Special main bearing sealing grease for shield tunneling machine as well as preparation method and application thereof

A technology of bearing sealing and special main, which is applied in the field of main bearing sealing grease, can solve the problem of few researchers and achieve the effects of avoiding poor pumping performance, good pumping performance and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

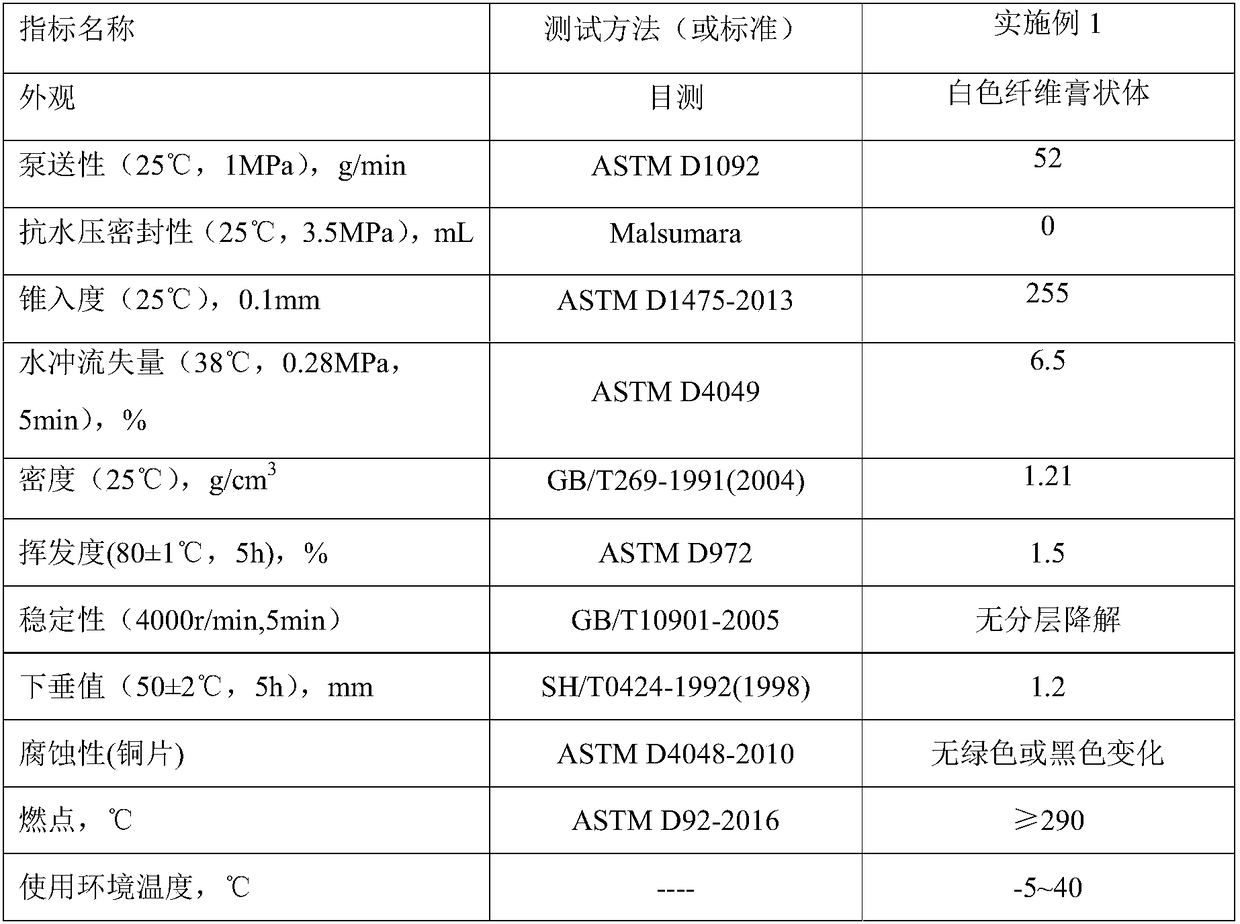

Examples

Embodiment 1

[0035] In this embodiment, the special main bearing sealing grease for the shield machine, its formula components and weight percentages are: 150N base oil 14%, organic soil 125 3%, aluminum hydroxide 14%, polyisobutylene 19.5%, lithium base grease 12% %, lignocellulose fiber 5%, calcium carbonate 28%, graphite 2.8%, molybdenum disulfide 0.5%, barium petroleum sulfonate 1% and antioxidant 1010 0.2%.

[0036] First, set the temperature of the mixing tank to 70°C, add 150N base oil, aluminum hydroxide, and polyisobutylene into the mixing tank, and stir evenly; then, pump the mixed solution in the mixing tank into the kneader, and set the temperature of the kneader to 50 ℃, continue to add graphite, molybdenum disulfide, lignocellulose fiber, organic soil 125, calcium carbonate and lithium base grease; finally, add antioxidant 1010 and barium petroleum sulfonate, continue stirring and kneading for about 2 hours, and the material is ready Special main bearing sealing grease for sh...

