlash-gas

A low pressure suction side refrigerant to liquid refrigerant heat exchanger, located in the refrigeration circuit in such a way that the sensor (and external equalizer tube, if applicable) is located downstream of the low pressure refrigerant outlet of the heat exchanger, provides for effectively eliminating both the superheat and flash gas loss regions of the evaporator which in turn increases the mass flow through the evaporator and increases the refrigerating capacity of the evaporator at very little increase in compressor power thereby providing for increased system efficiency for refrigerating or cooling purposes. On the heating side, heat rejection capacity of a heat pump is increased even more dramatically because of the heat reclaim of the flash gas loss heat, which provides for even greater efficiency increases for heating applications.

Owner:OLIVE TREE PATENTS 1 +1

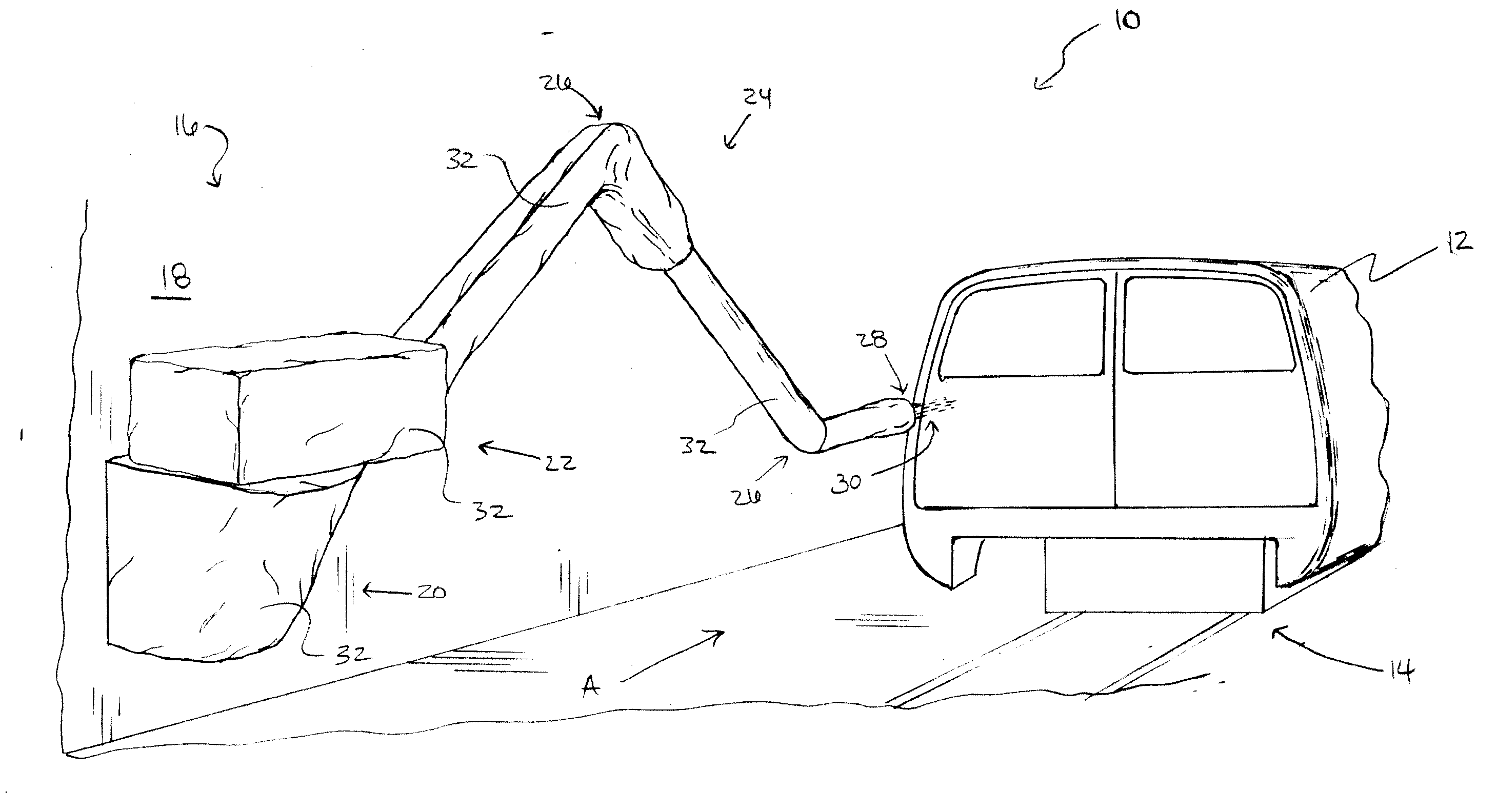

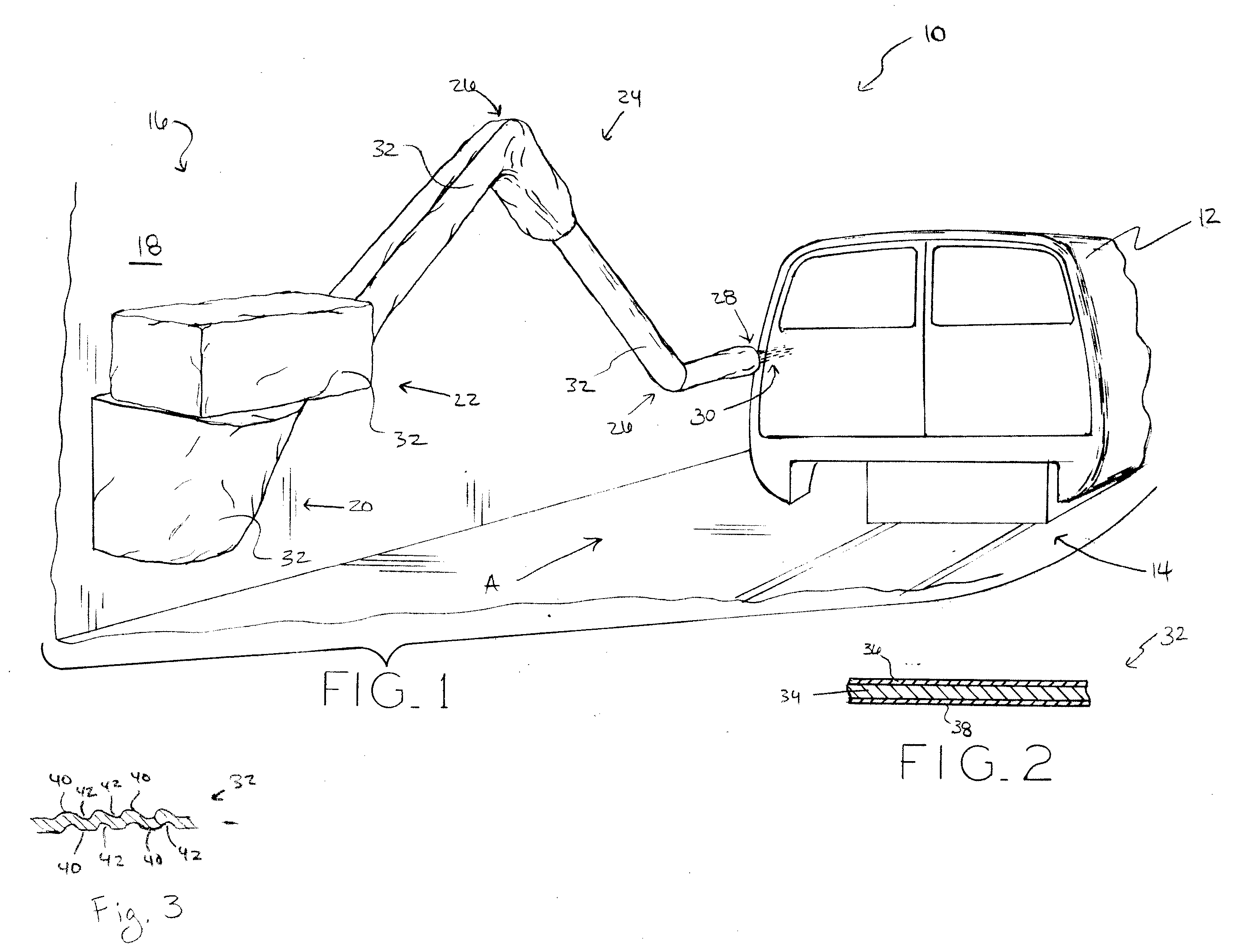

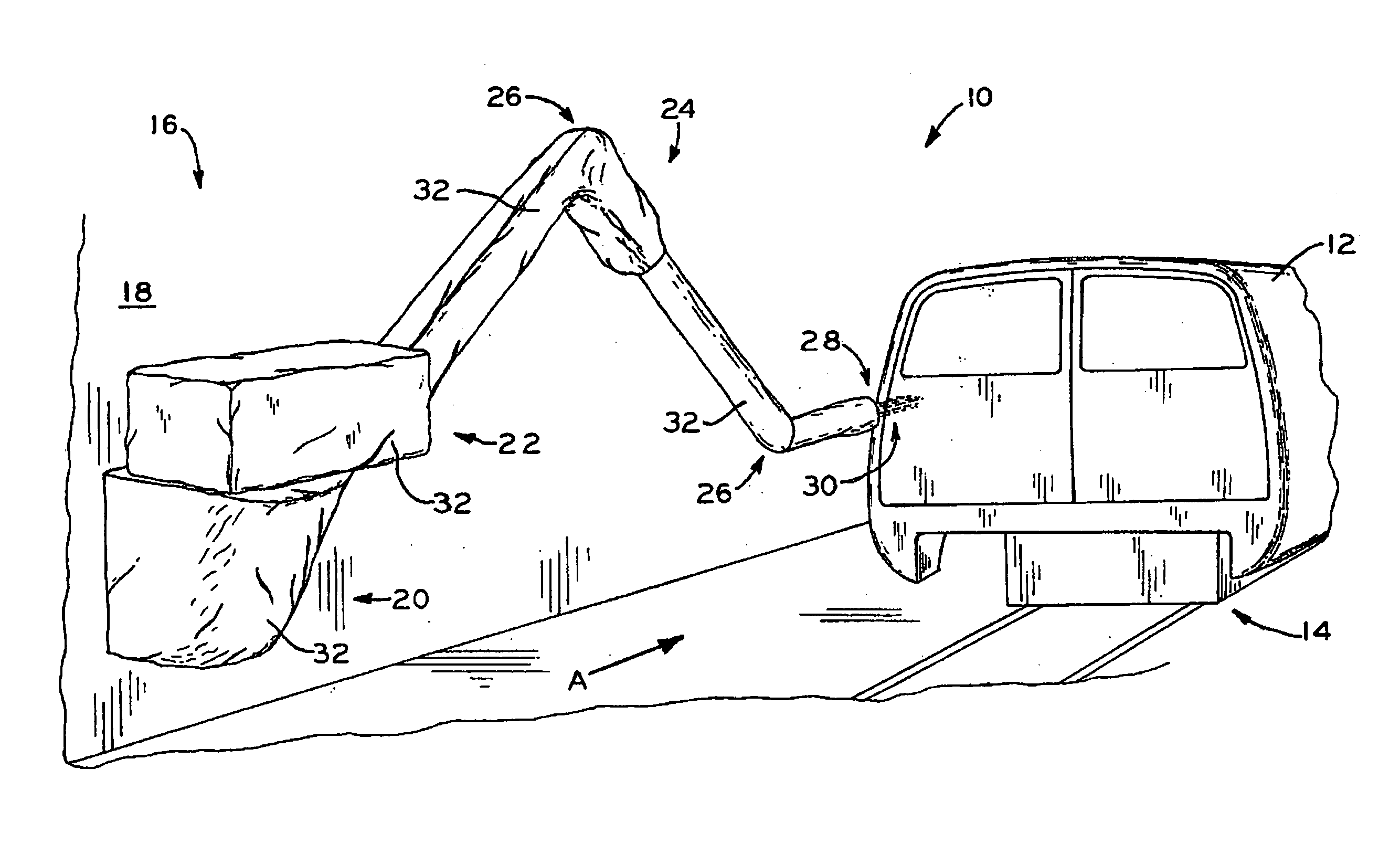

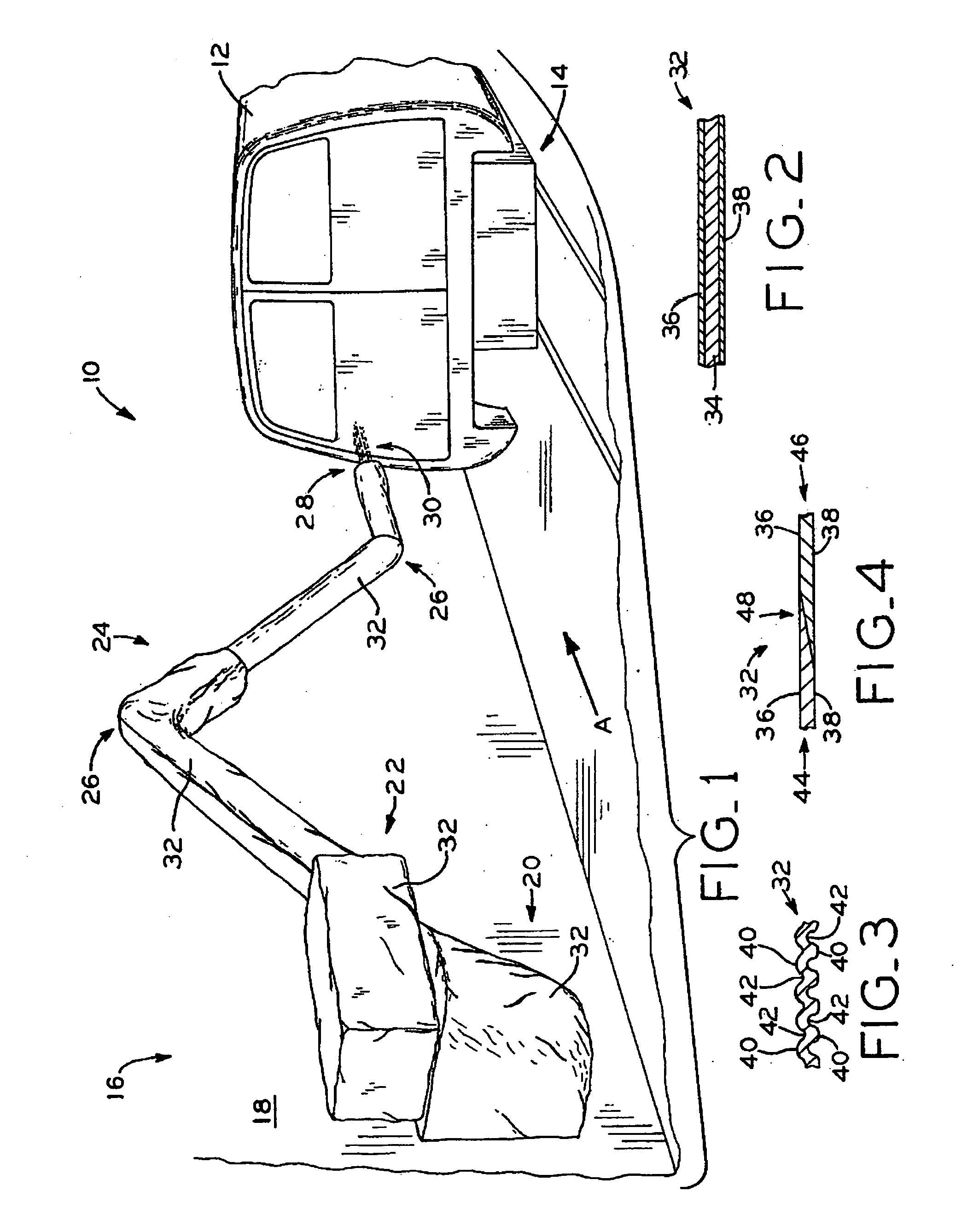

Polymeric cover for robots

ActiveUS20080237921A1Improve abilitiesAdhesivity increasedProgramme-controlled manipulatorLiquid surface applicatorsEngineeringPolymer

The present invention involves a cover for a spraying device of a robot which is formed from a polymer with enhanced residue retention properties. The polymer may be processed to increase the surface energy of the polymer. For example, the polymer may be subjected to a corona treatment in order to increase its surface energy. The corona treatment process may be performed on the polymer as received, prior to cutting or otherwise manipulating the polymer. Also, the polymer may be embossed to provide the enhancement. To assemble the polymer into a robot cover, the polymer as received may be cut into individual sections for assembly. The sections may then be assembled to one another by heat sealing the sections together. The heat sealing provides a bond between the individual sections of polymer that secures the individual sections together to create the robot cover. The polymer may also be formed into tubular sections for securing to the spraying device.

Owner:BUTTERWORTH INDS

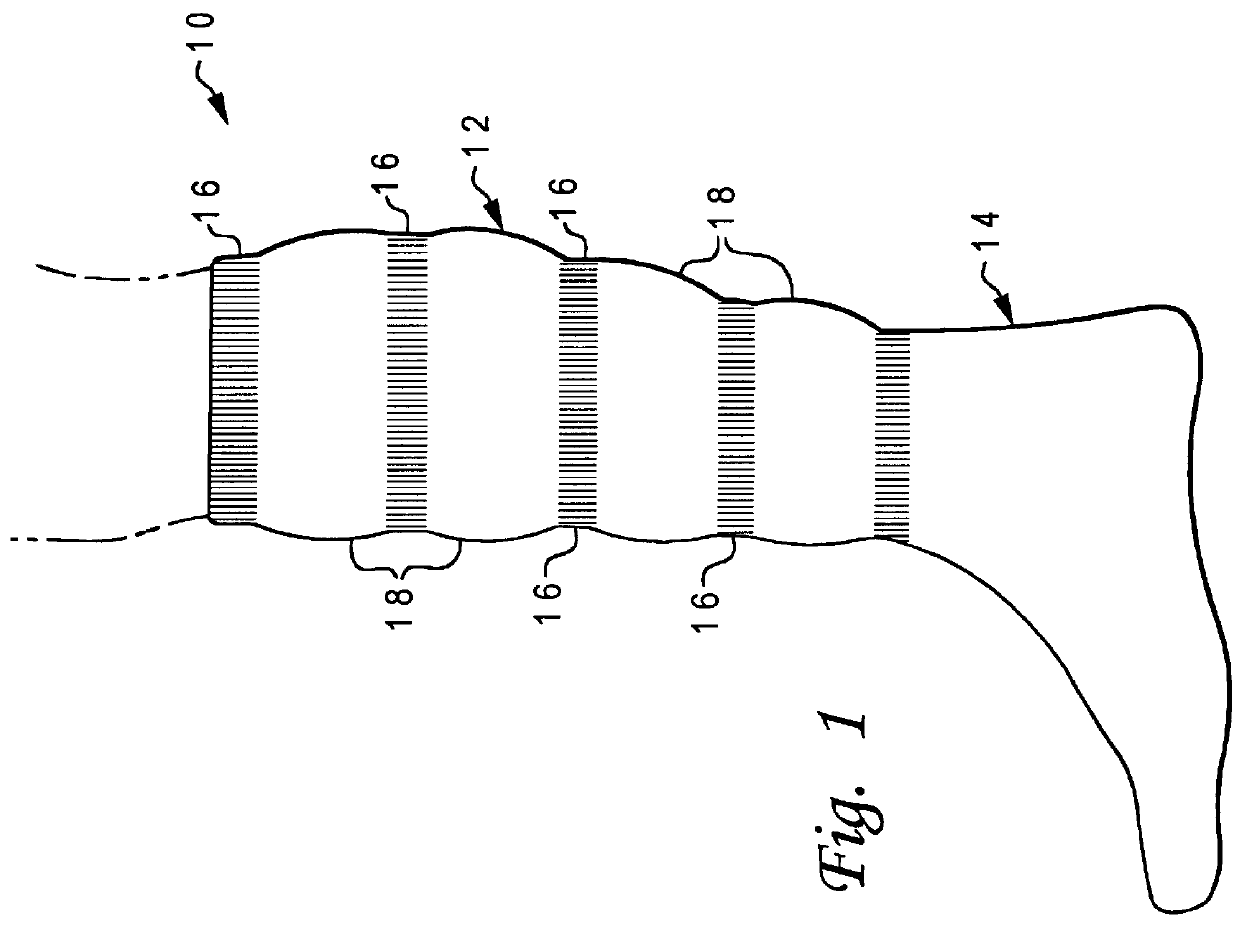

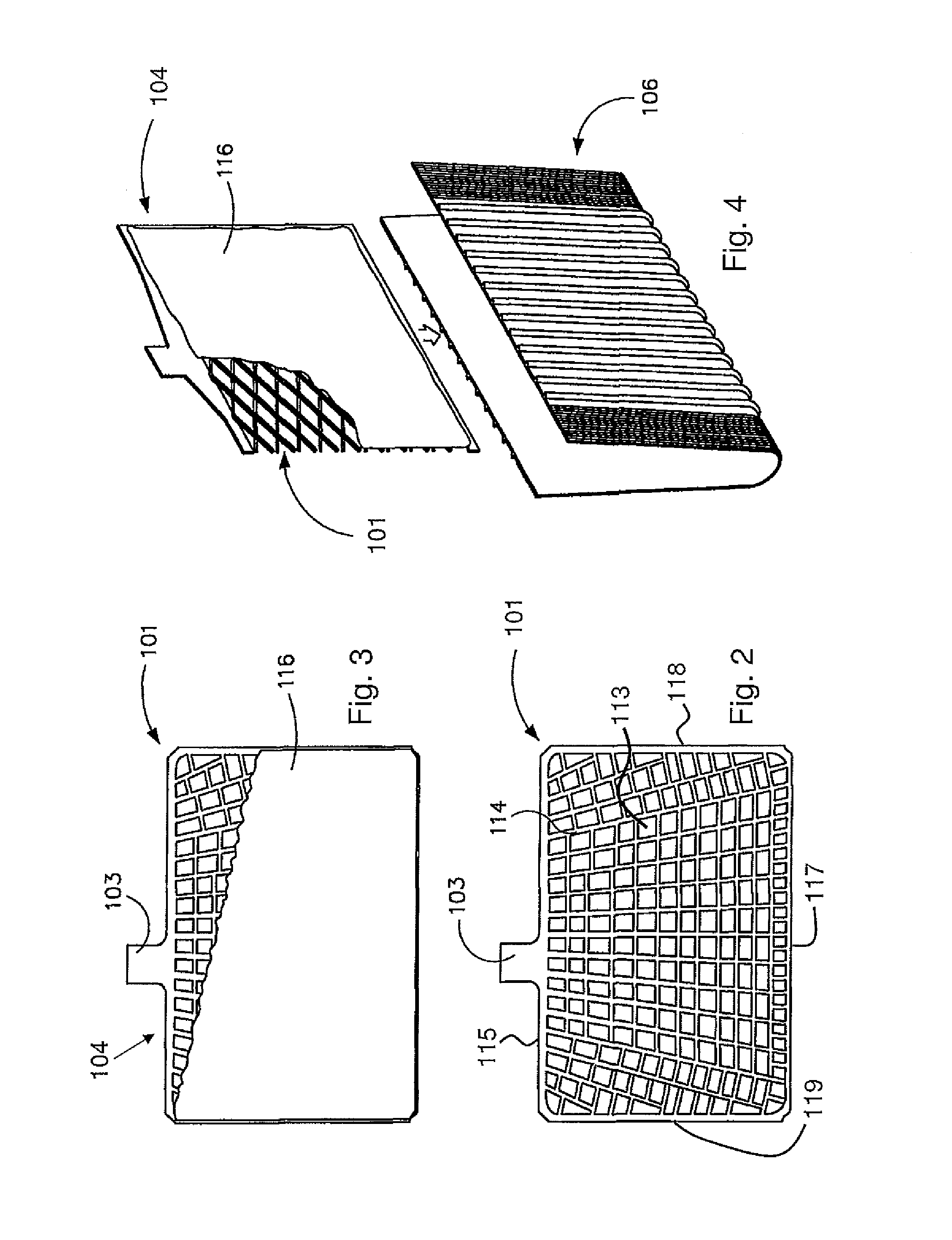

Moisture-absorbent sock

InactiveUS6032295AAccelerated dissipationIncrease the effective surfaceValve arrangementsOrnamental textile articlesYarnEngineering

A sock whose leg portion has wicking regions interspersed among fabric folds which are adapted to increase the effective surface area of the leg portion. The foot and leg portions of the sock may be constructed of the same material, such as synthetic, hydrophobic yarns, and formed in a unitary manner, either by weaving or knitting. The wicking regions may be formed using stitching along outer edges of a plurality of diamond shapes. Alternatively, the wicking regions may be formed by a set of first fabric bands, wherein the fabric folds comprise a set of second fabric bands, and the first and second bands alternate horizontally along a length of the tubular leg portion. The first fabric bands are preferably elastic or stretchable to maintain the first fabric bands in intimate contact with a wearer's skin.

Owner:MARSHALL JAMES B

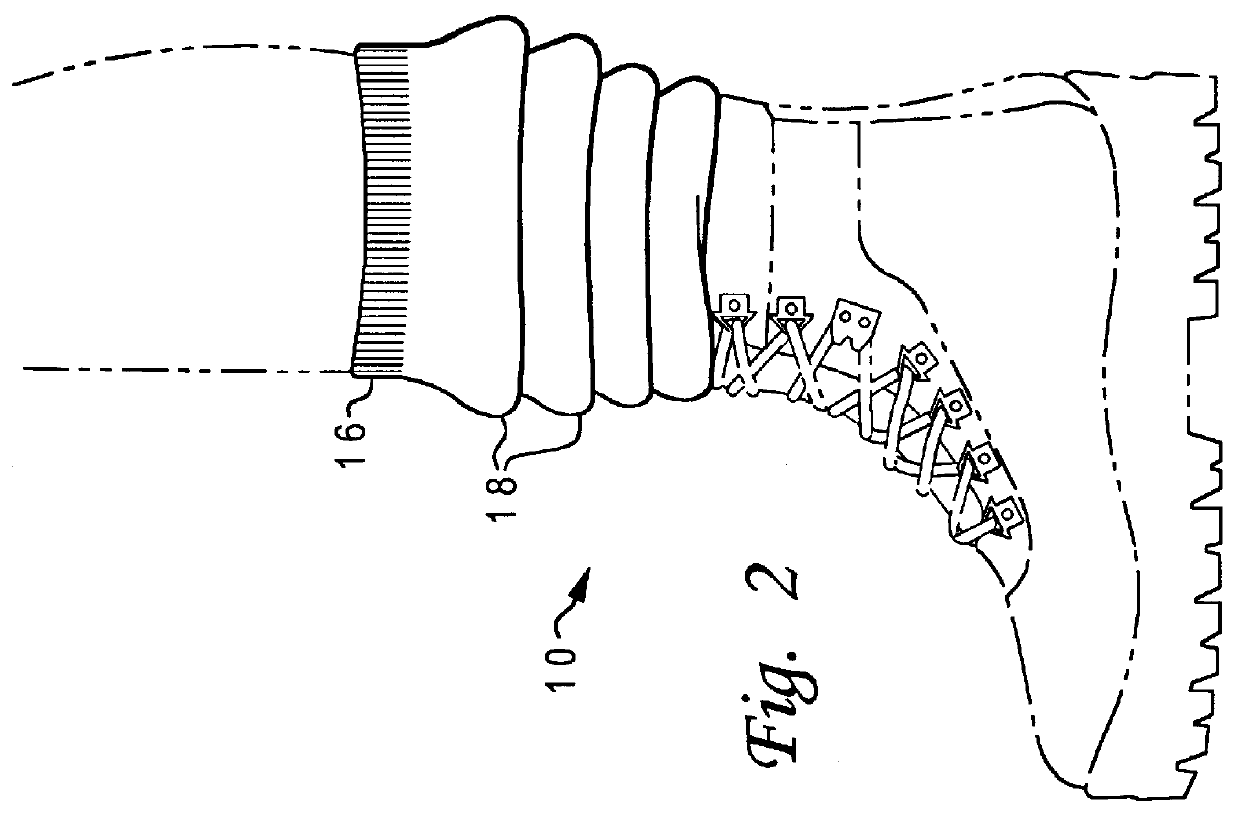

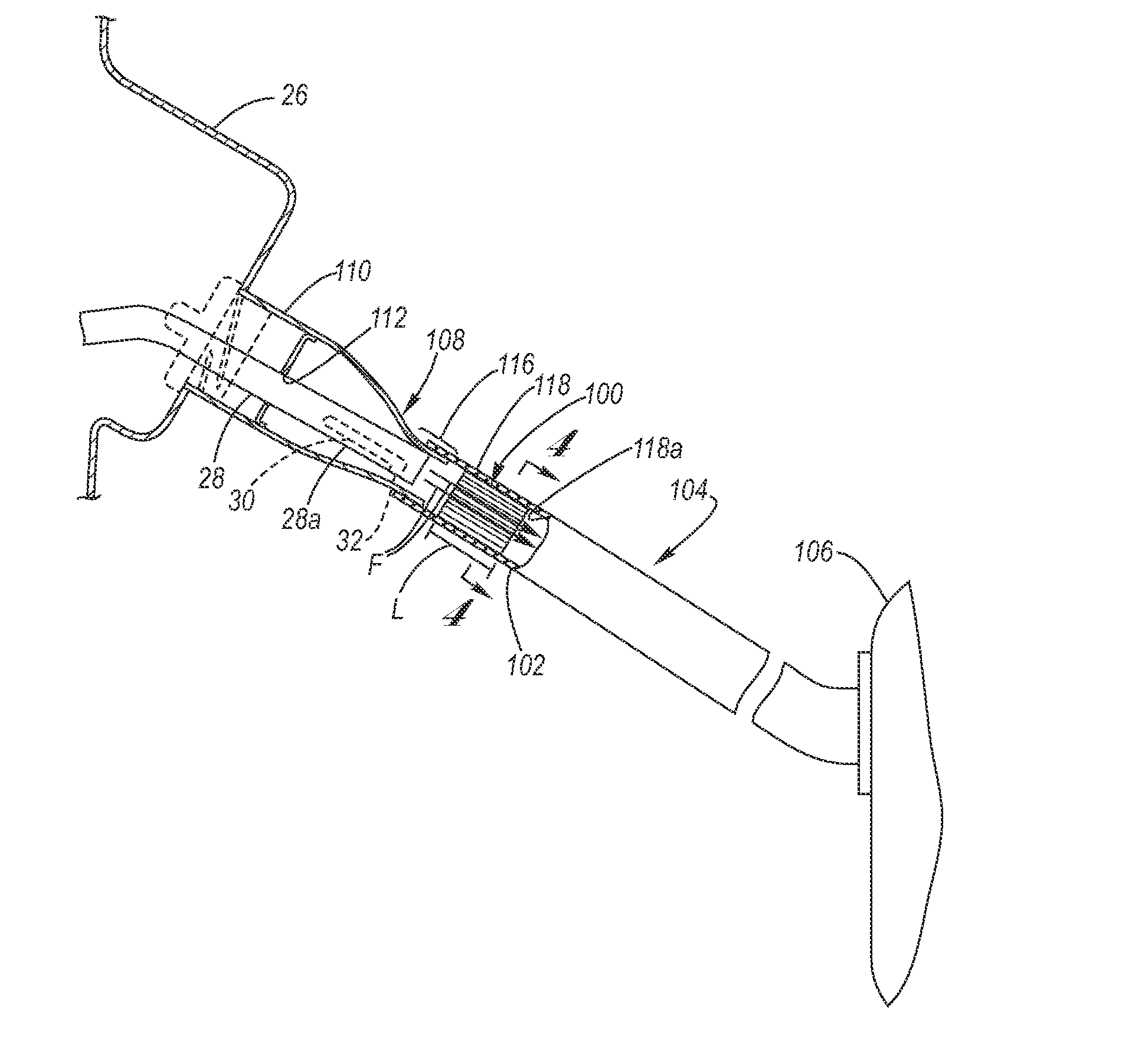

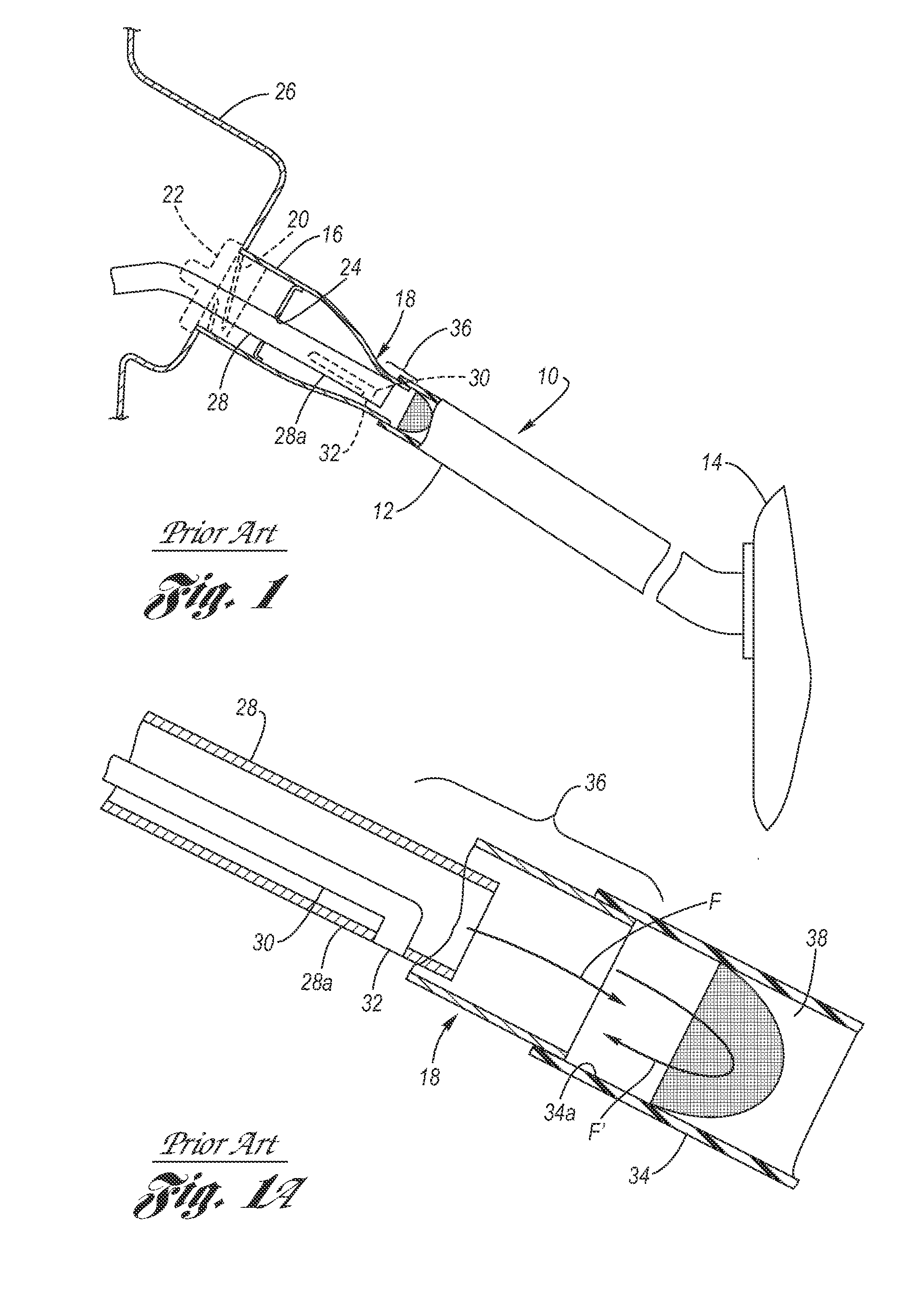

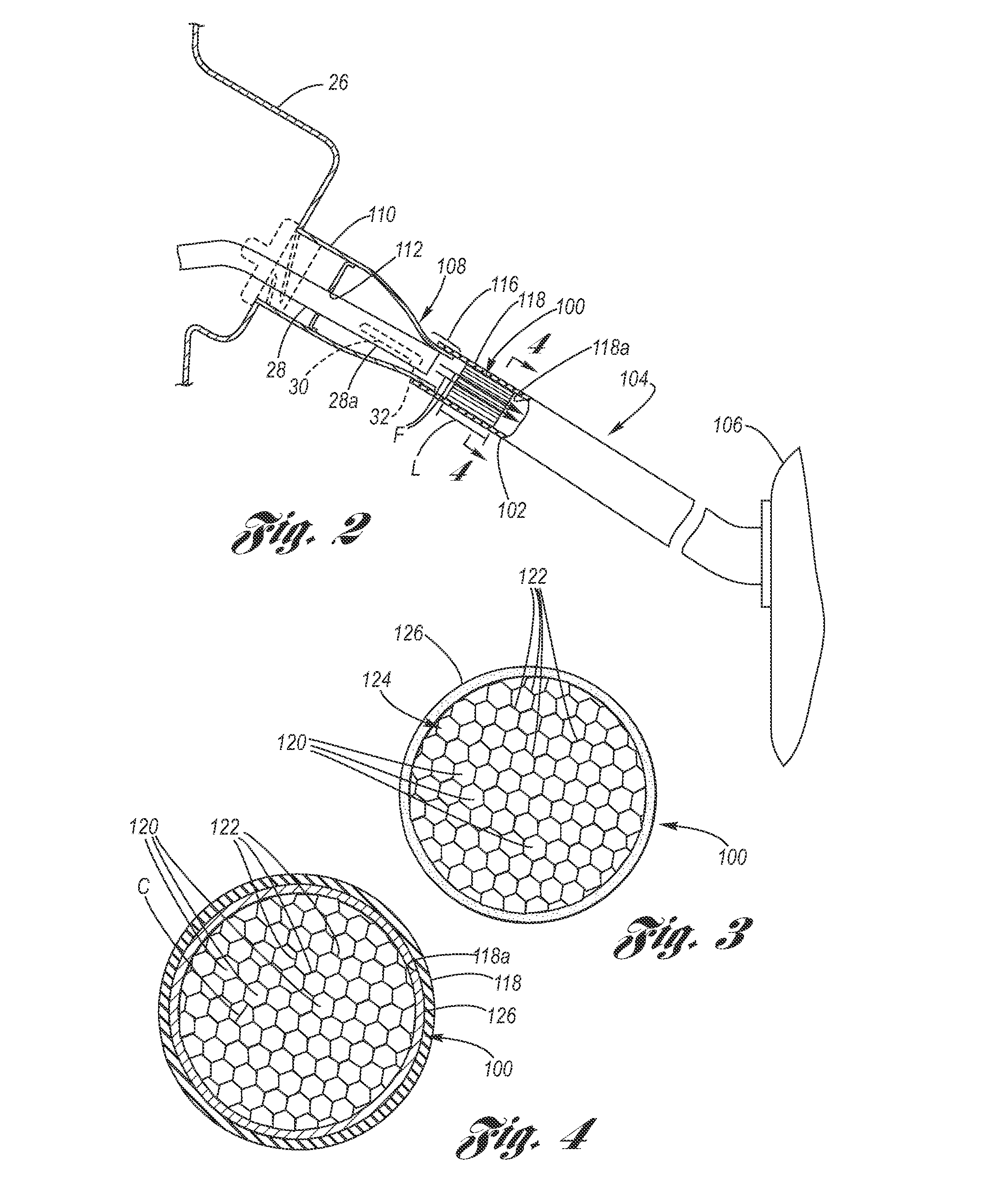

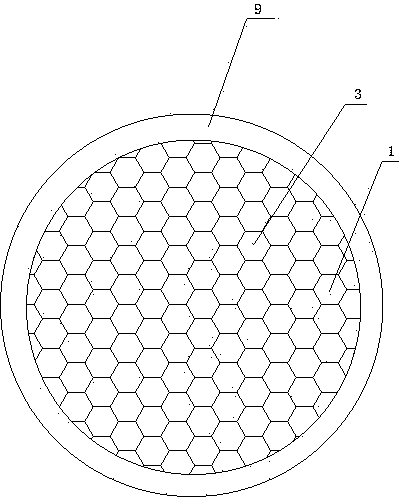

Honeycomb Flame Arrester and Flow Straightener for a Fuel System Fuel Fill Pipe

InactiveUS20080271814A1Ensure efficient flowSpeed up the flowFire rescueLiquid transferring devicesFlame arresterEngineering

A motor vehicle filler pipe flame arrester and fuel flow straightener configured to effectively quench a moving flame front, while providing laminar fuel flow therethrough. A multi-channel (or multi-cell) configuration, most preferably a honeycomb configuration, provides effective flame arresting due to its heat sink capacity and large effective surface area for flame arrestment, while attendantly limiting availability of fuel and oxygen to the flame, thereby providing quenching of a flame wave as it propagates through the channels. Service station pump nozzle shut-off sensor disruption is avoided because the channels encourage laminar flow of the fuel through the multi-channel filler pipe flame arrester and fuel flow straightener.

