Wide-temperature-range urea-based shield tail sealing grease and preparation method thereof

A technology of shield tail sealing and wide temperature range, which is applied in the field of wide temperature range urea-based shield tail seal grease and its preparation, can solve the impact of research and development costs and quality control of shield tail seal grease for tunnel construction and propulsion efficiency , Shield tail sealing grease is greatly affected by temperature, shield tail sealing grease becomes thinner, etc., to achieve the effect of easy industrial production, good water pressure resistance and sealing performance, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

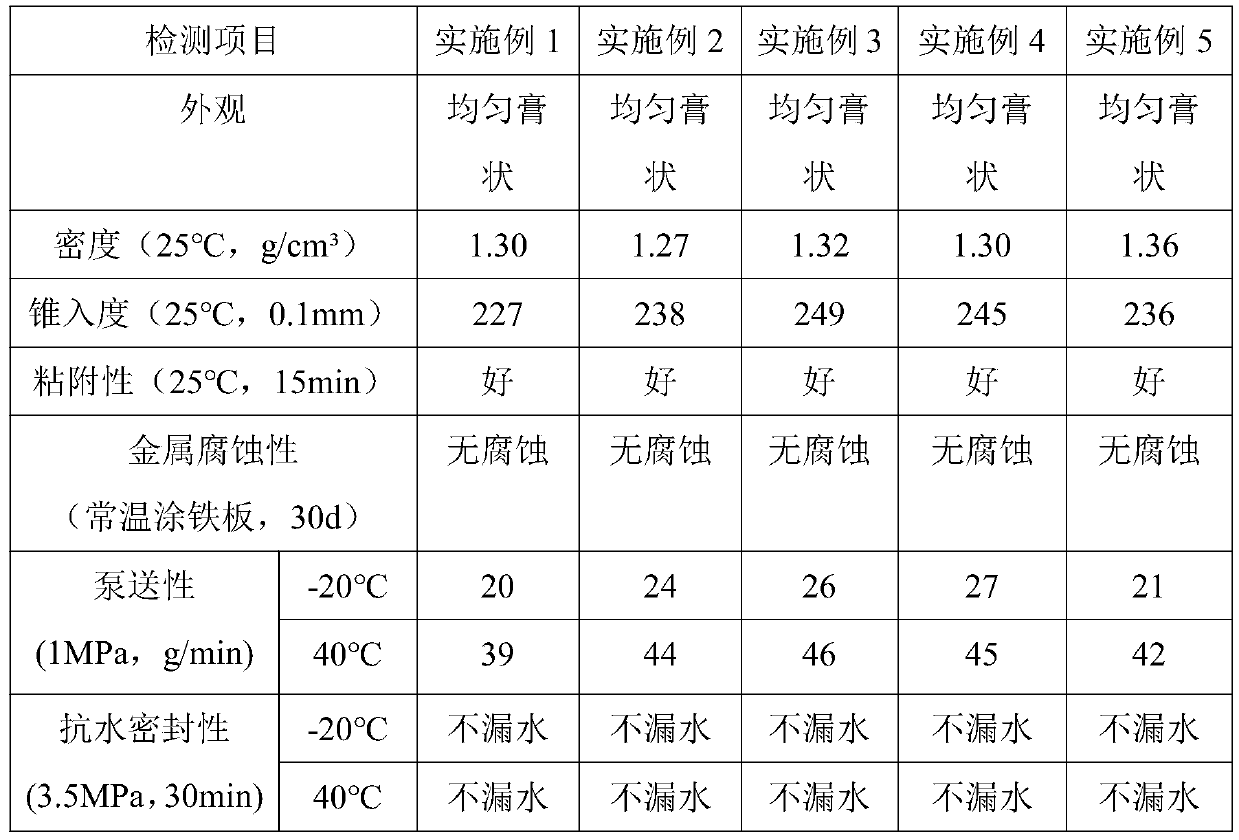

Examples

Embodiment 1

[0029] The shield tail sealing grease of the shield machine in the present embodiment has the following components and parts by weight: 10 parts of urea-based resin, 50 parts of calcium carbonate, 10 parts of calcium-based bentonite, 10 parts of gear oil B, and 5 parts of sodium-based grease , cellulose fiber 5 parts

[0030] Preparation:

[0031] Step A: Weigh 80 parts of PTMG1000, add to a three-necked flask, and slowly heat to 110-120°C under stirring;

[0032] Step B: dehydration, then lower the temperature to 50°C, add 32 parts of TDI, and raise the temperature to 85°C for 3h;

[0033] Step C: Add 29 parts of ALT402 latent curing agent, 1 part of leveling agent, and 0.5 part of defoamer, stir rapidly and vacuum defoam for 40 minutes, and discharge to obtain a single-component polyurea resin with a mass fraction of NCO of 6%.

[0034] Step D: put gear oil, cellulose fiber, and sodium-based grease into the kneader, heat up to 80-100°C under stirring conditions, keep const...

Embodiment 2

[0038] The shield tail sealing grease of the shield machine in the present embodiment has the following components and parts by weight: 15 parts of urea resin, 40 parts of calcium carbonate, 10 parts of sodium bentonite, 10 parts of 150SN mineral oil, and 5 parts of sodium grease parts, cellulose fiber 5 parts

[0039] Preparation:

[0040] Step A: Weigh 80 parts of PTMG1000, add to a three-necked flask, and slowly heat to 110-120°C under stirring;

[0041] Step B: dehydration, then lower the temperature to 50°C, add 40 parts of HMDI, heat up to 85°C for 3h;

[0042] Step C: Add 26 parts of ALT402 latent curing agent, 1 part of leveling agent, and 0.5 part of defoamer, stir rapidly and vacuum defoam for 40 minutes, and discharge to obtain a single-component polyurea resin with a mass fraction of NCO of 6%.

[0043] Step D: put 150SN mineral oil, cellulose fiber, and sodium-based grease into the kneader, heat up to 80-100°C under stirring conditions, keep constant temperature...

Embodiment 3

[0047] The shield tail sealing grease in the present embodiment has the following components and parts by weight: 20 parts of urea-based resin, 40 parts of calcium carbonate, 10 parts of sodium bentonite, 10 parts of ester synthetic oil, lithium-based grease 5 parts, wood fiber 5 parts

[0048] Preparation:

[0049] Step A: Weigh 80 parts of PTMG1000, add to a three-necked flask, and slowly heat to 110-120°C under stirring;

[0050] Step B: dehydration, then lower the temperature to 50°C, add 42 parts of IPDI, heat up to 85°C for 3h;

[0051] Step C: Add 30 parts of latent curing agent, 1 part of leveling agent, and 0.5 part of defoamer, stir rapidly and vacuum defoam for 40 minutes, and discharge to obtain a one-component polyurea resin with a mass fraction of NCO of 6%.

[0052]Step D: put ester synthetic oil, wood fiber, and organic grease into the kneader, heat up to 80-100°C under stirring conditions, keep constant temperature until completely mixed evenly, then stop st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com