Wide steel strip for paper cutting blade and manufacturing method thereof

A wide-width steel and steel strip technology, which is applied to the wide-width steel strip for paper cutting blades and its manufacturing field, can solve the problems of low limit temperature, low precision, insufficient spheroidization rate, etc., achieve broad development prospects and ensure thickness accuracy. , the effect of high slitting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

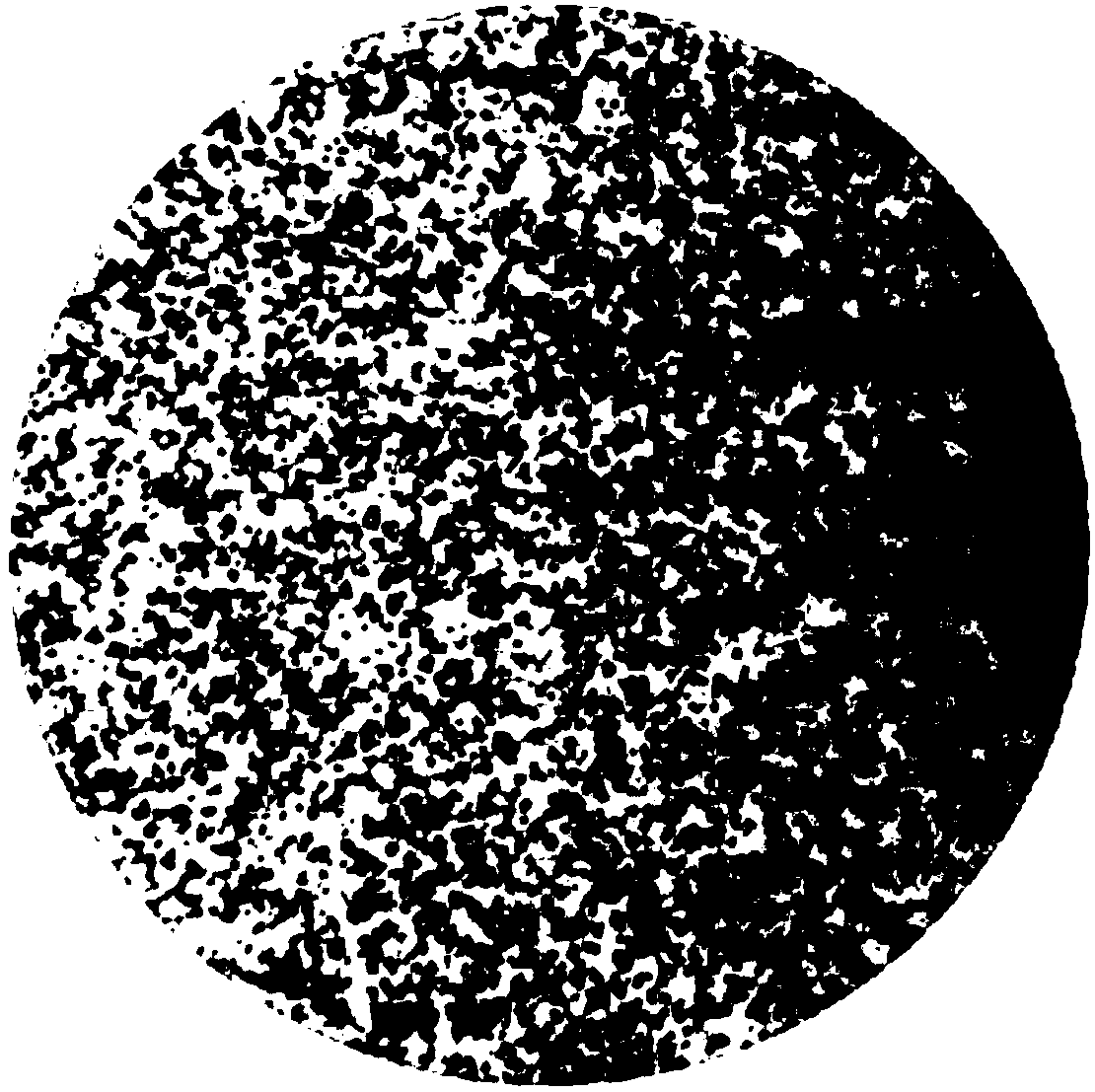

Image

Examples

Embodiment 1

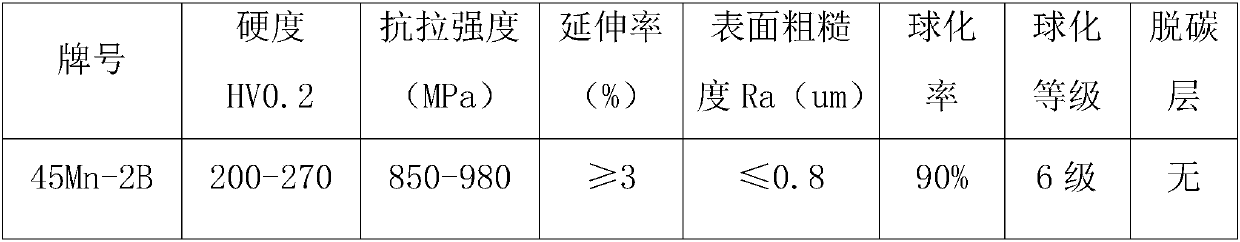

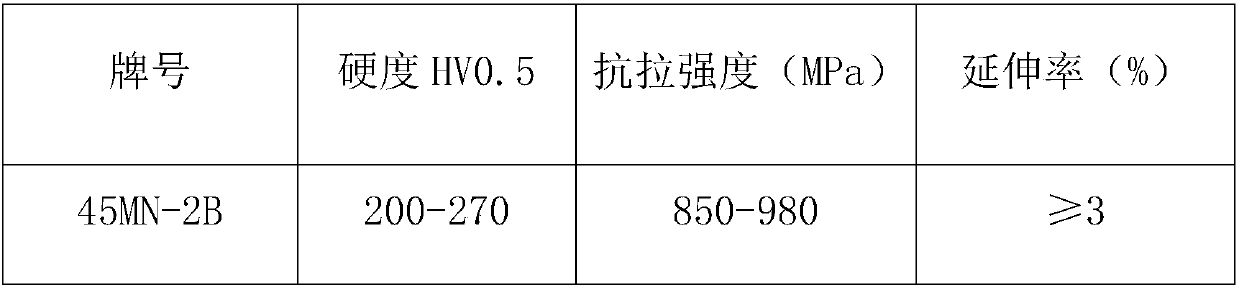

[0065] Embodiment 1 (45Mn-2B):

[0066] (1) Preparation of converter steelmaking continuous casting billet:

[0067] The refined molten steel is poured into the tundish through the rotation of the rotary table, and then injected into the continuous casting slab crystallizer through double nozzles, and continuously cast into a continuous casting slab of 220*1250*2500mm; the chemical composition of the molten steel is shown in the following table:

[0068] serial number

C(%)

Si(%)

Mn(%)

P(%)

S(%)

Cr(%)

1

0.44

0.21

0.83

0.012

0.002

0.19

2

0.45

0.22

0.82

0.012

0.003

0.22

3

0.46

0.22

0.81

0.011

0.002

0.2

[0069] (2) Hot rolling:

[0070] The continuous casting slab obtained in step (1) is transported by the roller table to the heating furnace, heated to 1100±50°C, dephosphorized by high-pressure water and rolled for 13 passes, and then cooled by the laminar flow cooling syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com