Owner:GM GLOBAL TECH OPERATIONS LLC

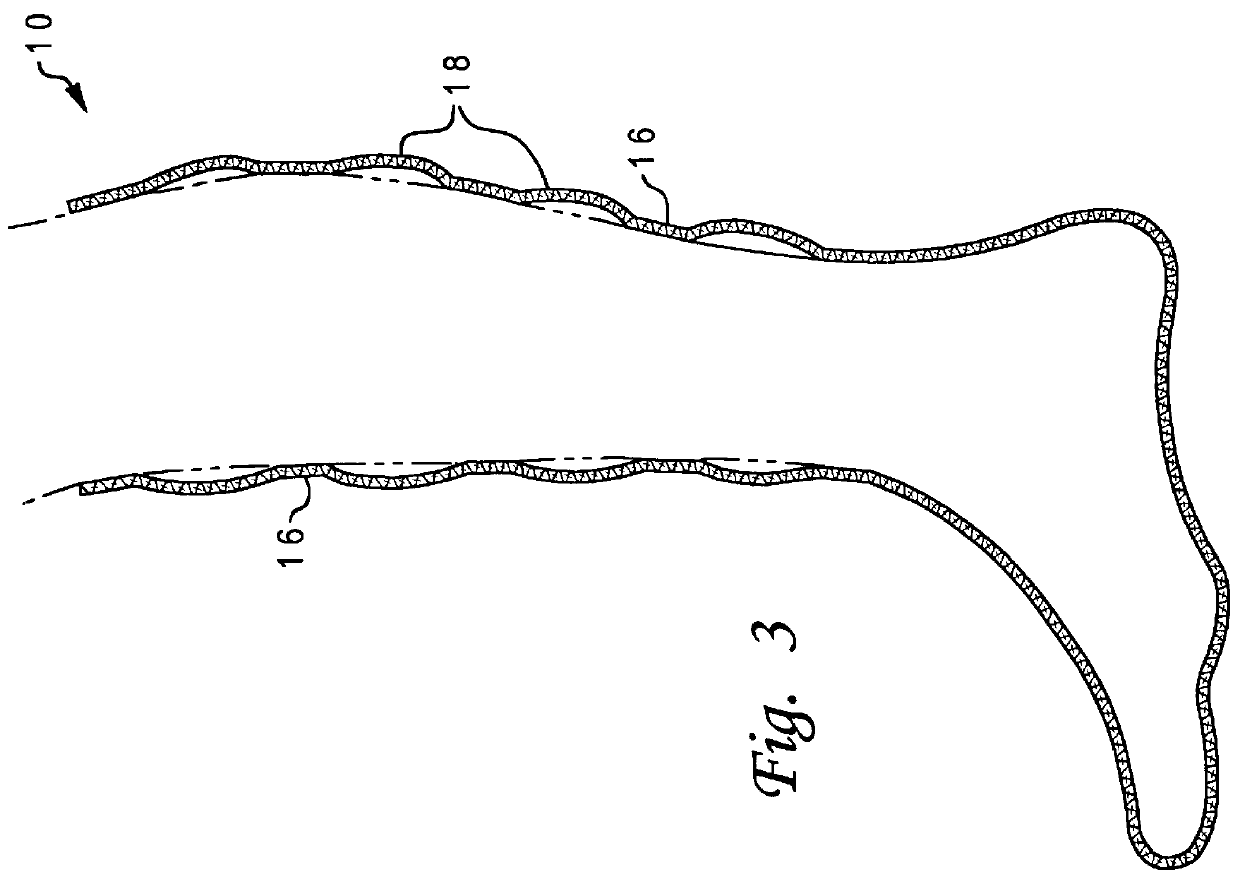

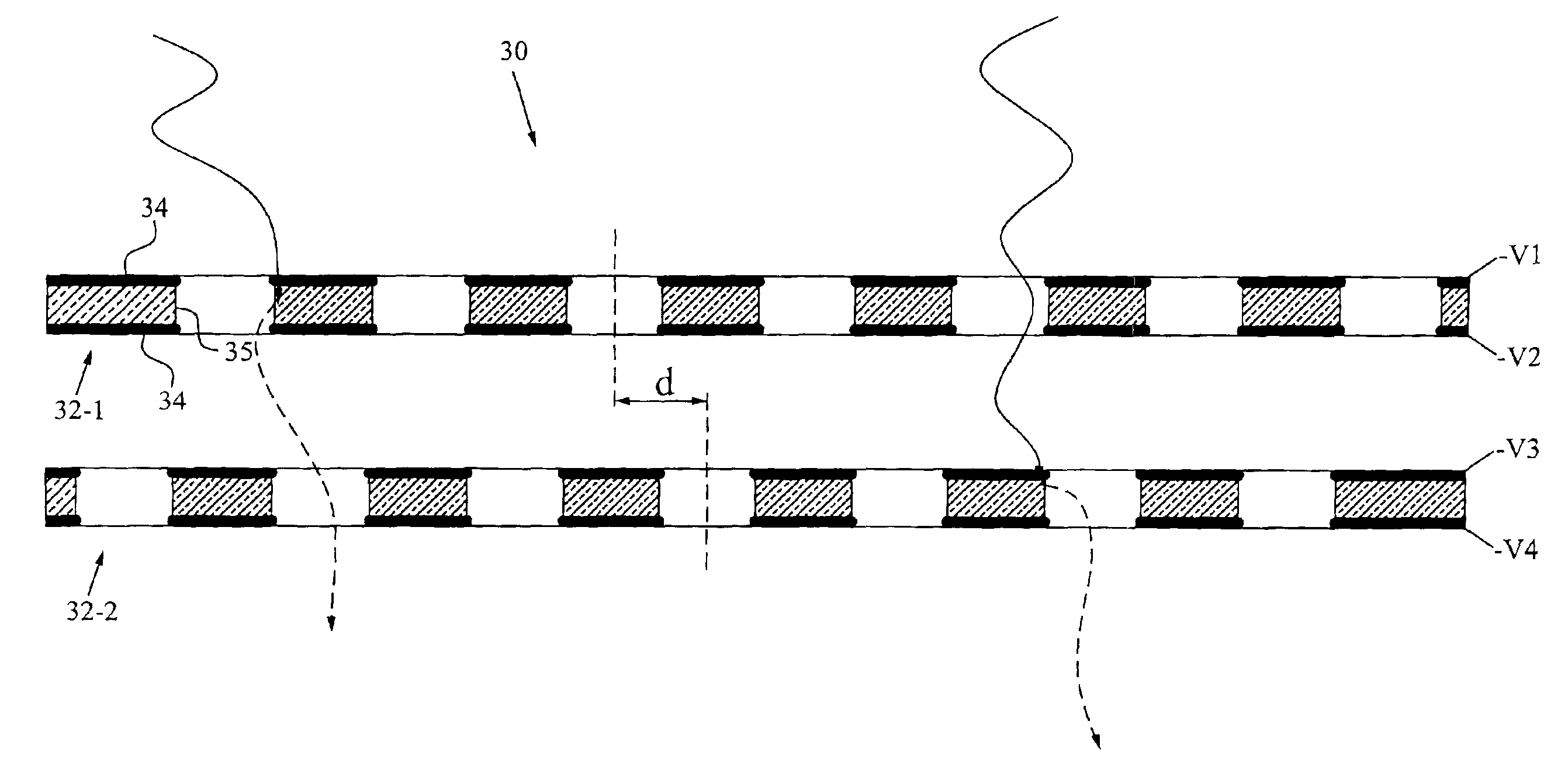

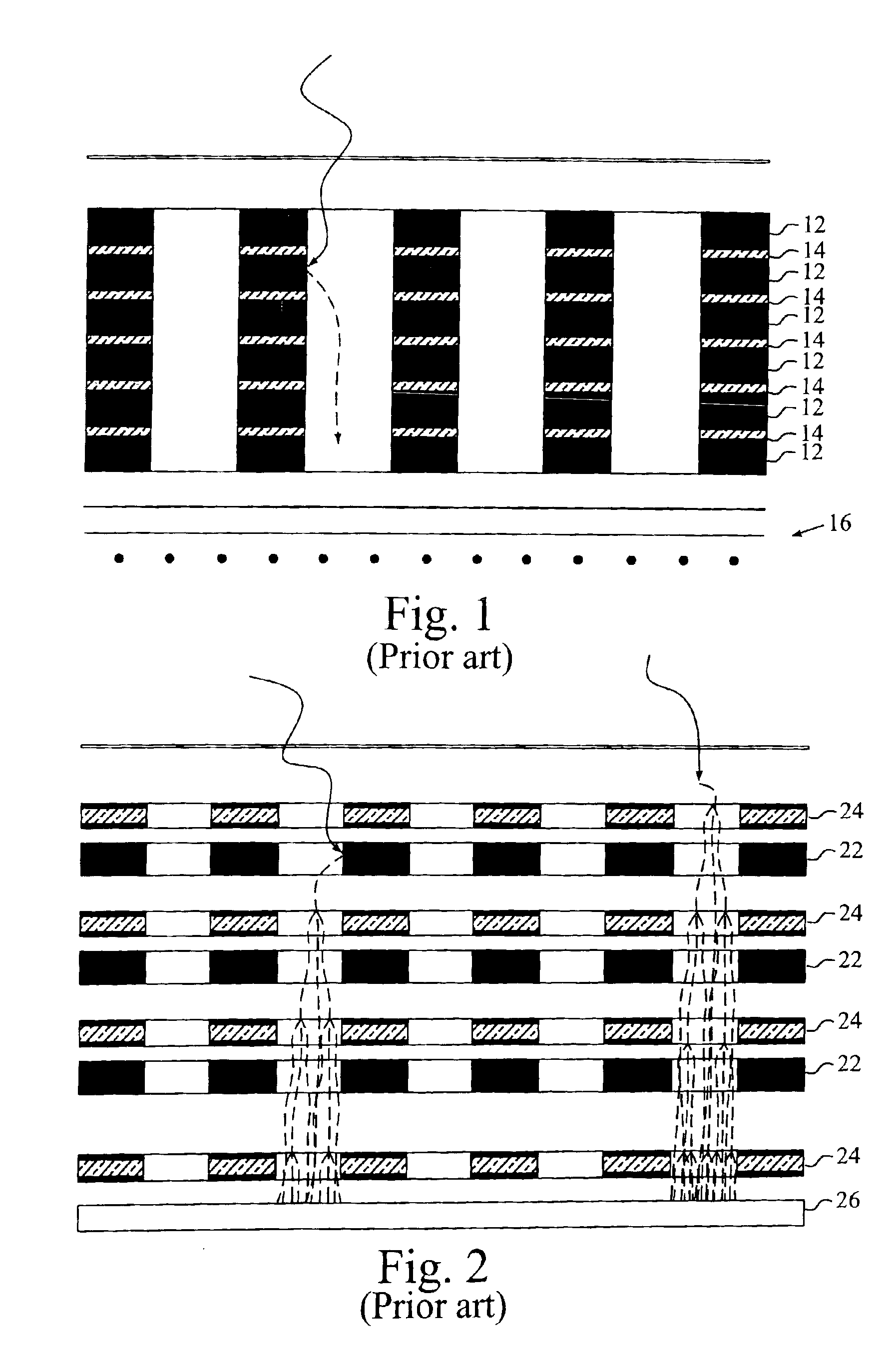

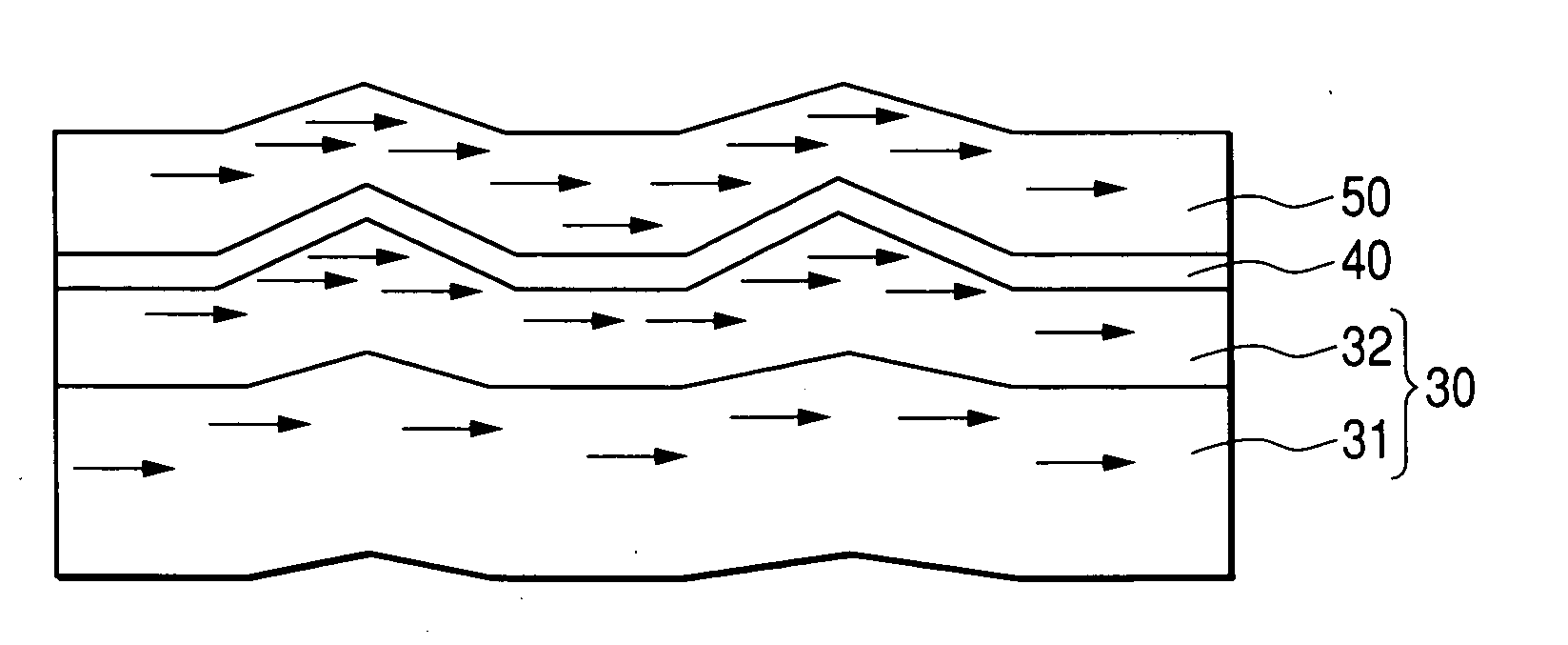

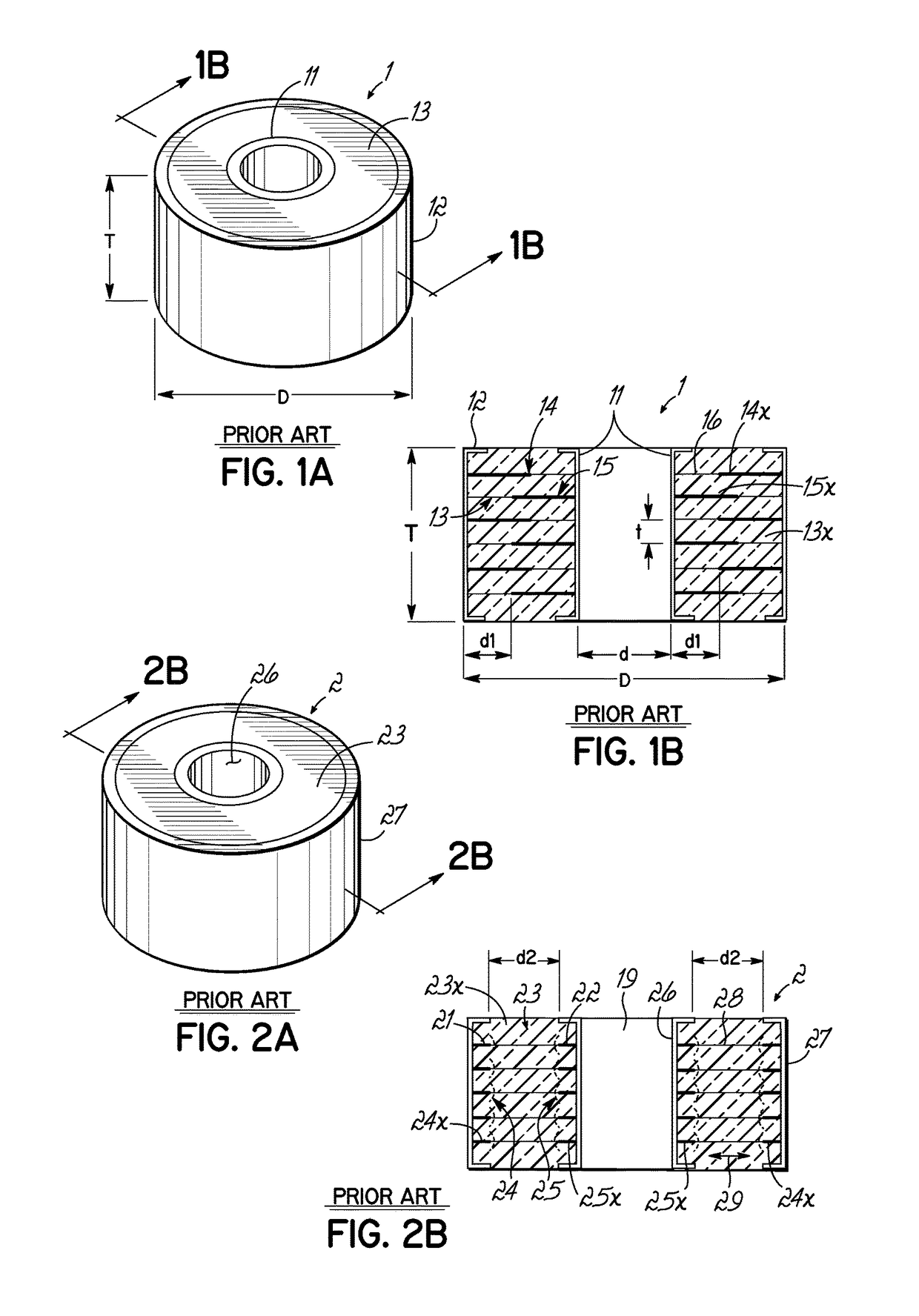

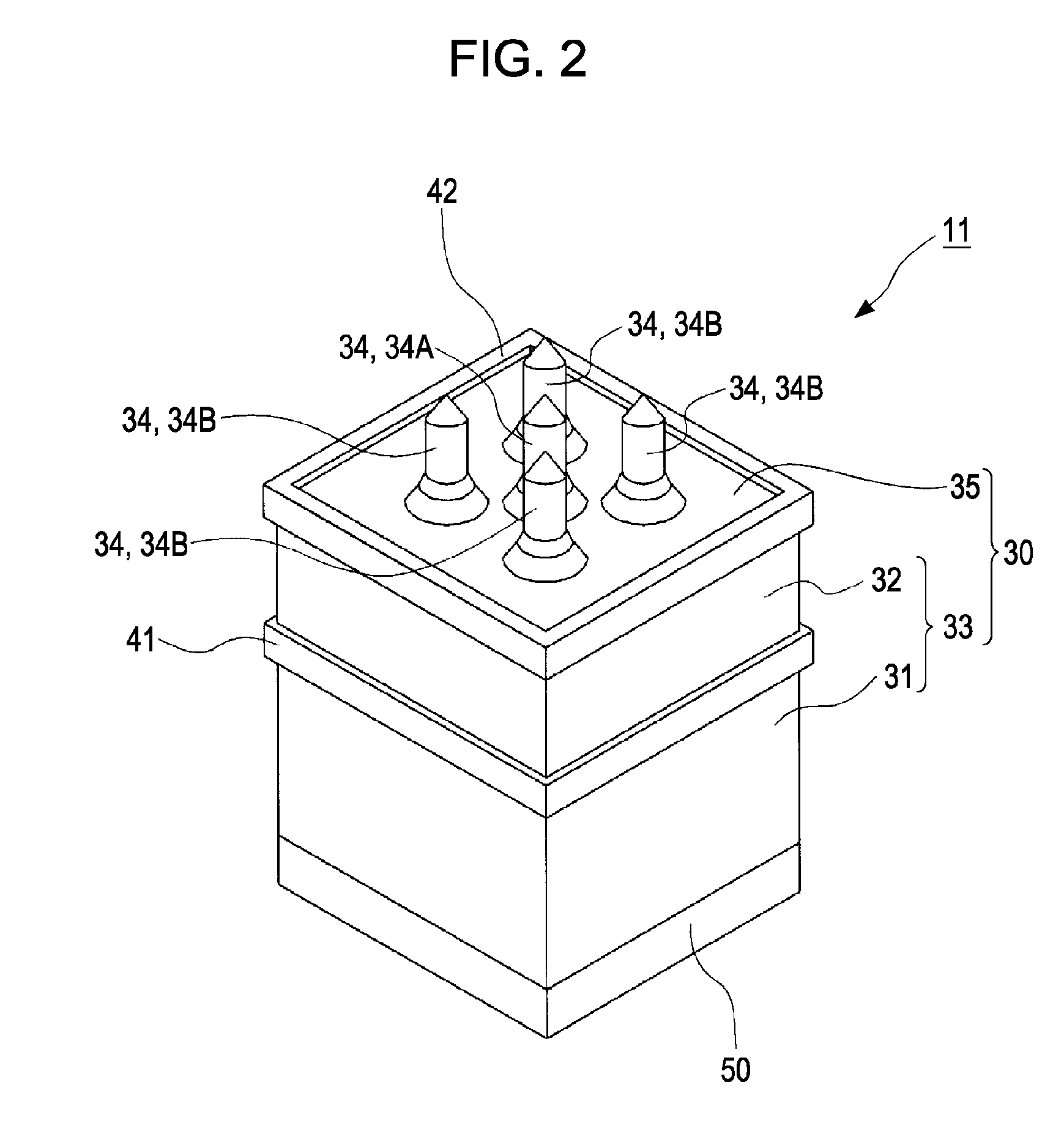

Multi-layered radiation converter

InactiveUS6891166B2Quality improvementImprove efficiencyElectric discharge tubesSolid-state devicesHigh absorptionElectron

The invention relates to a multi-layered radiation converter, a radiation detector comprising such a converter as well as a radiation-based imaging system using such a detector. Each converter layer (32) in the radiation converter is adapted for interaction with incident radiation to cause the emission of electrons into drift holes defined in the converter layer. The drift holes of one converter layer (32-1) are staggered with respect to the drift holes of another converter layer (32-2). By mutually shifting the converter layers such that the drift holes of two different layers are no longer well-aligned, but rather staggered with respect to each other, the effective conversion area will be increased, and the probability of incoming radiation passing through the stack without interaction with the converter layers will be significantly reduced. In this way, high absorption efficiency for incident radiation inside the multi-layered converter structure is ensured, while still maintaining transparency for emitted electrons through the drift holes.

Owner:C-RAD IMAGING AB

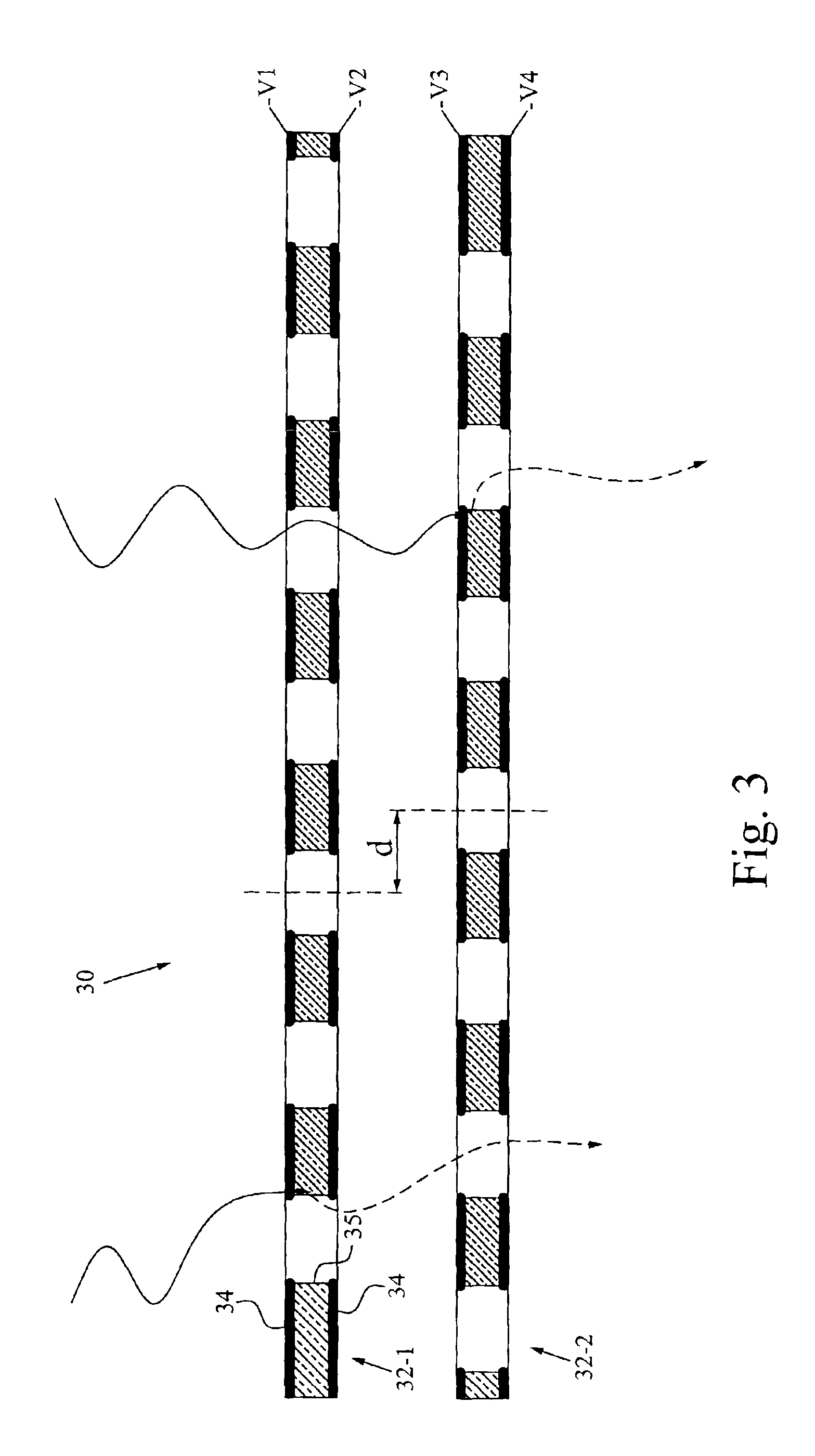

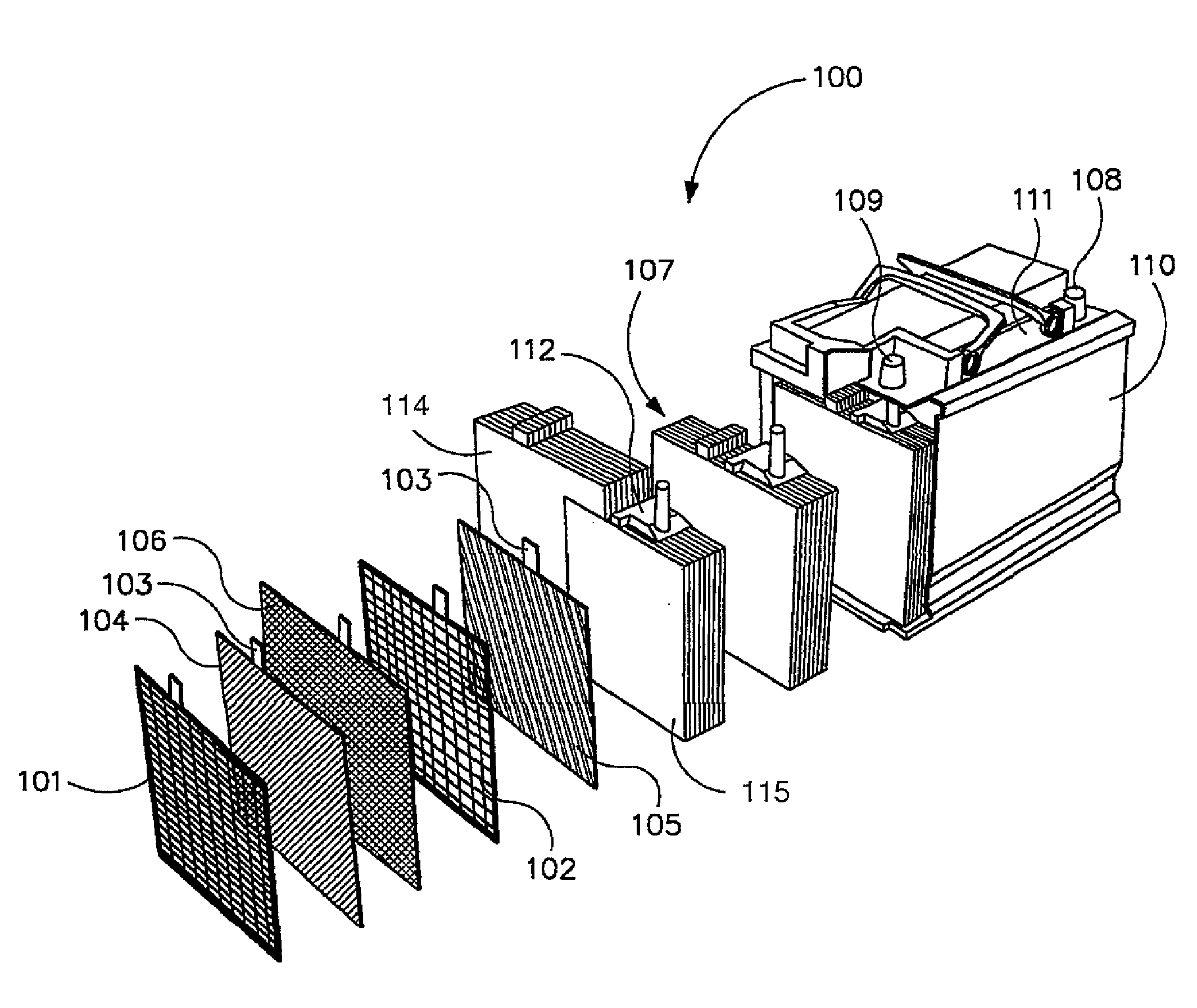

Electrode plate of an electrochemical battery and electrochemical battery comprising such electrode plate

ActiveUS20150104715A1Enhances performance and electricalEffective surface of the electrode plate is increasedElectrode manufacturing processesFinal product manufactureEngineeringElectrical and Electronics engineering

An electrochemical battery is disclosed. The electrochemical battery has an electrode plate comprising a frame and a generally flat grid connected to the frame, the frame comprising at least a top frame member having a contact lug, wherein the grid comprises a plurality of grid wires and a plurality of window-like open areas between the grid wires, further comprising an active mass within the open areas and / or on the grid wires, wherein the electrode plate comprises on one outer surface or on both opposing outer surfaces of the active mass a pattern of grooves, wherein the grooves extend diagonally from a position closer to the top frame member to a position further away from the top frame member. A method for producing an electrode plate is also disclosed.

