Production method for graphite bipolar plate of fuel cell

A technology of fuel cells and manufacturing methods, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low reliability and high cost of fuel cell stacks, and achieve the effects of improving processing efficiency, reducing costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

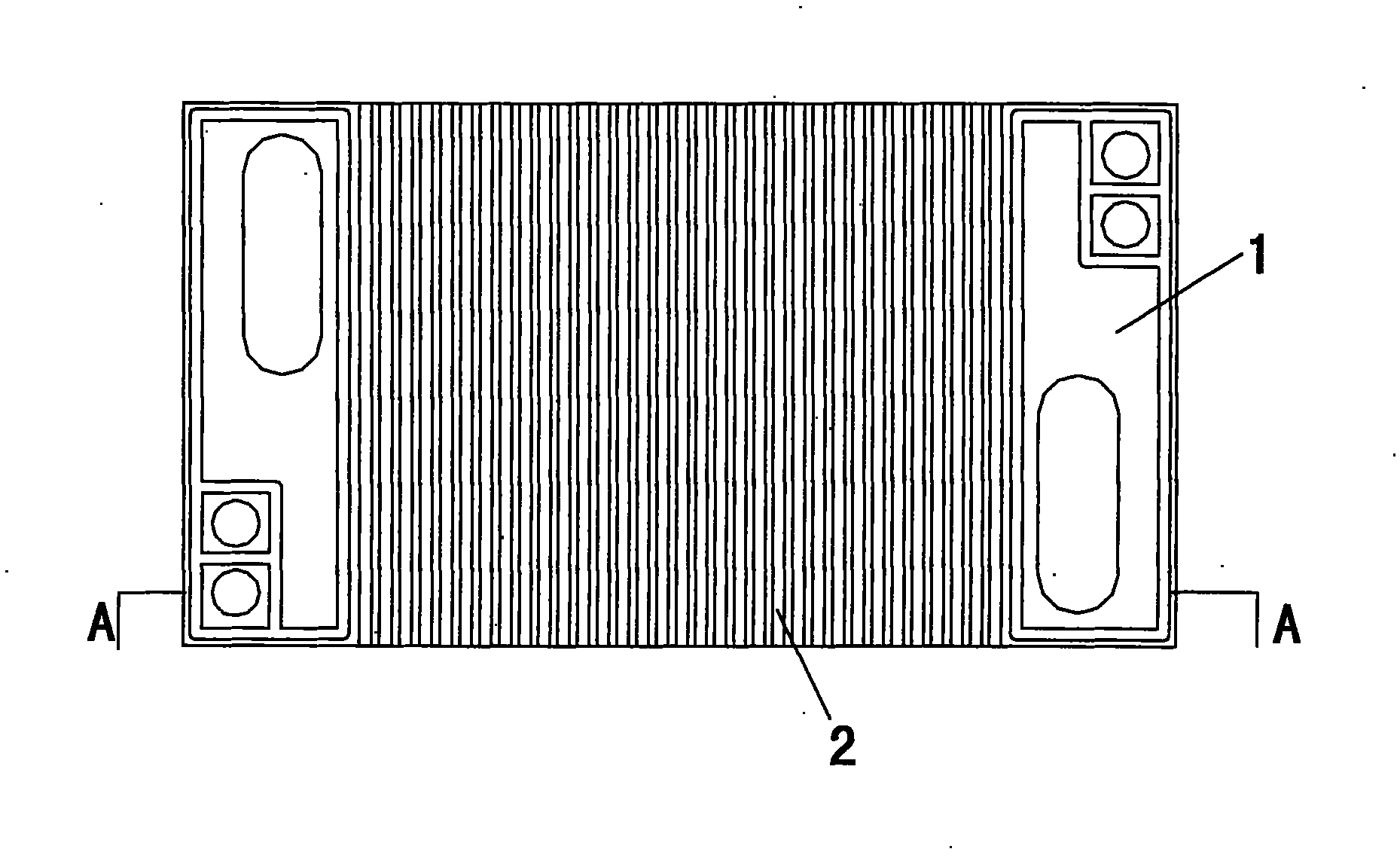

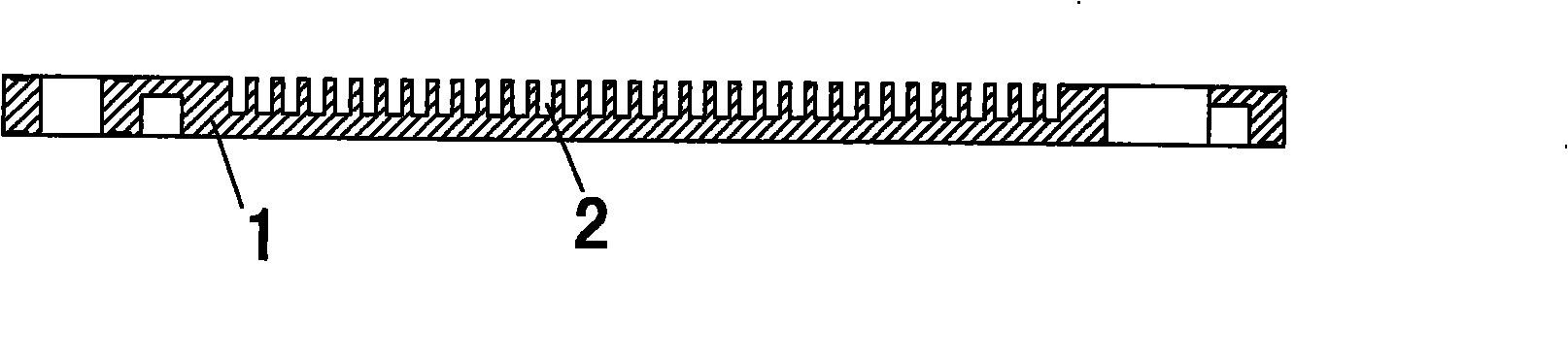

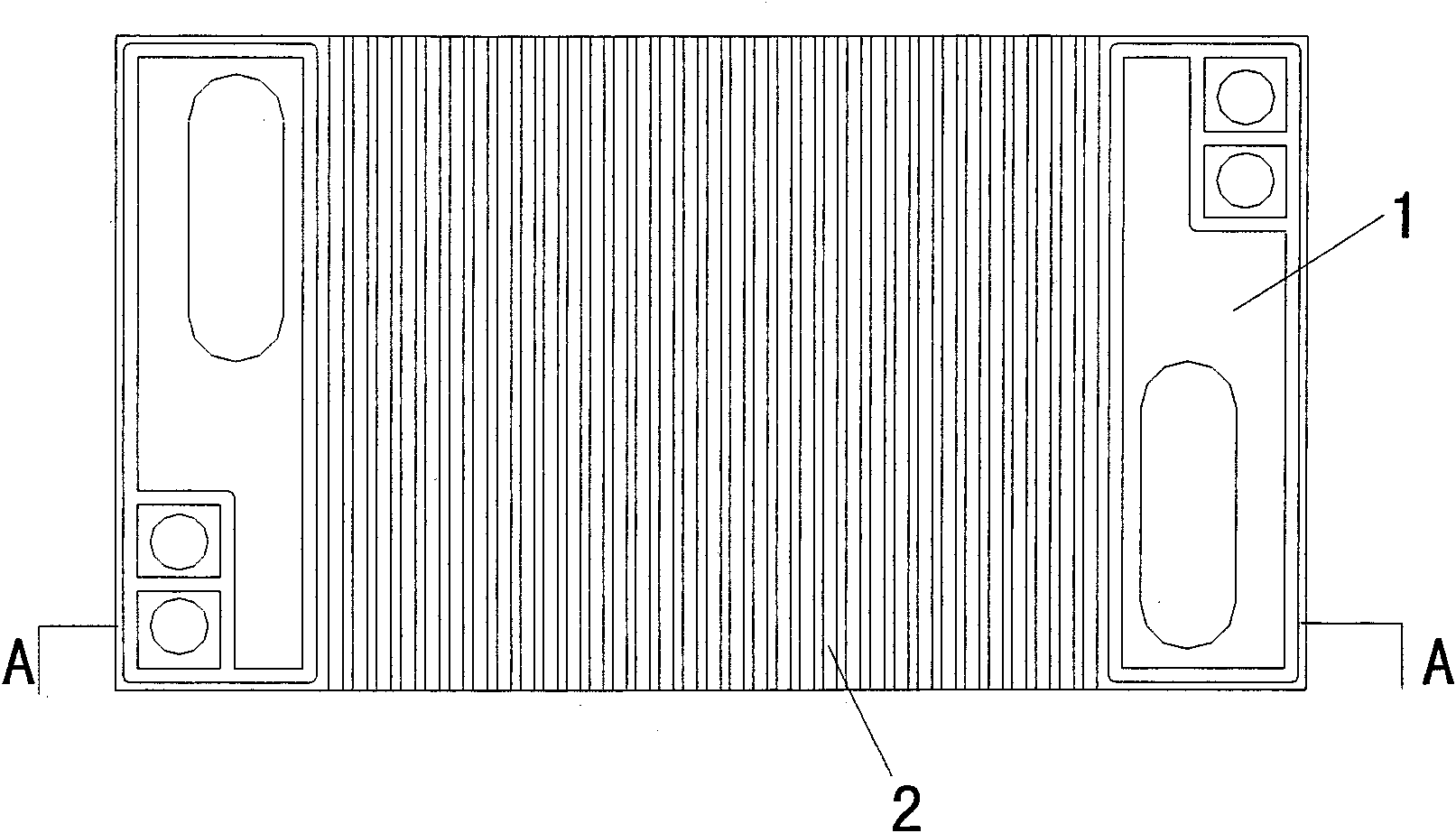

[0021] The manufacturing method of fuel cell graphite bipolar plate of the present invention is, at first take the high-purity graphite block of 1 baking or 1 immersion double baking as raw material, according to the specification mechanical cutting of required graphite bipolar plate, be cut into bipolar plate blank; Then The bipolar plate blank is flat ground into a bipolar plate sheet; and then a horizontal milling cutter composed of parallel multi-piece circular saw blades is used to process a straight-through flow field structure with multiple grooves distributed in parallel on the bipolar plate sheet. The semi-finished bipolar plate is formed; finally, the semi-finished bipolar plate is sealed with epoxy glue and then cured to become the finished bipolar plate.

[0022] figure 1 , figure 2 It is a structural schematic diagram of a fuel cell graphite bipolar plate manufactured by the manufacturing method of the present invention. As shown by the numbers in the figure, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com