Low-temperature heat-sealing polypropylene film and preparation method thereof

A polypropylene film and low-temperature heat-sealing technology, which is applied in the direction of chemical instruments and methods, layered products, and synthetic resin layered products, can solve problems such as poor transparency, difficult production operations, and low production capacity, and achieve good transparency and low heat. The effect of sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

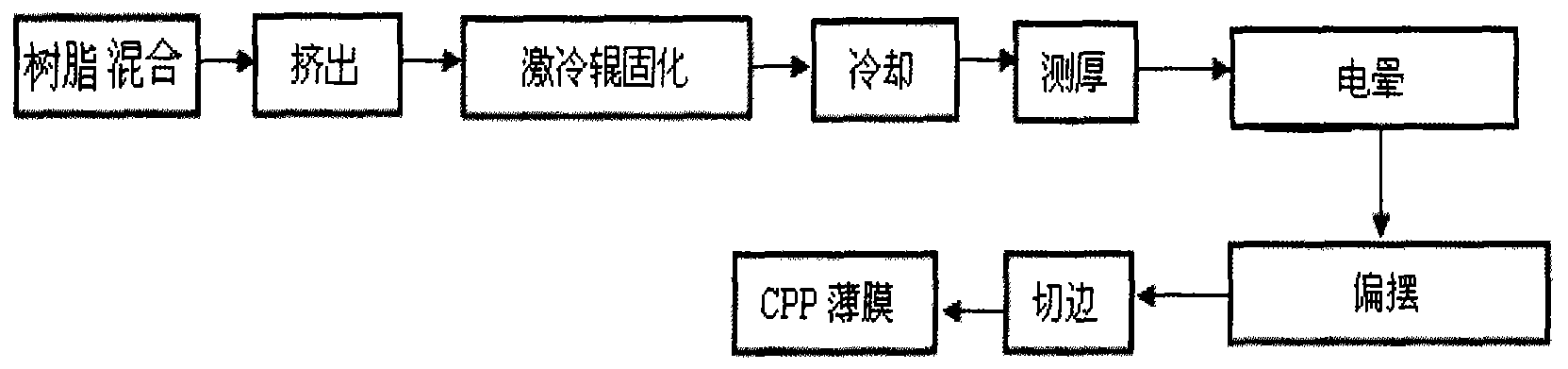

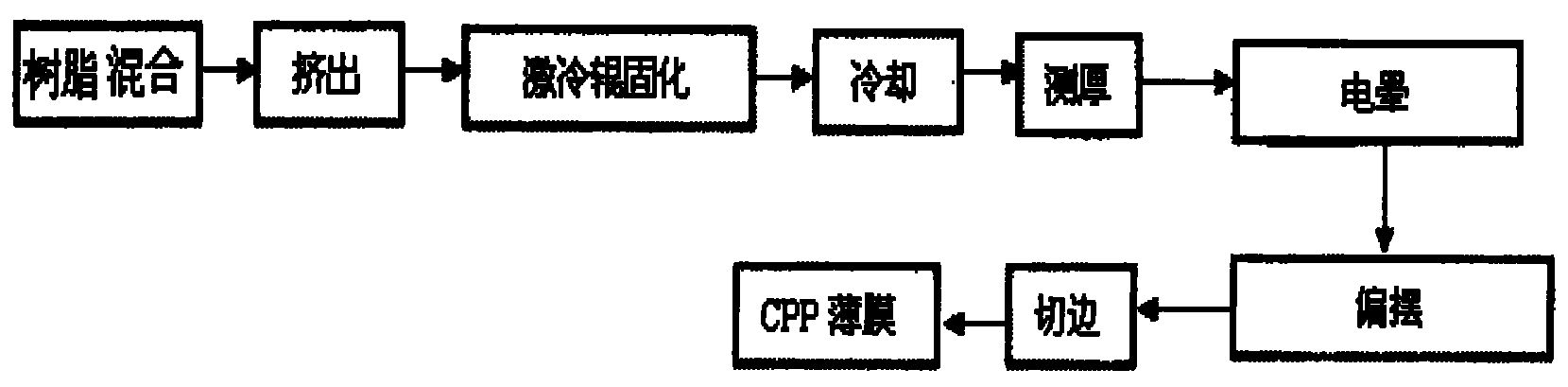

[0028] Such as figure 1 As shown: the preparation method of the present invention includes the following steps in sequence: extrusion process, chilled roll solidification process, cooling process, thickness measurement process, corona process, deflection process, edge trimming process.

[0029] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0030] The corona layer is composed of FC801M and ABPP10S, and the weight ratio of FC801M: ABPP10S is 100:1.

[0031] The middle layer is composed of FC801.

[0032] The heat-sealing layer is composed of WFX4TA and SE07PP, and the weight ratio of WFX4TA and SE07PP is 100:0.5.

[0033] In the chilling roll solidification process: the hot-melt film is rapidly cooled and shaped by the casting roll under the action of auxiliary devic...

Embodiment 2

[0038] The preparation method of the present invention includes the following steps in sequence: extrusion, chilled roll solidification, cooling, thickness measurement, corona, deflection, and edge trimming.

[0039] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0040] The corona layer is composed of FC801M and ABPP10S, and the weight ratio of FC801M: ABPP10S is 100:0.5.

[0041] The middle layer is composed of FC801.

[0042] The heat-sealing layer is composed of WFX4TA and SE07PP, and the weight ratio of WFX4TA and SE07PP is 100:0.5.

[0043] The corona layer is composed of FC801M and anti-sticking agent, and the weight ratio of FC801M:anti-sticking agent is 100:0.5.

[0044] The middle layer is composed of FC801.

[0045] The heat-sealing layer is composed of W...

Embodiment 3

[0052] The preparation method of the present invention includes the following steps in sequence: extrusion, chilled roll solidification, cooling, thickness measurement, corona, deflection, and edge trimming.

[0053] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0054] The corona layer is composed of FC801M and ABPP10S, and the weight ratio of FC801M: ABPP10S is 100:1.

[0055] The middle layer is composed of FC801.

[0056] The heat-sealing layer is composed of WFX4TA and SE07PP, and the weight ratio of WFX4TA and SE07PP is 100:1.

[0057] The thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer is 1:3:1.

[0058] In the chilling roll solidification process: the hot-melt film is rapidly cooled and shaped by the casting roll under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com