Owner:CLARIOS GERMANY GMBH & CO KG

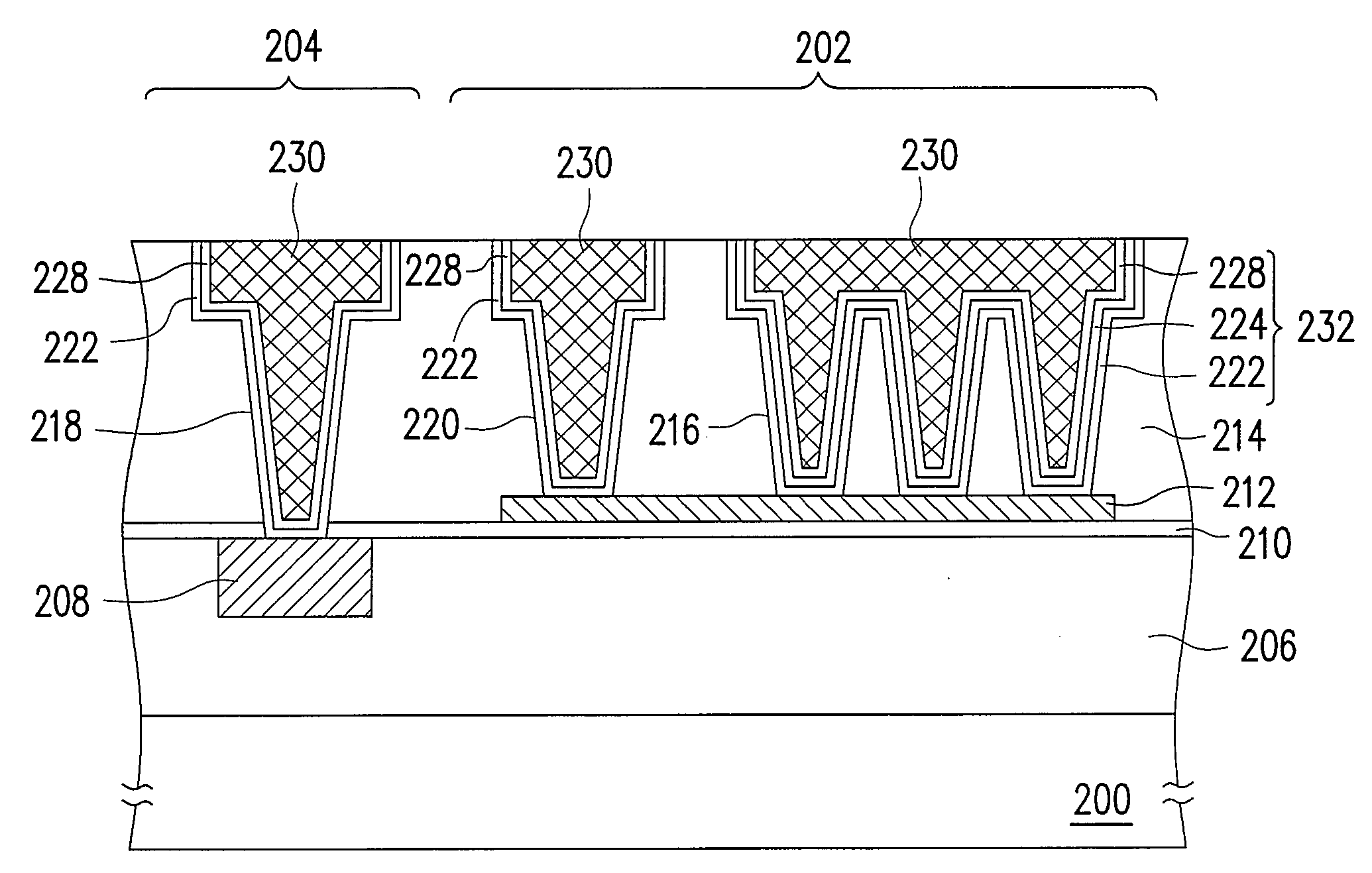

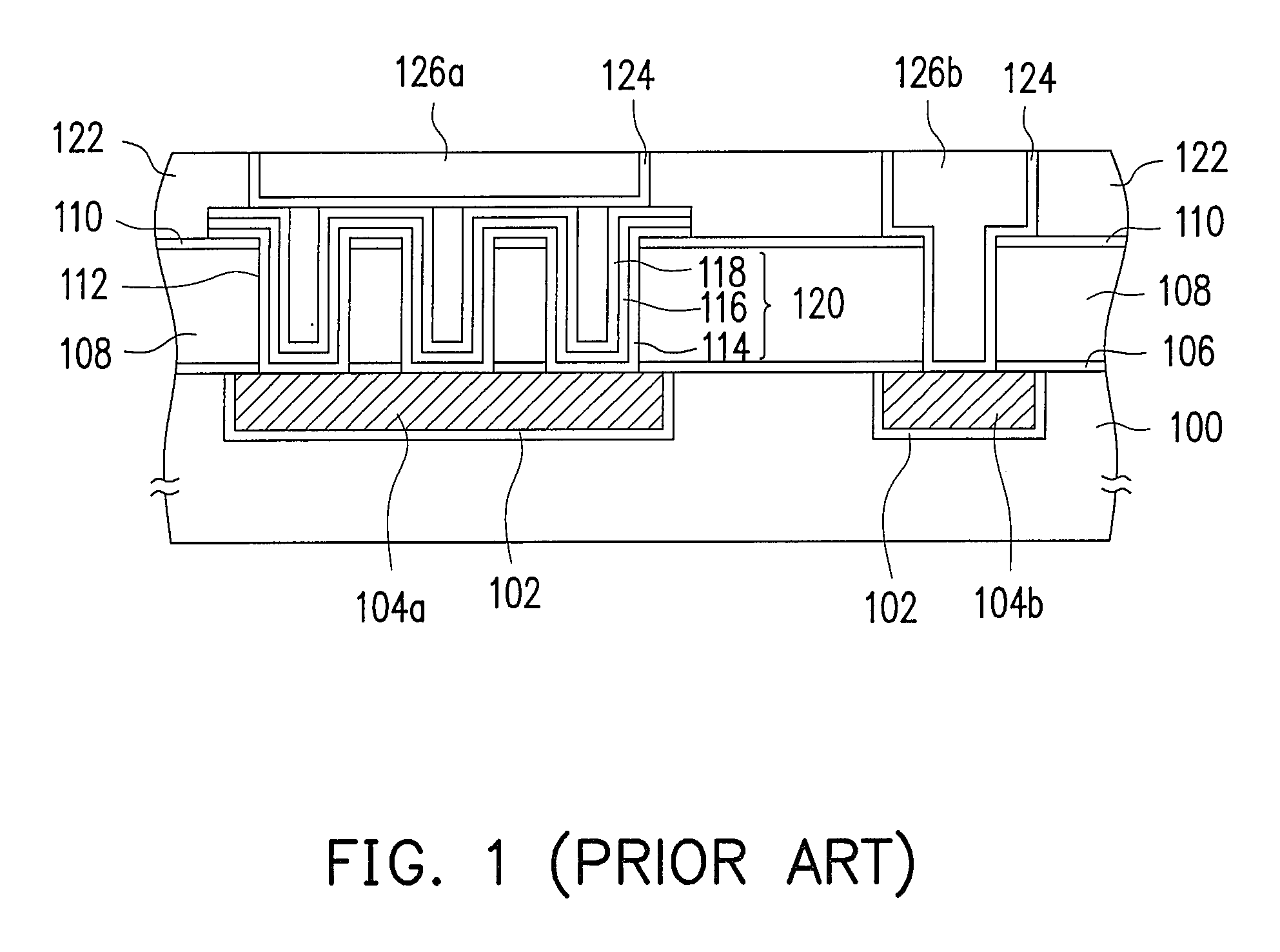

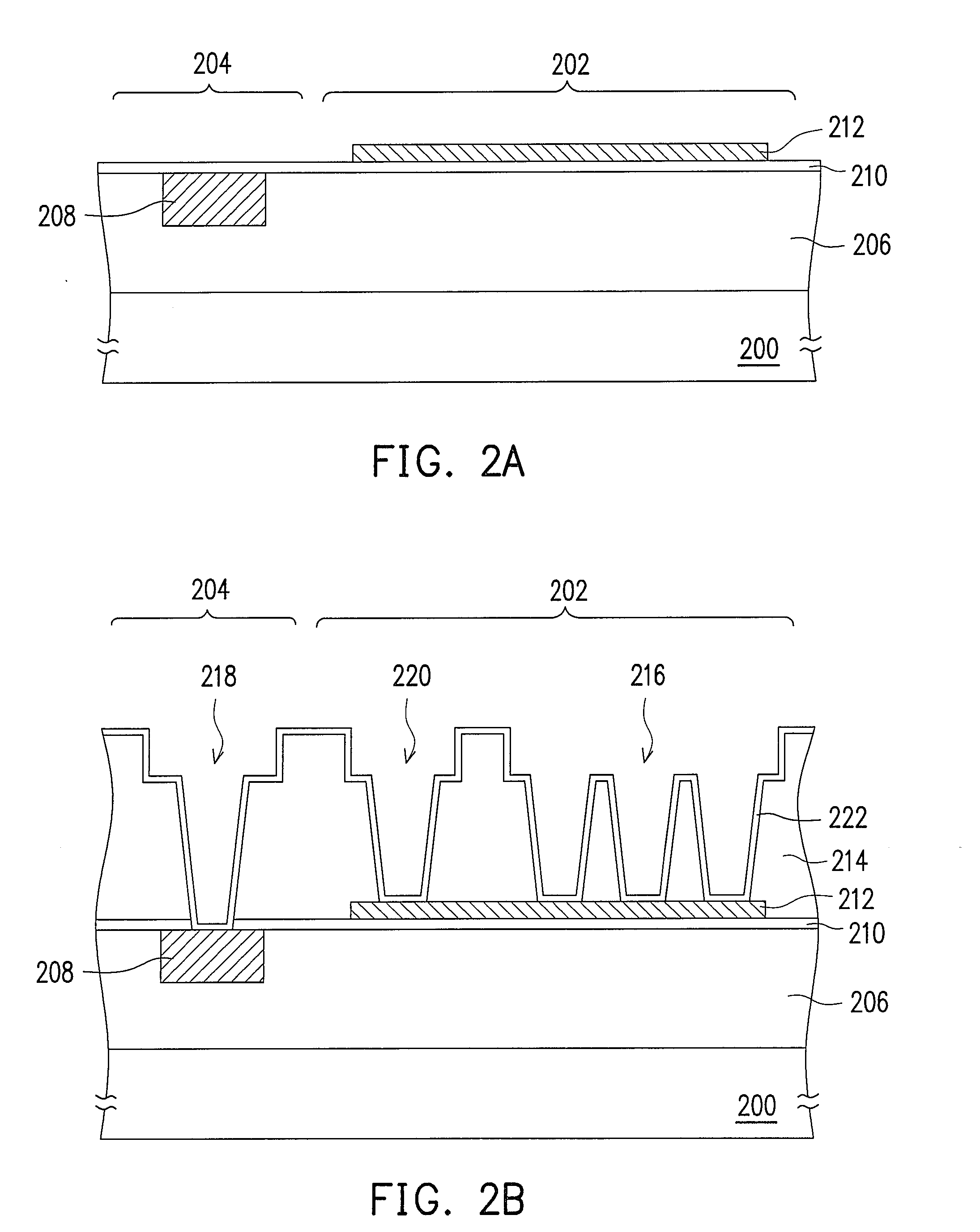

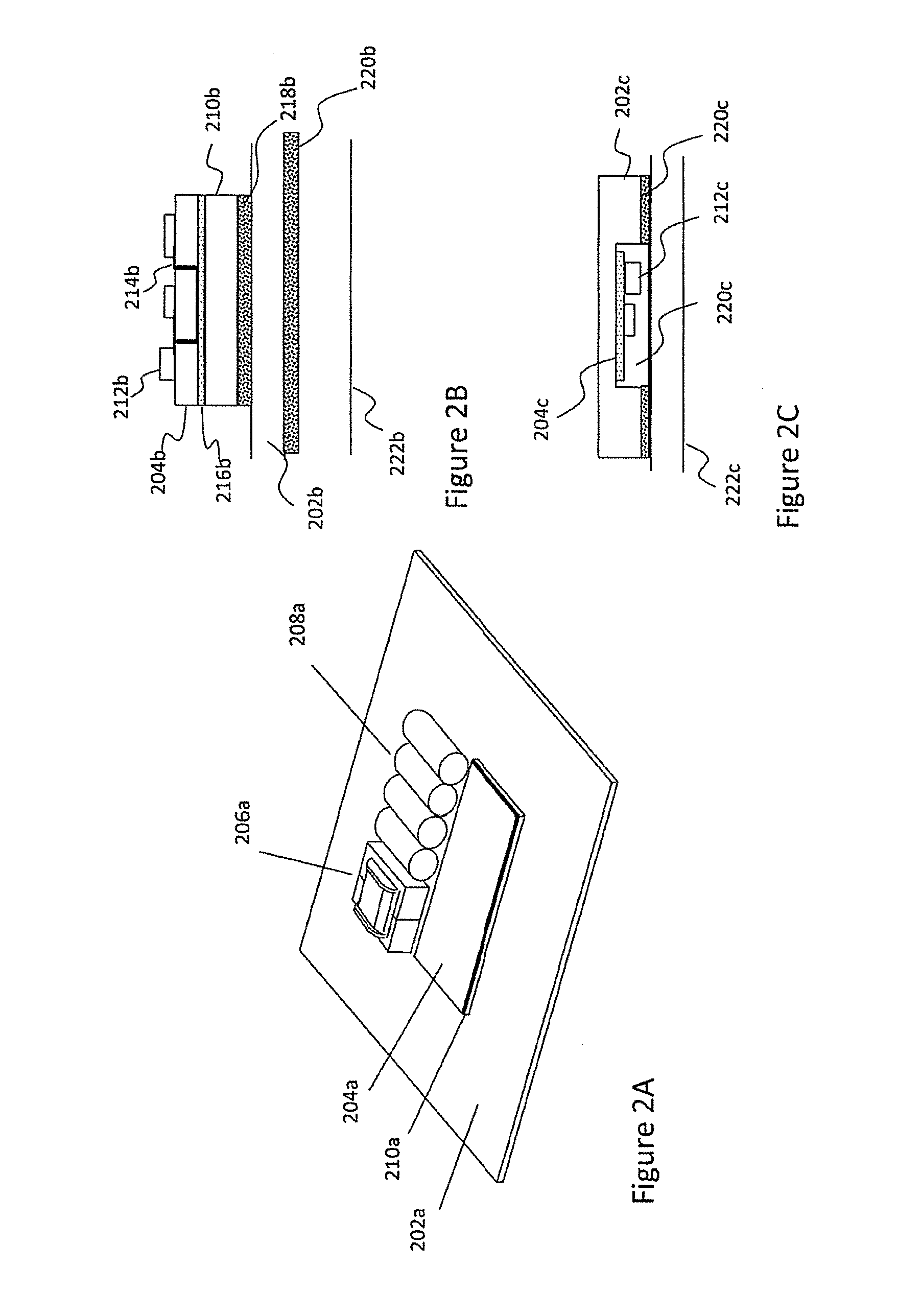

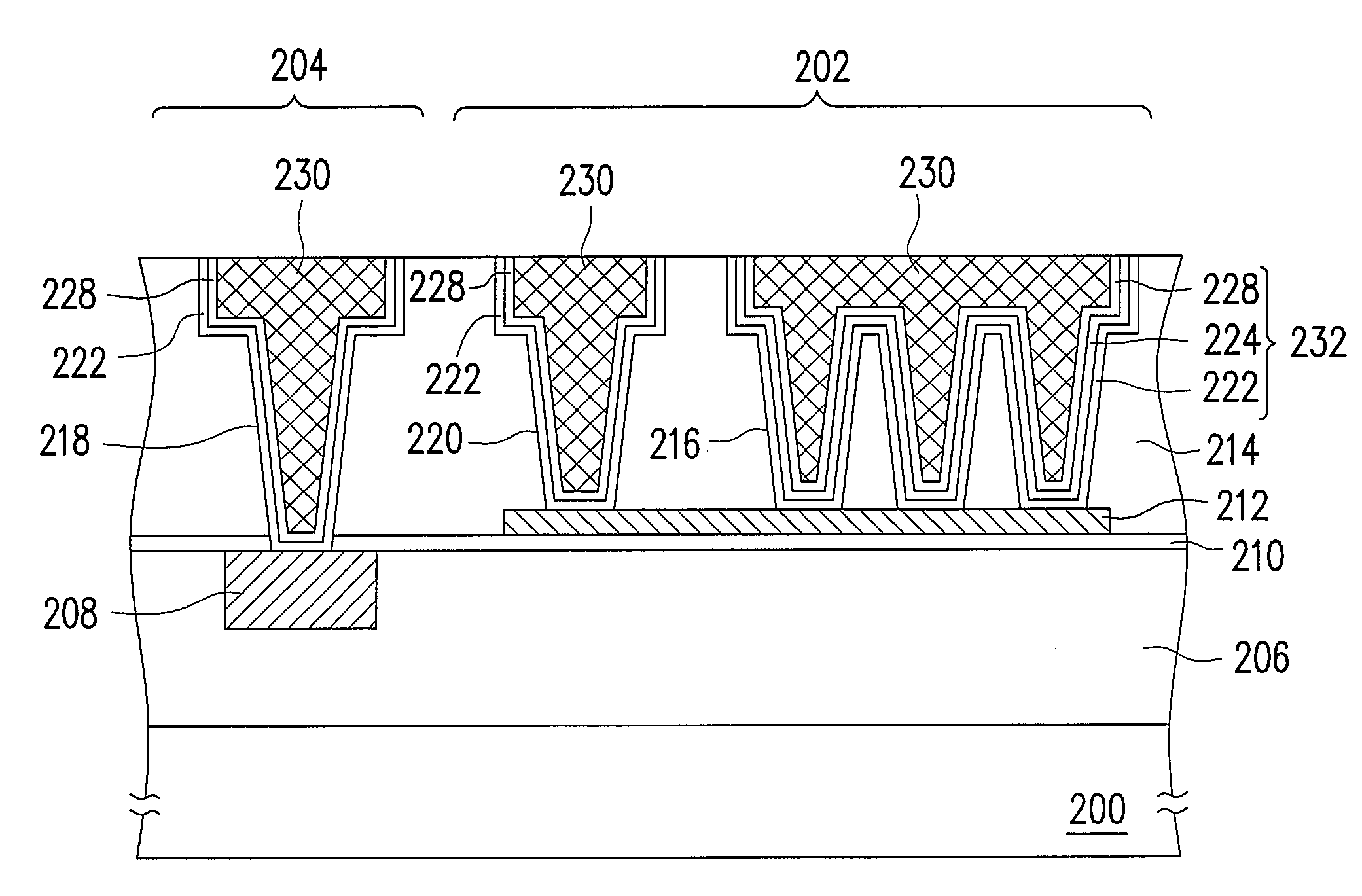

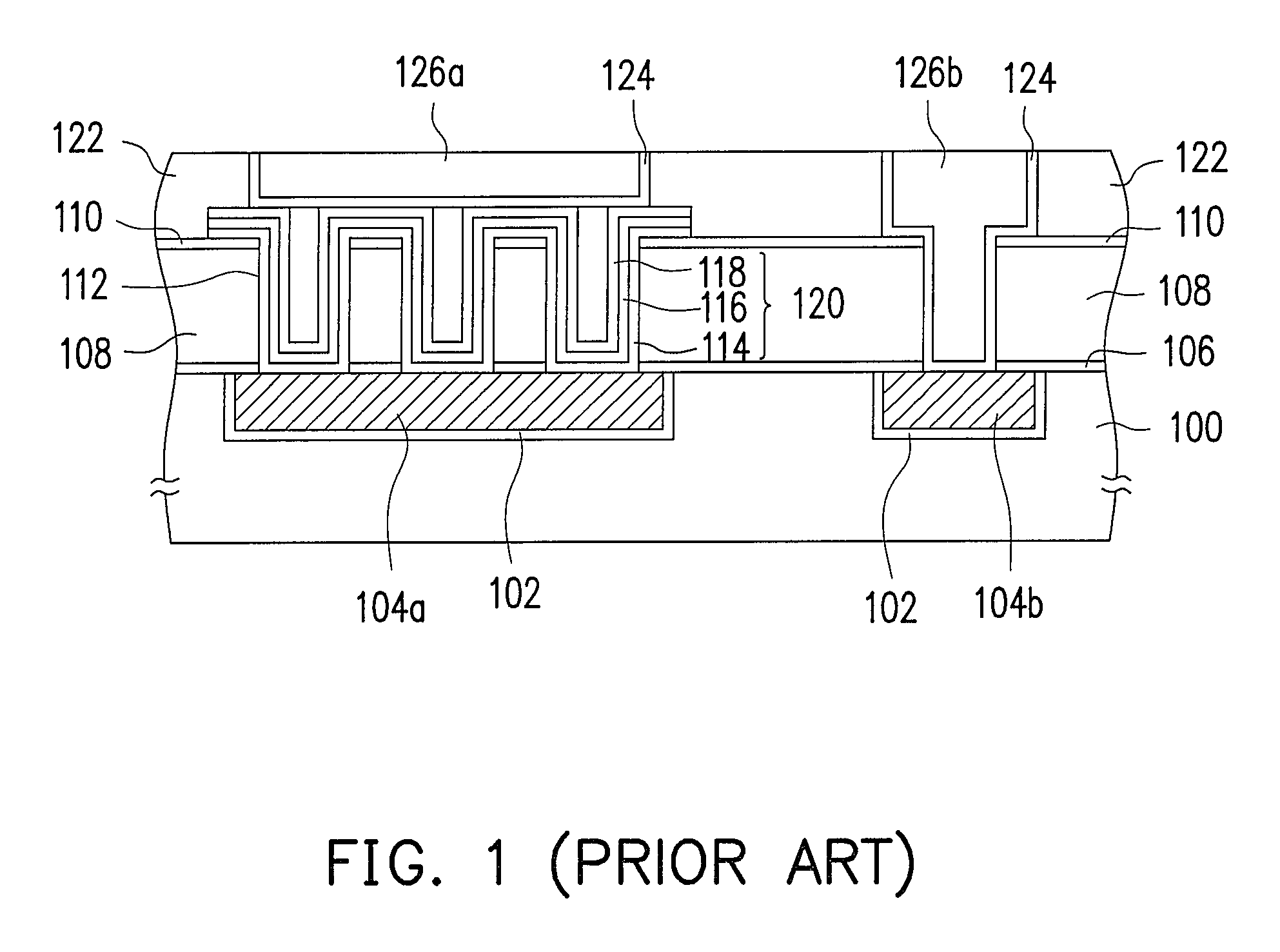

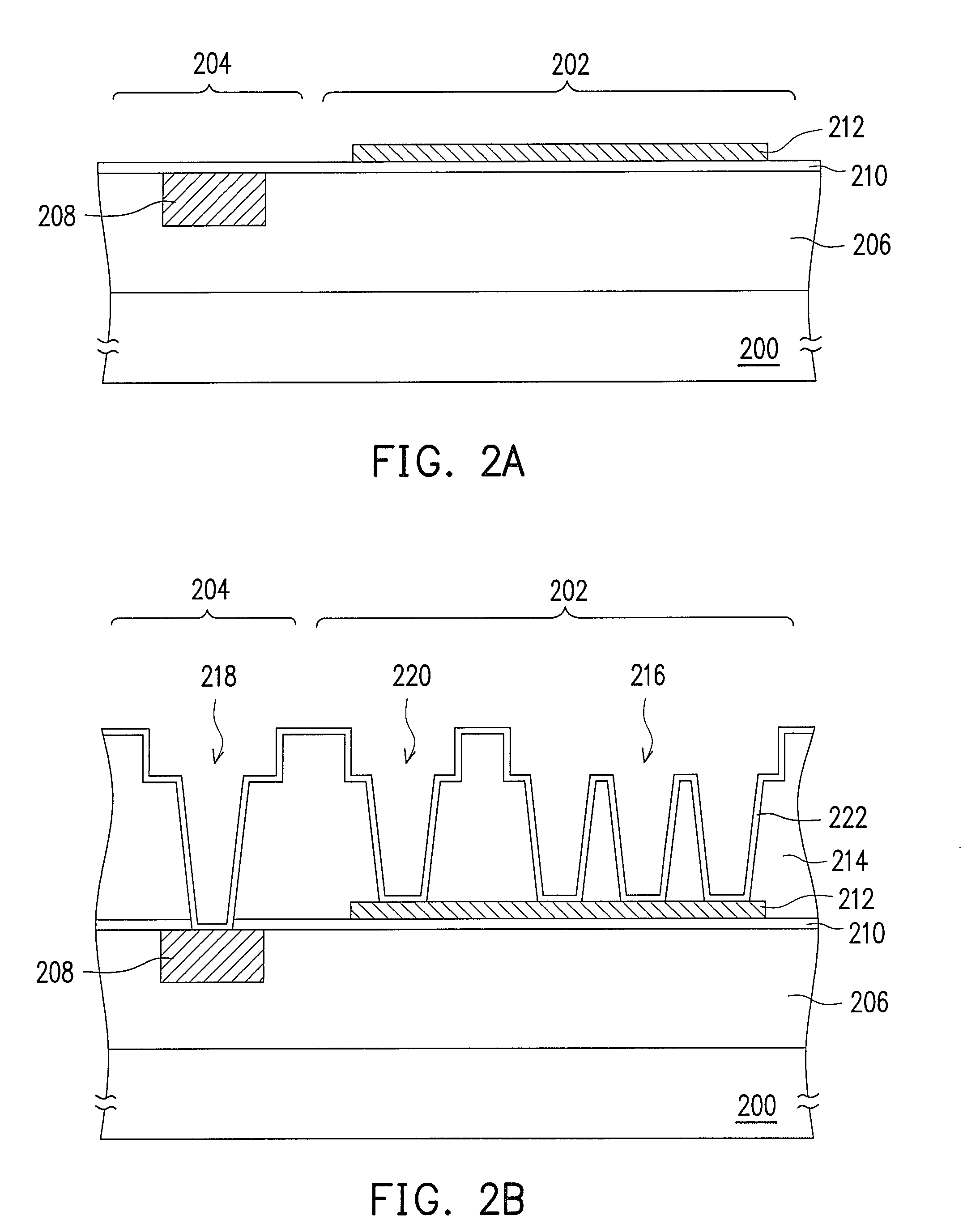

Capacitor structure and fabricating method thereof

ActiveUS20090079029A1Increase capacitanceReduce complexityTransistorSemiconductor/solid-state device detailsMetal interconnectOptoelectronics

A capacitor structure including a substrate, a butting conductive layer, a second dielectric layer, a plurality of openings, a bottom electrode layer, a capacitor dielectric layer, a top electrode layer, and a second metal interconnect layer is provided. The substrate has a first dielectric layer and a first metal interconnect layer located in the first dielectric layer in a non-capacitor region. The butting conductive layer is disposed over the first dielectric layer in a capacitor region. The second dielectric layer is disposed over the first dielectric layer and covers the butting conductive layer. The openings include a first opening exposing a portion of the butting conductive layer and a second opening exposing the first metal interconnect layer. The bottom electrode layer, the capacitor dielectric layer, and the top electrode layer are conformally stacked in the first opening sequentially. The second metal interconnect layer is disposed in the openings.

Owner:UNITED MICROELECTRONICS CORP

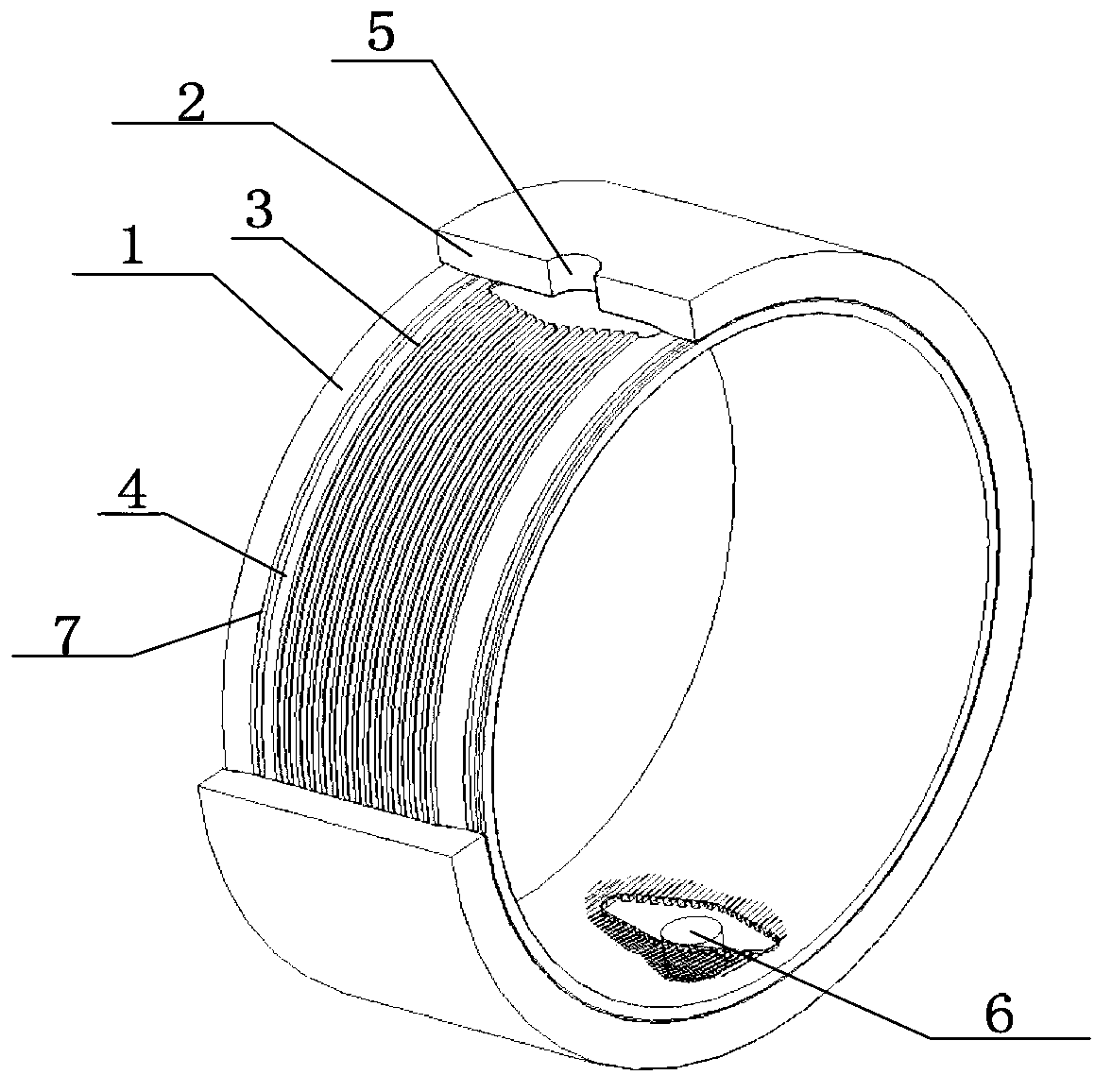

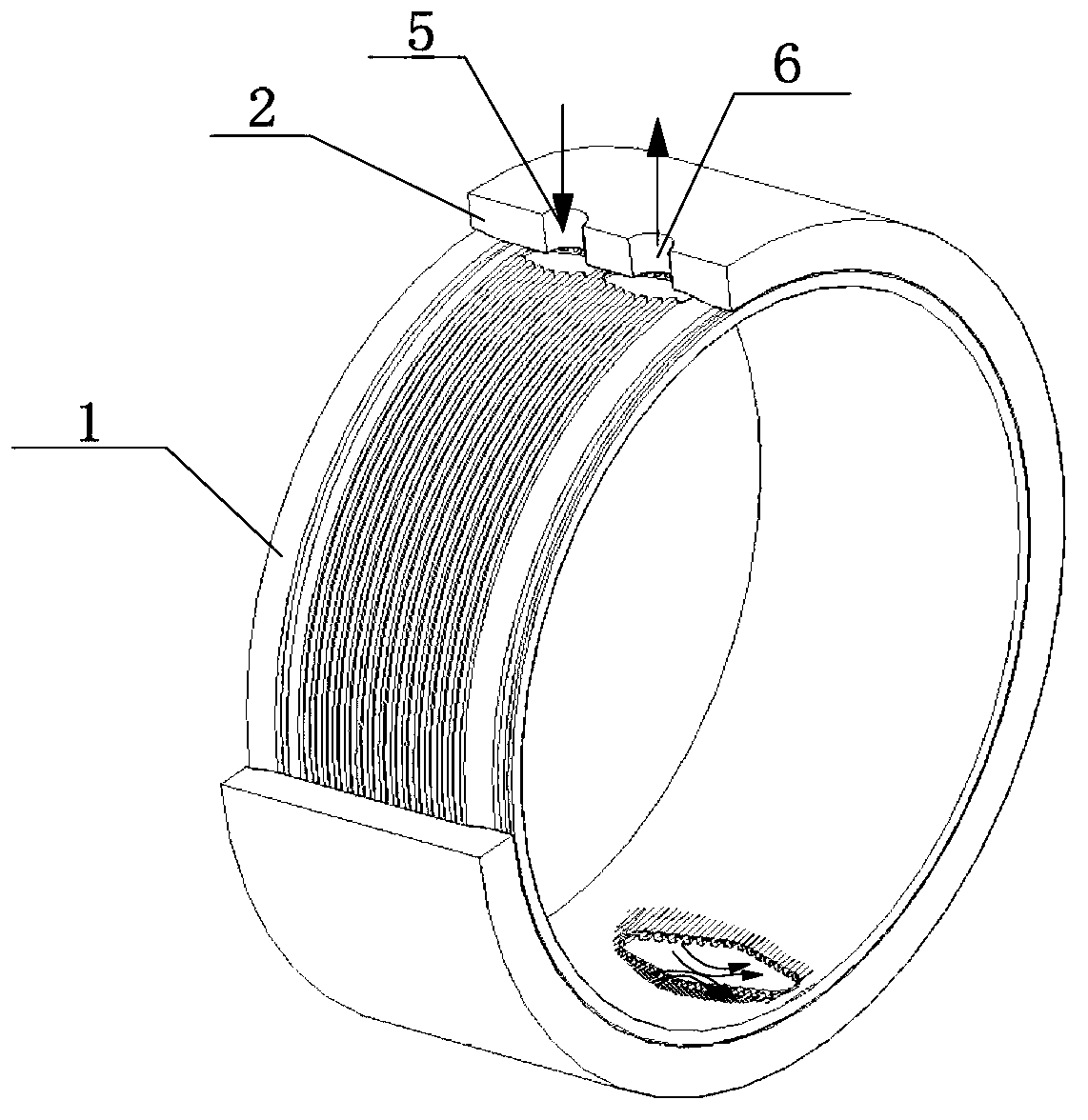

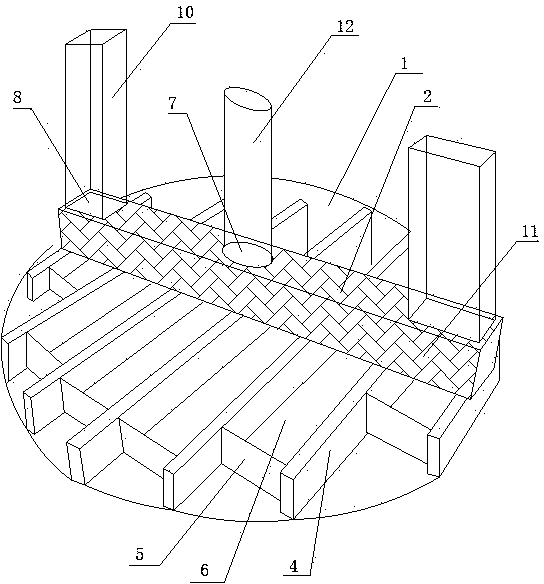

Cooling sleeve of liquid cooling electric motor

InactiveCN103001398AStable distribution/concentrationIncrease the effective surfaceCooling/ventillation arrangementEngineeringHeat sink

The invention relates to a cooling sleeve of a liquid cooling electric motor. The cooling sleeve comprises an inner cooing ring and an outer cooling ring, the outer cooing ring is sleeved on the inner cooling ring, the inner cooling ring has an inner surface and an outer surface, the inner surface and the outer surface surround to form an inner cavity, and at least two radiating fins are arranged on the outer surface of the inner cooling ring, and are arranged on the outer surface of the inner cooling ring, gaps are reserved among adjacent radiating fins so as to form a flowing passage. Besides, the outer cooling ring is provided with a coolant outlet and a coolant inlet, the radiating fins at positions corresponding to the coolant outlet and the coolant inlet are removed from the inner cooling ring, and fed coolant is distributed into the flowing passage uniformly.