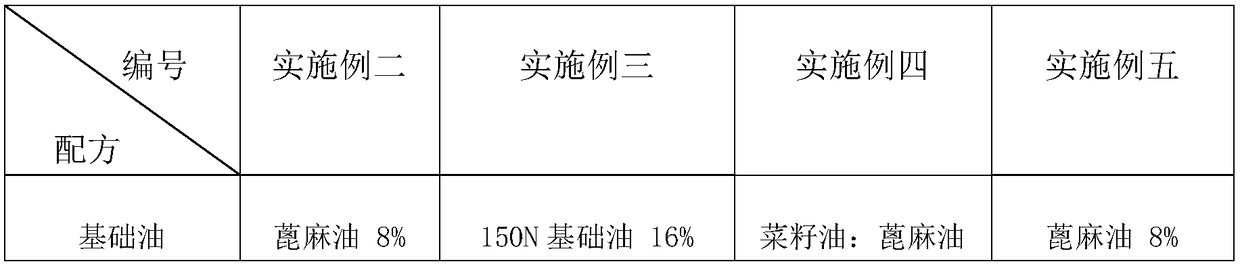

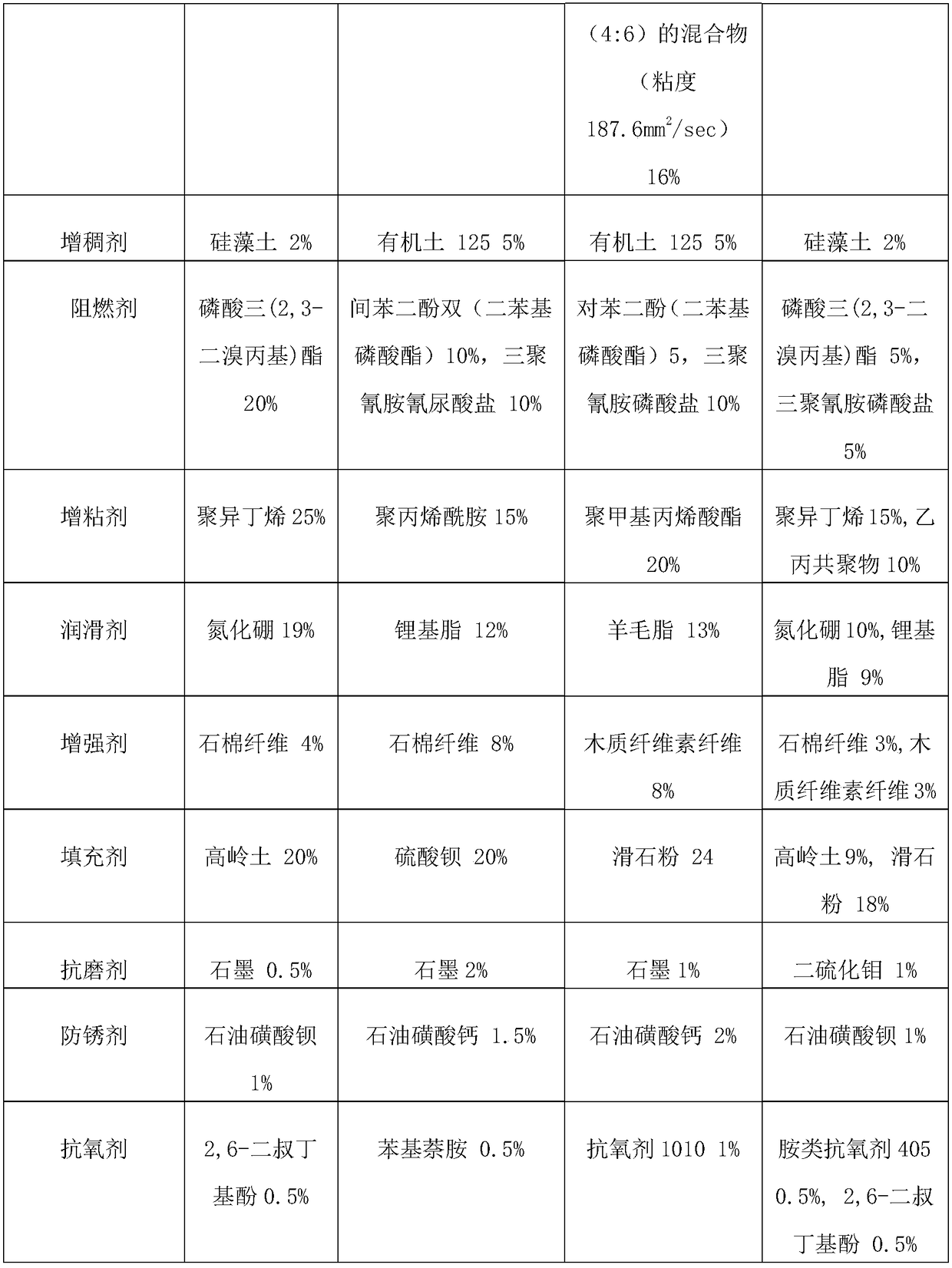

Embodiment 2 5

[0042]

[0043]

[0044] Each component of each embodiment is prepared according to the method in embodiment 1, and the corresponding shield machine special main bearing sealing grease is prepared, and according to the test standard in the embodiment, the shield machine special main bearing prepared in embodiment 2-5 is The physical and chemical properties of sealing grease were tested. The test results show that the physical and chemical properties of the sealing grease for the main bearing of the shield machine prepared in Examples 2-5 also reach the performance level of the sealing grease for the main bearing of the shield machine prepared in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com