Antiviral transfer sheet and method for producing same, and antiviral shrink film and method for producing same

A technology of shrink film and manufacturing method, applied in the direction of chemical instruments and methods, botany equipment and methods, disinfectants, etc., can solve the problems of rising, curling and increasing the frequency of curling, etc., to save antiviral agents, smooth the surface, The effect of maintaining transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] A transfer sheet was prepared and transferred by in-mold injection molding to obtain an antiviral molded article, and the antiviral properties, total light transmittance, and haze of the antiviral molded article were measured.

[0150] The production method and the like of the transfer sheet are as follows.

[0151] Base sheet: PET film, thickness 50μm (micron)

[0152] Antiviral agent: mixed with TiO 2 Powder 60 parts by weight and Cu 2 O powder 40 parts by weight of powder

[0153] TiO2 The primary particle size of the powder (white powder) is 15nm, Cu 2 The primary particle diameter of the O powder (dark brown powder) was 50 nm.

[0154] Hard coat agent: Urethane acrylate UV curable resin

[0155] Molding resin: Acrylic resin

[0156] Molded product size: 50mm×50mm×1mm

[0157] Molten resin temperature: 240℃~260℃

[0158] On the base sheet, the antiviral agent is 0.02g / m 2 The amount of antiviral agent, methyl ethyl ketone and a small amount of hard coating ...

Embodiment 2

[0176] Using the antiviral molded article produced in Example 1, the antibacterial properties of the antiviral molded article were measured. The antiviral molded articles used in the measurement were sample No. 1 and sample No. 9. In the paragraph describing Example 2, the term "antibacterial property" means antibacterial property as the text indicates, and the term "antibacterial property" does not mean antiviral property.

[0177] The measurement of the antimicrobial property complied with JIS-R-1756 (test method for antiviral property of a visible light-responsive photocatalyst). As the light condition, the light of the white fluorescent lamp was filtered out the ultraviolet rays below 380nm in the N169 filter, so that the illuminance was 1000lx.

[0178] Test method: 50 μL (microliter) of Staphylococcus aureus bacteria solution was dropped on the sample, irradiated with light for 24 hours, and recovered with SCDLP solution. The recovered liquid was mixed with NB medium, ...