Owner:YANTAI DINGLI NEW ENERGY VEHICLE POWER SYST

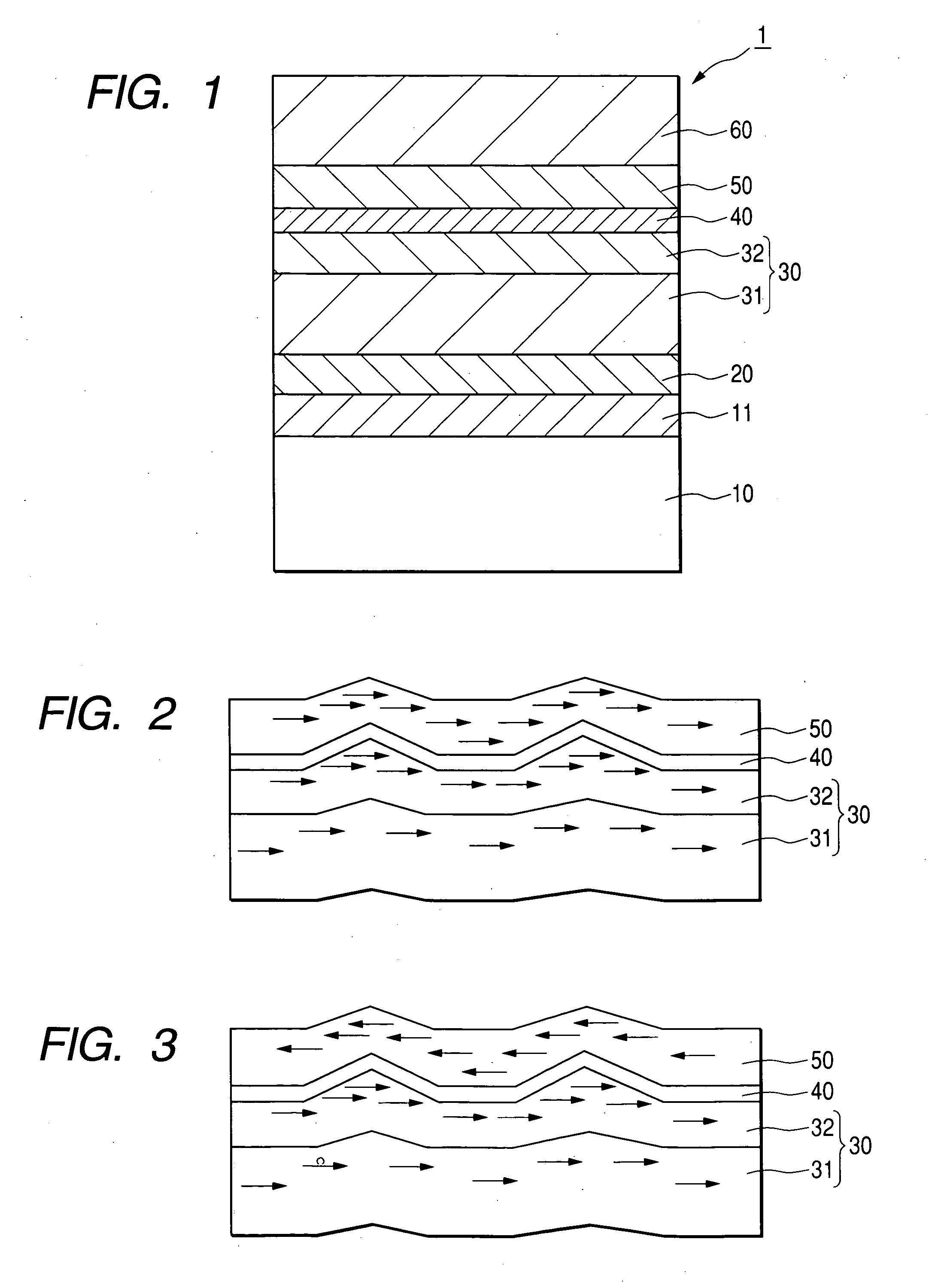

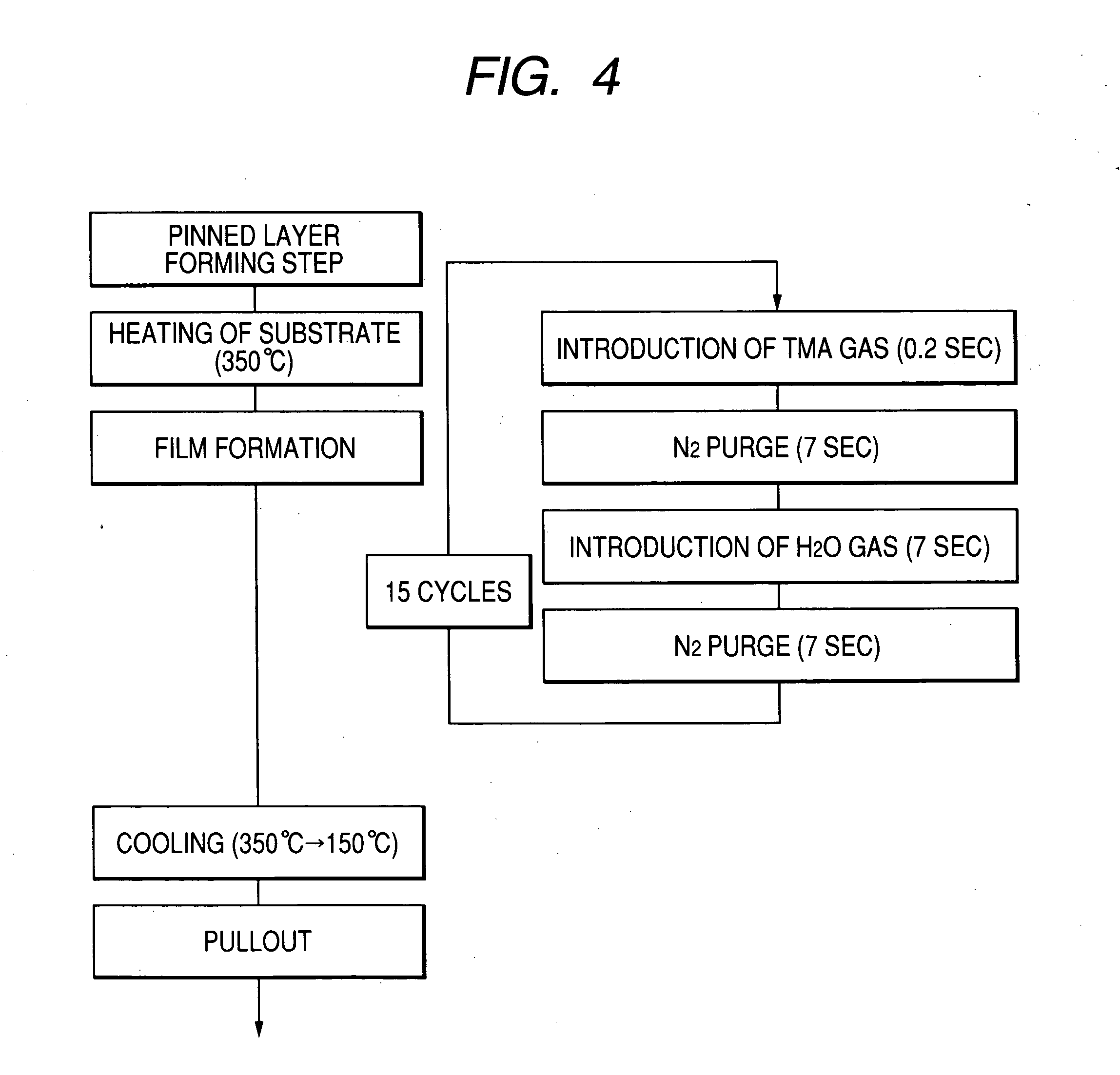

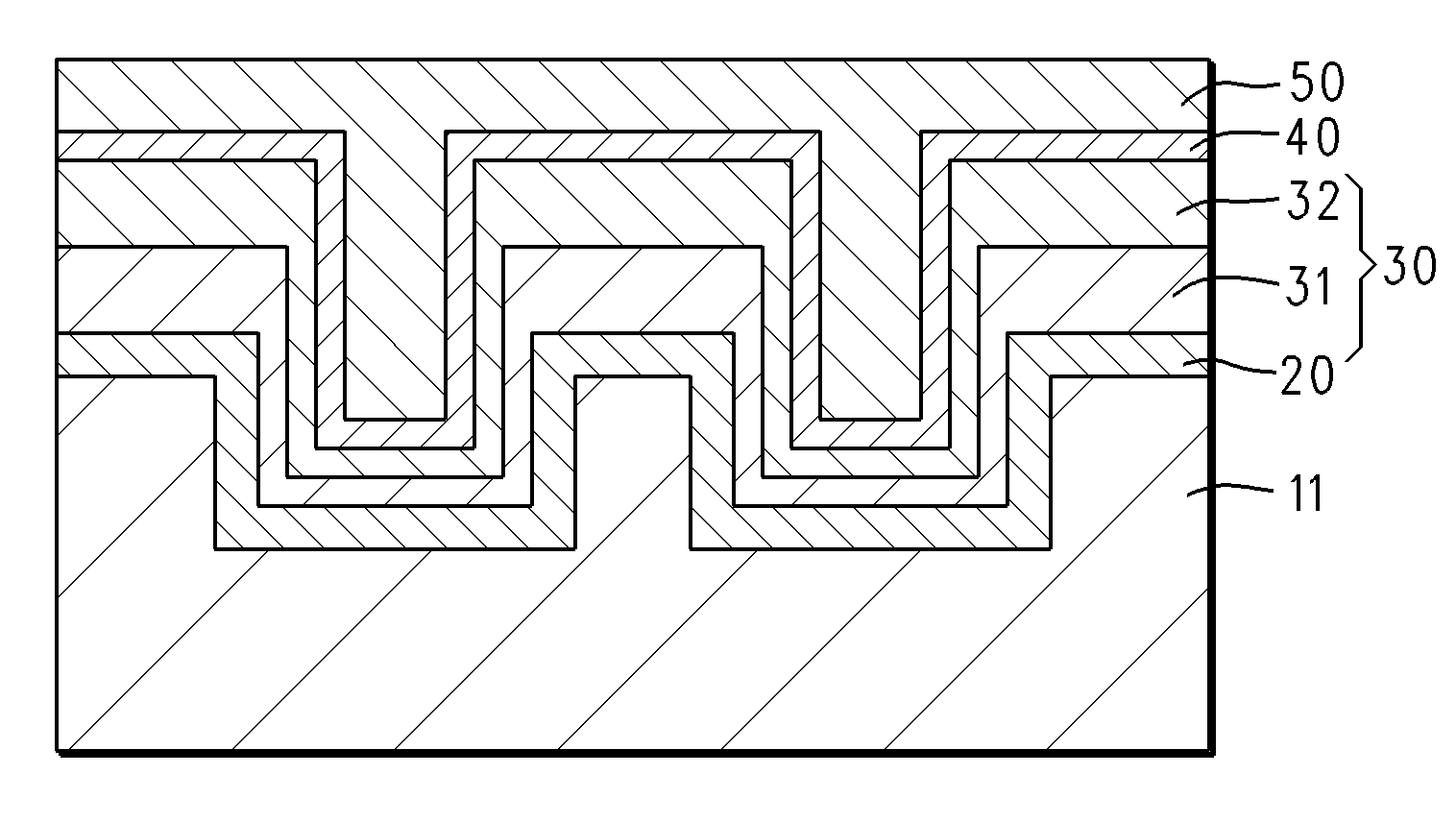

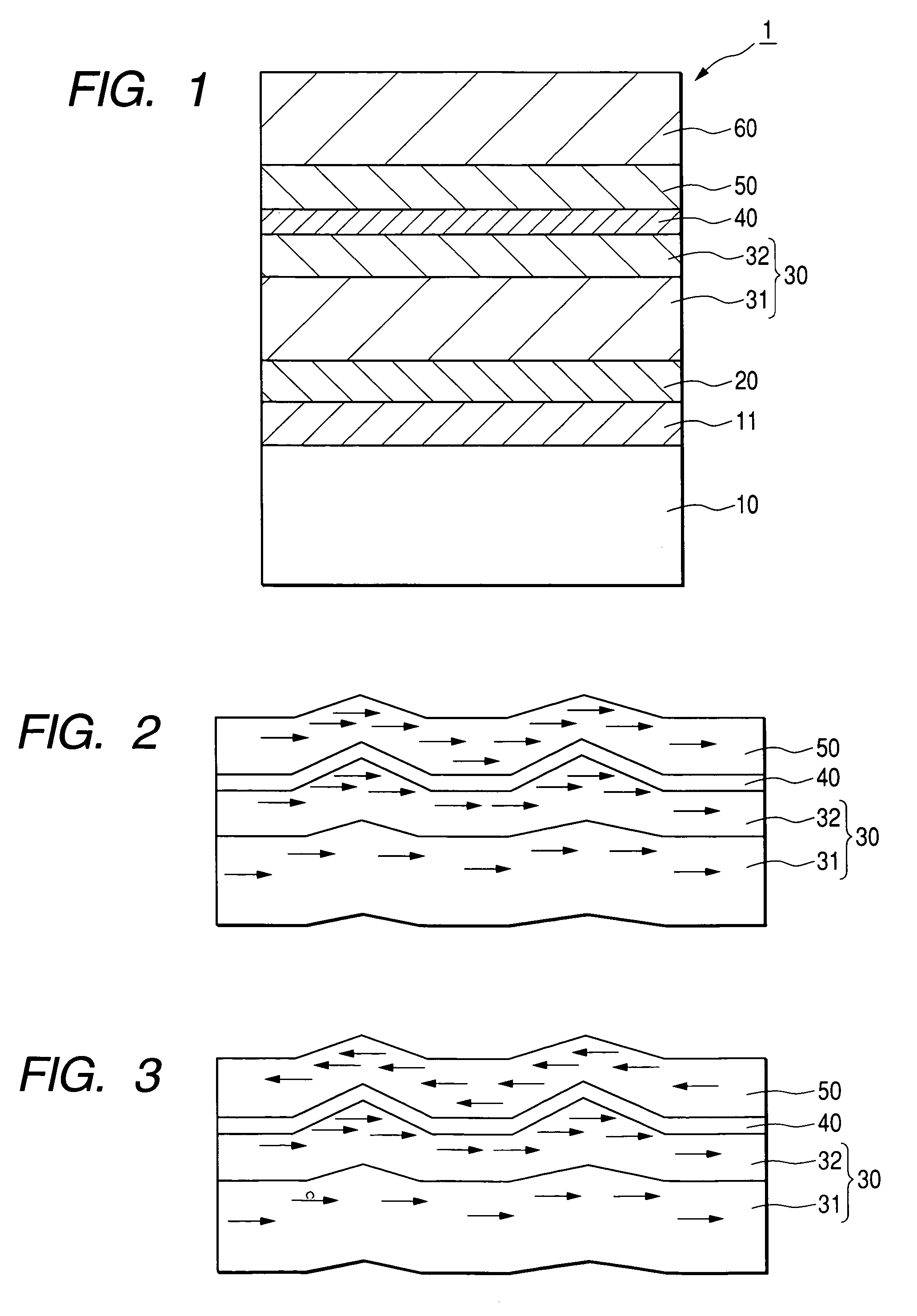

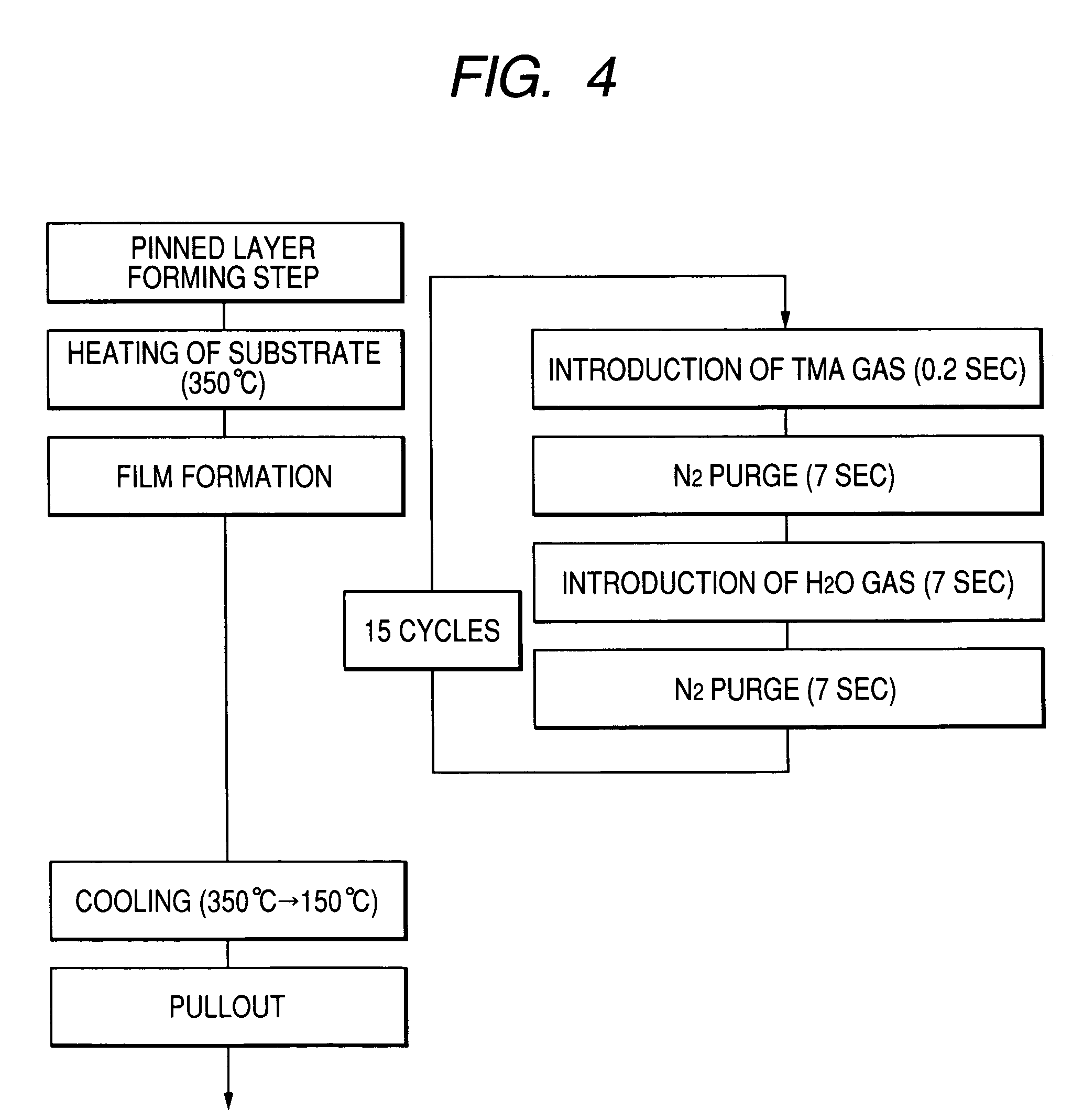

Tunnel magnetoresistance device

InactiveUS20050225905A1Good drapabilityLarge MR ratioNanomagnetismMagnetic measurementsMagnetic reluctanceOptoelectronics

The TMR device has a structure including a lower electrode layer, a pinned layer, a tunnel barrier layer, a free layer, and an upper electrode layer which are successively formed on a substrate. The tunnel barrier layer has substantially a stoichiometric composition. The tunnel barrier layer may be a thin film of an oxide of AL formed by ALD method.

Owner:DENSO CORP

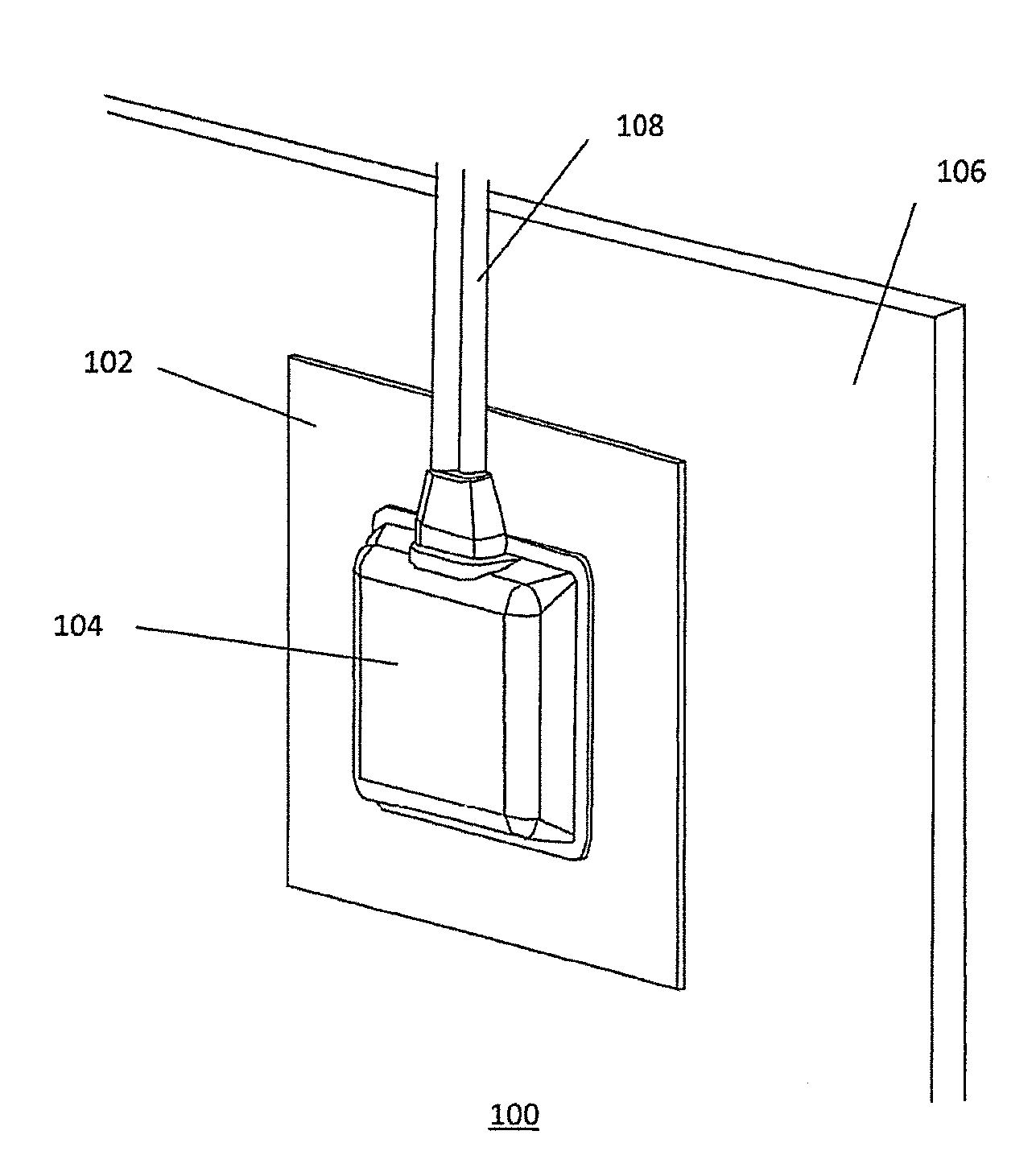

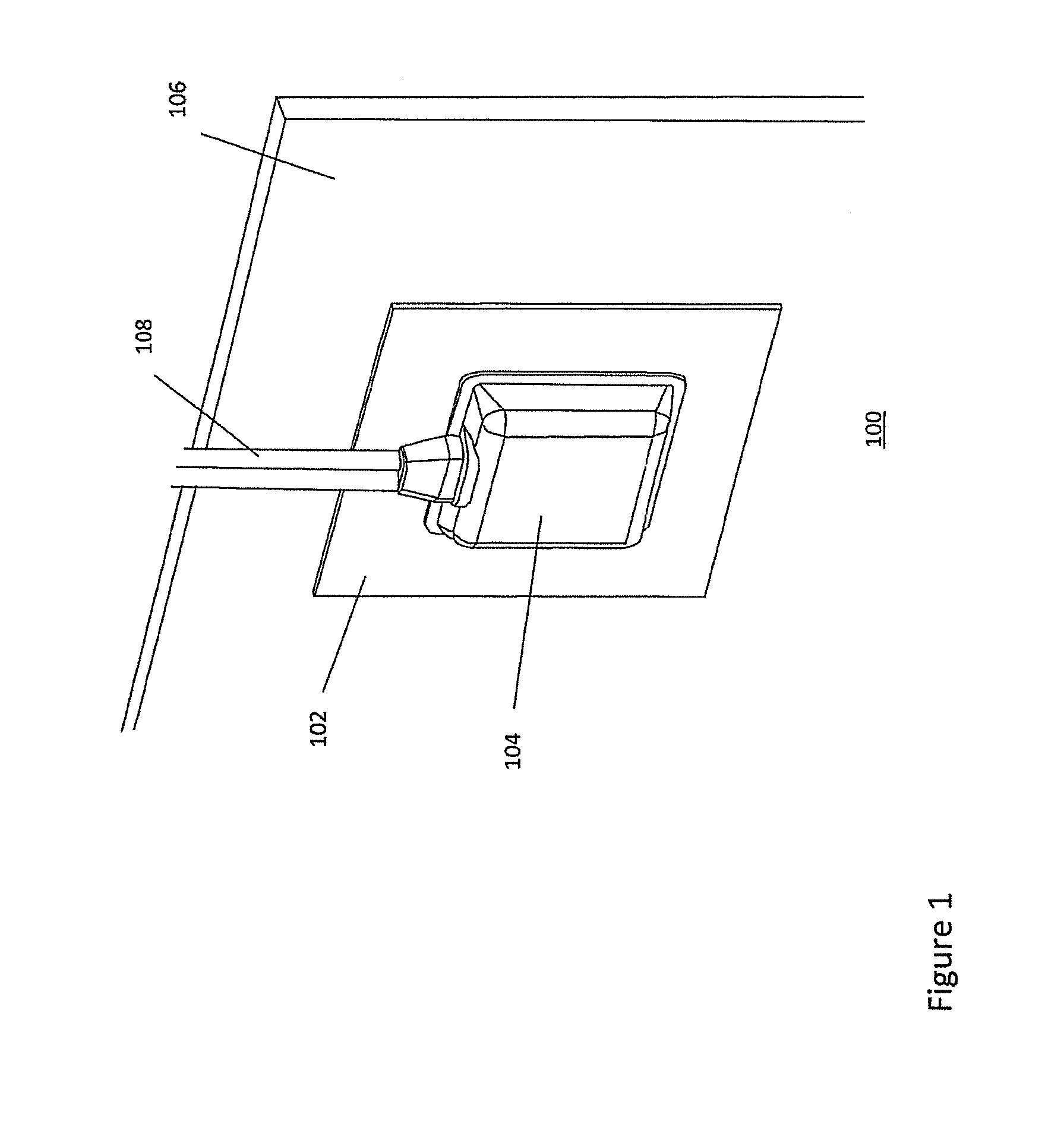

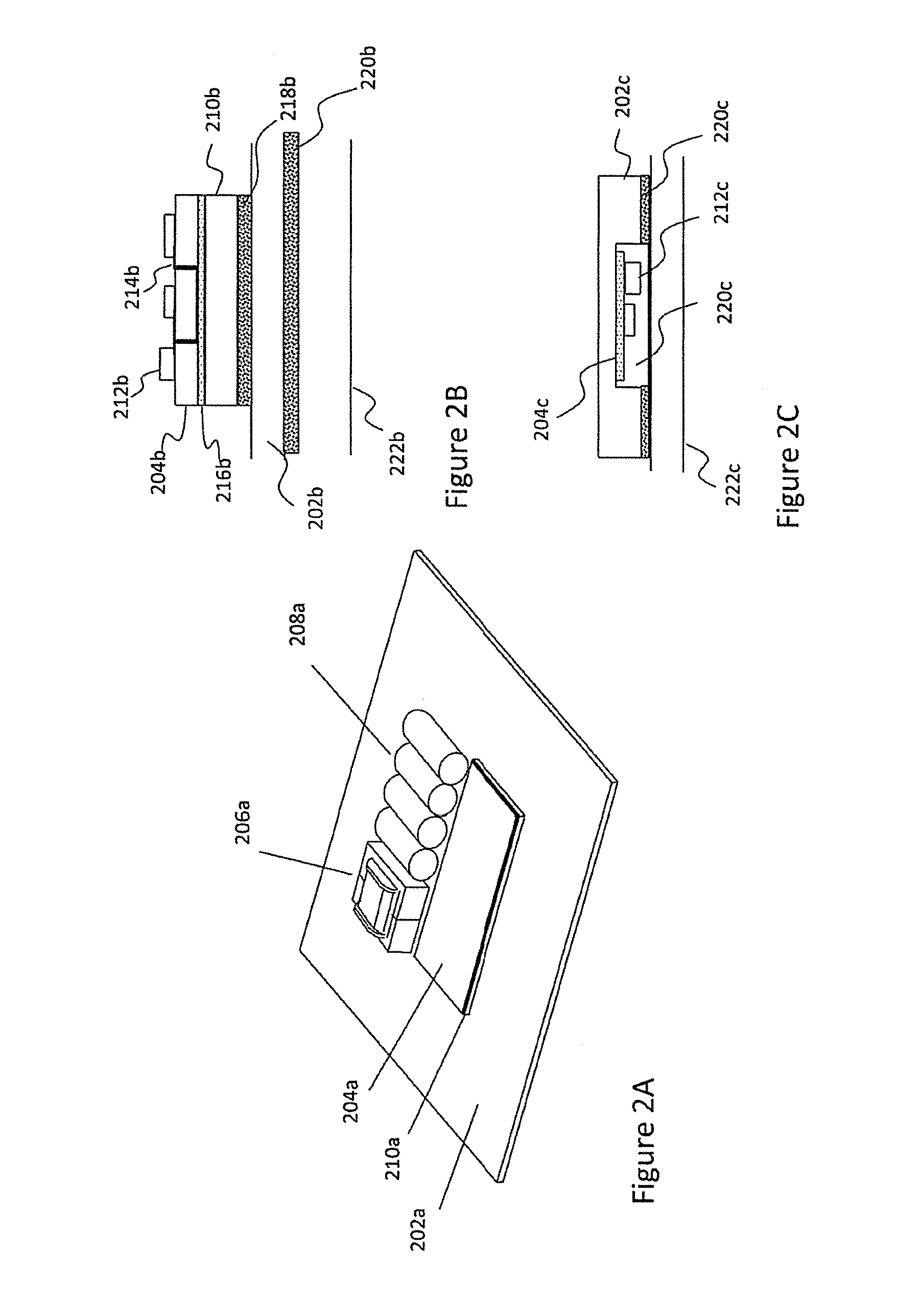

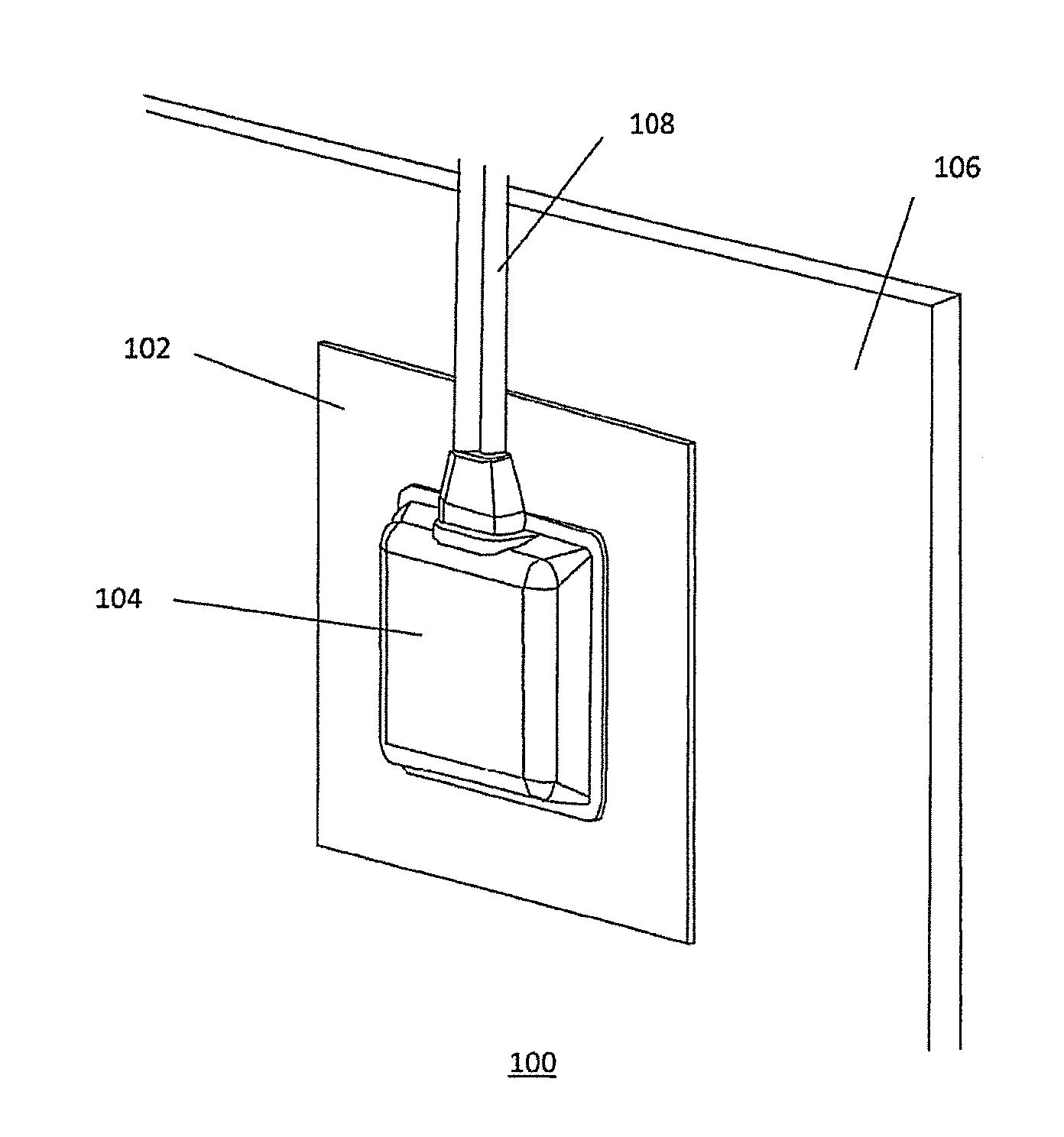

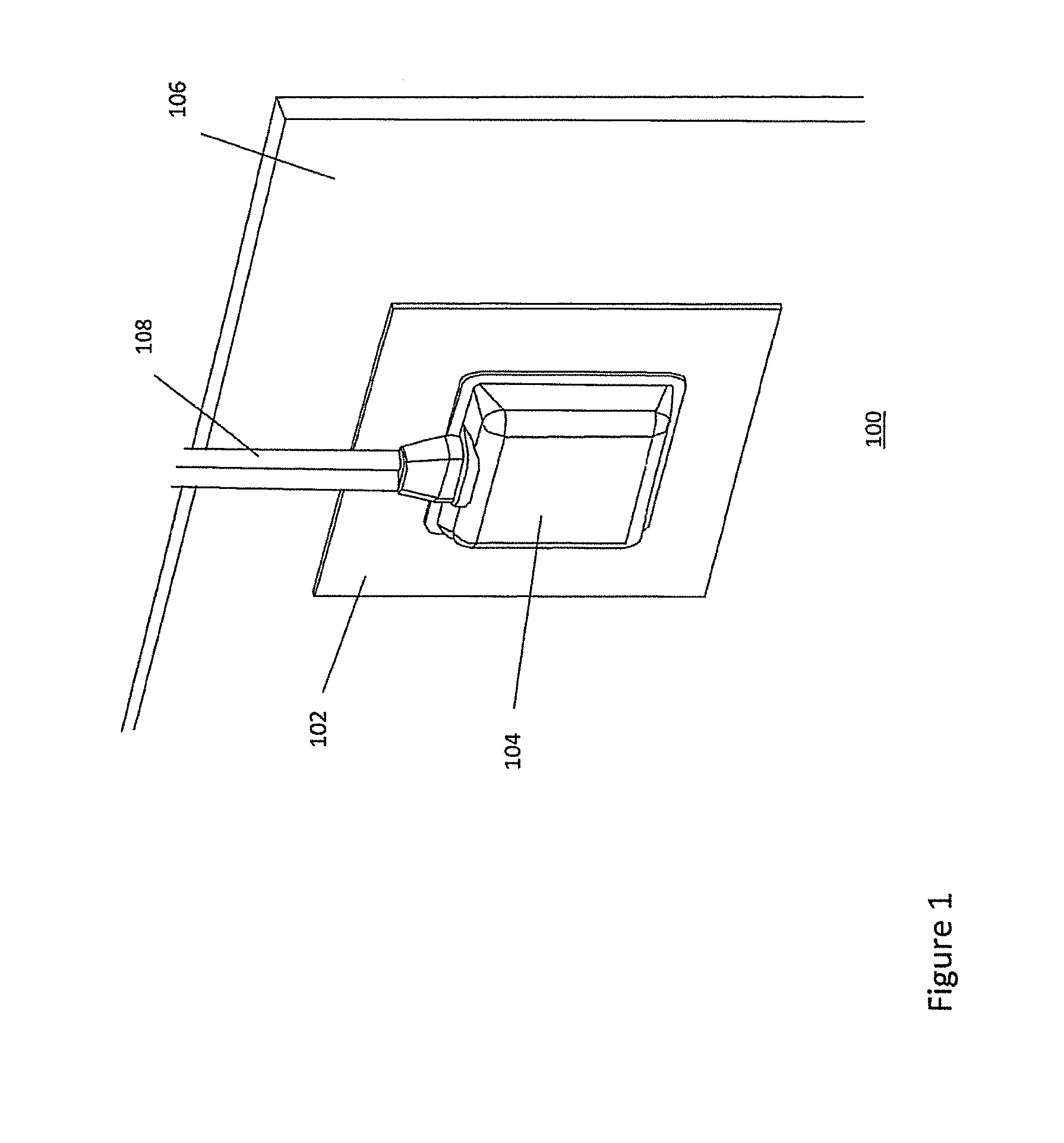

Thermally mounting electronics to a photovoltaic panel

ActiveUS20120167950A1Increase in sizeEfficient transportPV power plantsPhotovoltaic energy generationEngineeringConductive materials

An electronics assembly for a photovoltaic panel includes a substrate of a thermally conductive material, wherein the substrate defines a thermal contact area for thermally contacting the electronics assembly to a photovoltaic panel; and at least one electronic component provided on the substrate and in thermal contact with the substrate, so that when the electronics assembly is in thermal contact with the photovoltaic panel. The thermal contact provides a heat conductive channel between the at least one electronic component and the photovoltaic panel, wherein the heat conductive channel enables the electronics assembly to use the photovoltaic panel as a heat sink for heat produced by the at least one electronic component.

Owner:SOLARNATIVE GMBH

Polymeric cover for robots having an increased total surface energy

InactiveUS20080271669A1Improve abilitiesAdhesivity increasedProgramme-controlled manipulatorLiquid surface applicatorsPolymeric surfaceSpray nozzle

The present invention involves cover for robots having spray nozzles wherein the surface material of the covers have been enhanced for residue retention. The robot covers of the present invention may be formed from a polymer, which in one exemplary embodiment may be polyethylene. For example, the polymer may be received in the form of a cast or blown extruded plastic film. In one exemplary embodiment, the polymer may be processed to increase the surface energy and / or surface area of the polymer. By increasing at least one of the surface energy and the surface area of the polymer, the total energy of the surface of the polymer is increased.

