Steel strip for LED bracket and manufacturing method thereof

A technology for an LED bracket and a manufacturing method, which is applied in the field of steel strips for LED brackets and their manufacturing, can solve the problems of poor thickness accuracy, inability to meet the quality requirements for producing LED brackets, and insufficient hardness of ordinary cold-rolled steel strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

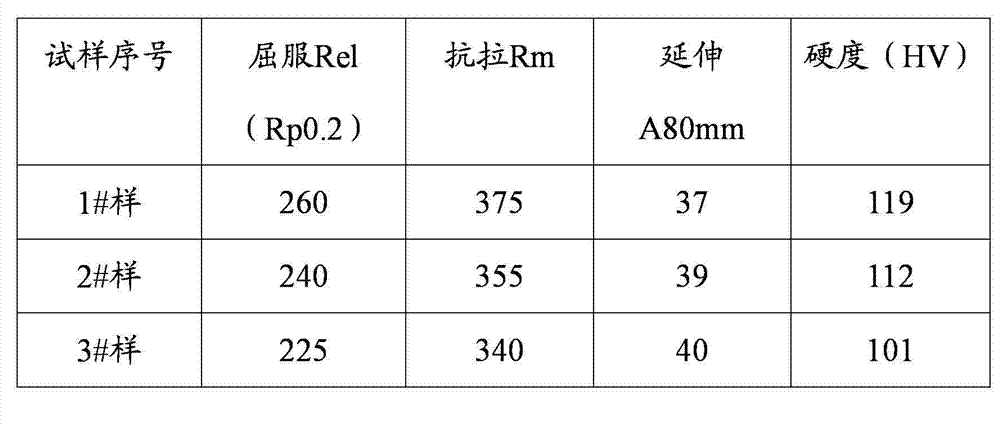

Examples

Embodiment 1

[0047] (1) Hot rolling:

[0048] The composition of hot-rolled raw materials is shown in the table below:

[0049] serial number

C

Si

mn

P

S

Al

1

0.06

0.015

0.28

0.012

0.011

0.02

2

0.05

0.012

0.25

0.015

0.01

0.021

3

0.03

0.01

0.2

0.012

0.009

0.029

[0050] The balance is Fe and trace unavoidable impurities;

[0051] The finishing temperature of hot rolling is 870±20℃, and the coiling temperature of finishing rolling is 580±20℃;

[0052] (2) pickling

[0053] Hot-rolled steel coils are pickled by a push-pull shallow-trough turbulent-flow pickling unit, using hydrochloric acid pickling, the concentration is controlled between 7% and 17% (w / w), and the surface oxide scale is removed.

[0054] (3) cold rolling

[0055] After pickling, the steel coil is rolled by a double-stand reversible rolling mill, and the roughness of the rolling mill roll is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com