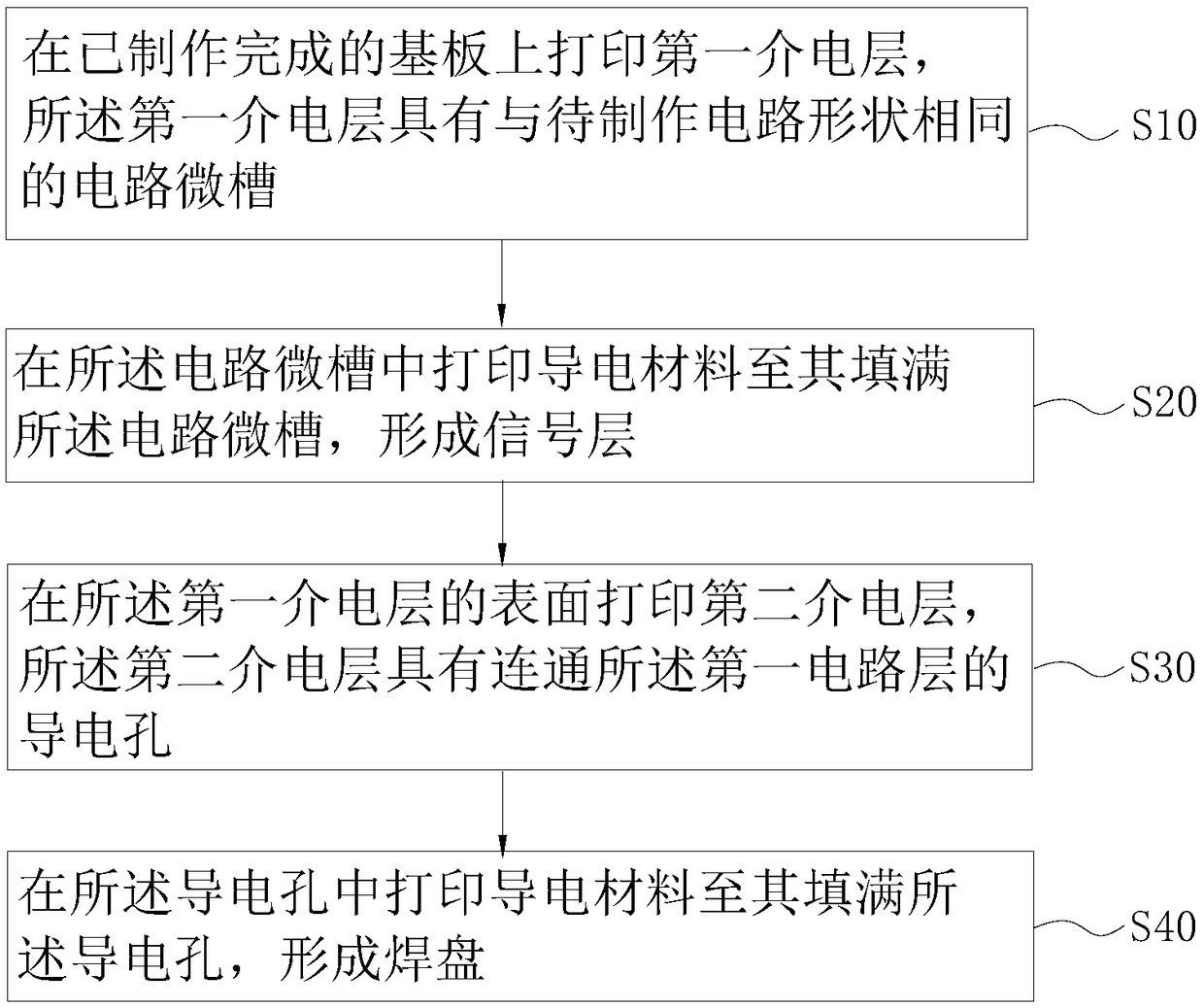

Method for manufacturing printed circuit board

A technology for printed circuit boards and manufacturing methods, applied in the fields of printed circuit manufacturing, printed circuit, multilayer circuit manufacturing, etc., can solve the problems of thin signal layer and easy diffusion of ink droplets, etc., achieve high material utilization rate and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