Owner:BUTTERWORTH INDS

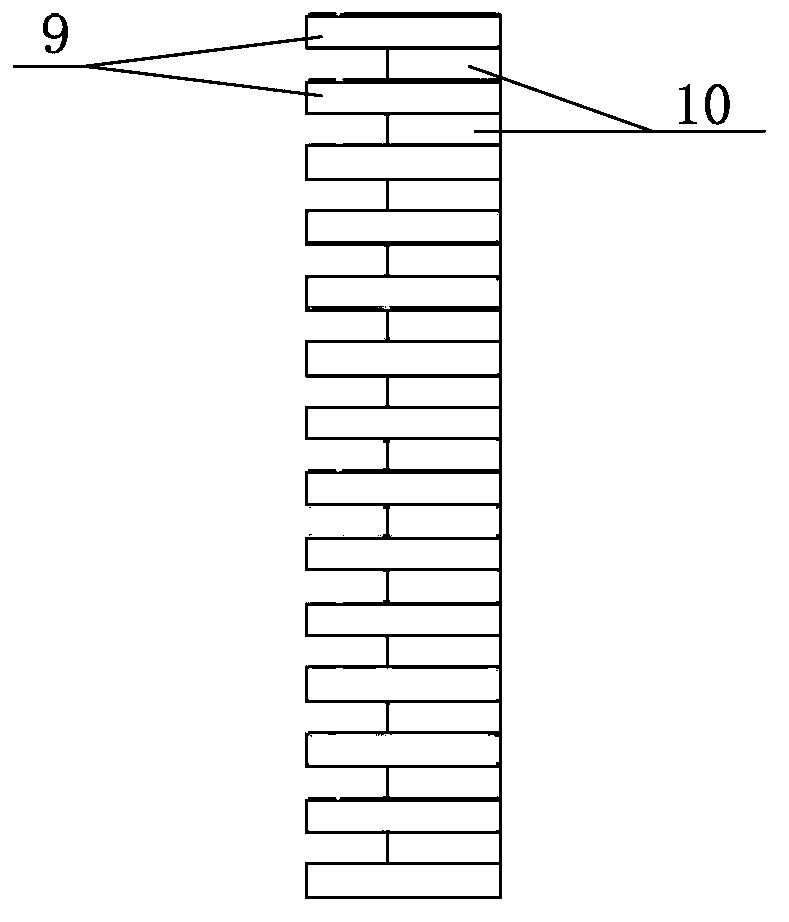

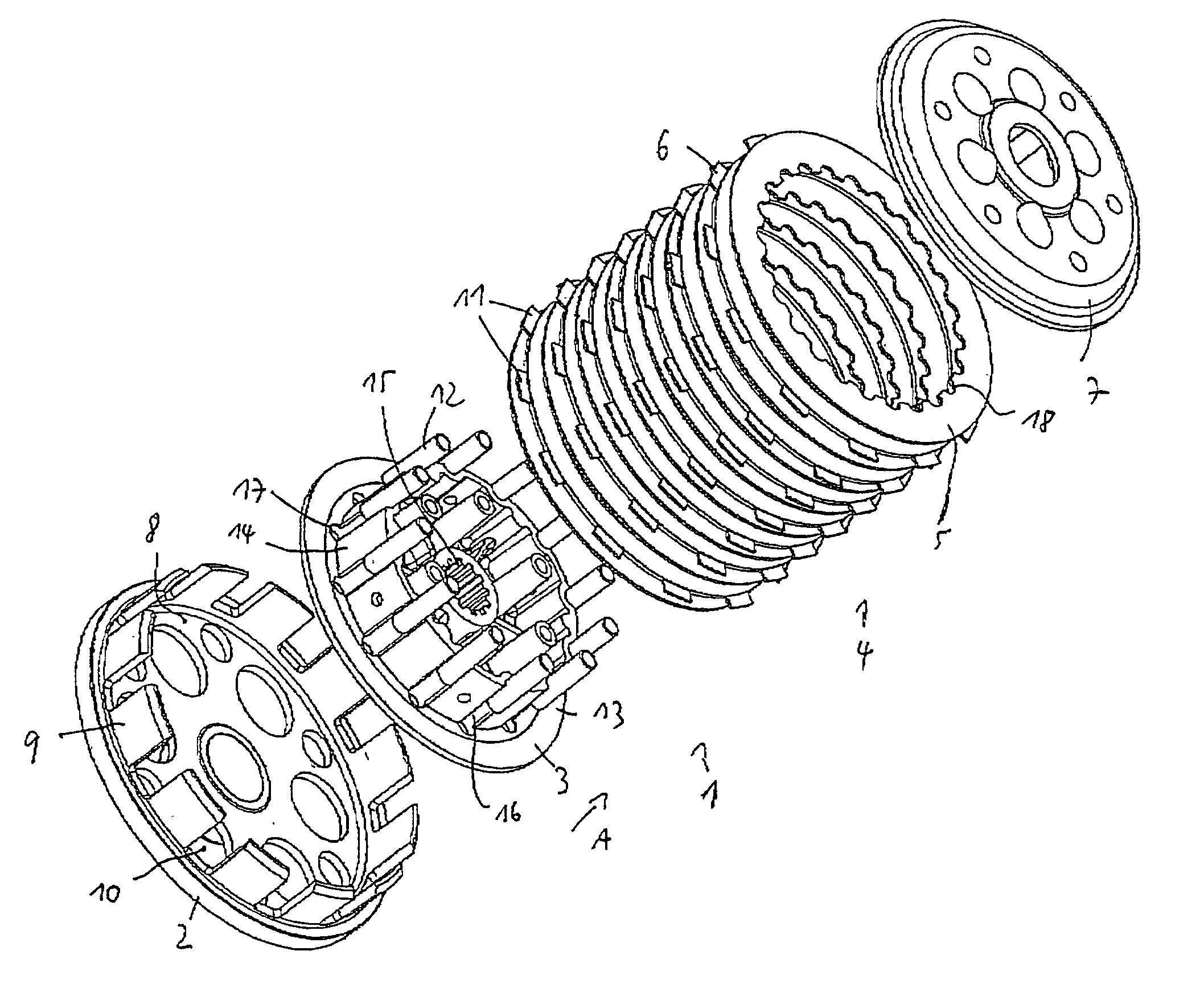

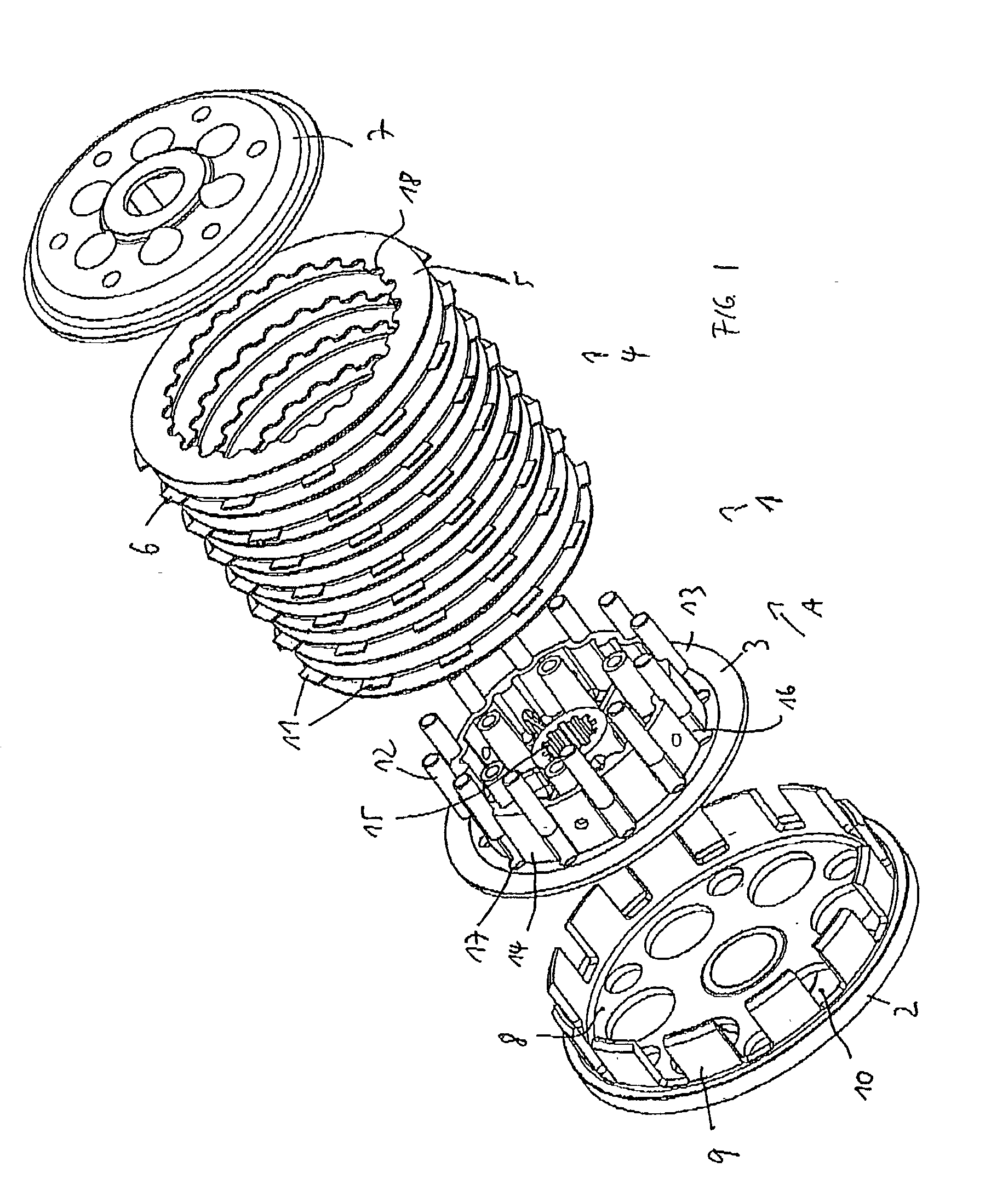

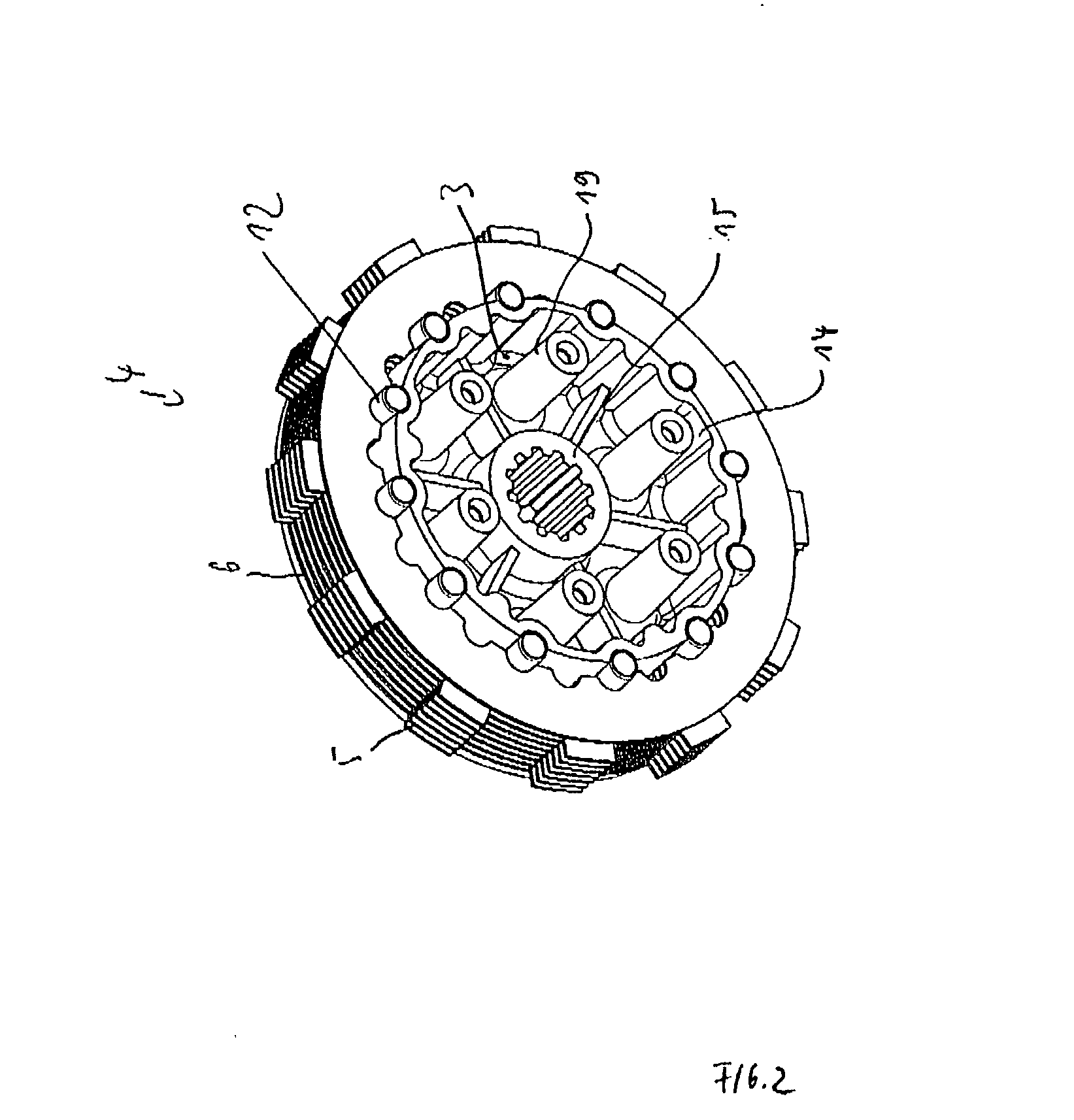

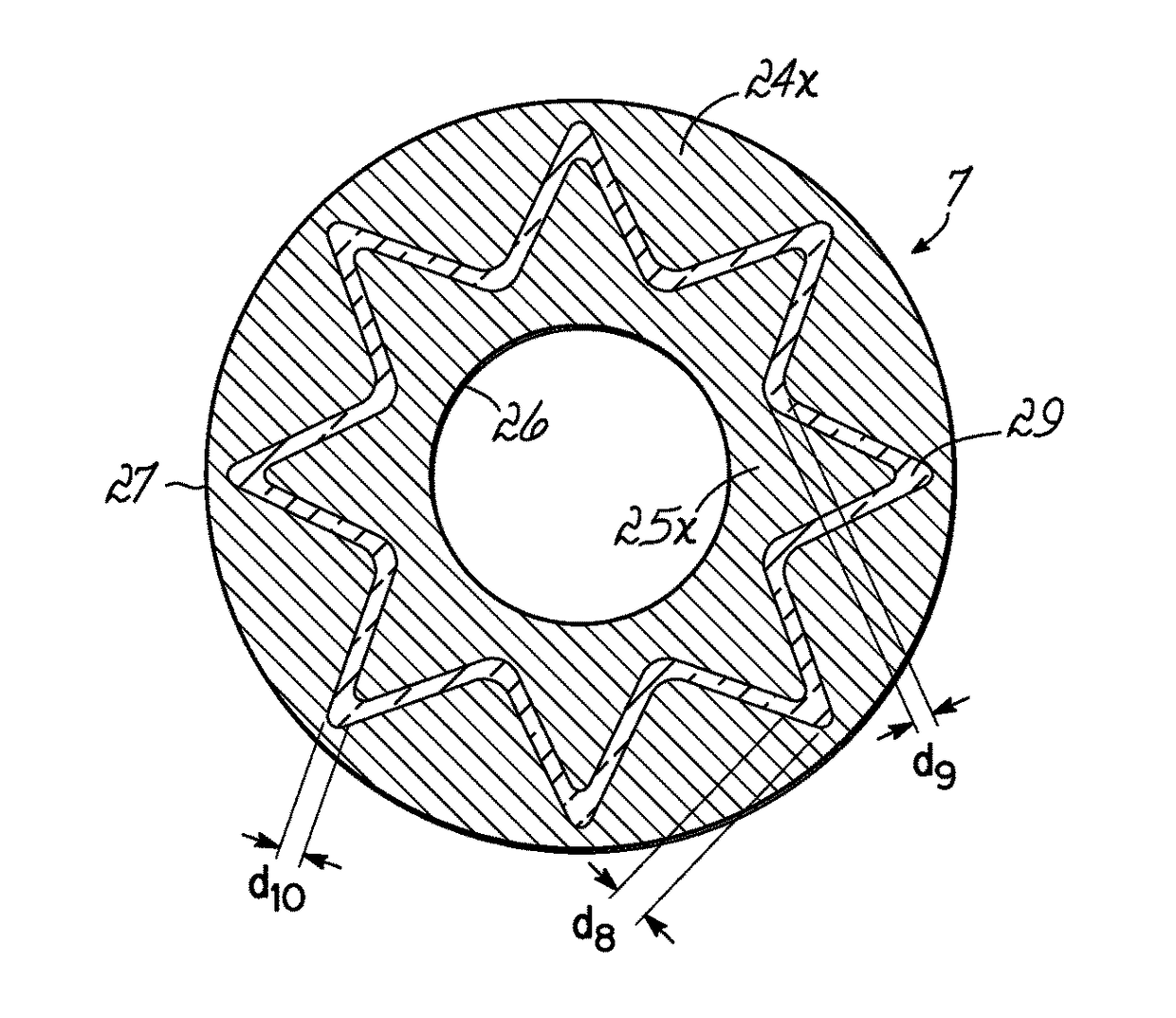

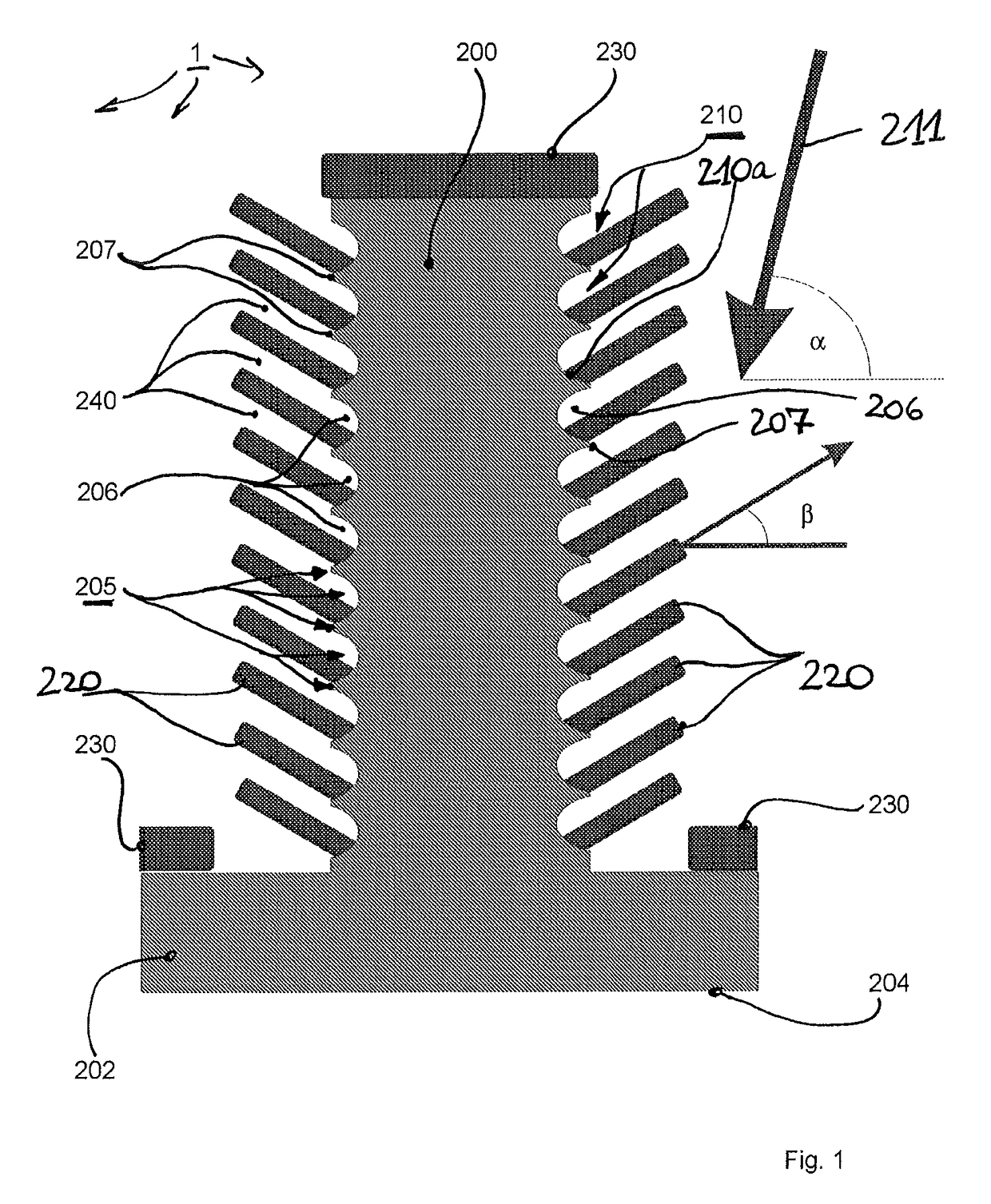

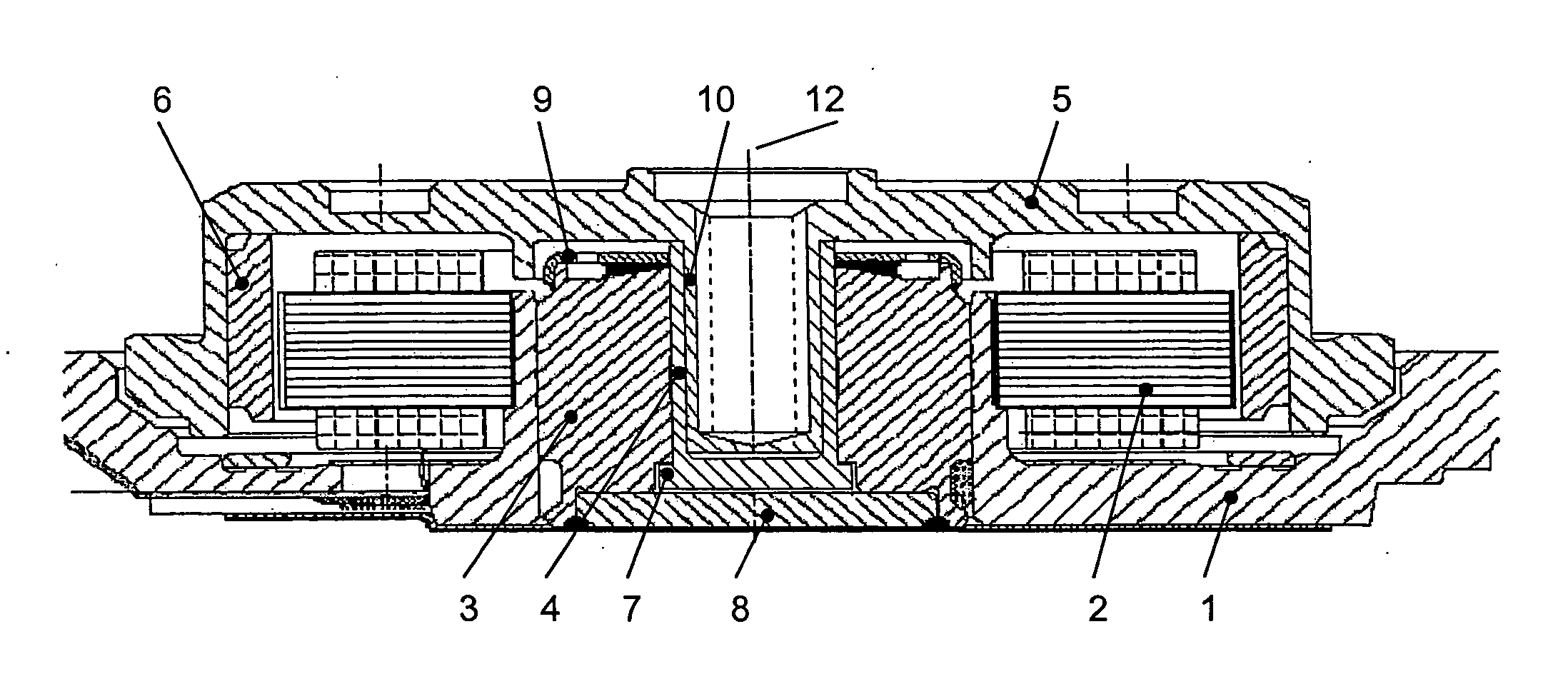

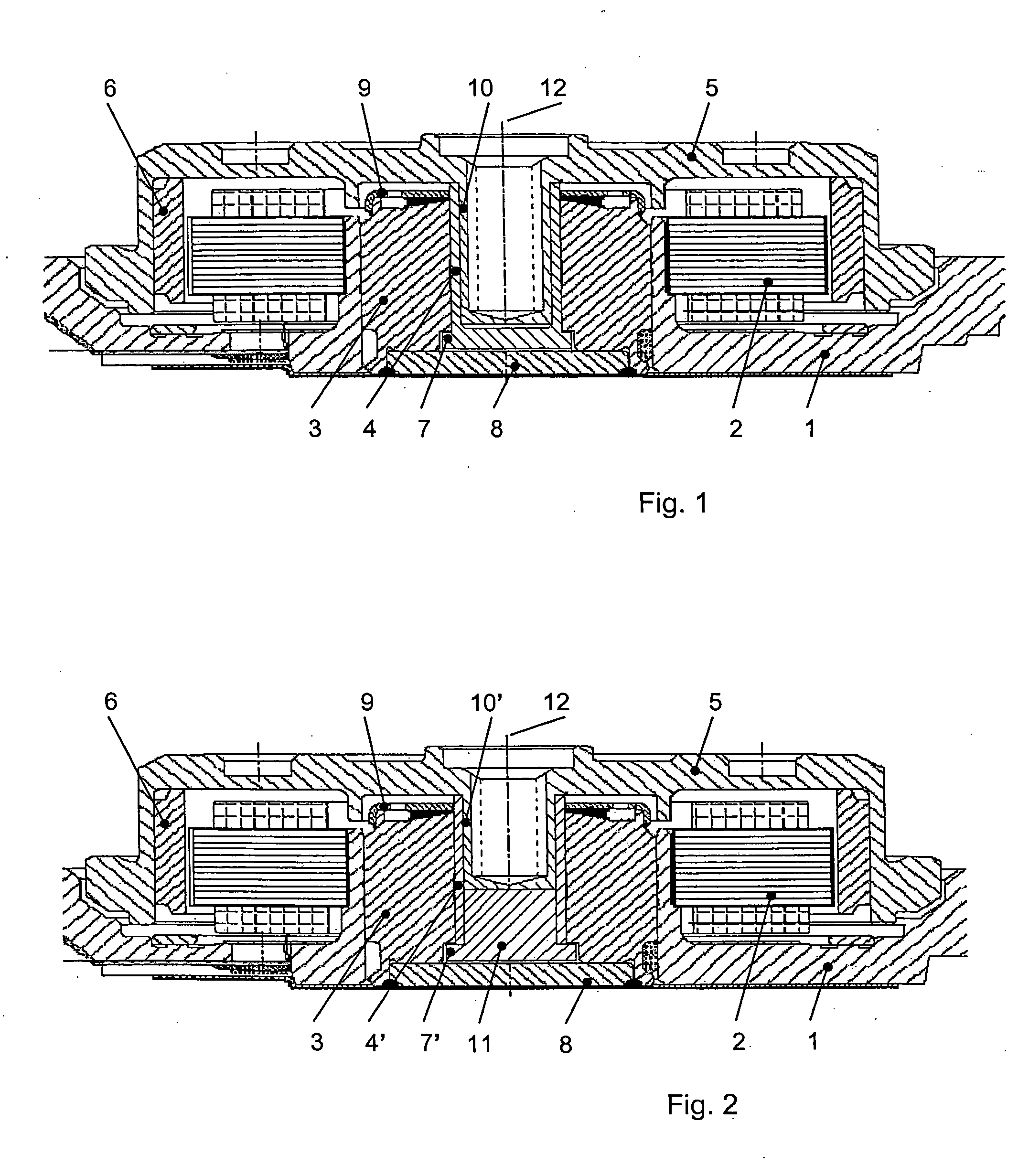

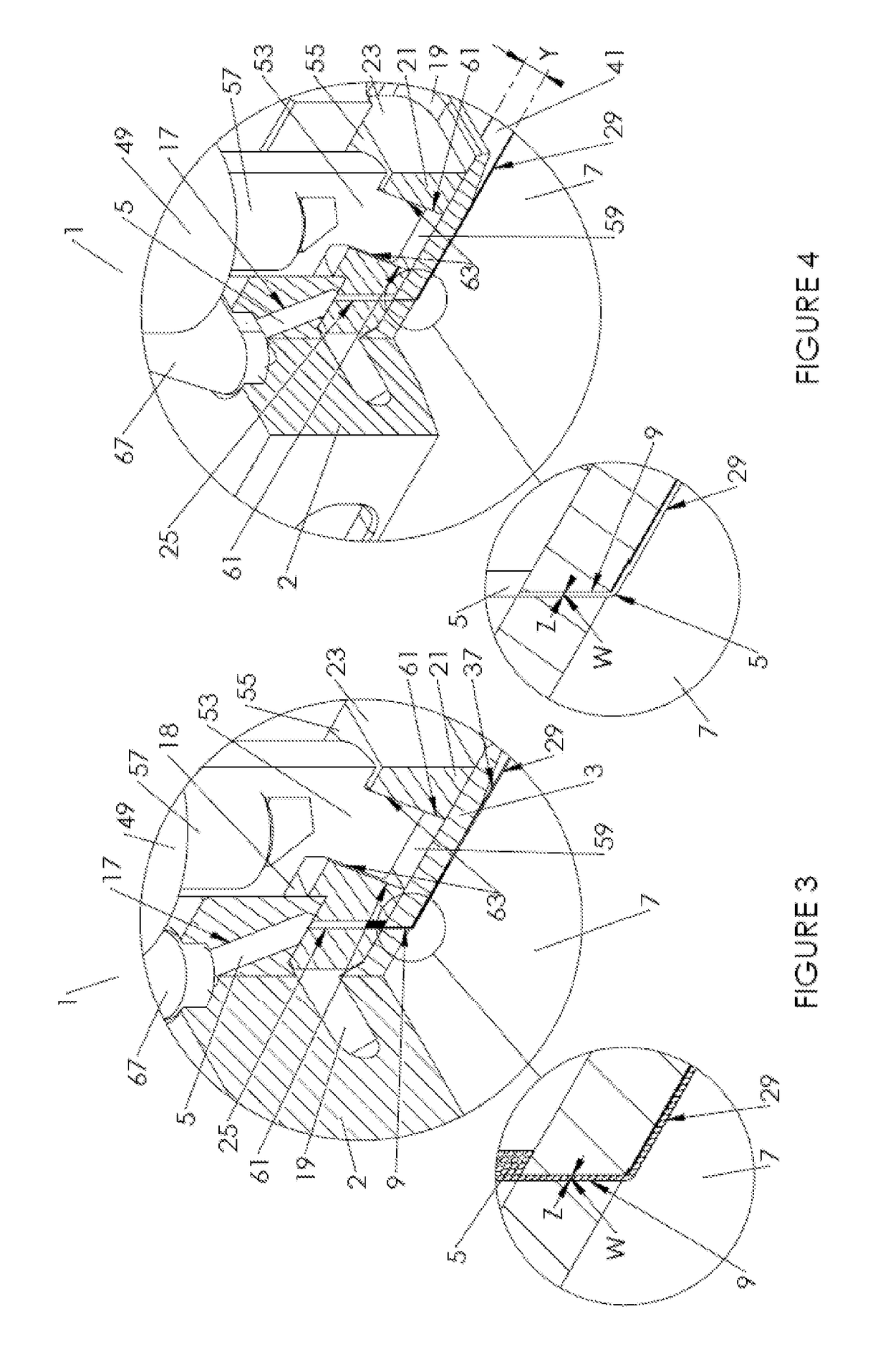

Clutch

InactiveUS20020195307A1Increase the effective surfaceShorten the axial lengthFriction clutchesEngineeringTorque transmission

A clutch (1) with a multiplicity of clutch discs (5, 6) in the form of friction discs (6) and pressure discs (5), arranged between a clutch basket (2) and a clutch hub (3), and with means of positive torque transmission between the clutch discs (5, 6), the clutch basket (2) and with the clutch hub (3), wherein the means of torque transmission between the clutch hub (3) and the pressure discs (5) are provided by movable driver elements (12).

Owner:KTM SPORTMOTORCYCLE AG

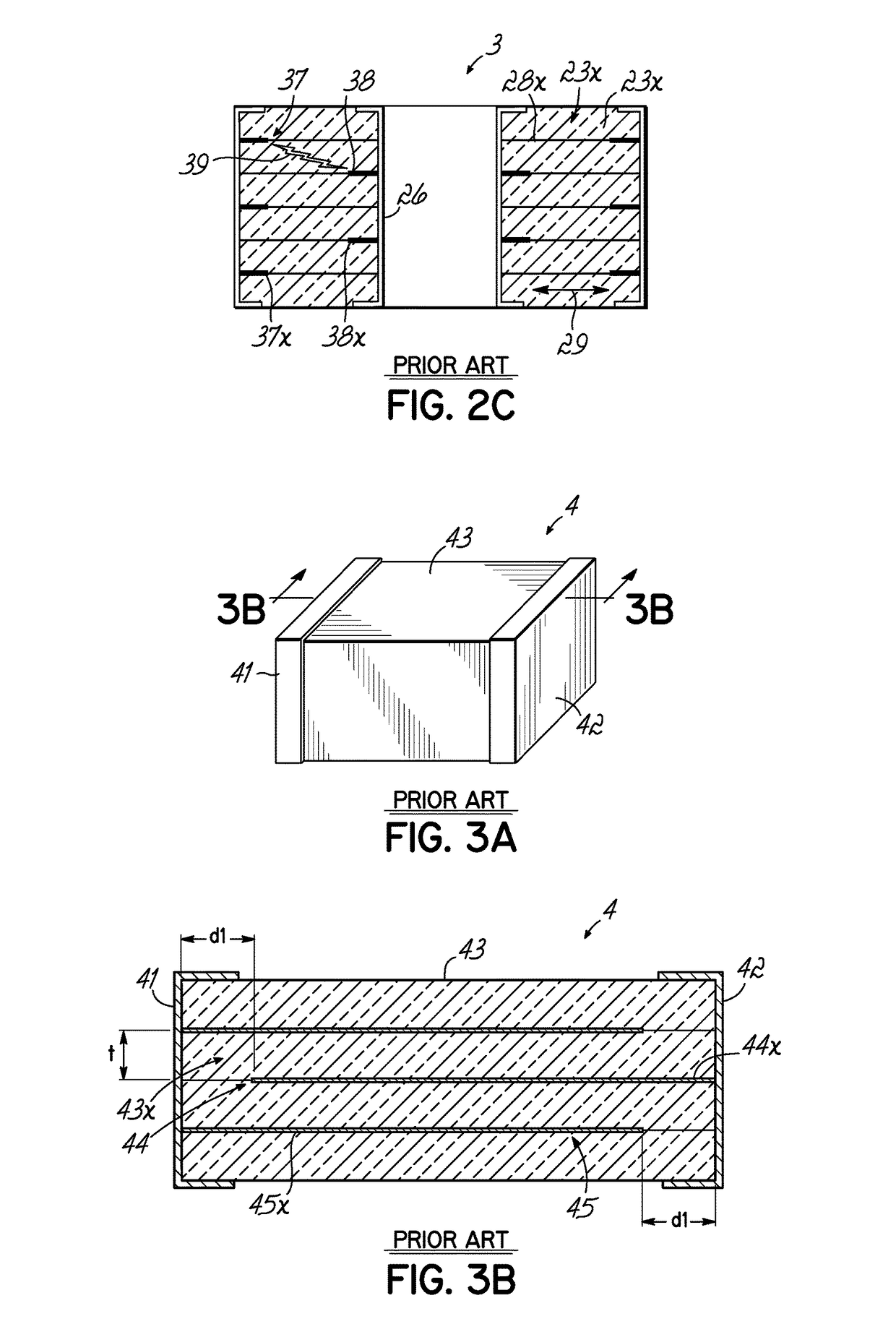

High voltage fringe-effect capacitor

ActiveUS9786437B1Increase capacitanceIncrease valueAnti-noise capacitorsFixed capacitor electrodesPlanar electrodeFringing capacitance

A multilayer chip capacitor includes electrodes comprised of numerous, closely spaced conductive layers interposed within a dielectric laminate. Adjacent conductive layers are essentially non-overlapping, so that fringe capacitance between opposing electrodes provides substantially all of the capacitance. The conductive layers may be shaped to form a non-planer boundary between electrodes. An additional high frequency integrated capacitor is formed from external electrode plates. The non-planar electrode boundary principle is also applied to discoidal capacitors in the form of a non-concentric electrode boundary.

