Thickness measuring method for cold rolling strips

A cold-rolled plate and thickness measurement technology, which is applied in metal rolling, length measuring devices, metal rolling, etc., can solve the problems of difficult to ensure the thickness accuracy of cold-rolled strips, difficult storage of radioactive sources, slow response speed, etc., to achieve Solve the risk of social harm, the method is reasonable, and the effect of using reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

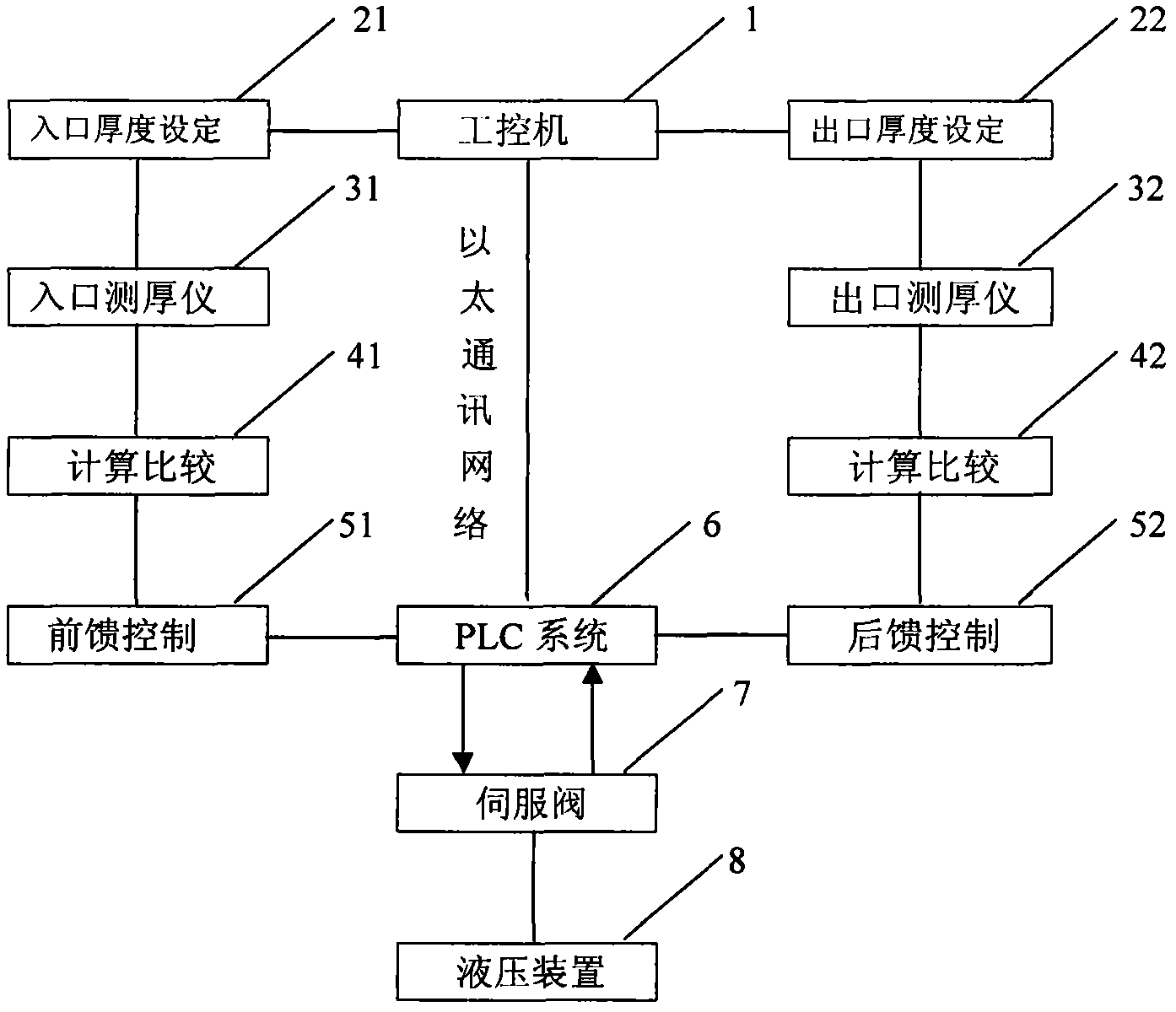

[0014] A method for measuring the thickness of a cold-rolled strip. The entrance thickness setting 21 and the exit target setting 22 of the steel strip are input through the man-machine interface of the industrial control computer 1. During operation, when the thickness fluctuates before rolling, the entrance thickness gauge 31 transmits the measured value to the PLC system 6, and after calculation and comparison by the entrance calculation and comparison 41, the PLC system 6 controls the hydraulic device 8 through the servo valve 7 to respond to realize the feed-forward control 51, changing the size of the rolling force, adjusting After the reduction is qualified, rolling is carried out; the exit thickness gauge 32 transmits the data deviation value between the rolled thickness and the exit target setting 22 to the PLC system 6 at any time, and when the exit thickness is detected to change, it is calculated by the exit After comparison 42 is calculated and compared, the PLC sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com