Preparation method and application of environment-friendly type shield tail sealing grease

An environment-friendly, shield-tail sealing technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor pumpability and sealing and water-stop performance, uneven quality of sealing grease, and increased shield cost, etc., to achieve water resistance Strong pressure-tightness, excellent pumpability, and the effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

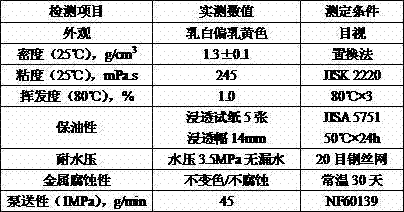

Image

Examples

specific Embodiment approach

[0015] The preferred embodiment of the environment-friendly shield tail sealing grease of the present invention is:

[0016] Including the following components according to the mass ratio: lubricating oil 14-30%, oil plasticizer 7-22%, thickener 3-15%, grease 3-12%, natural degradable fiber 3-8% %, filling granular material 35-60%, color enhancer 1-3%, preservative 0.1-2%.

[0017] Described lubricating oil is the mixture of any one or more of the following: 32 # Mechanical hydraulic oil, 46 # Mechanical hydraulic oil, 68 # Mechanical hydraulic oil, anti-wear hydraulic oil.

[0018] The oil plasticizer is any one or a mixture of the following: chlorinated paraffin-42, chlorinated paraffin-52, chlorinated paraffin-70, DOP, DBP.

[0019] The thickener is any one or a mixture of the following: PIB, OCP, HSD, PMA, coumarone resin, agar, gum arabic, rosin and its derivatives, petroleum resin, and the like.

[0020] Described lubricating grease is the mixture of any one or more...

Embodiment l

[0032] First, the 200kg 32 # Add the mechanical hydraulic oil into the heating kettle, heat up to about 80°C while stirring, then add 30kg of thickener (m(PB2400):m(5T)=l:4), continue stirring and kneading for about 1~4h to mix evenly After that, cool down to 30~50°C. Afterwards, the lubricating oil and the thickening agent that will mix homogeneously are transferred in the grease kneader, and 100kg oil product plasticizer chlorinated paraffin-42,50kg 2 # Lithium base grease, 565kg of light calcium carbonate (5:3:2 in batches) were added to the oil kneader and kneaded until uniform under stirring conditions; finally, 35kg of degradable wood fiber, 5kg of preservatives and 15kg of anatase were added Type titanium dioxide, kneading and stirring at constant temperature for 1~3h, you can get the seal tail grease.

Embodiment 2

[0034] First, the 220kg 46 # Add the mechanical hydraulic oil into the heating kettle, heat up to about 80°C while stirring, then add 50kg of thickener (m(C5):m(rosin derivative)=2:3), continue stirring and kneading for about 1~4h After mixing evenly, cool down to 30~50°C. The lubricating oil that mixes homogeneously and the thickener are transferred in the grease kneader afterwards, and the oil product plasticizer chlorinated paraffin-52, 50kg complex soap base fat of 75kg, heavy calcium carbonate 550kg (add in batches 5: 3:2) Under the condition of stirring, add it into the oil kneader and knead until uniform; finally add 35kg of degradable wood fiber, 5kg of preservative and 15kg of anatase titanium dioxide, knead and stir at constant temperature for 1~3h, and then you can get the shield Tail seal grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com