Owner:PRESIDIO COMPONENTS

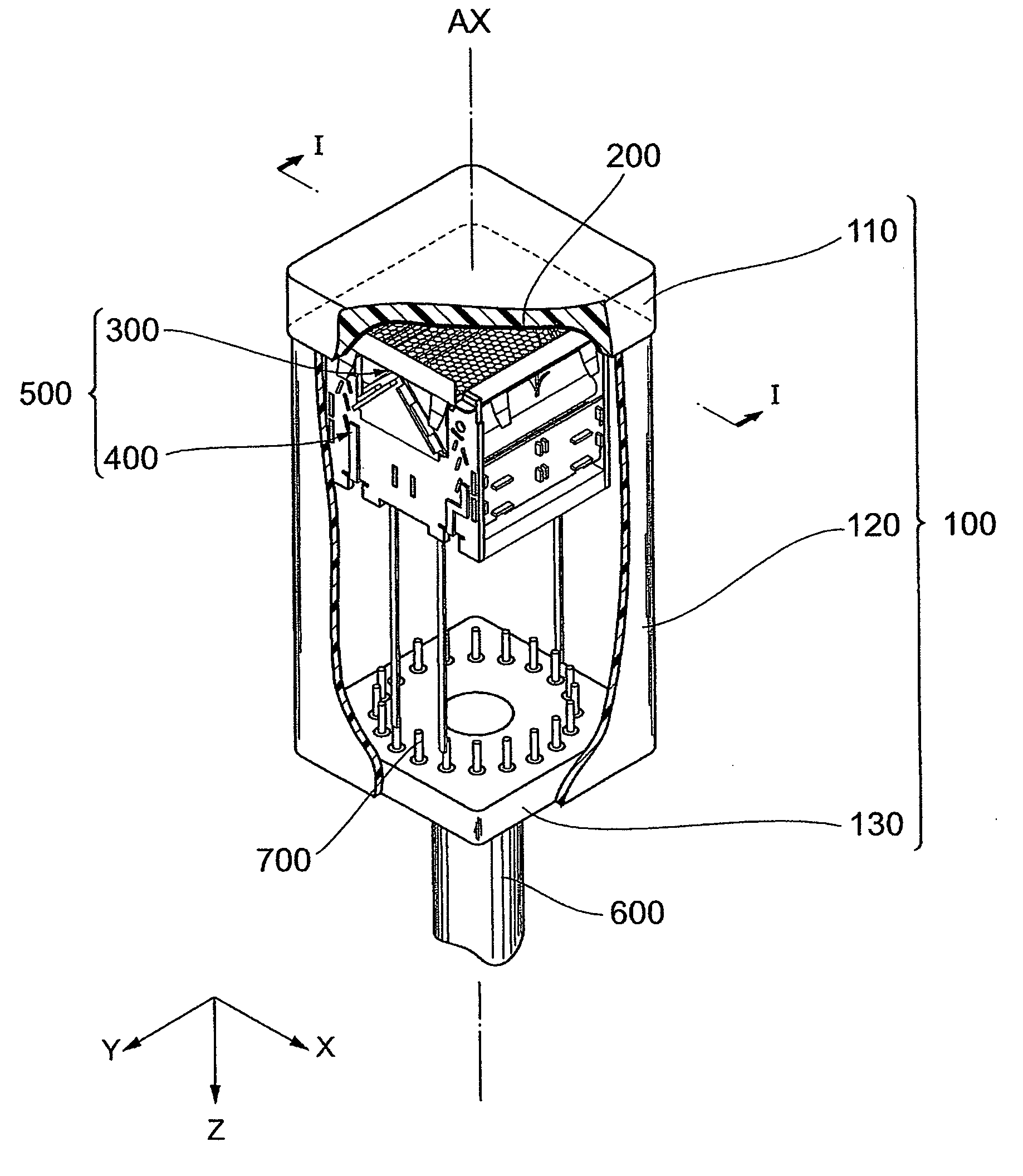

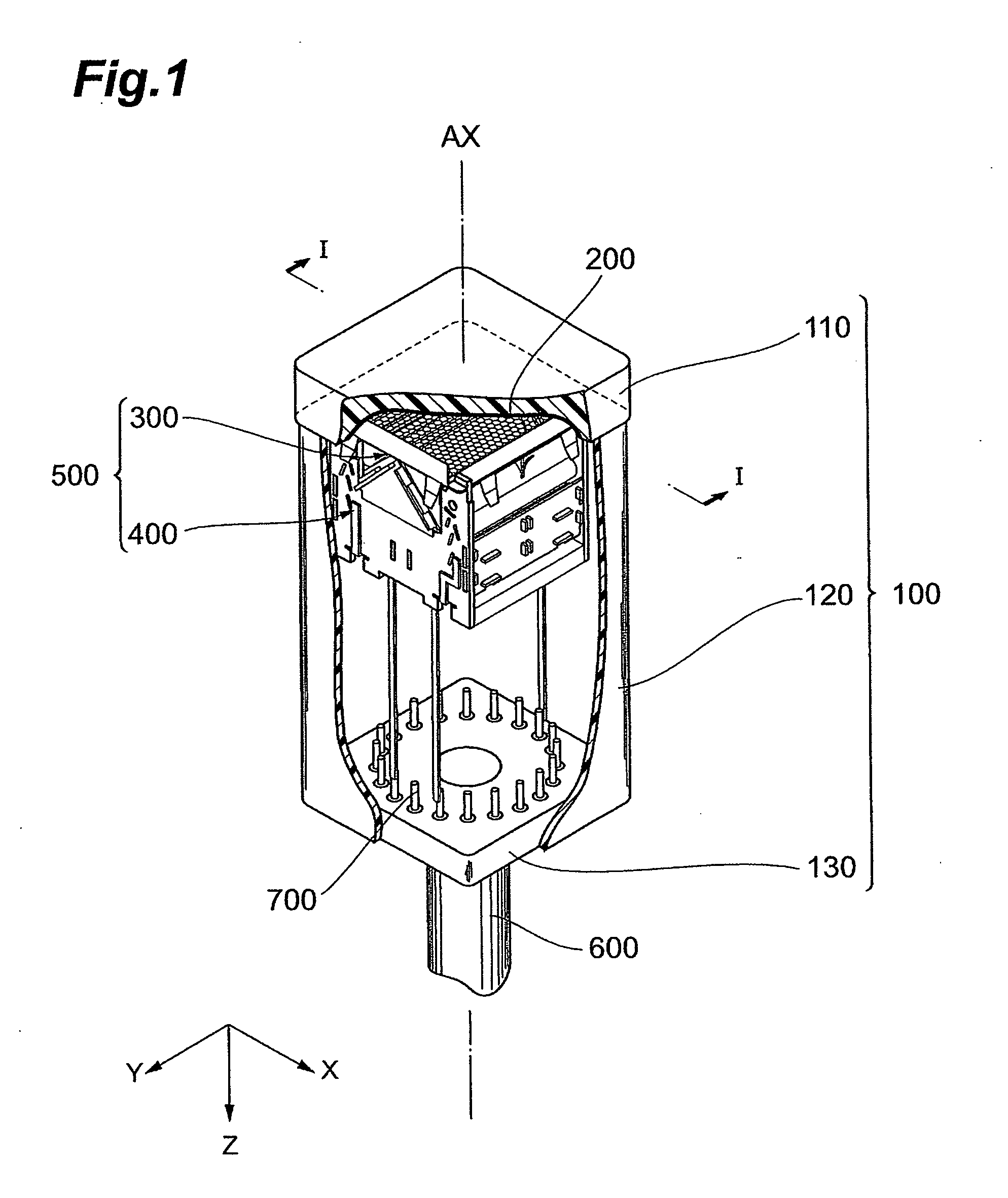

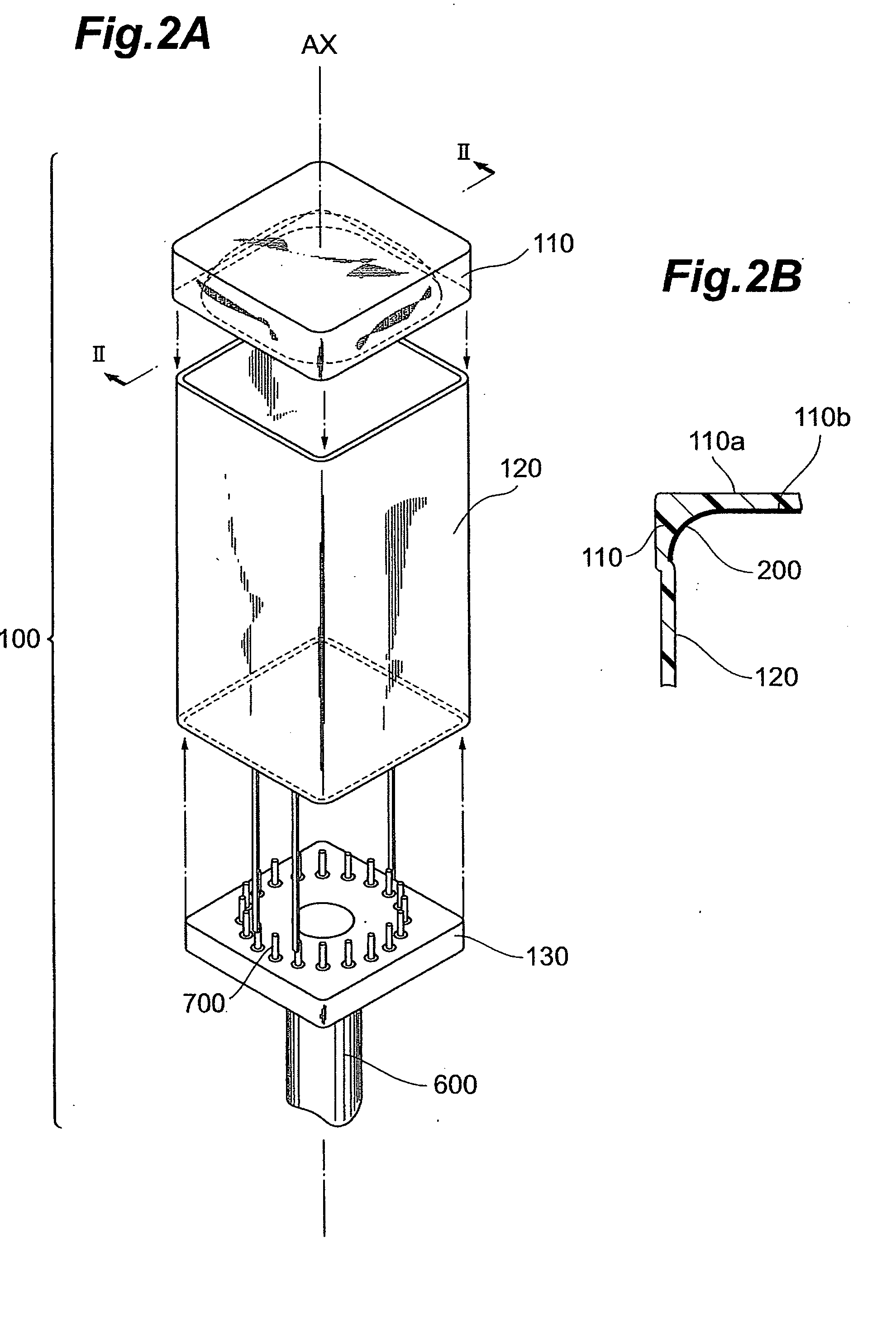

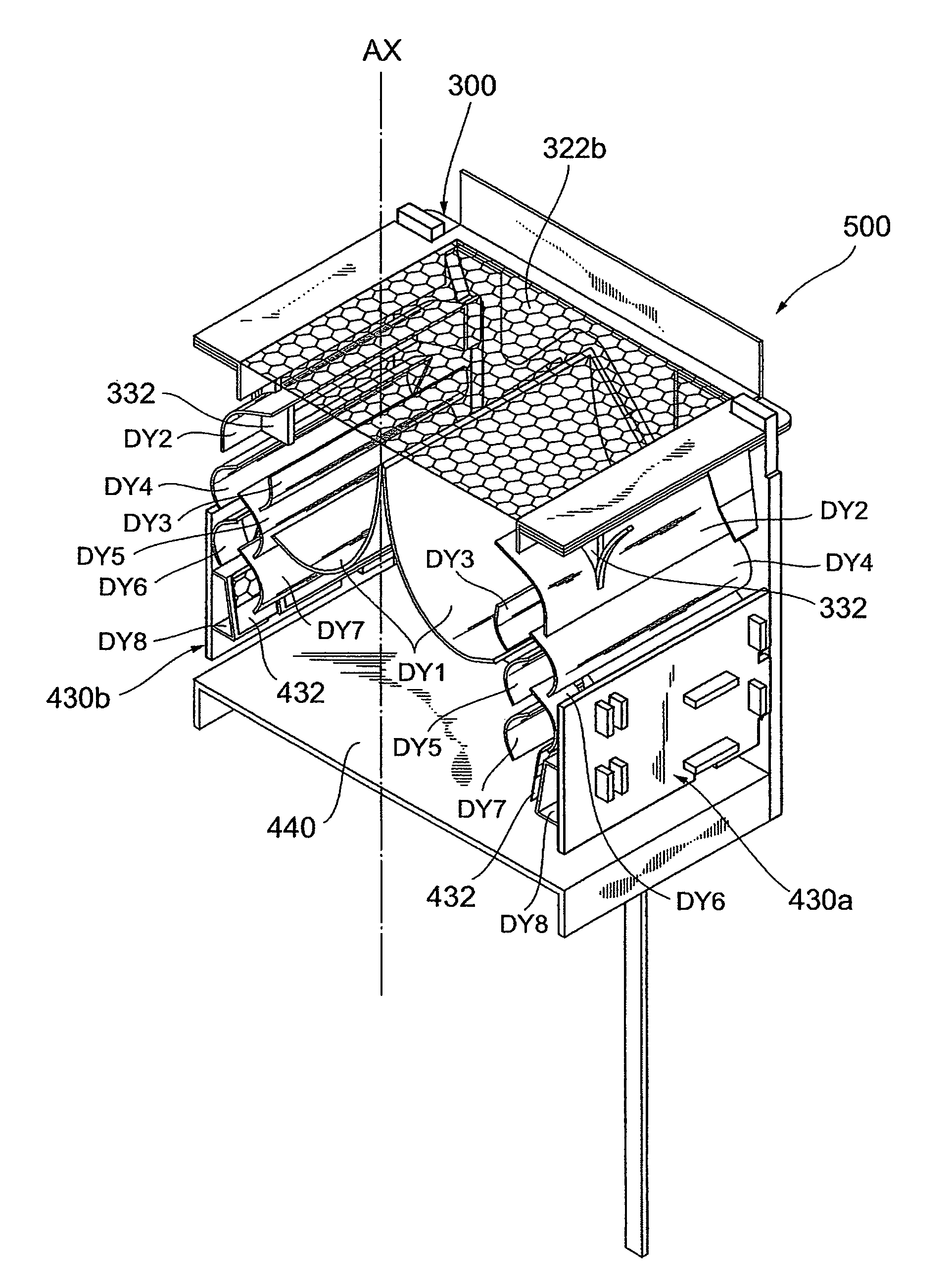

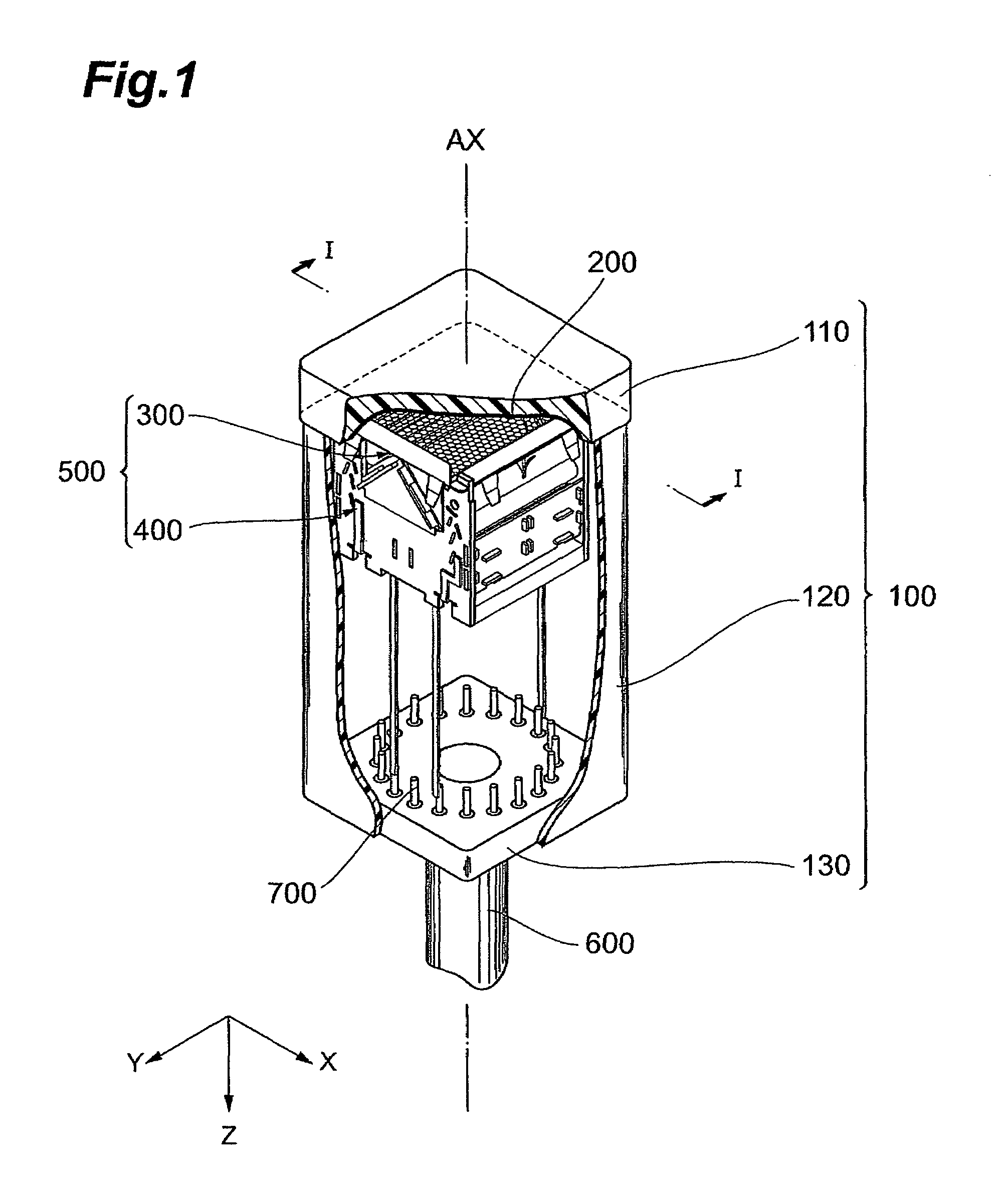

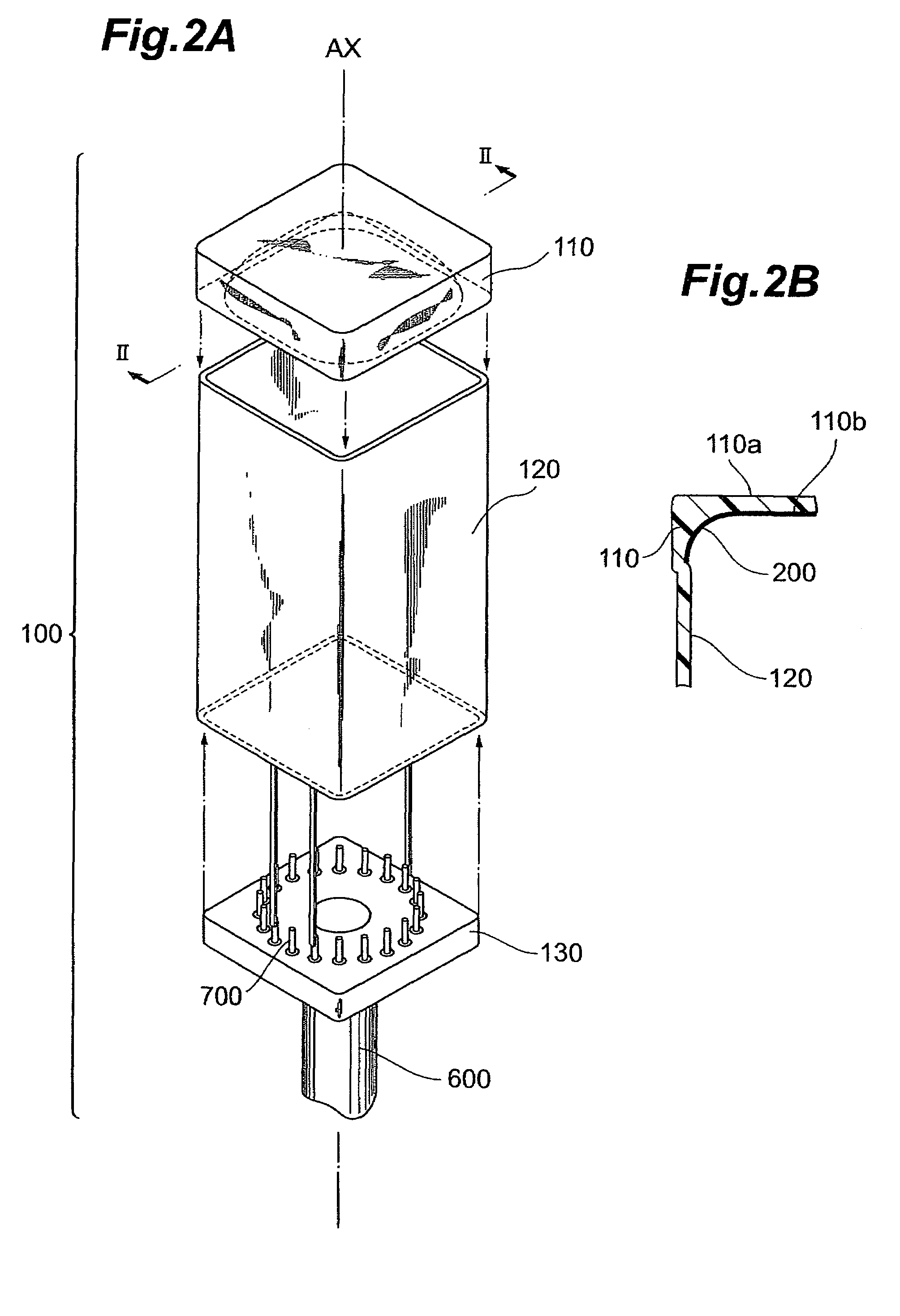

Photomultiplier

InactiveUS20080088233A1Reduce electron transit time differenceImprovement of electron transit time difference in electronMutiple dynode arrangementsPhotocathodeSecondary electrons

The present invention relates to a photomultiplier that realizes significant improvement of response time properties with a structure enabling mass production. The photomultiplier comprises an electron multiplier section for cascade-multiplying photoelectrons emitted from said photocathode. The electron multiplier has a structure holding at least two dynode sets while sandwiching the tube axis of a sealed container in this the electron multiplier is housed. In particular, the first dynodes respectively belonging to the two dynode sets are arranged such that their back surfaces opposing respective secondary electron emitting surfaces face each other while sandwiching the tube axis. In this arrangement, because each first dynode itself is positioned near the tube axis, the efficiency of collection of photoelectrons arriving at the periphery of the first dynode is improved significantly.

Owner:HAMAMATSU PHOTONICS KK

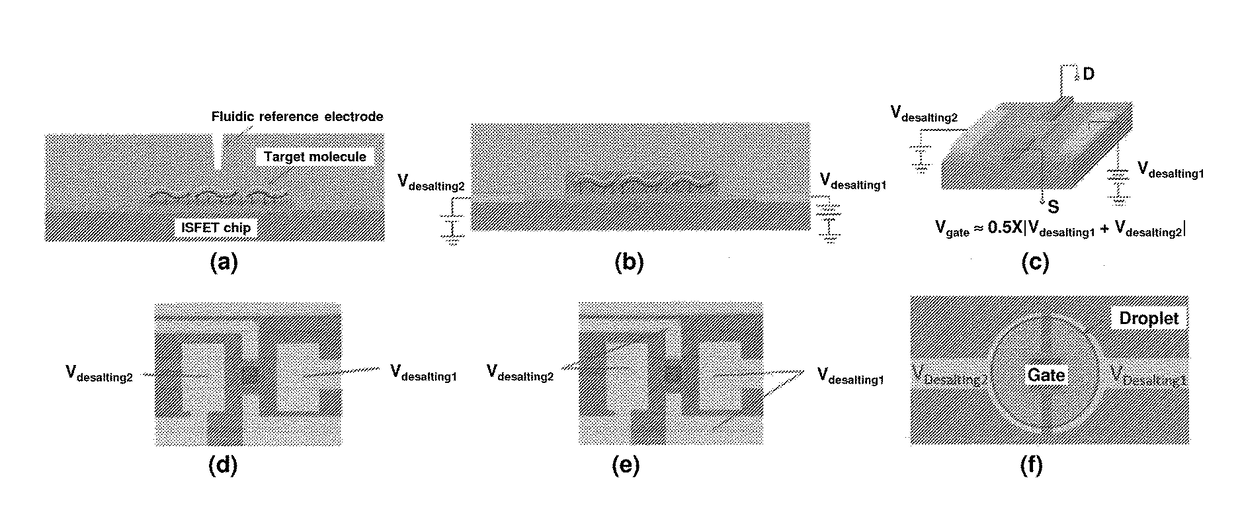

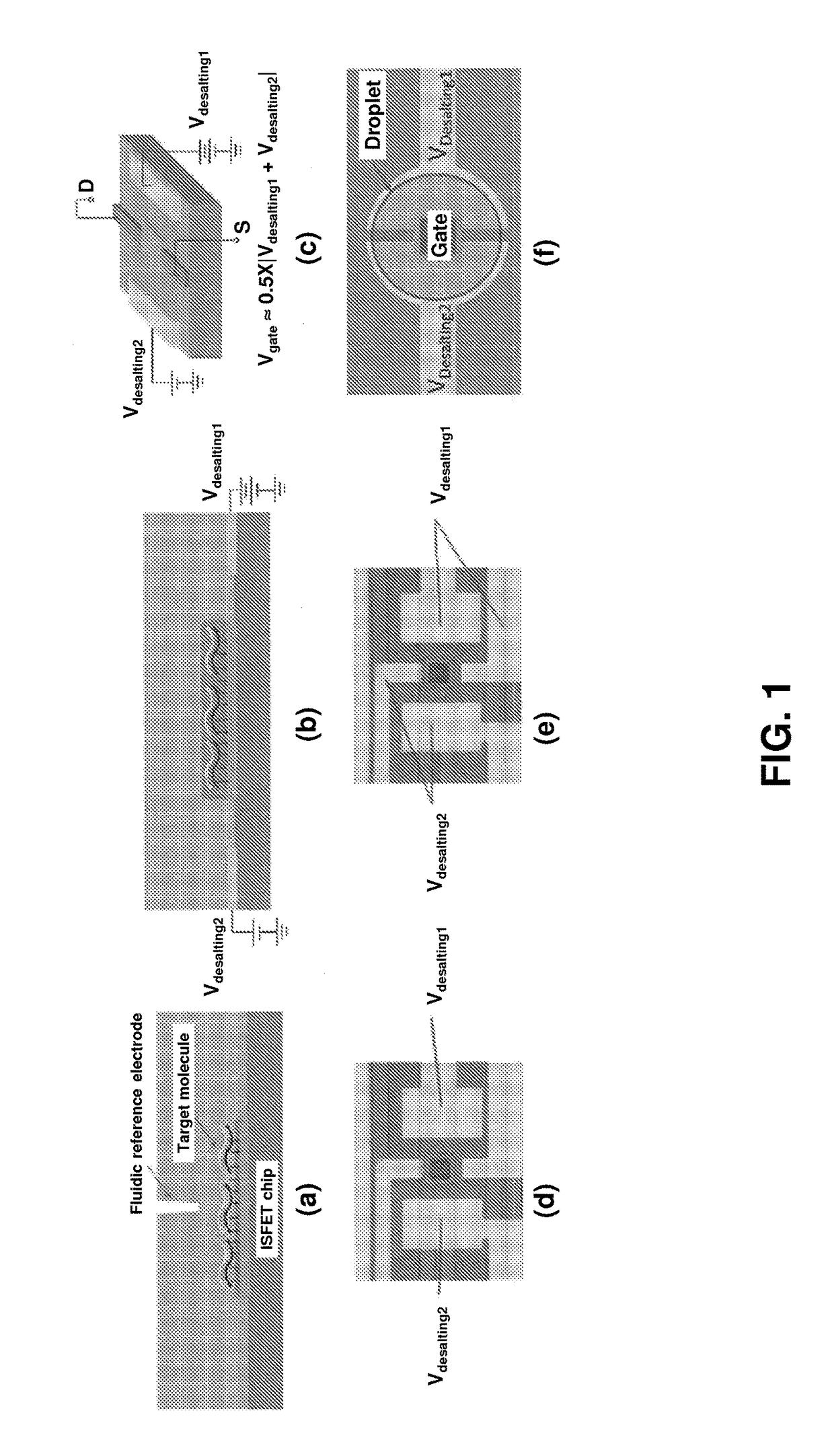

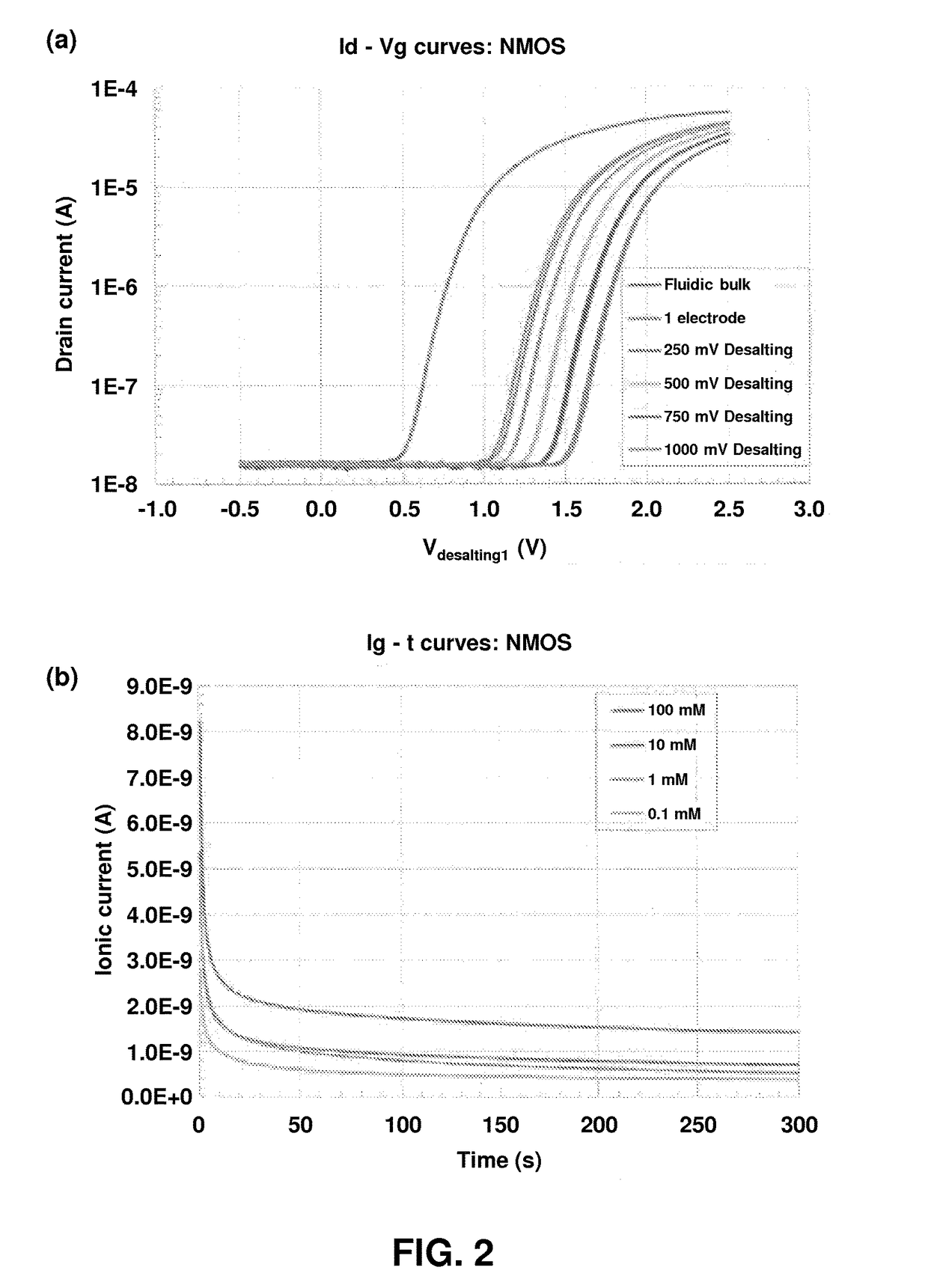

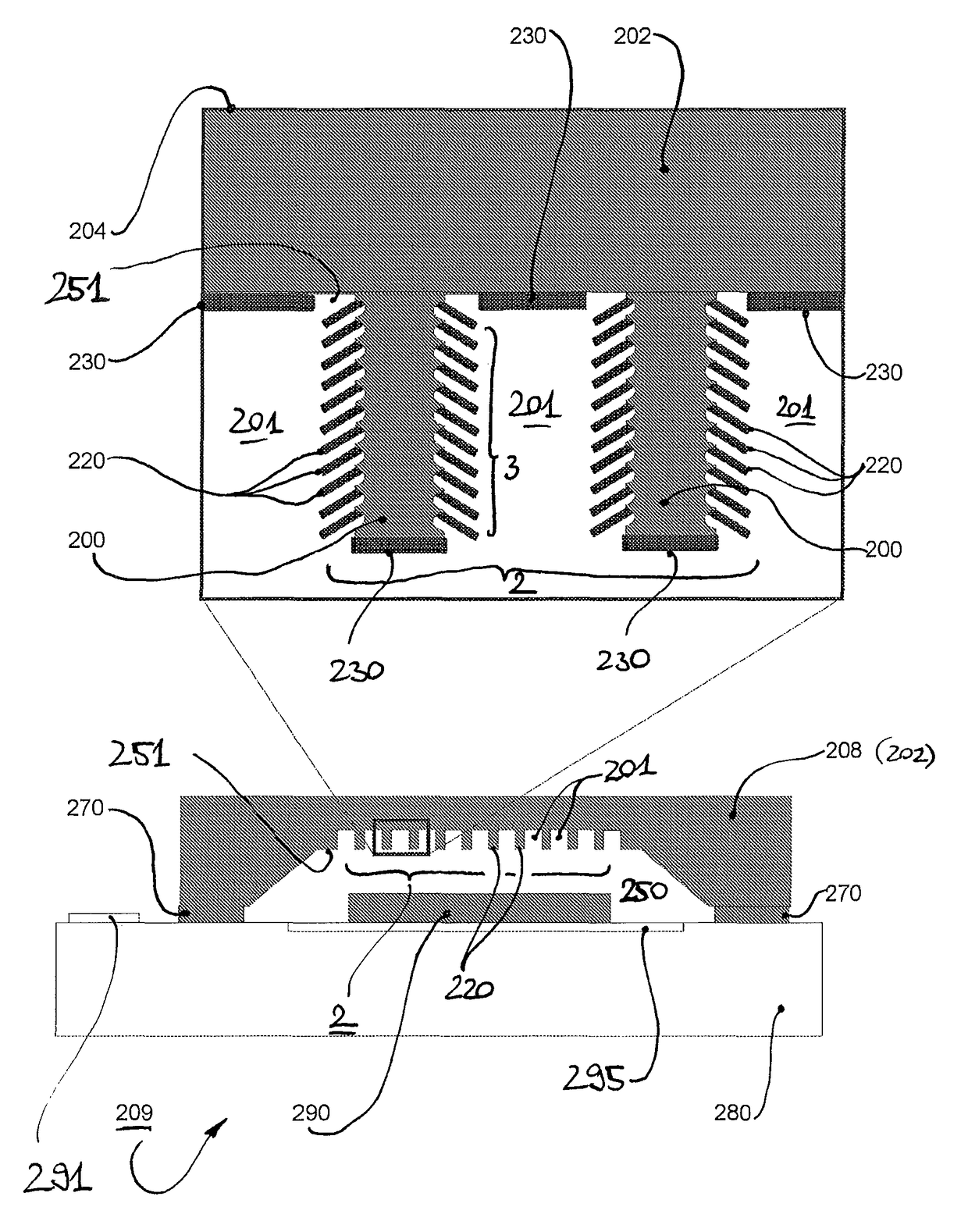

Label Free Analyte Detection by Electronic Desalting and Field Effect Transistors

ActiveUS20170176379A1Improved sensor response and detection characteristicFacilitate label free analyte sensingMaterial analysis by electric/magnetic meansChemical field-effect transistorGate voltage

Provided are methods and devices for the label free detection of analytes in solution, including analytes suspended in a biological fluid. A field effect transistor (FET) is positioned in close proximity to a paired set of reference electrodes and the reference electrodes electrically biased to provide desalting and a stable gate voltage to the FET. In this manner, charged ions are depleted in the sensing region of the sensor and device sensitivity to analyte detection improved by the removal of charge that otherwise interferes with measurement. Also provided are methods and systems providing increased in reference electrode surface area and / or decrease in droplet volume to further improve label-free detection of analytes.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method for forming a micro-surface structure and for producing a micro-electromechanical component

ActiveUS9637377B2Easy to manufactureOvercome disadvantagesPrinted circuit assemblingRadiation pyrometryEngineeringSurface structure

The present invention relates to a method for forming a micro-surface structure on a substrate, in particular for producing a micro-electromechanical component, a micro-surface structure of this type, a method for producing a micro-electromechanical component having a micro-surface structure of this type and such a micro-electromechanical component. The invention is particularly relevant for components of microsystem technology (MST, micro-electromechanical systems MEMS) and the construction and connection technology for hermetically housing micro components, preferably using getter materials.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

