Mounting method for air duct external flange of rail vehicle

A rail vehicle and installation method technology, which is applied to the heating/cooling of railway vehicles, transportation and packaging, railway car body parts, etc., can solve the problems that the outer flange circumference of the air duct cannot be fully welded, and the sealing condition is not ideal, etc., to achieve Good use value, simple structure, easy process to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

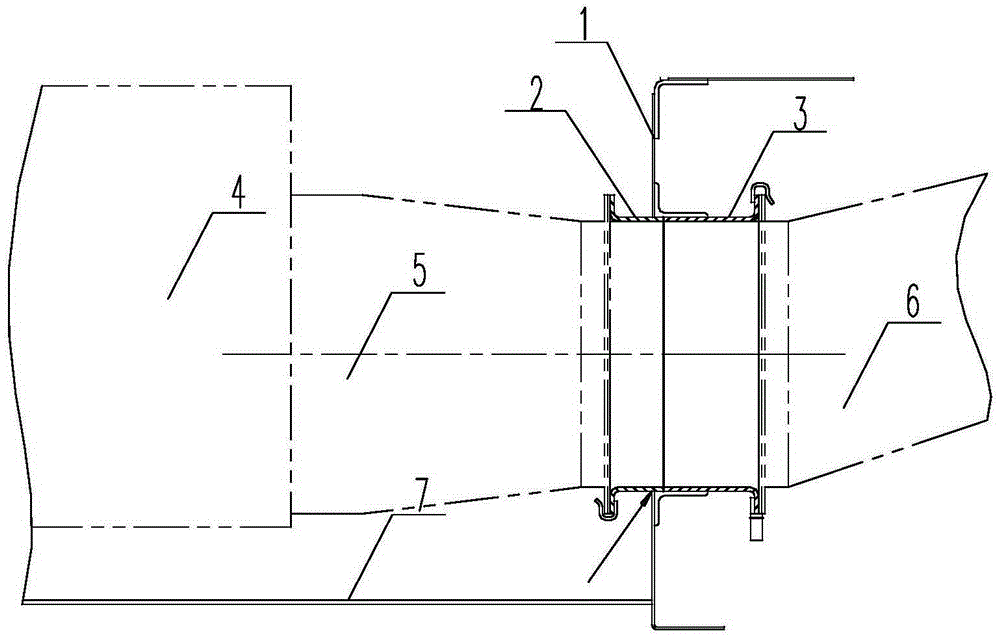

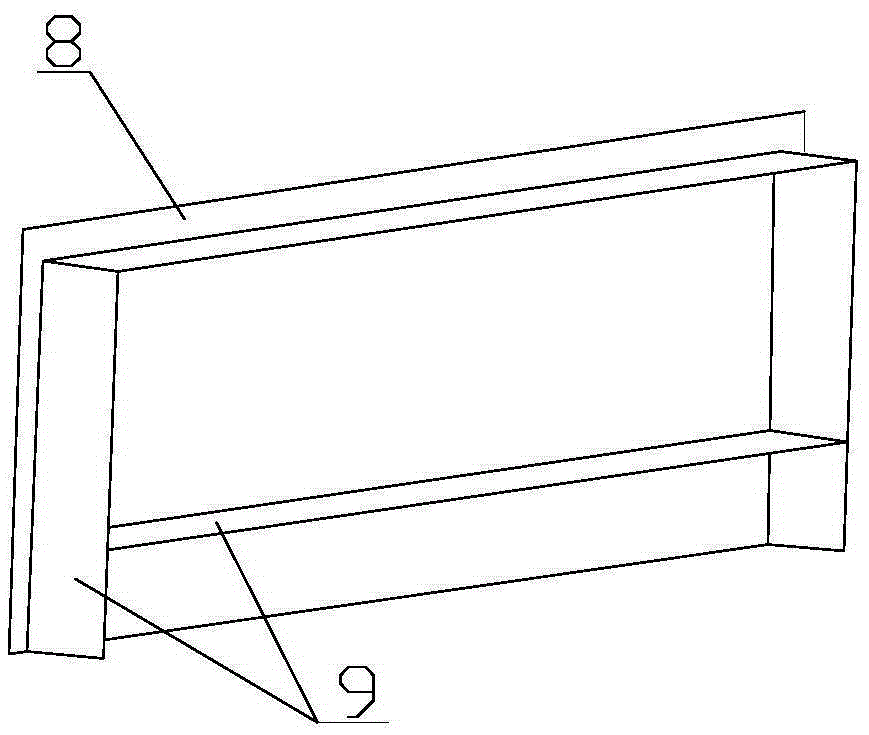

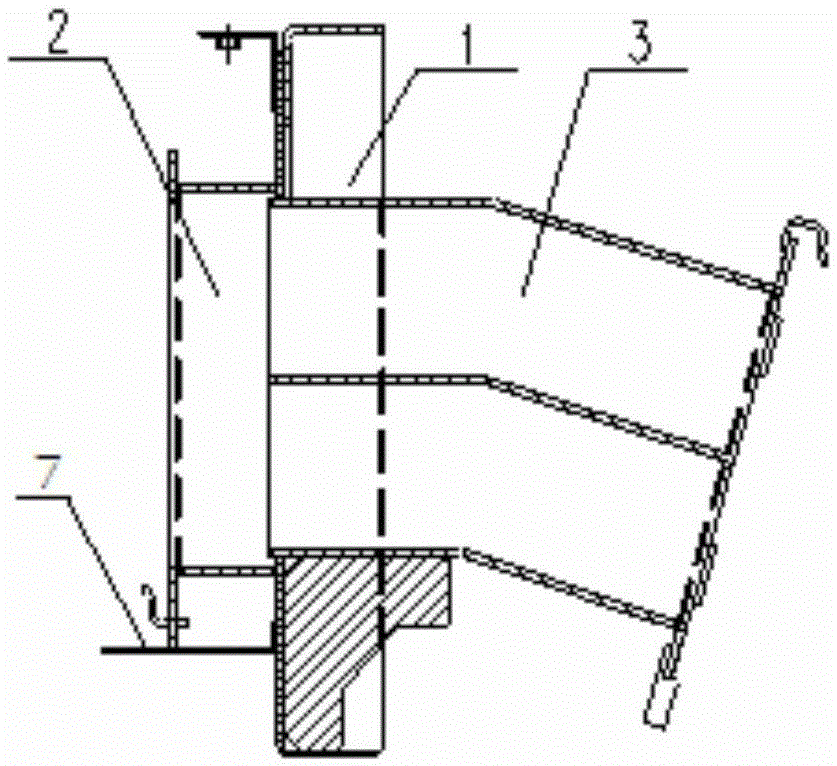

[0021] like Figure 1 to Figure 4 As shown, the outer flange of the rail vehicle air duct to be installed in this embodiment includes an outer flange tube 8 and an outer flange side 9, the outer flange tube 9 is surrounded by four wing plates, and the left and right sides of the outer flange tube 9 are The plates are parallel to each other and their bottom ends are flush with the bottom ends of the outer flange 8 .

[0022] The installation steps are as follows:

[0023] The first step is to put the pre-welded outer flange of the air duct on the car;

[0024] The second step is to move the outer flange of the air duct to the designated position, so that the left and right wing plates of the outer flange tube 9 and the outer flange side 8 fall together on the flat roof plate 7 of the vehicle, and the four wing plates of the outer flange tube 9 lean against Vehicle middle end roof plate 1;

[0025] In the third step, the bottom ends of the left and right wing plates of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com