Embodiment 3

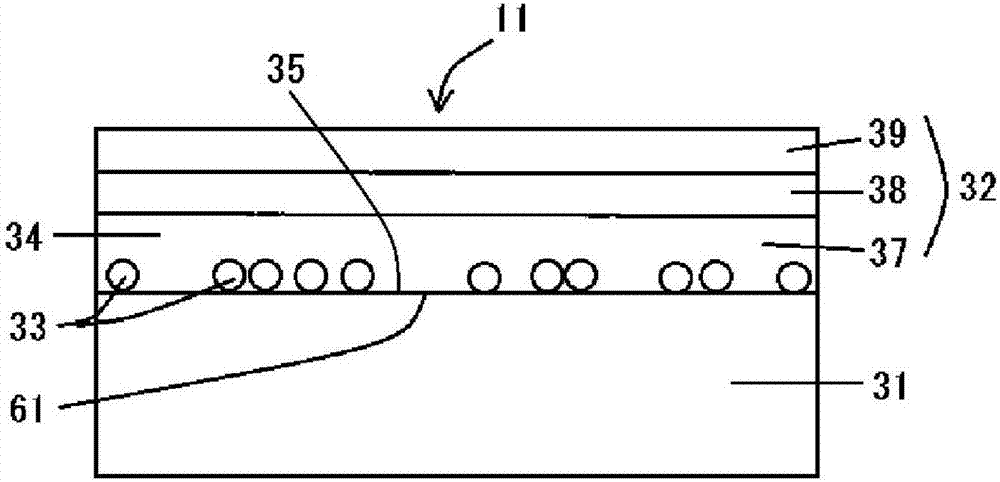

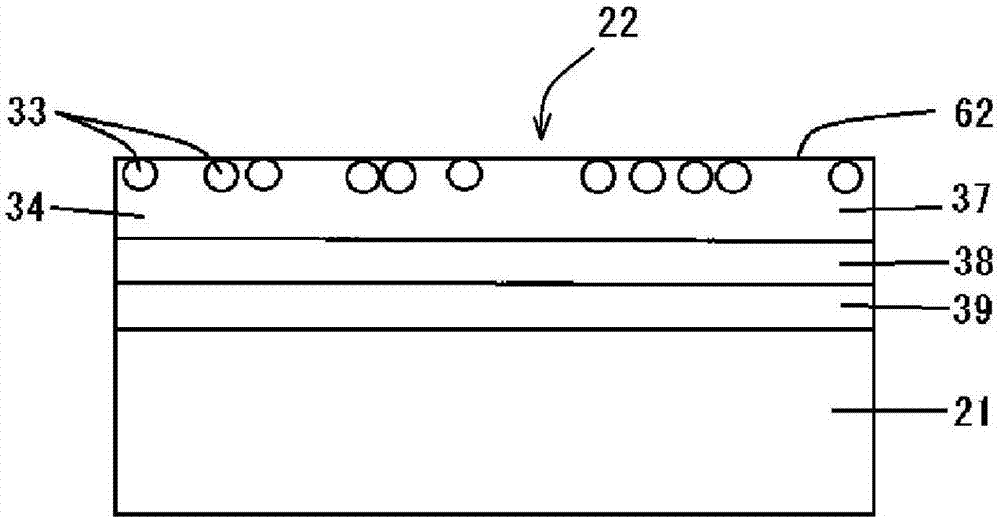

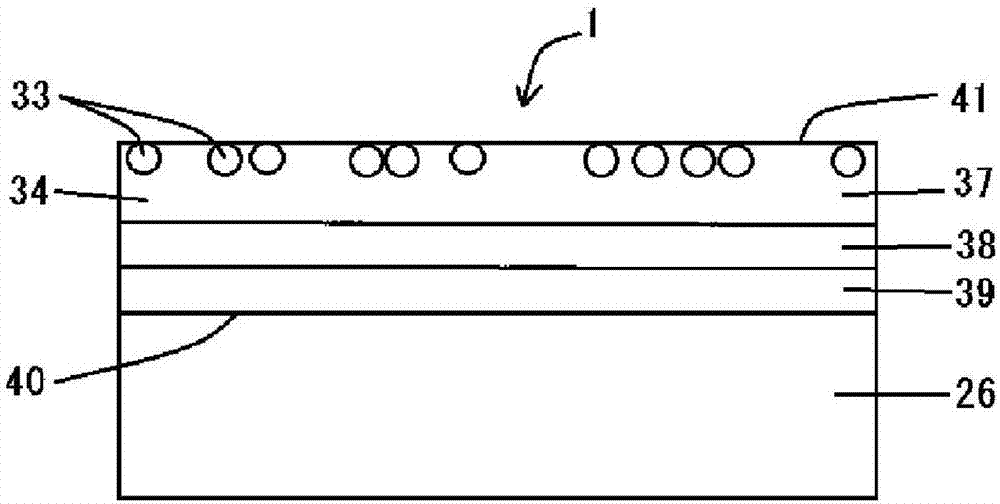

[0187] The transfer sheet 11 was produced, and the transfer conditions were investigated, and the transfer was performed on a shrink base material, and the antiviral shrink film 1 was produced, and the shrink processability was evaluated.

[0188] The production method and the like of the transfer sheet are as follows.

[0189] Base sheet: PET film, thickness 50μm

[0190] Antiviral agent: mixed with TiO 2 Powder 60 parts by weight and Cu 2 O powder 40 parts by weight of powder

[0191] TiO 2 The primary particle size of the powder (white powder) is 15nm, Cu 2 The primary particle diameter of the O powder (dark brown powder) was 50 nm.

[0192] Shrink base material: a biaxially stretched polystyrene sheet with a thickness of 60 μm, and its thermal shrinkage rate is 14% in the MD direction and 75% in the TD direction when heated at 100° C. for 10 seconds. Here, thermal contraction rate (%)=100×(length before heating−length after heating) / length before heating.

[0193] H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com