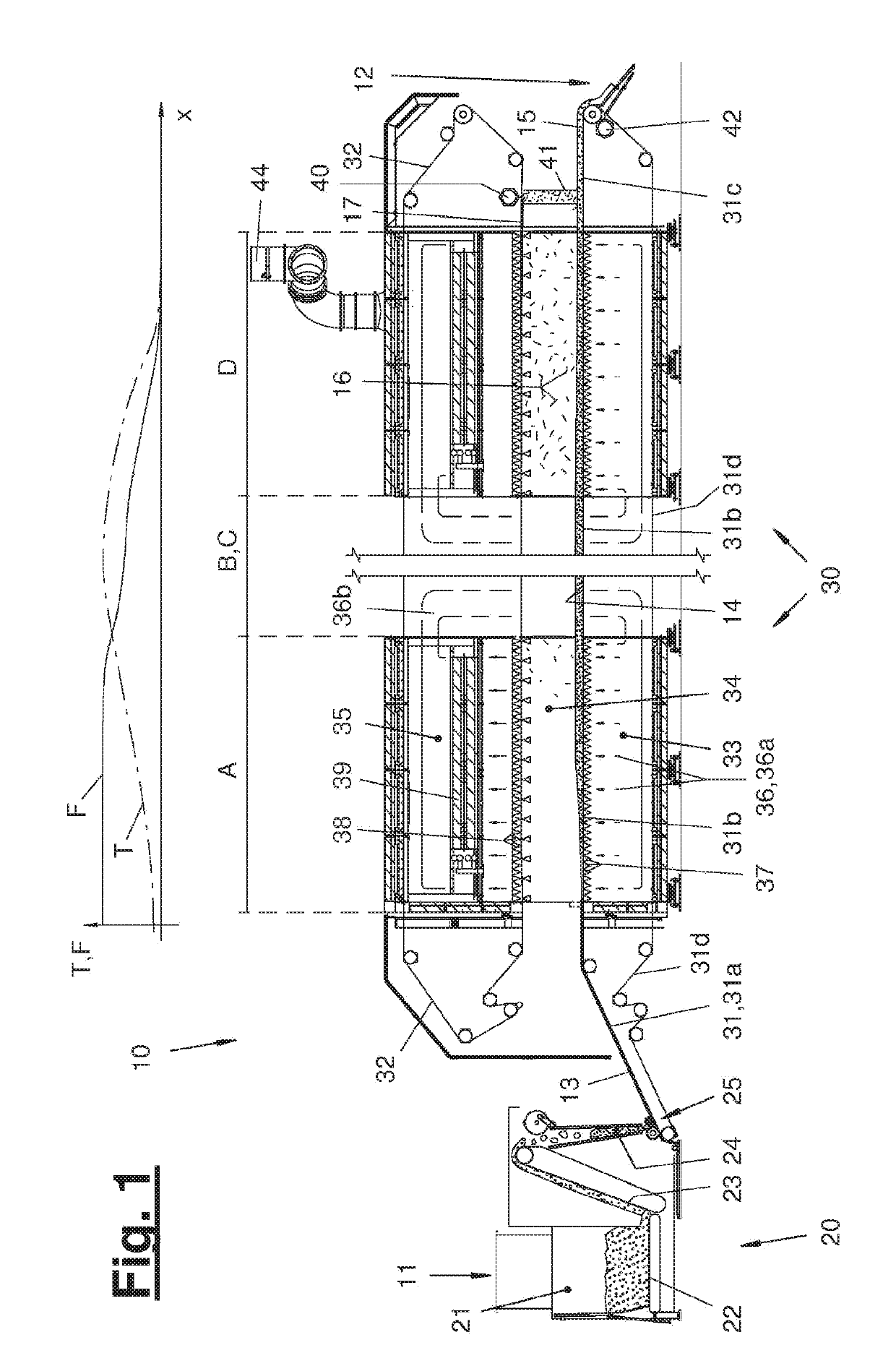

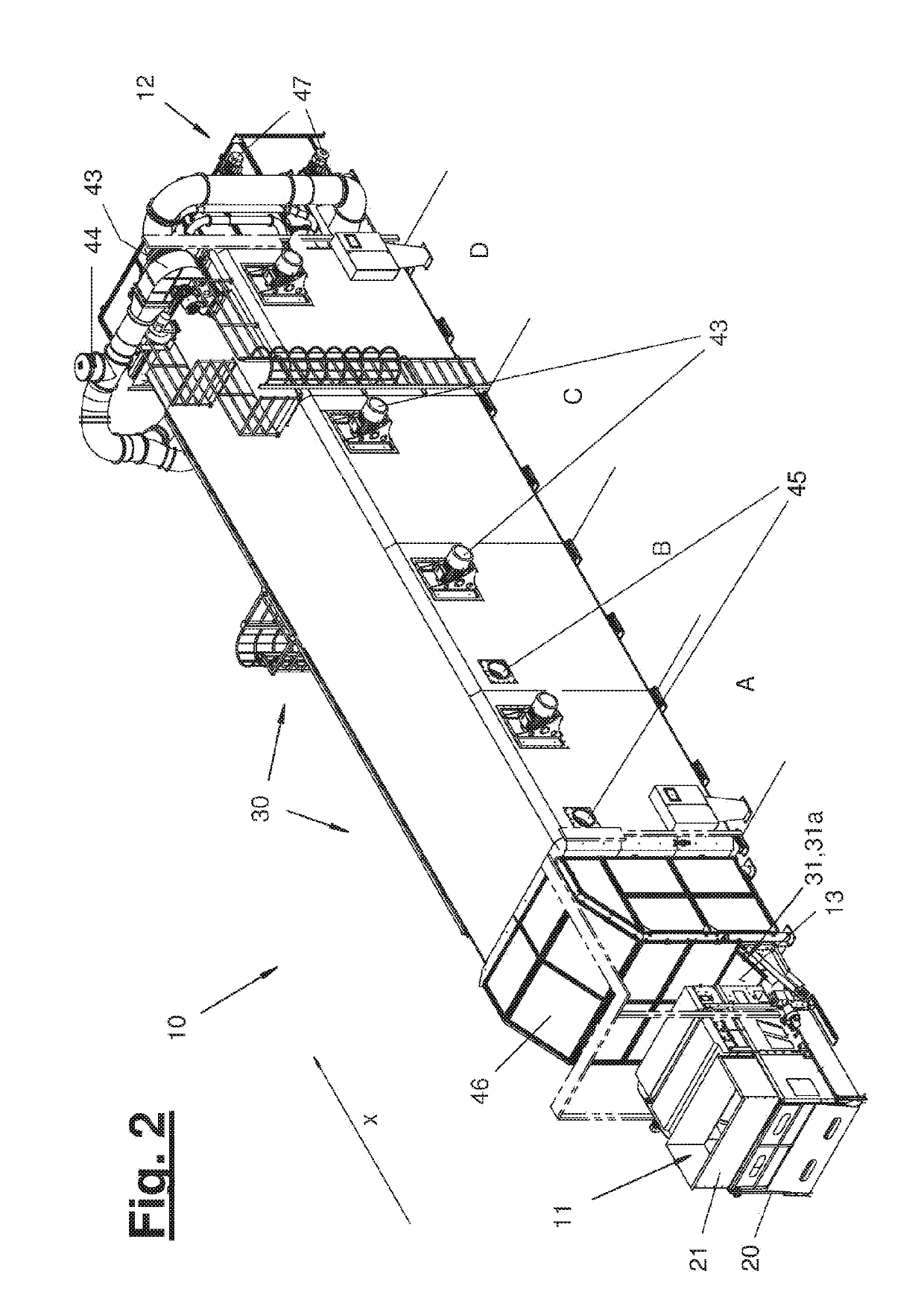

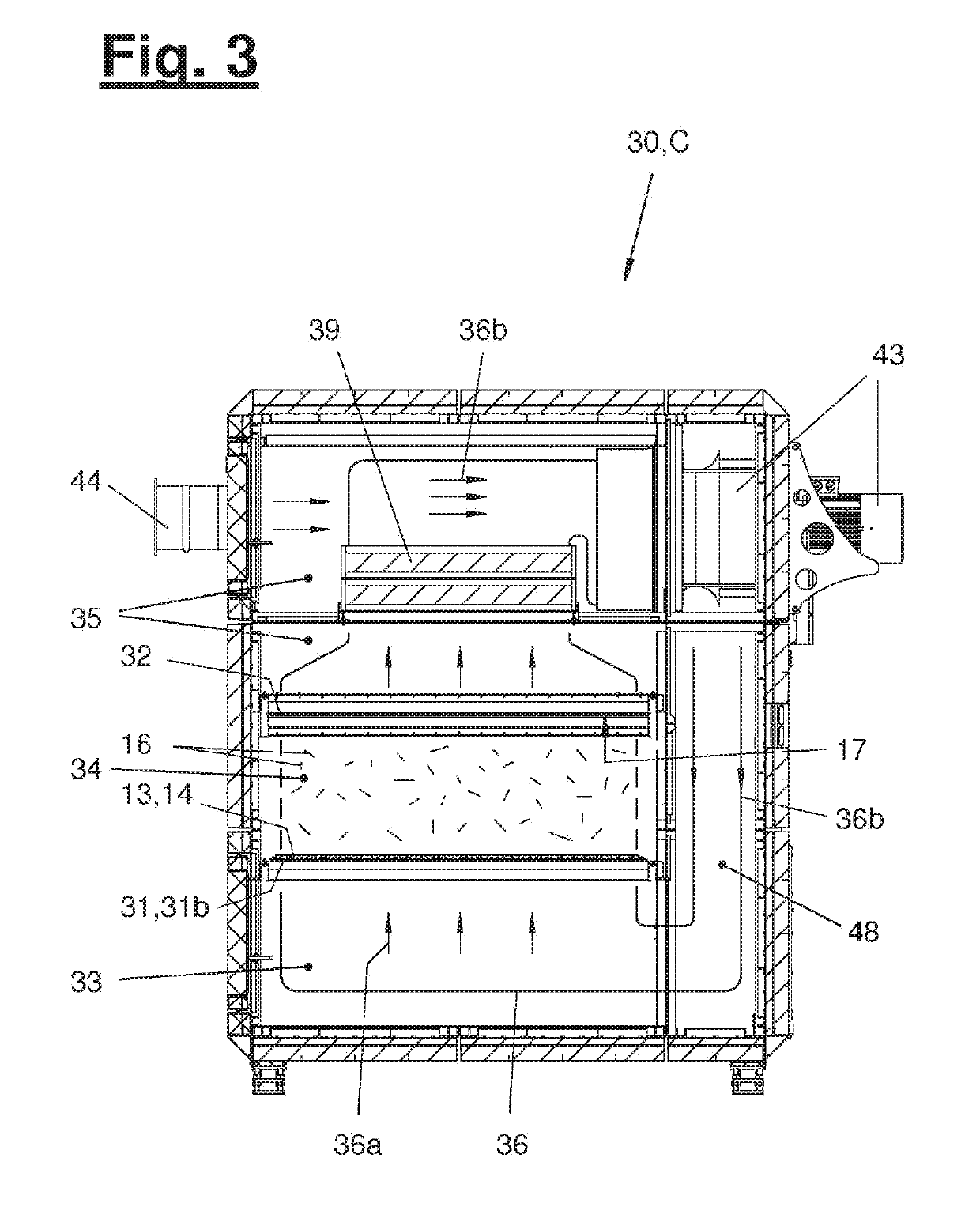

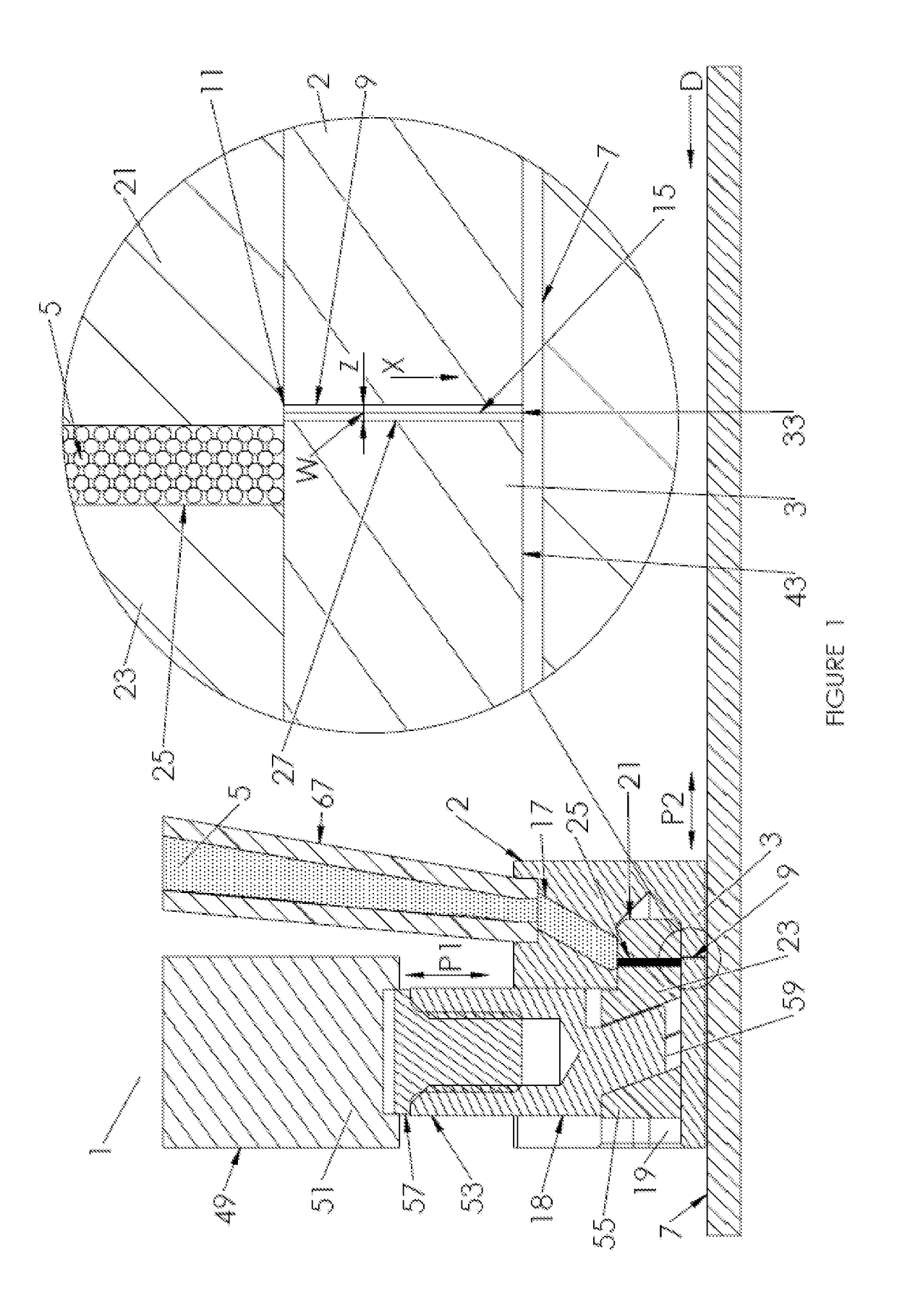

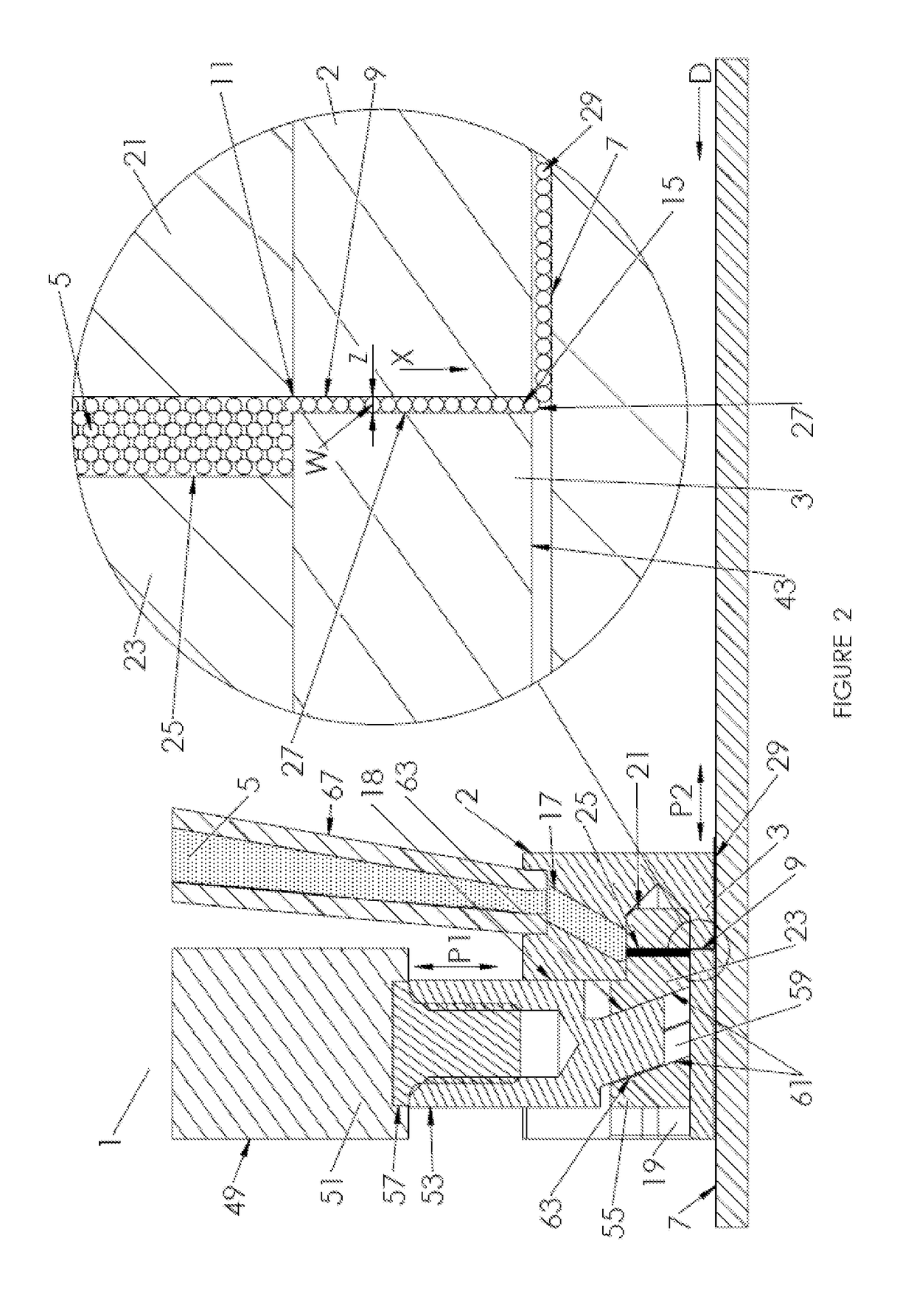

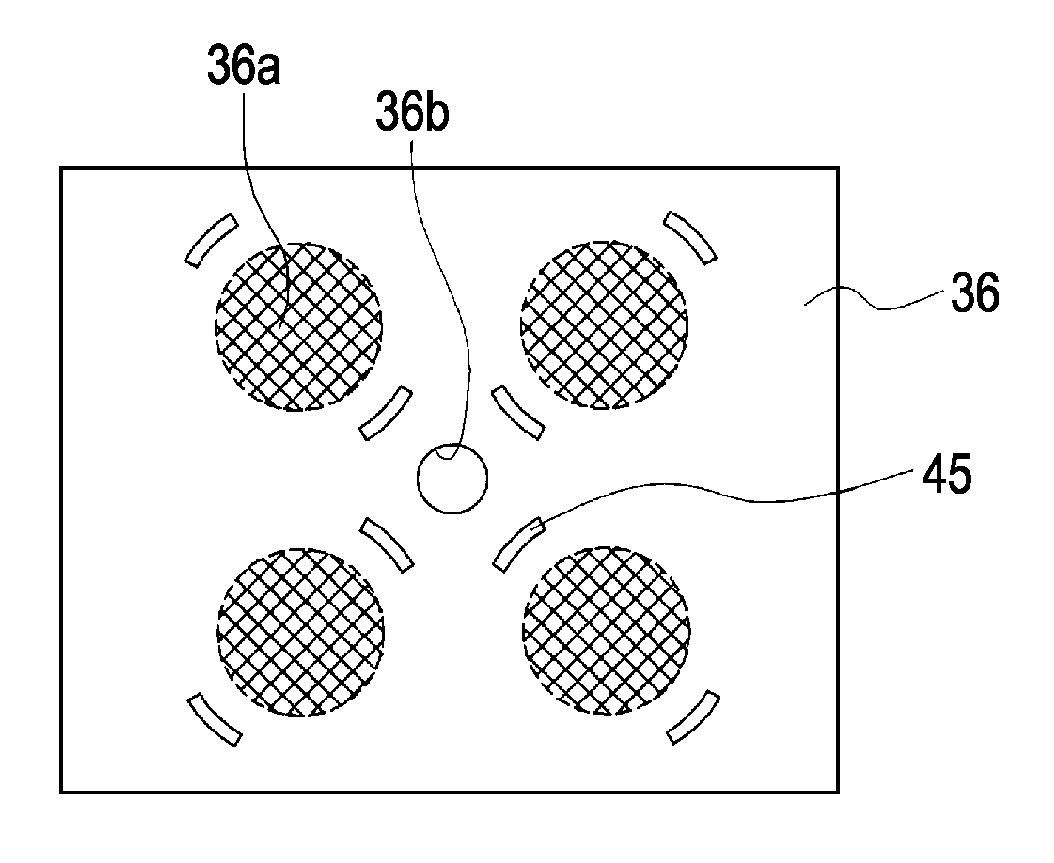

Textile fiber drying

ActiveUS20190316839A1Advanced technologyFine surfaceDrying solid materials with heatDrying gas arrangementsTextile fiberMechanical engineering

A method and a fiber-treatment system dry wet or damp fibers. A fiber mat (13) including wet or damp fibers is formed on a treatment band (31) which is moved in a conveying direction (x). An air flow (36, 36a) composed of heated drying air is generated in the fiber dryer (30). The heated drying air is guided in an upward direction through the treatment band and the fibers contained in the fibre mat (13, 14) are loosened and dried. Linters (16) possibly produced by any moving fibers are captured by a filter band (32) arranged above the treatment band, which is also moved in the conveying direction (x). At the outlet of the fiber dryer, the fibers are detached from a support (17) formed on the filter band, in particular when guiding the detached fibers back towards the dried fibers guided to the treatment band (31, 31c).

Owner:AUTEFA SOLUTIONS GERMANY GMBH

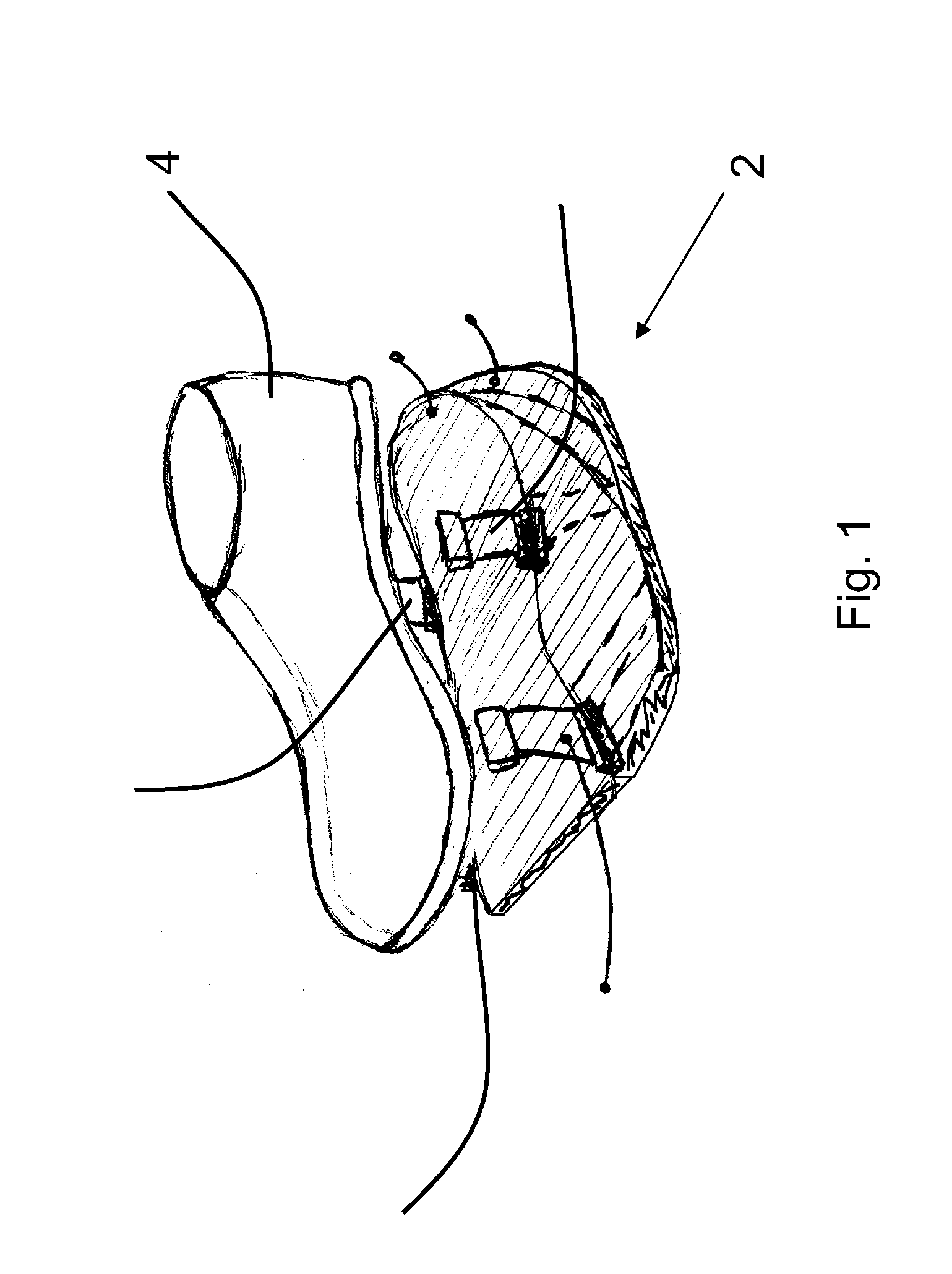

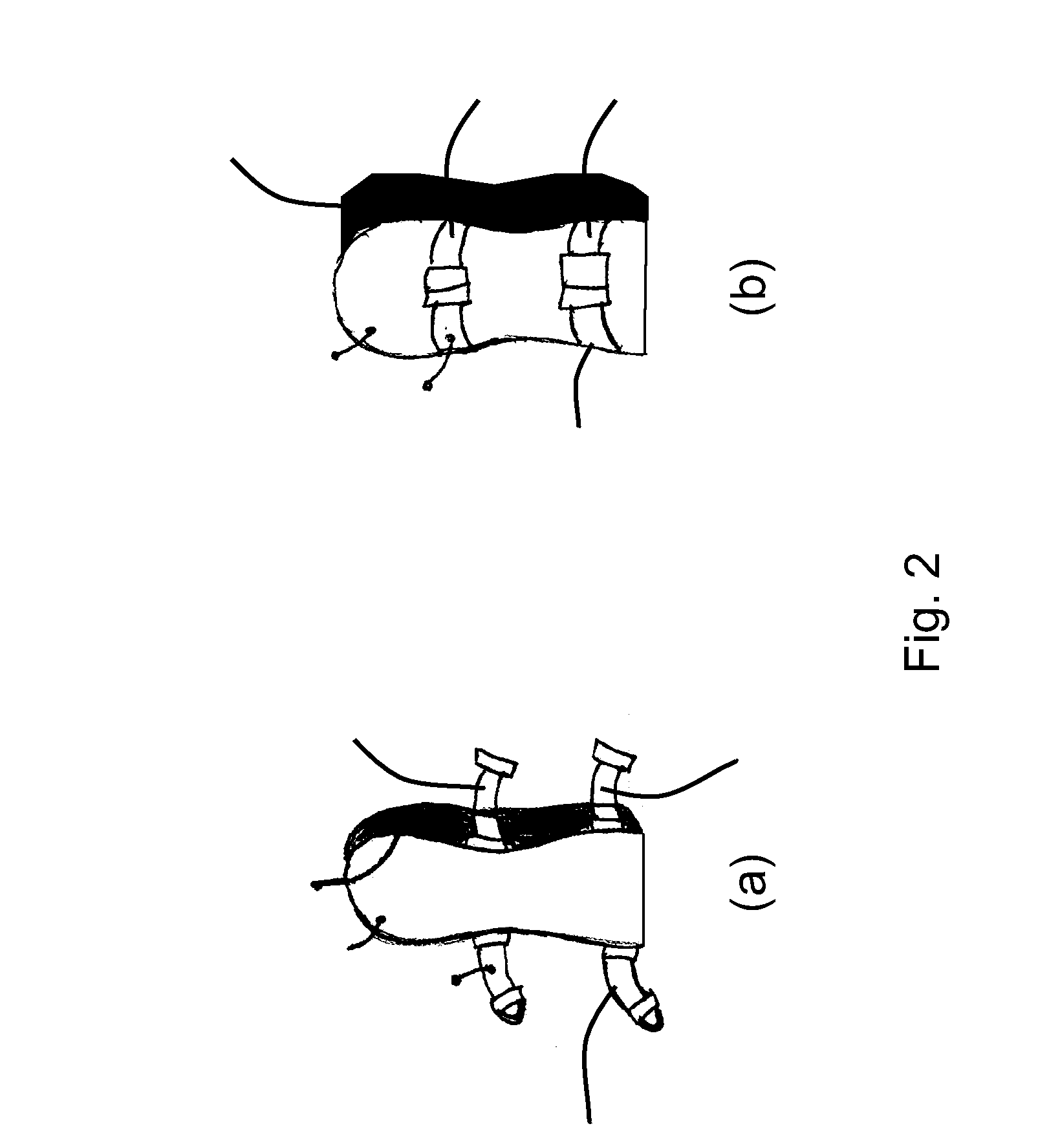

Stabiliser Assembly

InactiveUS20130138031A1Improve stabilityIncrease the effective surface areaSolesNon-surgical orthopedic devicesEngineeringEffective surface area

The present invention relates to an assembly to improve the stability of a user of the assembly, the assembly comprising: a brace for connecting to a lower leg portion, the brace comprising a stabiliser connecting portion; and a stabiliser for connecting to a shoe, the stabiliser comprising a brace connecting portion and an extension portion having a shoe connection portion configured in use to connect the extension portion to the shoe so that the extension portion extends laterally from the shoe to increase the effective surface area of the shoe sole at only a lateral side and to improve the stability of a user of the stabiliser, wherein the brace and the stabiliser are couplable together by the stabiliser connecting portion and the brace connecting portion so that, when said lower leg portion is connected to the brace and said shoe is connected to the stabiliser, an outward lean of said lower leg portion with respect to said shoe is limited to a predetermined angle, thereby providing a stabilising force to improve the stability of a user of the assembly, and wherein the stabiliser connecting portion and the brace connecting portion are uncoupled during normal locomotion of a wearer of the assembly, thereby providing unimpeded movement for normal locomotion.

Owner:BIOLOGICAL COPROCESSORS

Spindle motor

InactiveUS20050140226A1Increase effective lengthIncrease the effective surfaceMagnetic circuit rotating partsRecord information storageRotational axisHard disc drive

The invention relates to a spindle motor, particularly for the purpose of driving the platters in hard disk drives having a baseplate, a stator arrangement that is stationary with respect to the baseplate, a shaft and a bearing system to rotatably support a rotary driven rotor connected to the shaft. In order to create a spindle motor in which it is possible to connect the shaft to the rotor with a high holding force and improved running precision, provision is made according to the invention for the shaft to be at least partly formed as a hollow shaft and for the rotor to have a shaft shoulder aligned concentric to its rotational axis which is inserted into the hollow shaft and firmly connected to the shaft.

Owner:MINEBEAMITSUMI INC

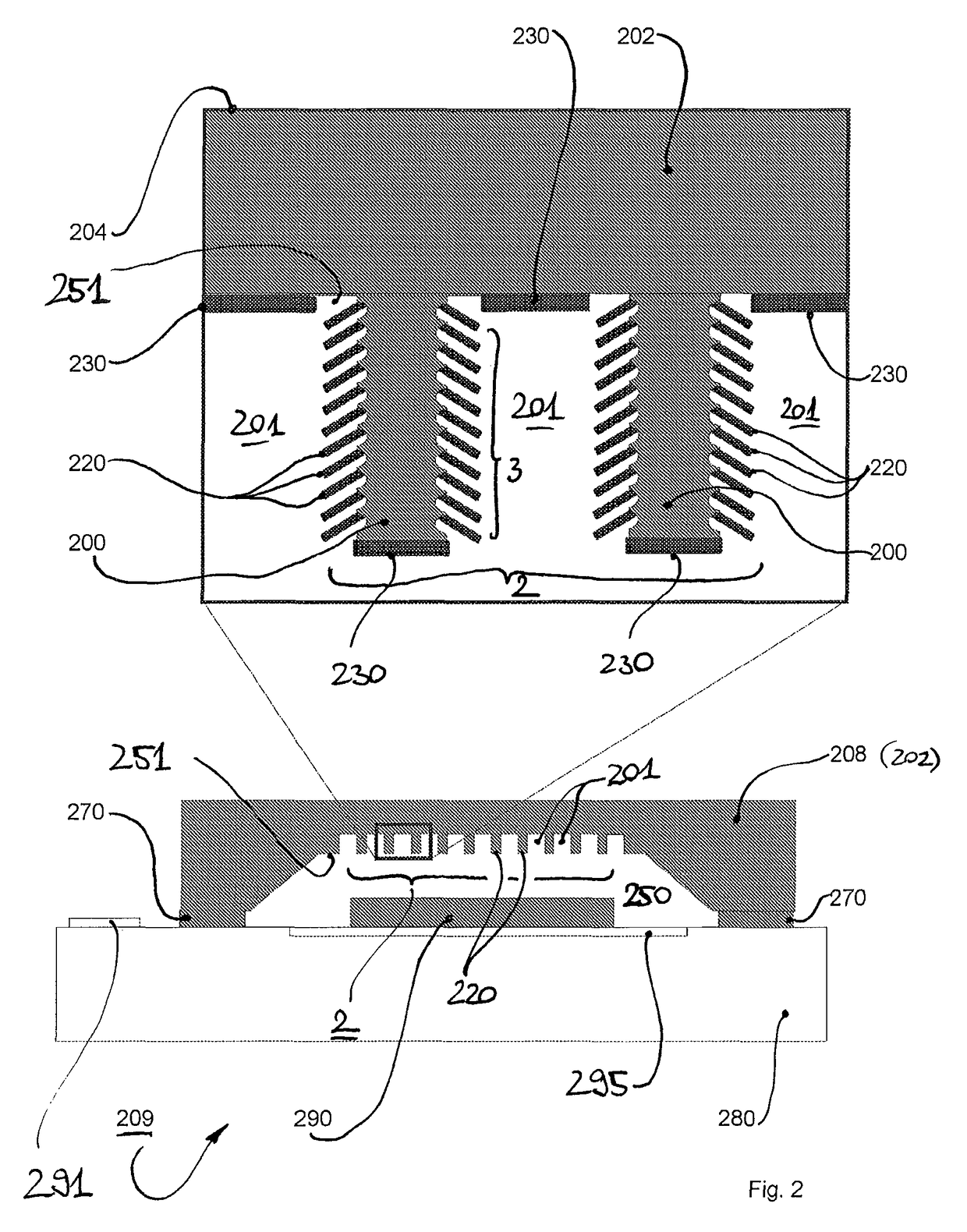

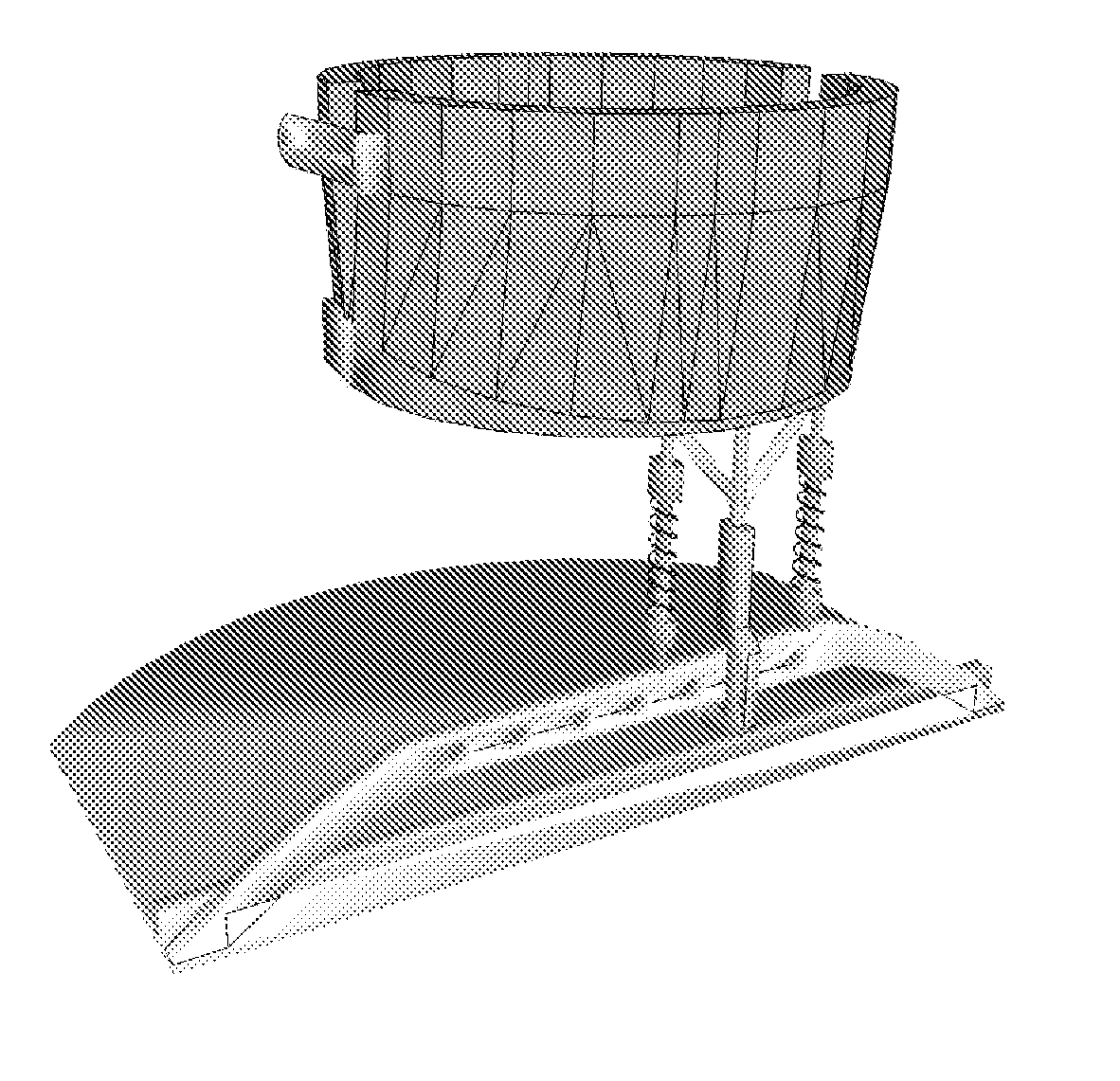

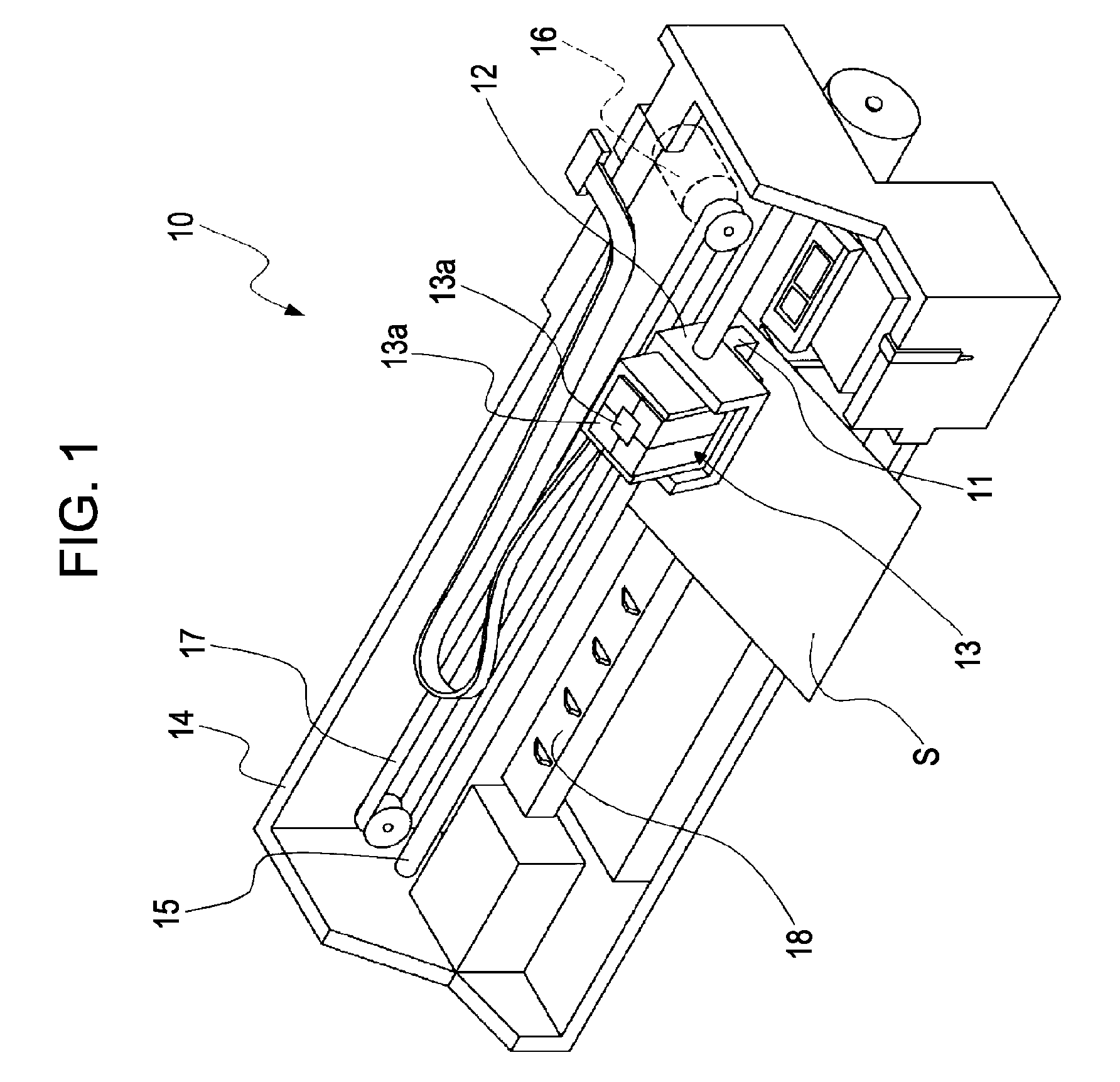

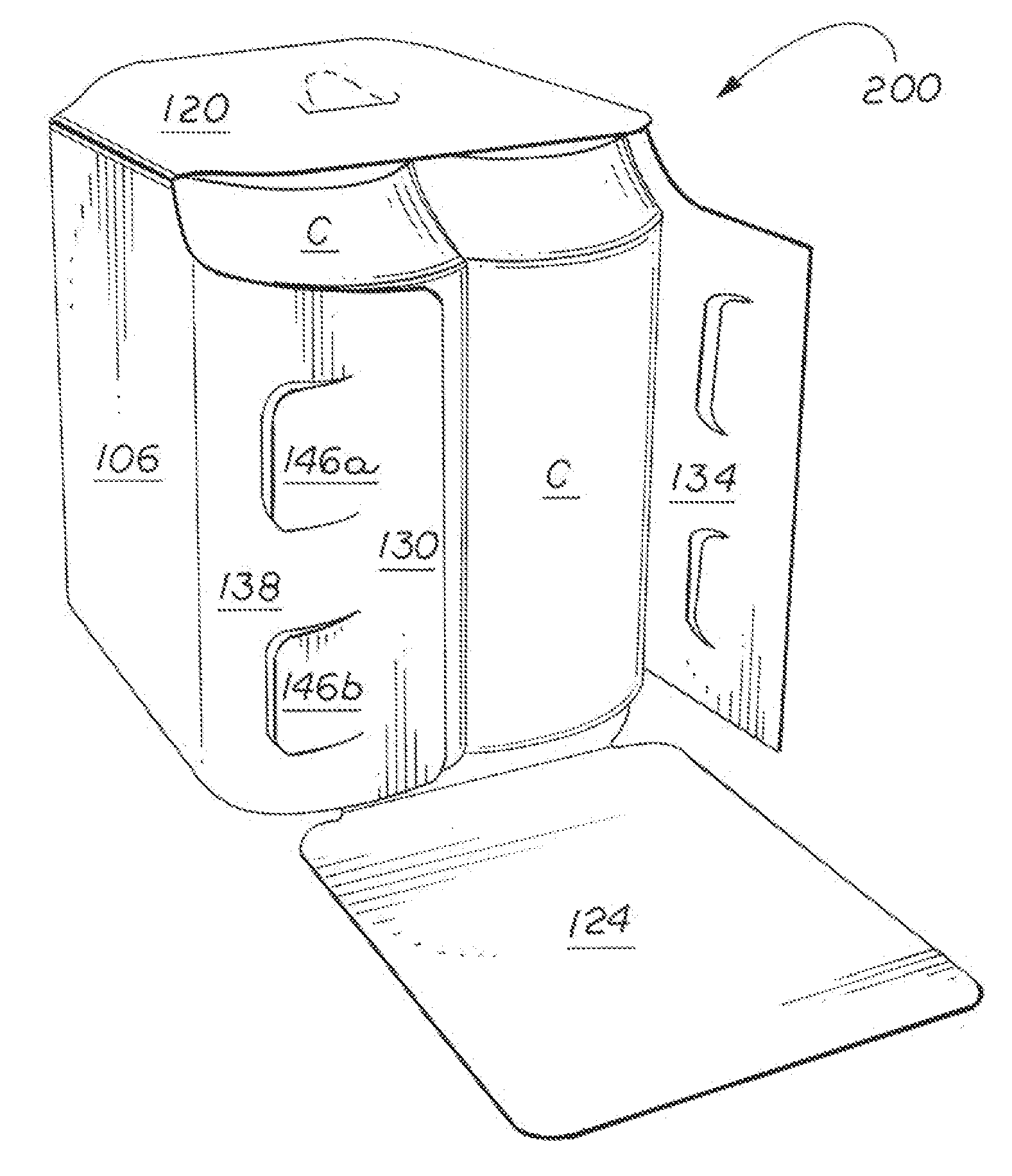

A Three Dimensional Printing Apparatus, a Material Dispensing Unit Therefor and a Method

InactiveUS20180361663A1Uniform thicknessQuick buildManufacturing enclosuresManufacturing heating elementsControl flowEngineering

A material dispensing unit (1; 10) for a three dimensional printing apparatus (100; 200) has a nozzle (3) for depositing particulate material (5; 220a, 220b; 224; 226) on a build surface (7), where the nozzle defines a through passage (9) for the material. The through passage has an inlet end (11) for receiving the material and an outlet end (15) for dispensing the material. A valve (21) is provided at least one of at, within or in fluid communication with the through passage for controlling flow of the material via the through passage, the valve being operable between open and closed positions. Flow of said material into the through passage is blocked when in the closed position and, when in the open position, flow of the material into the through passage is allowed. A method of forming a three dimensional object (31) is also disclosed, as is a three dimensional printing apparatus (200) comprising one or more dispensing units (la; b) for dispensing particulate material (220a, 220b; 224; 226), an enclosure (137) for containing the material dispensed by the one or more dispensing units and one or more heating elements (210, 212) for heating the material contained in the enclosure to a first predetermined temperature.

Owner:BURT MAXIMILIAN BARCLAY

Photomultiplier having multiple dynode arrays with corresponding insulating support member

InactiveUS7449834B2Reduce the differenceExtension of timeMutiple dynode arrangementsPhotocathodeDynode

The present invention relates to a photomultiplier that realizes significant improvement of response time properties with a structure enabling mass production. The photomultiplier comprises an electron multiplier section for cascade-multiplying photoelectrons emitted from said photocathode. The electron multiplier has a structure holding at least two dynode sets while sandwiching the tube axis of a sealed container in this the electron multiplier is housed. In particular, the first dynodes respectively belonging to the two dynode sets are arranged such that their back surfaces opposing respective secondary electron emitting surfaces face each other while sandwiching the tube axis. In this arrangement, because each first dynode itself is positioned near the tube axis, the efficiency of collection of photoelectrons arriving at the periphery of the first dynode is improved significantly.

Owner:HAMAMATSU PHOTONICS KK

Tunnel magnetoresistance device with tunnel barrier layer containing residual carbon

InactiveUS7656622B2Good drapabilityLarge MR ratioNanomagnetismMagnetic measurementsResidual carbonMagnetic reluctance

The TMR device has a structure including a lower electrode layer, a pinned layer, a tunnel barrier layer, a free layer, and an upper electrode layer which are successively formed on a substrate. The tunnel barrier layer has substantially a stoichiometric composition. The tunnel barrier layer may be a thin film of an oxide of AL formed by ALD method.

Owner:DENSO CORP

Liquid ejecting head and liquid ejecting apparatus

Owner:SEIKO EPSON CORP

Thermally mounting electronics to a photovoltaic panel

ActiveUS8933324B2Increase in sizeEfficient transportPV power plantsPhotovoltaic energy generationConductive materialsThermal contact

An electronics assembly for a photovoltaic panel includes a substrate of a thermally conductive material, wherein the substrate defines a thermal contact area for thermally contacting the electronics assembly to a photovoltaic panel; and at least one electronic component provided on the substrate and in thermal contact with the substrate, so that when the electronics assembly is in thermal contact with the photovoltaic panel. The thermal contact provides a heat conductive channel between the at least one electronic component and the photovoltaic panel, wherein the heat conductive channel enables the electronics assembly to use the photovoltaic panel as a heat sink for heat produced by the at least one electronic component.