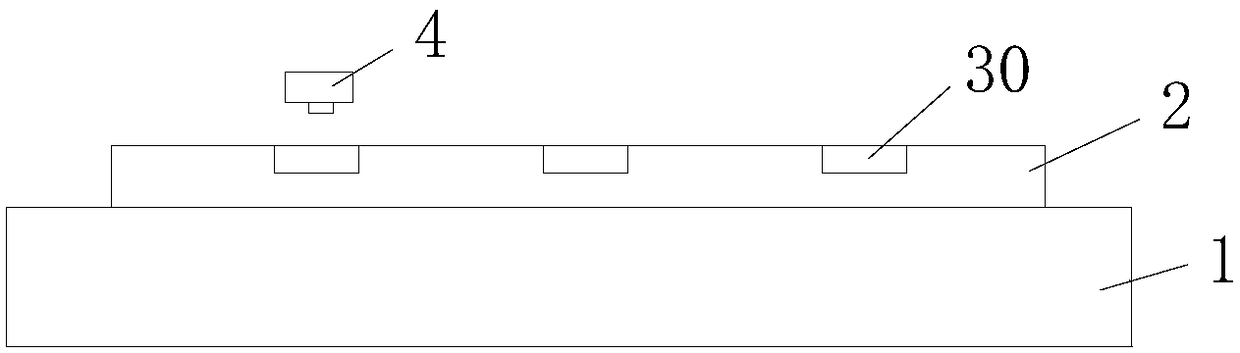

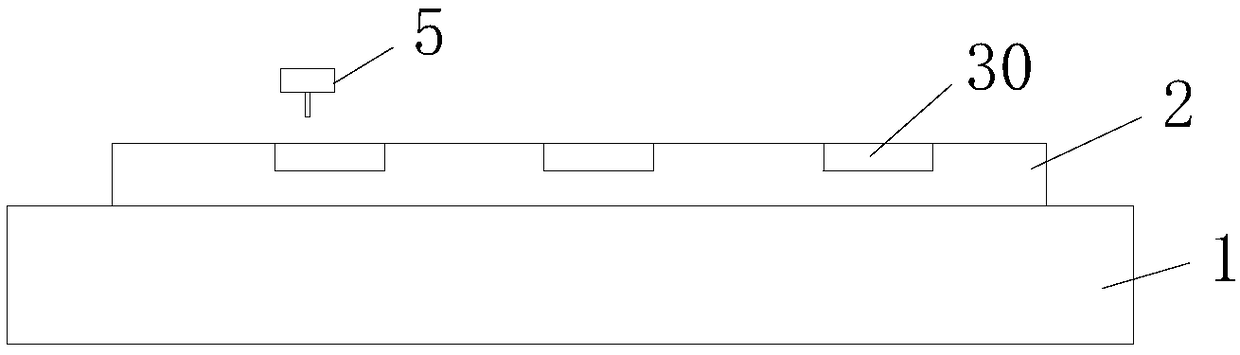

[0049] Further, as a specific implementation of the method for manufacturing a printed circuit board provided by the present invention, step S10 includes:

[0050] placing or printing an insulating layer completely covering the substrate 1 on the completed substrate 1;

[0051] According to the shape of the circuit to be fabricated, the circuit microgroove 30 is etched out by laser etching to form the first dielectric layer 2 .

[0052] In this embodiment, there is no hole or groove on the insulating layer, and the area corresponding to the circuit to be fabricated and the area corresponding to the first dielectric layer 2 are completely covered, and the material of the insulating layer is completely consistent with the material of the first dielectric layer 2. Similarly, after printing, laser etching is used to etch circuit microgrooves. The insulating layer can also be printed by inkjet printing equipment. Before printing, the shape and position information of the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com