Outer flange structure of air flue of railway vehicle

A rail vehicle and outer flange technology, which is applied in flange connection, railway vehicle heating/cooling, railway vehicle body parts, etc., can solve problems such as unsatisfactory sealing conditions and inability to achieve full welding of the outer flange of the air duct, etc. Achieve the effect of good use value, simple structure and easy process realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

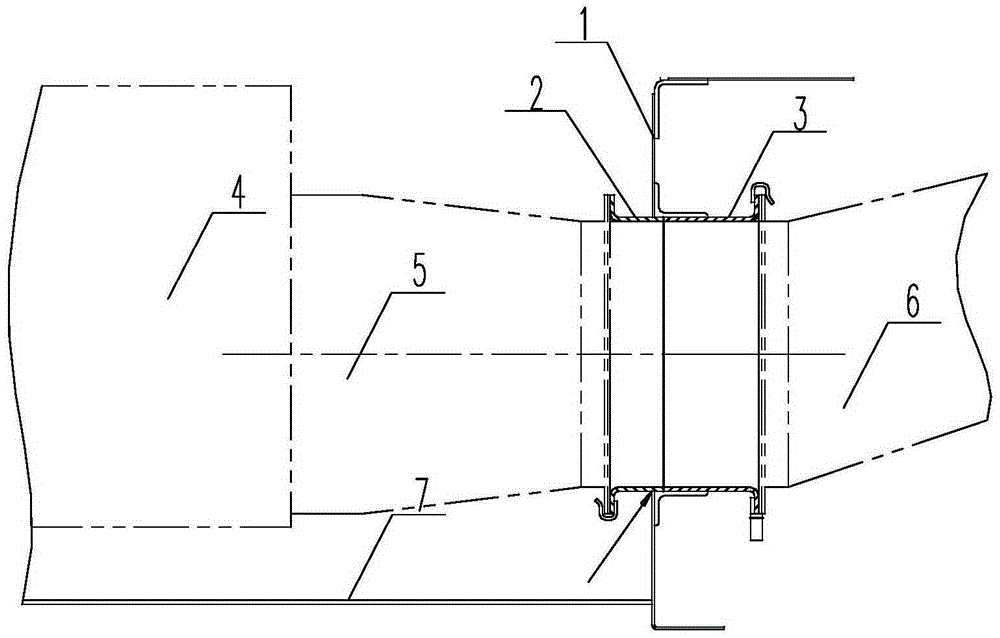

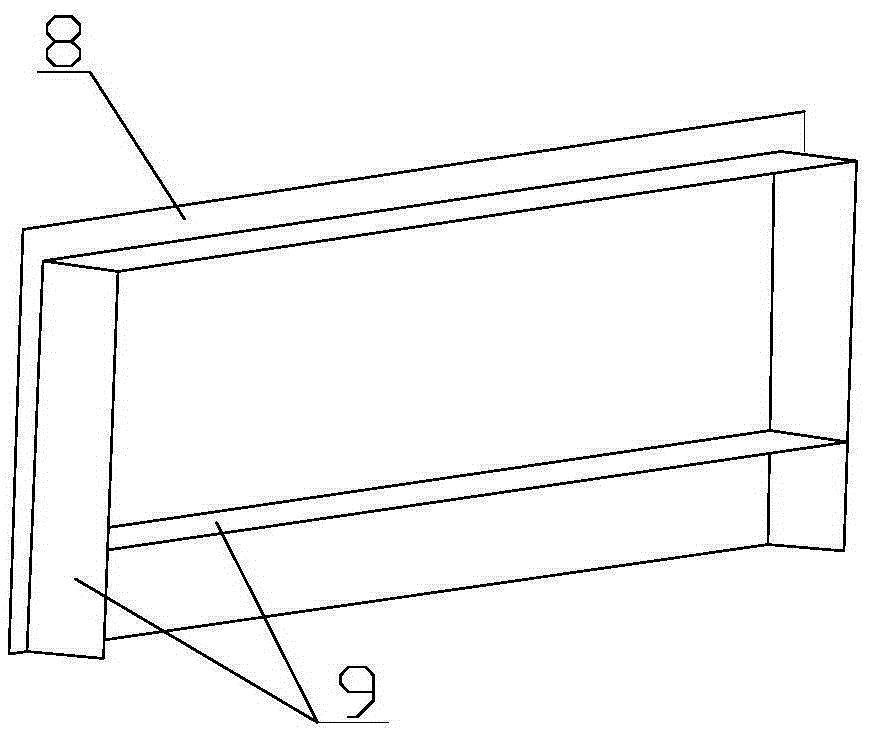

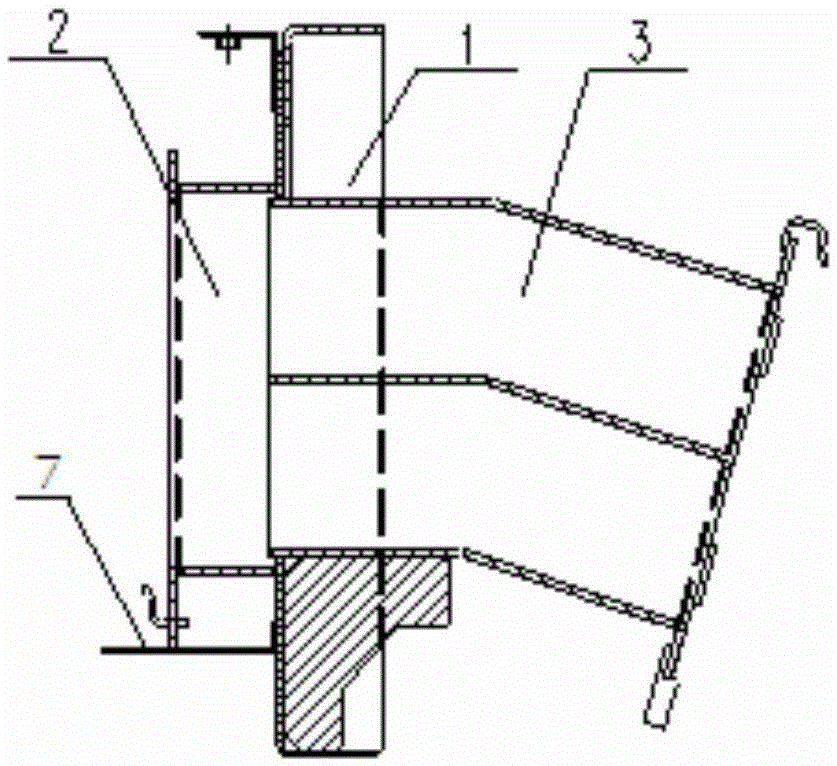

[0019] like Figure 1 to Figure 4 As shown, the outer flange structure of the rail vehicle air duct in this embodiment includes an outer flange tube 8 and an outer flange edge 9, the outer flange tube 9 is surrounded by four wing plates, and the left and right side wing plates of the outer flange tube 9 are connected to each other. parallel, and its bottom end is flush with the bottom end of the outer flange 8, the left and right wing plates of the outer flange 9 and the outer flange 8 fall together on the flat roof 7 of the vehicle, and the four sides of the outer flange 9 A wing plate is welded and fixed with the vehicle middle end top plate 1; the bottom end of the left and right sides wing plates of the outer flange tube 9 and the bottom end of the outer flange side 8 are welded on the flat roof plate of the vehicle.

[0020] In order to achieve sealing, in this embodiment, full welding is used between the four wing plates of the outer flange cylinder 9 and the roof plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com