Owner:SOLARNATIVE GMBH

Capacitor structure having butting conductive layer

ActiveUS7709878B2Increase capacitanceReduce complexityTransistorSemiconductor/solid-state device detailsMetal interconnectOptoelectronics

A capacitor structure including a substrate, a butting conductive layer, a second dielectric layer, a plurality of openings, a bottom electrode layer, a capacitor dielectric layer, a top electrode layer, and a second metal interconnect layer is provided. The substrate has a first dielectric layer and a first metal interconnect layer located in the first dielectric layer in a non-capacitor region. The butting conductive layer is disposed over the first dielectric layer in a capacitor region. The second dielectric layer is disposed over the first dielectric layer and covers the butting conductive layer. The openings include a first opening exposing a portion of the butting conductive layer and a second opening exposing the first metal interconnect layer. The bottom electrode layer, the capacitor dielectric layer, and the top electrode layer are conformally stacked in the first opening sequentially. The second metal interconnect layer is disposed in the openings.

Owner:UNITED MICROELECTRONICS CORP

Improved liquid distributor

InactiveCN103816844AImprove interphase contactImprove efficiencyChemical/physical/physico-chemical processesInitial distributionMass transfer

The invention discloses an improved liquid distributor. The liquid distributor comprises a distribution plate and a liquid inlet header pipe; the middle of the distribution plate is uniformly provided with shunting holes, and the upper part of the distribution plate is uniformly provided with multiple partitions; each adjacent partitions are connected through a separation plate, and liquid accumulation grooves are formed among the partitions and the separation plates; the liquid inlet header pipe is placed above the liquid accumulation grooves, the bottom of the liquid inlet header pipe is communicated through the liquid accumulation grooves, the middle of the liquid inlet header pipe is provided with a round hole, and two ends of the liquid inlet header pipe are each provided with a liquid inlet hole. Uniform initial distribution or redistribution of a liquid is carried out at a certain height, so that the effective surface for mass transfer and heat transfer is increased, the interphase contact is improved, and thus the efficiency of a tower is improved; the liquid accumulation grooves are formed among the partitions and the separation plates, space in each grooves is large, and the fluidity is good; and then the liquid is shunted out through the shunting holes, and the distribution is uniform.

Owner:MINGSHENG CHEM MACHINERY NANTONG

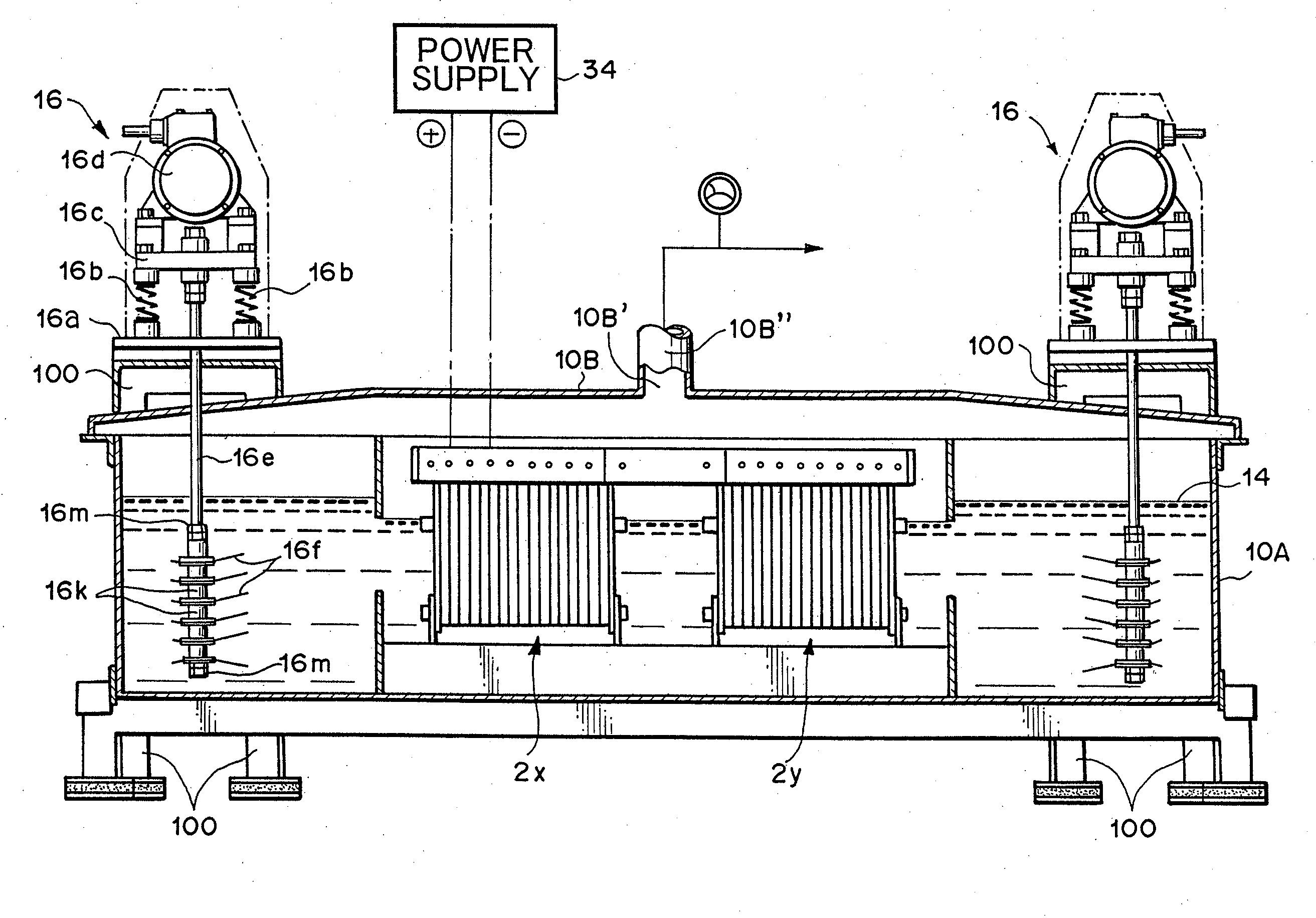

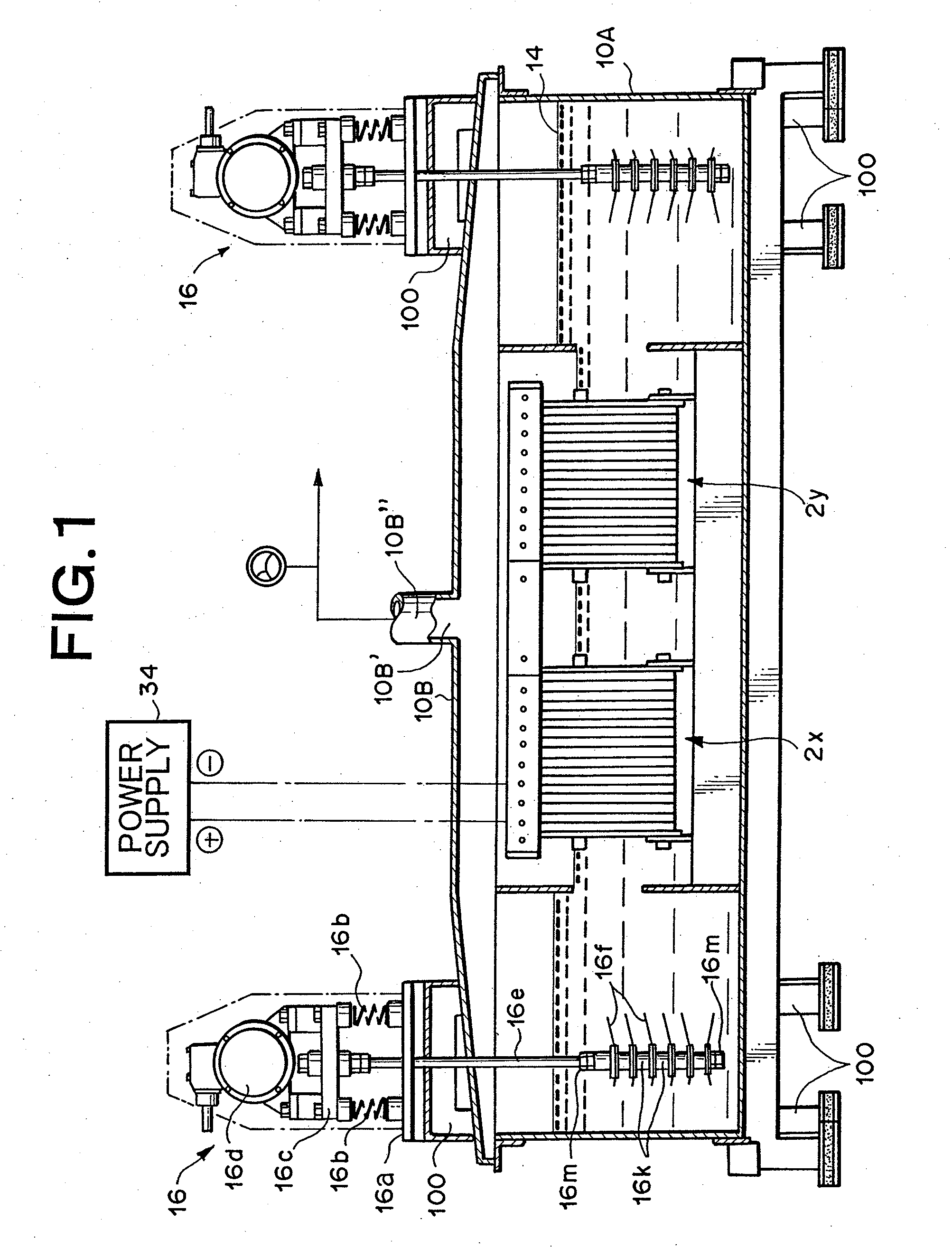

Hydrogen-oxygen gas generator and hydrogen-oxygen gas generating method thereof

InactiveUS20090045049A1Obstruct passageAmple and satisfactory uniformityCellsElectrodesHydrogenTrapping

Owner:OMASA RYUSHIN

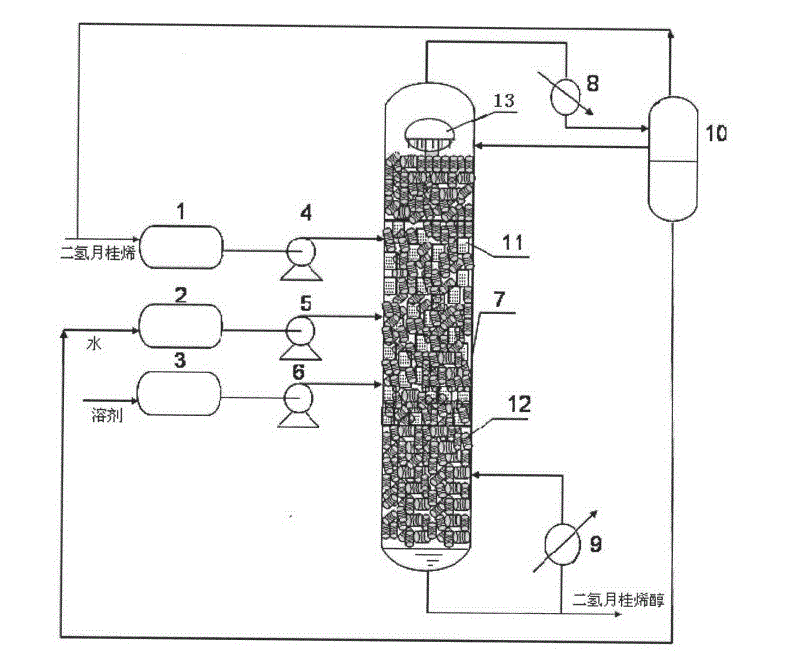

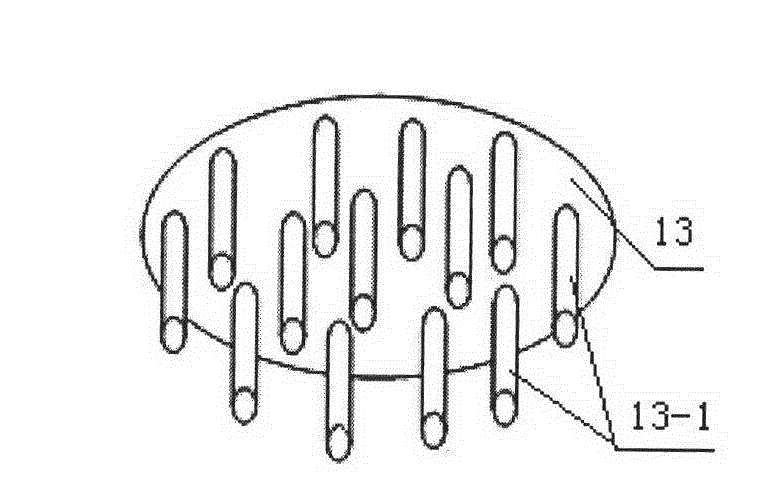

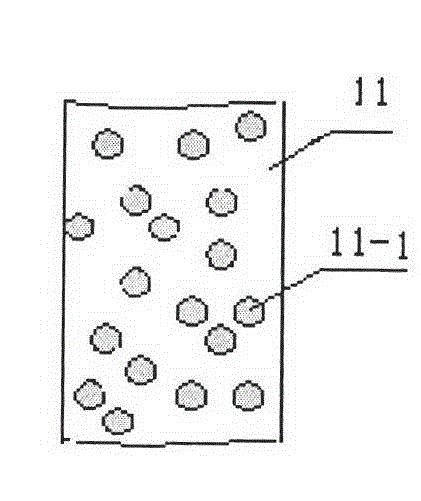

Method for preparing dihydromyrcenol through reaction distillation continuity

InactiveCN102617288ARealize continuous productionReduce heat loadOrganic compound preparationChemical industryEffective surfaceFilling materials

The invention relates to a method for preparing dihydromyrcenol through reaction distillation continuity. Corrugated gauze filling materials and solid acid catalysts are filled in a reaction distillation tower, raw materials of dihydromyrcene, water and solvents are respectively preheated to 80 to 120 DEG C, 85 to 95 DEG C and 70 to 90 DEG C to be respectively fed from the upper part, the middle part and the lower part of a reaction section of the reaction distillation tower according to the flow rate ratio of (1-3): (1-3). The tower kettle temperature is controlled to be 105 to 120 DEG C, and the tower top condensing temperature is controlled to be 50 to 70 DEG C. An oil phase and a water phase are separated out from condensed liquid, partial oil phase reaches the tower top to flow back, and the water phase and the rest oil phase respectively return a raw material tank to be cyclically utilized. According to the method, the reaction and the distillation are simultaneously carried out, heat released by the reaction can be effectively utilized for heating materials, and a heat load of a tower kettle is reduced. The corrugated gauze filling materials in the reaction distillation tower and a tubular liquid distributor are favorable for improving the effective surfaces for mass transfer and heat transfer and improving the inter phase contact, dihydromyrcenol products with the purity being 95 percent are obtained from the tower bottom, and the reaction efficiency and the dihydromyrcenol conversion rate are higher.

Owner:淮安市产品质量监督检验所

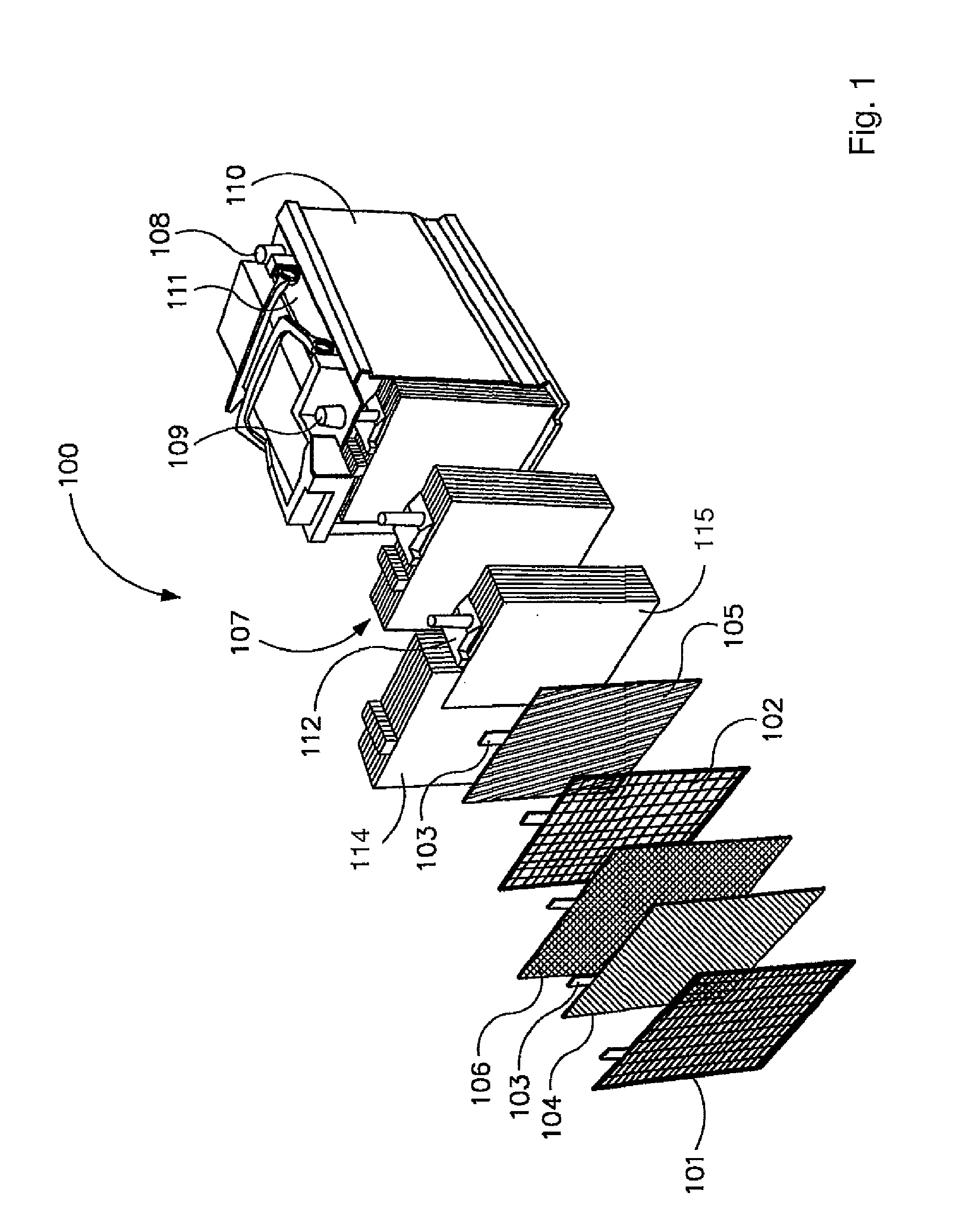

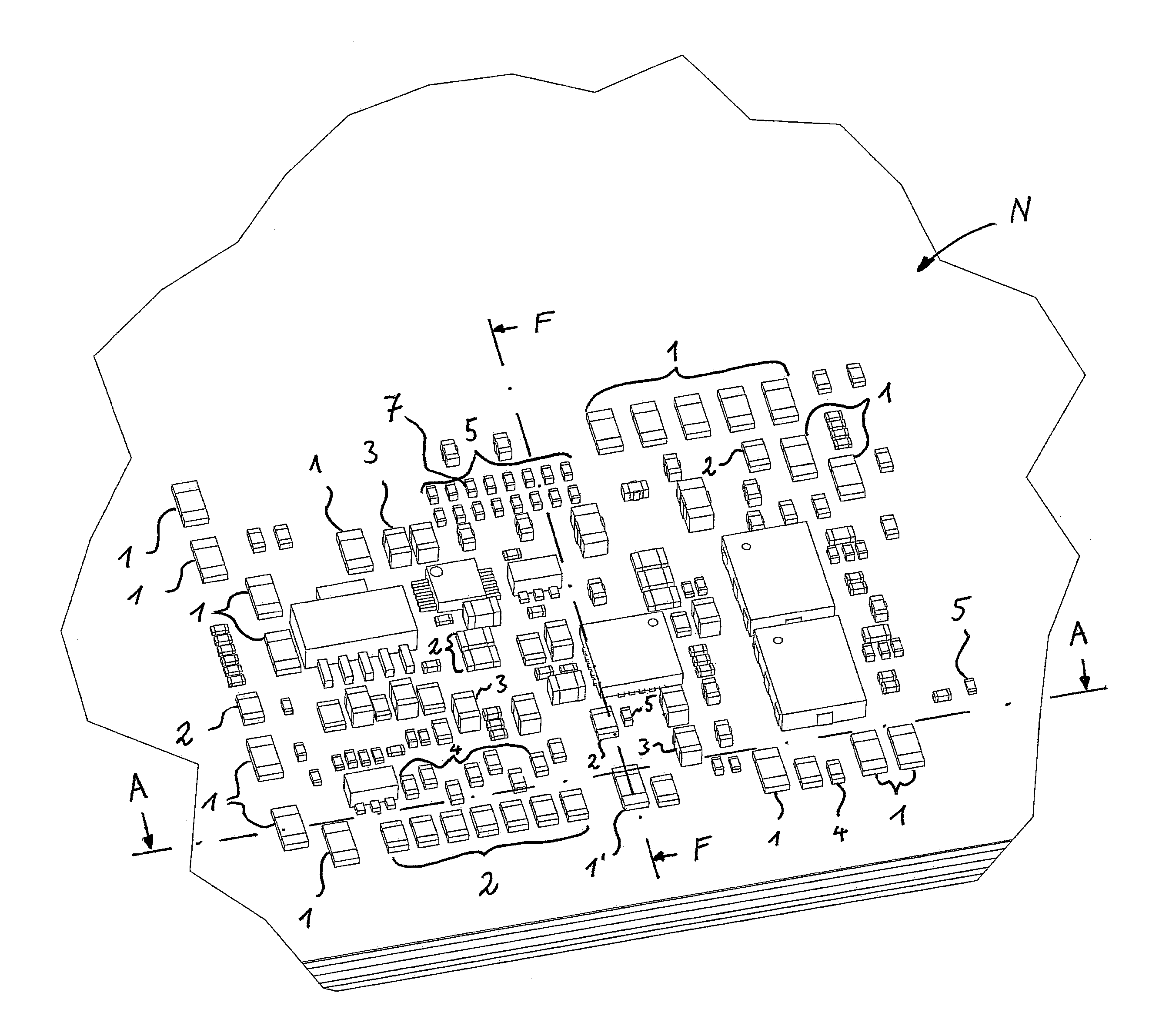

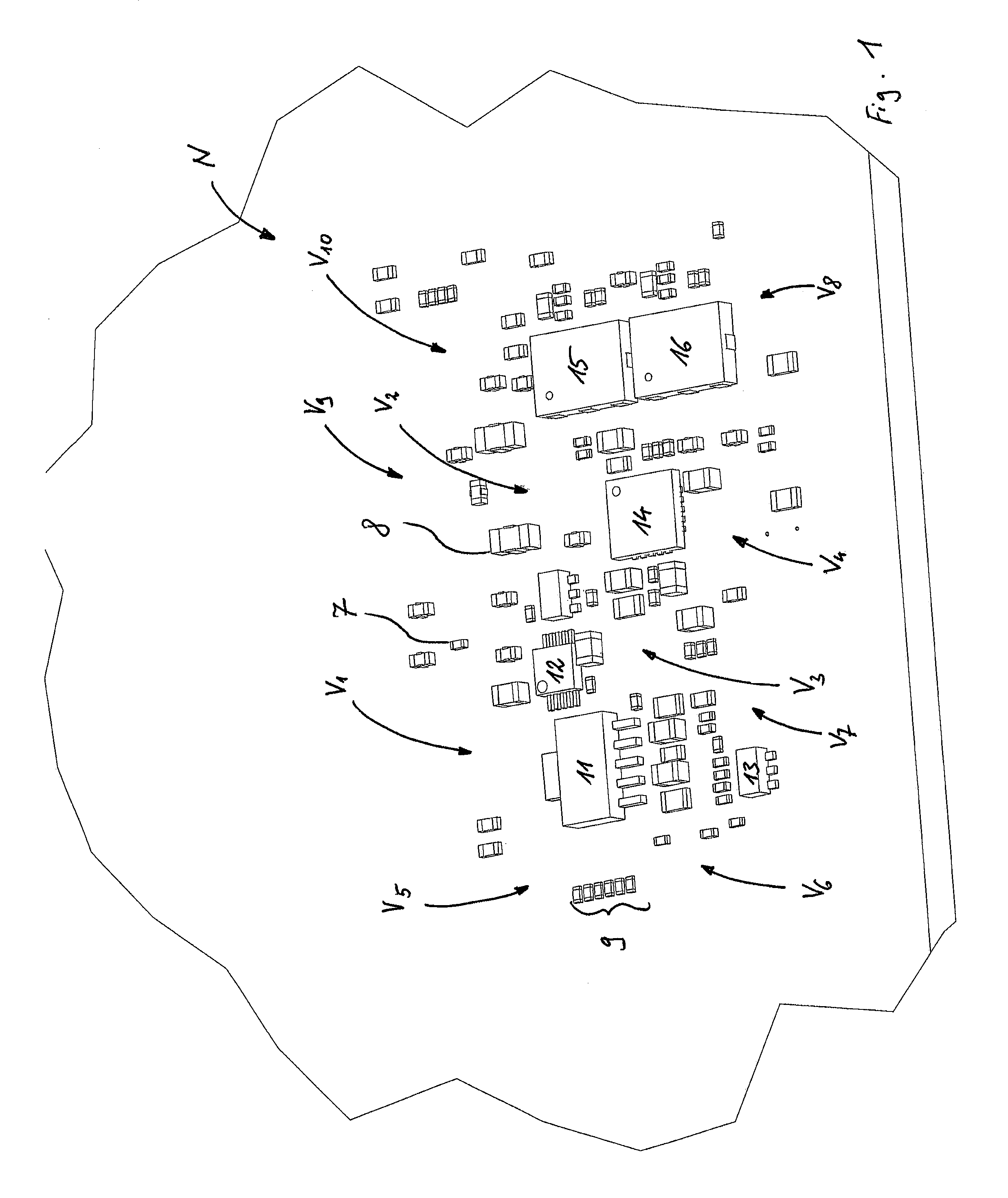

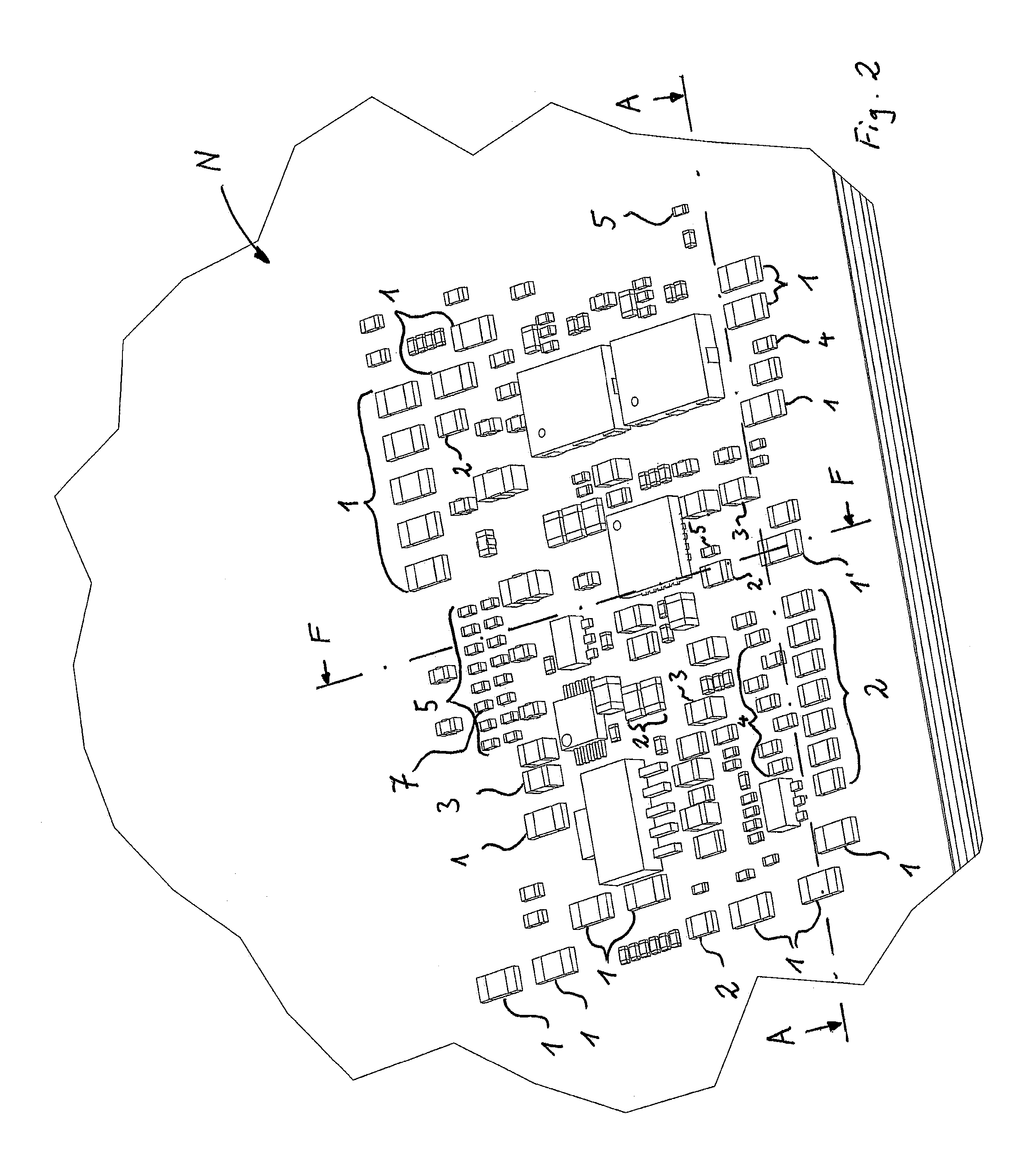

Method of cooling electronic circuit boards using surface mounted devices

ActiveUS8730677B2Increase the effective surfaceHeat dissipationPrinted circuit aspectsPrinted circuit manufactureSurface mountingEngineering

The invention relates to a method of cooling electronic circuit boards using surface mounted devices (SMD), the method comprising the steps of: after or during the board layout, filling empty spaces V1, V2, V3, V4, V5, V6, V7, V8, V9, V10 with at a number of heat sink devices 1, 2, 3, 4, 5 near a thermal hot spot and connecting the number of heat sink devices 1, 2, 3, 4, 5 to a thermally conducting path 25, 27, 29, 31, 33, 35 of the board N, respectively. Further, the invention relates to a heat sink device 1, 2, 3, 4, 5 adapted to implement the method according to the invention.

Owner:ADVA OPTICAL NETWORKING SE

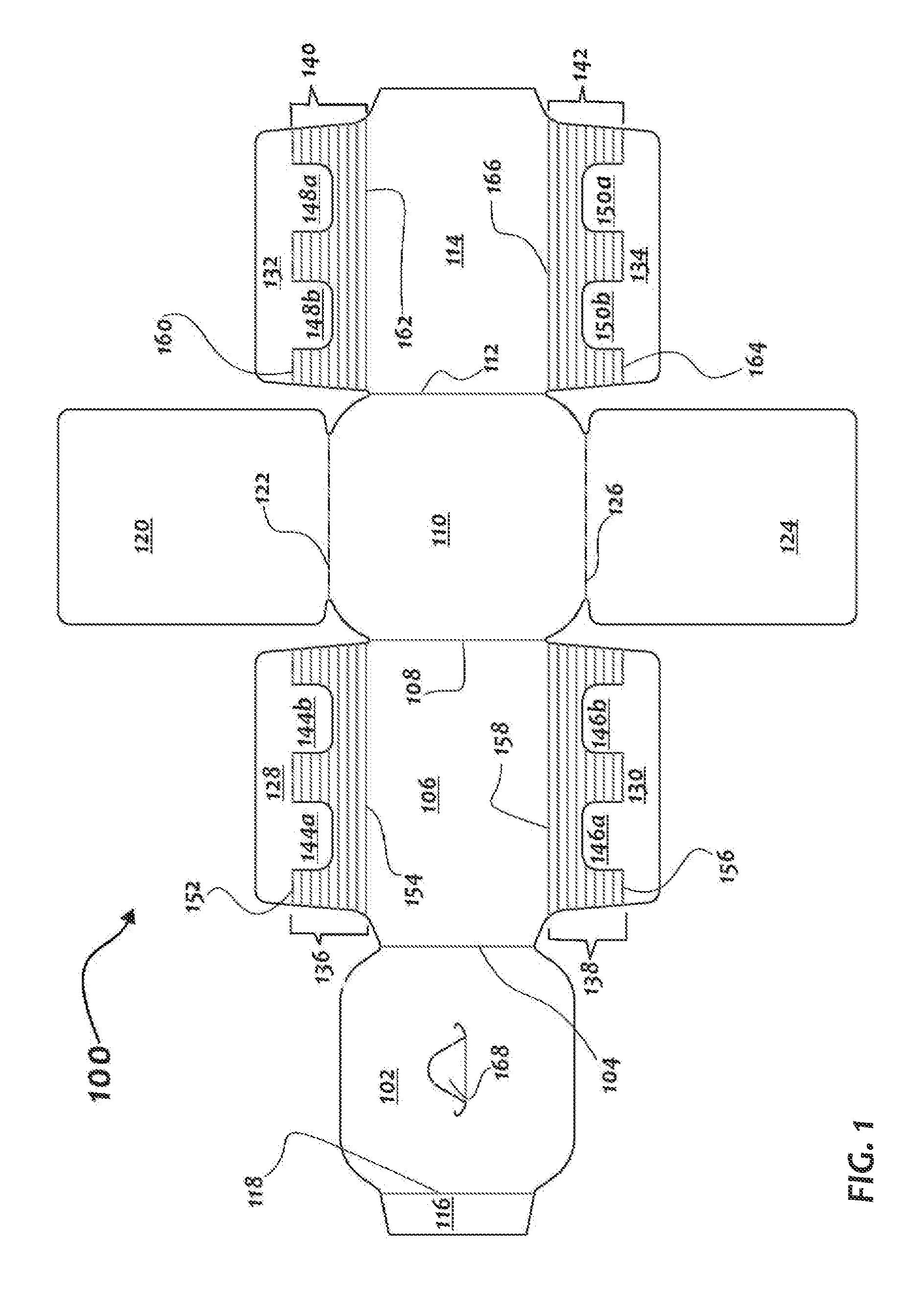

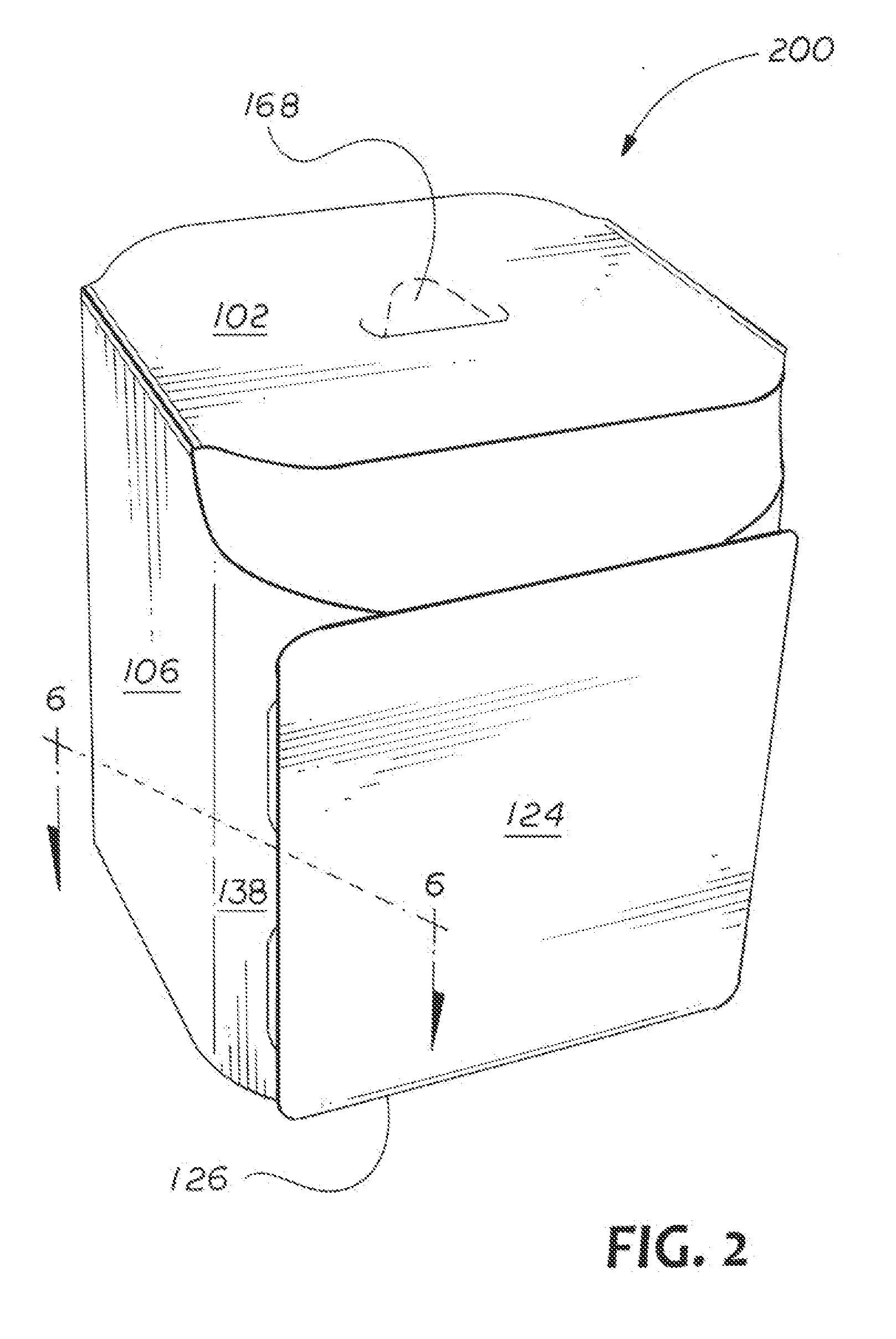

Extended glue strips for securing cartons

ActiveUS20120273379A1Less likelihoodIncrease the effective surfaceFlexible coversWrappersCartonEngineering

A carton with at least one rounded corner includes a bottom panel for supporting lower ends of substantially cylindrical articles, four side panels, at least one corner panel extending from one of the opposed side edges of a first one of the four side panels, and at least one glue strip extending from the at least one corner panel. The at least one glue strip includes at least one glue tab extending from the proximal edge of the at least one glue strip. The at least one glue tab is secured in a face contacting arrangement to a second one of the four side panels so as to connect the first one of the four side panels to the second one of the four side panels.

Owner:MEADWESTVACO PACKAGING SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com