Preparation method for TA15 titanium alloy thin strip

A titanium alloy and strip rolling technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of high cost, low yield, complicated processes, etc., and achieve high thickness and dimensional accuracy, rolling High force and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

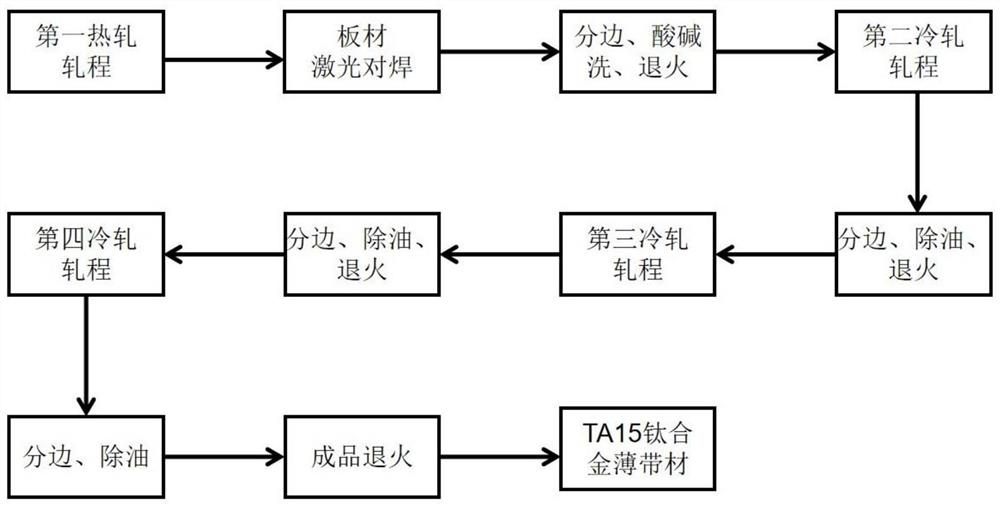

[0035] Such as figure 1 As shown, this embodiment includes the following steps:

[0036] Step 1. Place the TA15 plate with a thickness of 2mm, a width of 500mm, and a length of 3000mm in a heating furnace, heat and hold it at 930°C for 30min, and then use a four-roll reversible hot rolling mill to carry out the first rolling pass. Roll to obtain the first rolling range TA15 strip; the thickness of the first rolling range TA15 strip is 1mm, the width is 500mm, and the length is 6000mm; the mass content of iron in the described TA15 plate is 0.12%, and the mass content of oxygen is 0.09%;

[0037] Step 2: Carry out two-end butt-welding of the 4 strips of the first rolling schedule TA15 obtained in step 1 by laser welding, and carry out grinding and polishing treatment on the welds to obtain 1 strip of the first rolling schedule TA15 welded strip material;

[0038] Step 3, carry out alkaline pickling to the first rolling process TA15 welded strip obtained in step 2, and then u...

Embodiment 2

[0049] Such as figure 1 As shown, this embodiment includes the following steps:

[0050] Step 1. Place the TA15 plate with a thickness of 3mm, a width of 550mm, and a length of 4000mm in a heating furnace, heat and hold it at 950°C for 60 minutes, and then use a four-roll reversible hot rolling mill to carry out the first rolling process single-chip reversible heat Roll to obtain the first rolling TA15 strip; the thickness of the first rolling TA15 strip is 1.2mm, the width is 550mm, and the length is 8000mm; the mass content of iron in the TA15 plate is 0.16%, and the mass content of oxygen 0.08%;

[0051] Step 2. Use laser welding to butt-weld the two ends of the 6 strips of the first rolling schedule TA15 obtained in step 1, and perform grinding and polishing on the welds to obtain 1 strip of the first rolling schedule TA15 welded strip material;

[0052] Step 3, carry out alkaline pickling to the first rolling process TA15 welded strip obtained in step 2, and then use a...

Embodiment 3

[0063] Such as figure 1 As shown, this embodiment includes the following steps:

[0064] Step 1. Place the TA15 plate with a thickness of 2.2mm, a width of 520mm, and a length of 3500mm in a heating furnace, heat and keep it at 930°C for 45min, and then use a four-roll reversible hot rolling mill for the first rolling process. Hot rolling to obtain the first rolling TA15 strip; the thickness of the first rolling TA15 strip is 1.1mm, the width is 520mm, and the length is 7000mm; the mass content of iron in the TA15 plate is 0.17%, and the mass content of oxygen The content is 0.12%;

[0065] Step 2. Use laser welding method to butt-weld the two ends of the 5 first rolling schedule TA15 strips obtained in step 1, and carry out grinding and polishing treatment on the weld seam to obtain 1 first rolling schedule TA15 welded strip material;

[0066] Step 3, carry out alkaline pickling to the first rolling process TA15 welded strip obtained in step 2, and then use a slitting slit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com