Large high-speed electromotor whole structure

A high-speed motor, integral structure technology, applied in the manufacture of motor generators, magnetic circuit shape/style/structure, electromechanical devices, etc. Low protection level and other problems, to achieve the effect of reducing vibration, improving protection level requirements, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

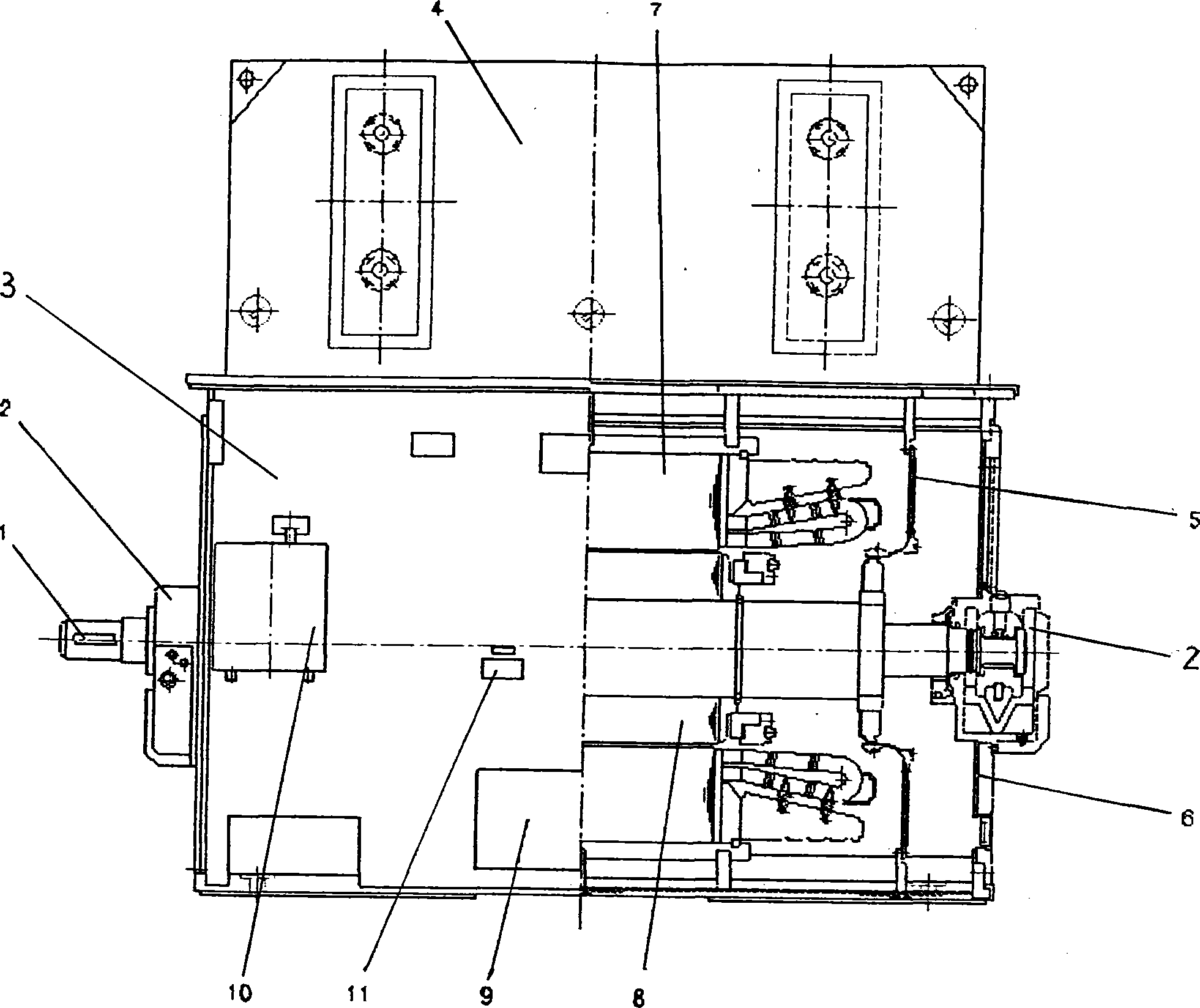

[0034] Please refer to the accompanying drawings shown in the structure schematic diagram of the overall structure of the large-scale high-speed motor of the present invention, a kind of overall structure of the large-scale high-speed motor, the motor includes a support 3, an end cover 6, a stator 7, a shaft 1, a rotor 8 and a bearing 2, and in addition There are cooler 4, motor windshield 5, cover plate 9, outlet box 10 and sign 11, wherein:

[0035] The machine base 3 is a box-type structure, and two or more reinforcing ribs are provided on the upper, lower, left, and right sides. become;

[0036] The end cover 6 is directly processed and integrally formed by a round steel plate with a thickness of 50mm±3, and the contact surface between the end cover 6 and the machine base 3 and the bearing is smooth and clean, and they are in close contact with each other and sealed;

[0037] In the stator 7, the stator core is welded and fixed by three round steel plates with a thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com