Medicinal film forming equipment, forming equipment control method and film forming method

A forming equipment and film forming technology, which is applied in the field of pharmaceutical film forming equipment and pharmaceutical film forming, can solve the problems of high cost, difficult continuous production, difficult film blowing, etc., to reduce labor intensity, continuous production, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Apparently, the described embodiments are only some of the embodiments of this application, not all of them.

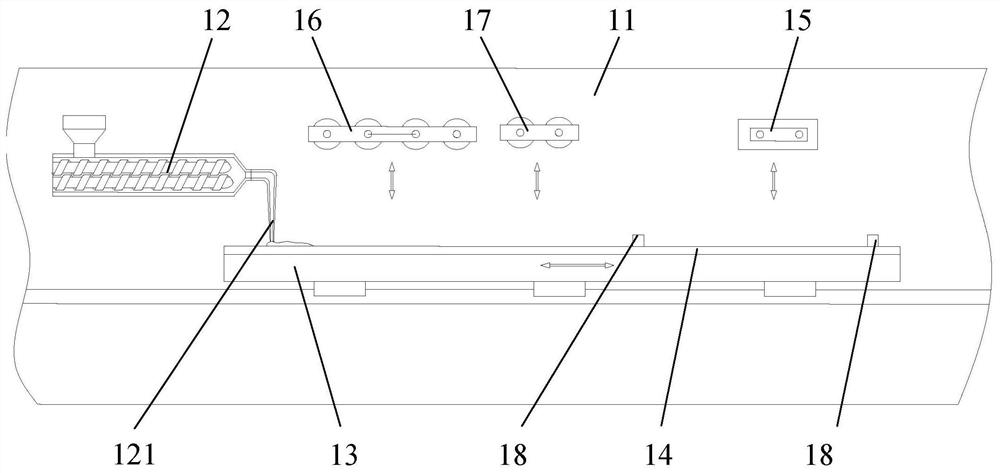

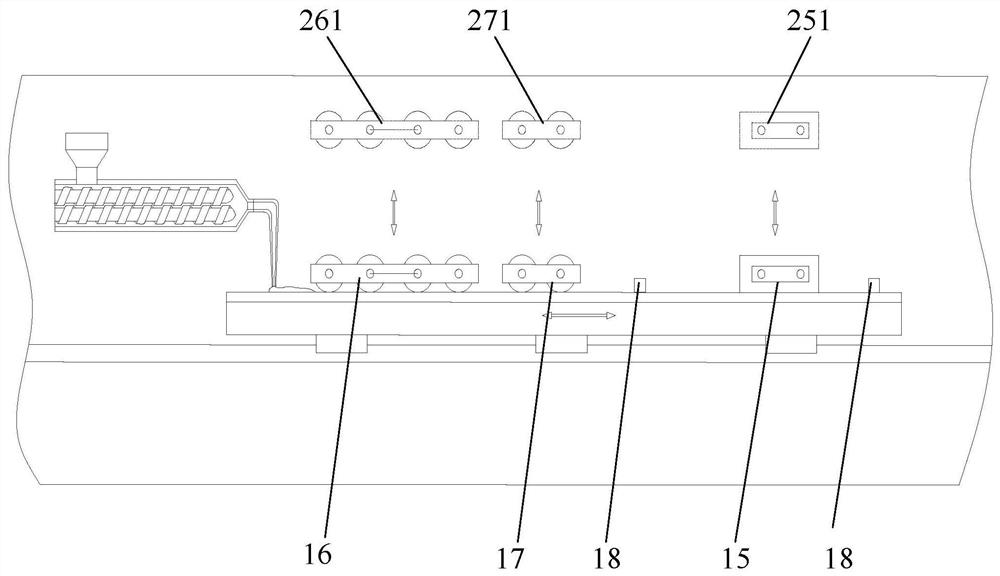

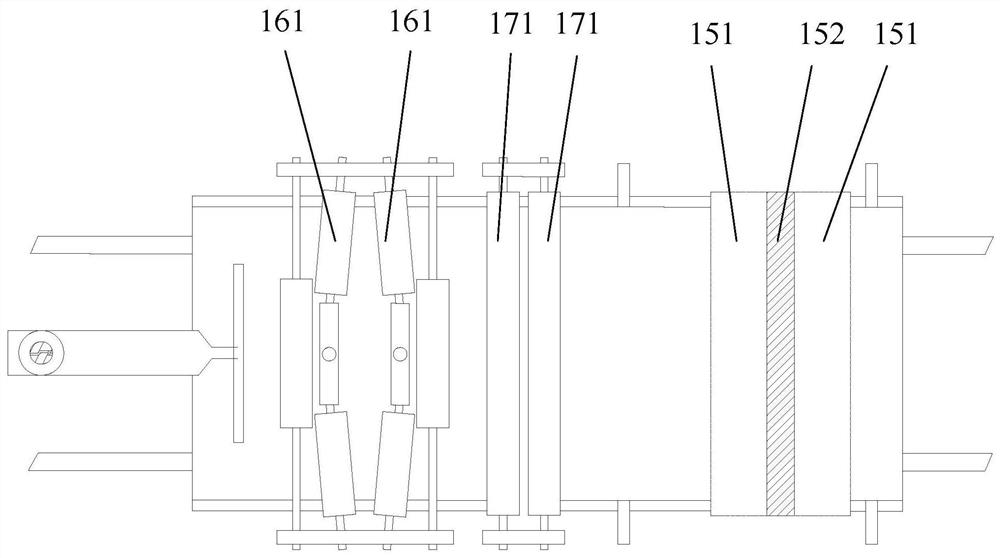

[0044] refer to Figure 1 to Figure 3 , The film forming equipment of the embodiment of the present application may include: a frame 11 , a mixing extrusion device 12 , a moving bed 13 , a spacer 14 , a pressing plate 15 , a first rolling device 16 , a second rolling device 17 and a scraper 18 .

[0045] The mixing and extruding device 12 is arranged on the machine frame 11 for mixing and extruding the film materials through the extrusion port 121 .

[0046] There may be various specific forms of the mixing and extruding device 12, which are not limited in this application. For example, single-screw extruders, twin-screw extruders, multi-screw extruders, or screwless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com