Novel glue sealing valve

A sealing valve, a new type of technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems such as the method and measure of glue flow, speed and accuracy that have not been invented, and meet the sealing requirements and meet the sealing requirements. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment, further illustrate the present invention.

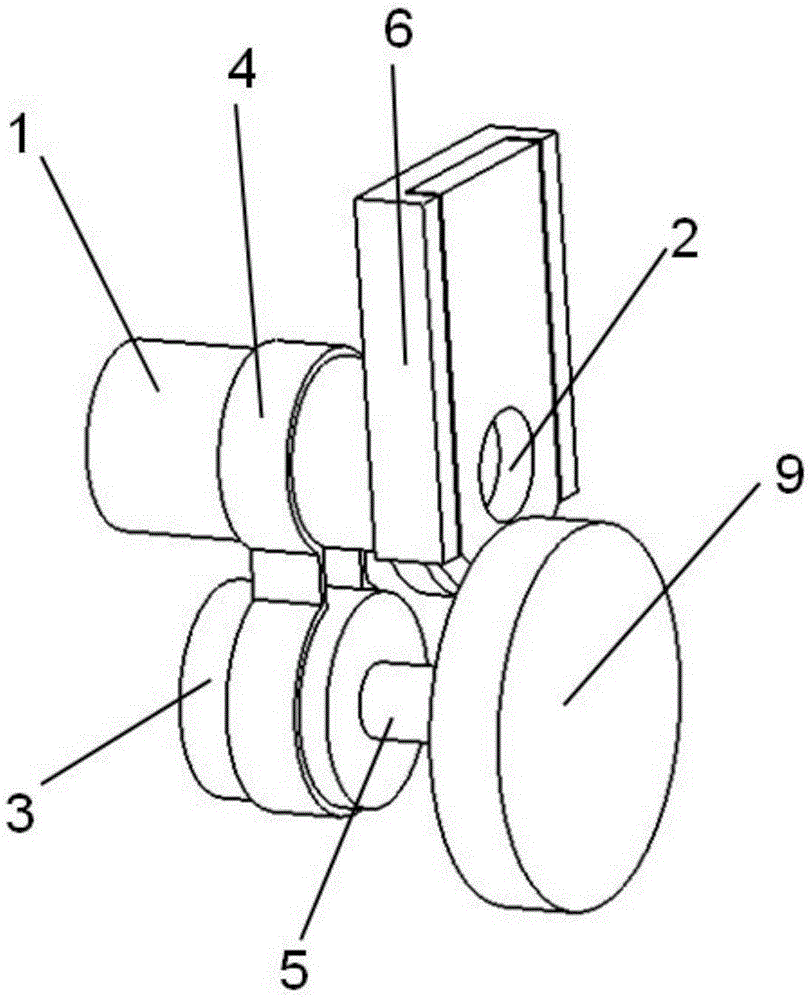

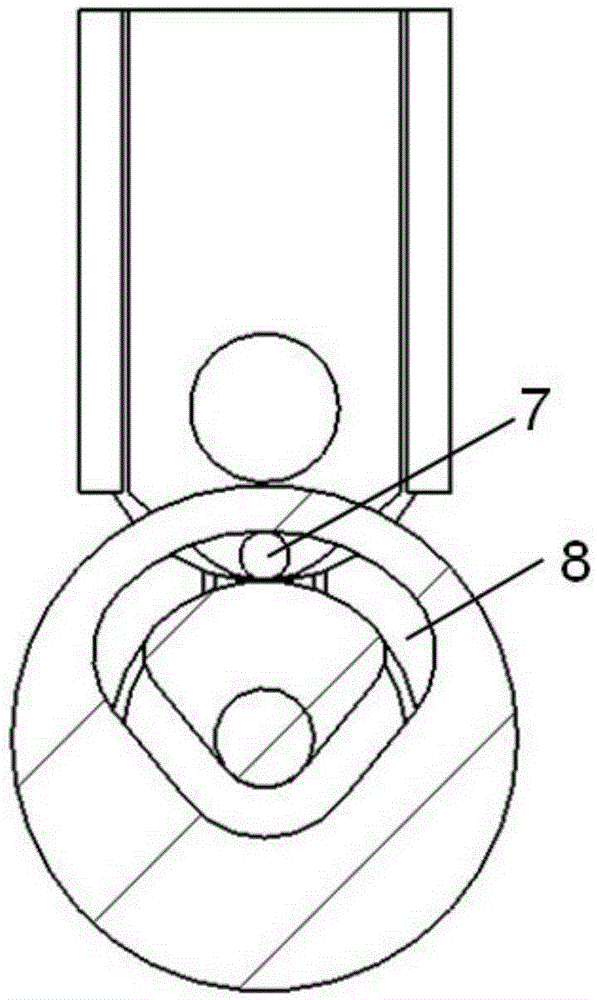

[0015] Such as figure 1 , 2 As shown, the new sealing valve is composed of a glue inlet section 1, a glue outlet hole 2, a motor 3, a fixed ring 4, a rotating shaft 5, a fixing frame 6, and a glue adjusting plate 9, and the fixing frame 6 is closely attached to the glue adjusting plate 9. Together, the lower end of the fixed frame 6 is provided with a slider 7, the glue outlet hole 2 is arranged at the lower end of the fixed frame 6, the glue inlet section 1 passes through the fixed ring 4 and communicates with the glue outlet hole 2 on the fixed frame 6, and the glue inlet section 1 passes through The fixed ring 4 is connected with the motor 3, one end of the rotating shaft 5 is connected with the motor 3, and the other end is connected with the rubber disc 9, the upper part of the rubber disc 9 near the end of the fixed frame 6 is provided with a slideway 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com