A pole piece strip cutting device with a pressing function

A pole piece and strip cutting technology, applied to battery electrodes, electrode manufacturing, electrode rolling/calendering, etc., can solve the problems of pole piece edge burr, pole piece cannot be tightened, easy to loosen, etc., and achieve low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

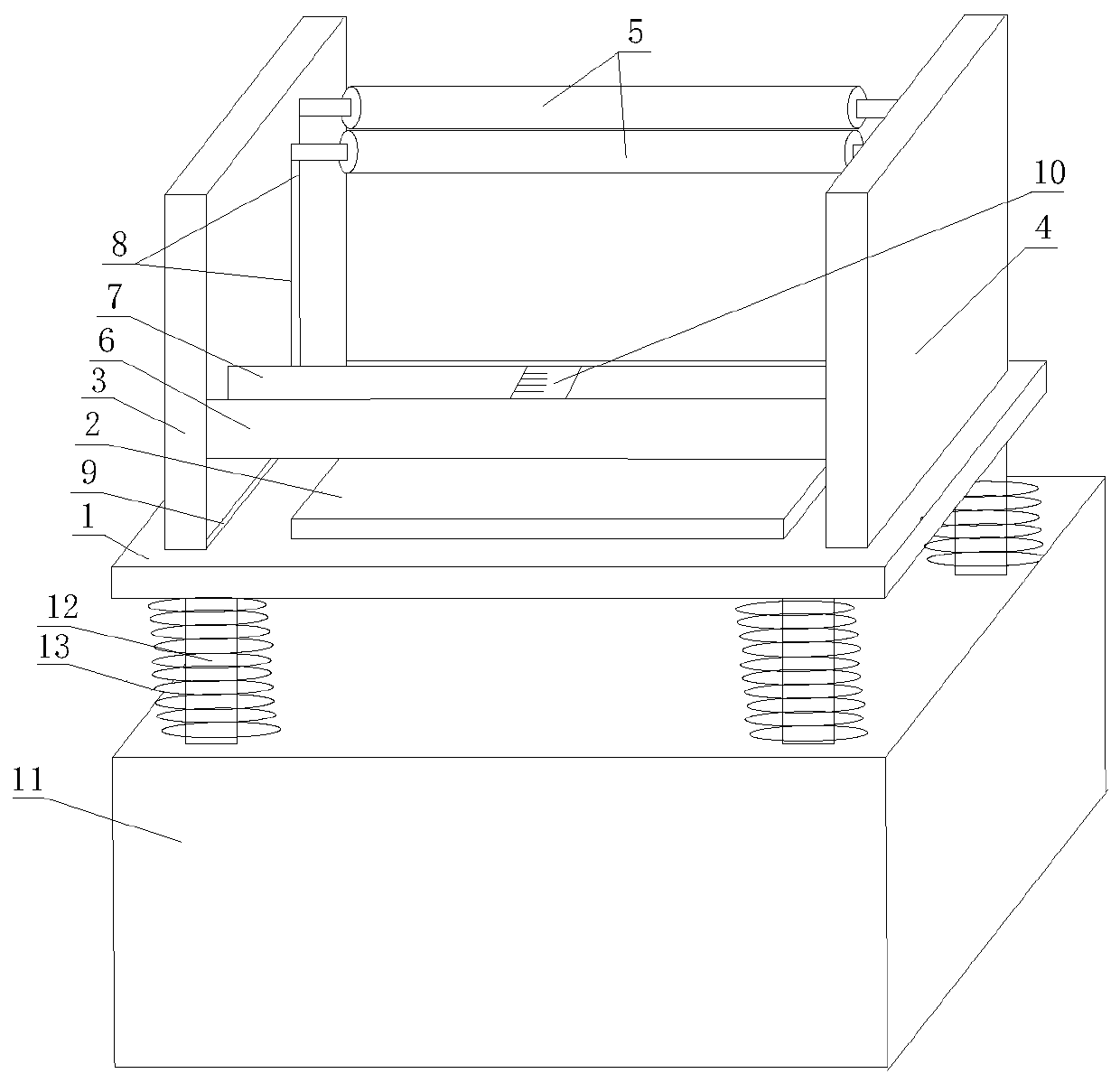

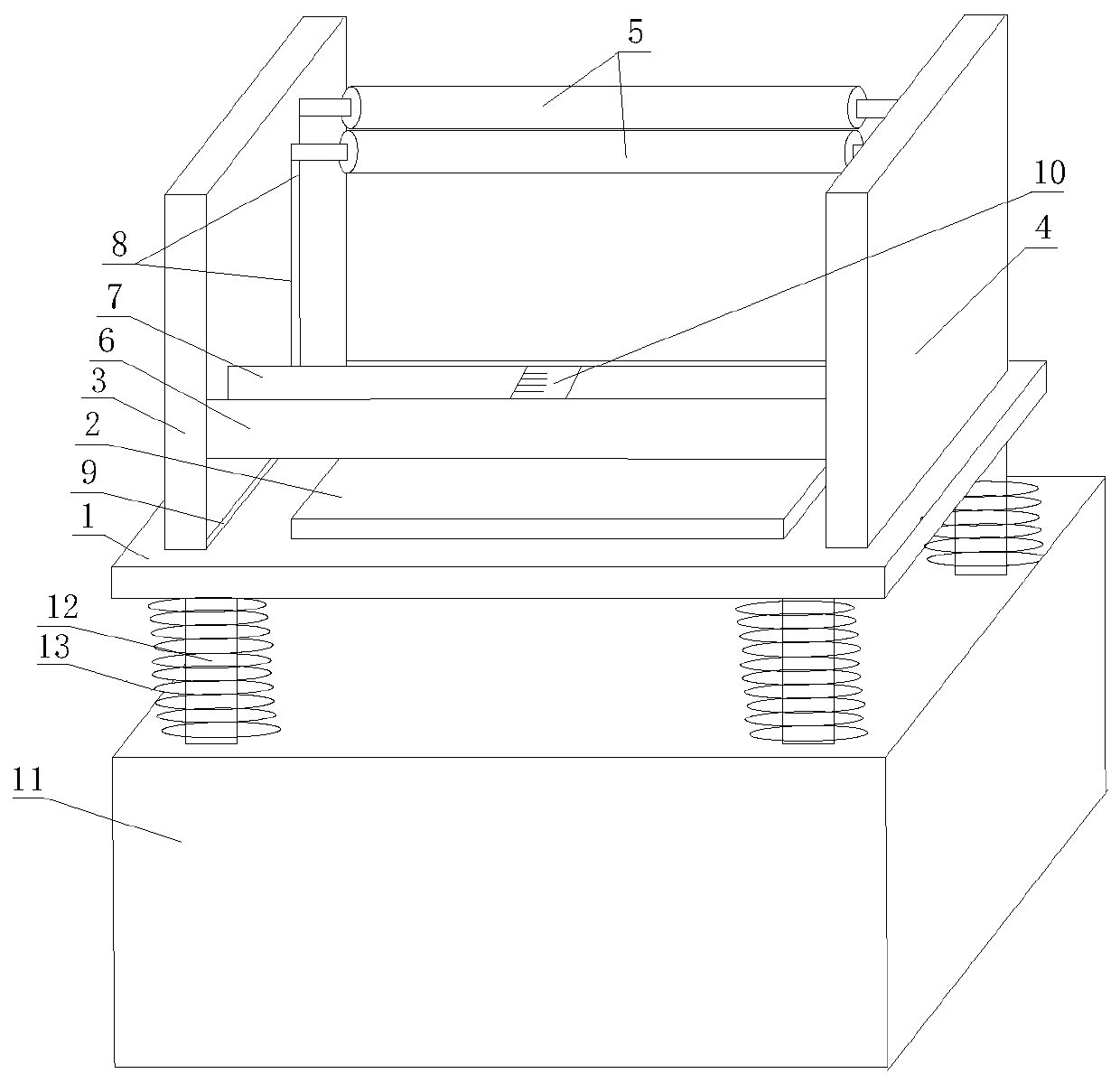

[0022] Such as figure 1 As shown, a pole piece cutting device with a pressing function of the present invention includes a base 1, a storage plate 2 is installed above the base 1, and a support plate A3 and a support plate B4 are respectively arranged on both sides of the support plate 2, and the support plate There are two circumscribed finale shafts 5 placed in parallel between A3 and support plate B4. One end of the finale shaft 5 is connected to the support plate A3, and the other end of the finale shaft 5 is connected to the support plate B4. The finale shaft 5 is located directly above the middle position of the storage board 2. 5 is connected with the support plate A3 and the support plate B4 through a chute, and the top of the storage plate 2 is also provided with a fixed plate 6 and a cutter 7, and the fixed plate 6 and the cutter 7 are placed in parallel between the support plate A3 and the support plate B4 Between, one end of the cutter 7 is connected with the suppo...

Embodiment 2

[0025] Based on Embodiment 1, a scale 10 is connected to the fixing plate 6 , and the other end of the scale 10 is connected to the cutter 7 . The ruler is used to assist in measuring the width of the pole piece, so that the pole piece strips cut out are more accurate. The scale adopts a stainless steel scale and the measurement length of the scale is just the width of the pole piece. The scale can be replaced according to different pole pieces, and the measurement result is more accurate.

Embodiment 3

[0027] Based on the above embodiment, a control cabinet 11 with a shelf inside is connected to the bottom of the base 1 . The control cabinet 11 is connected with the base 1 through the telescopic column 12, and the telescopic column 12 is covered with a spring 13, one end of the spring 13 is connected with the control cabinet 11, and the other end of the spring 13 is connected with the base 1. The control cabinet can be used to store replacement tools, and the support plate A, support plate B, fixed plate, and cutter can all be replaced; the present invention can realize semi-automation, and can electrically control the sliding of the fixed plate, cutter, and finale. The control systems in the present invention are all arranged in the control cabinet to maintain the integrity of the device. The telescopic column can adjust the height of the base, that is, the height of all parts above the base, and can be used with other lithium-ion battery processing equipment; the spring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com