Fuel gas generator

A technology of gas generators and combustion chambers, which is applied in the direction of burners, burning with various fuels, combustion chambers, etc., to achieve good light transmission, improve compression resistance, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

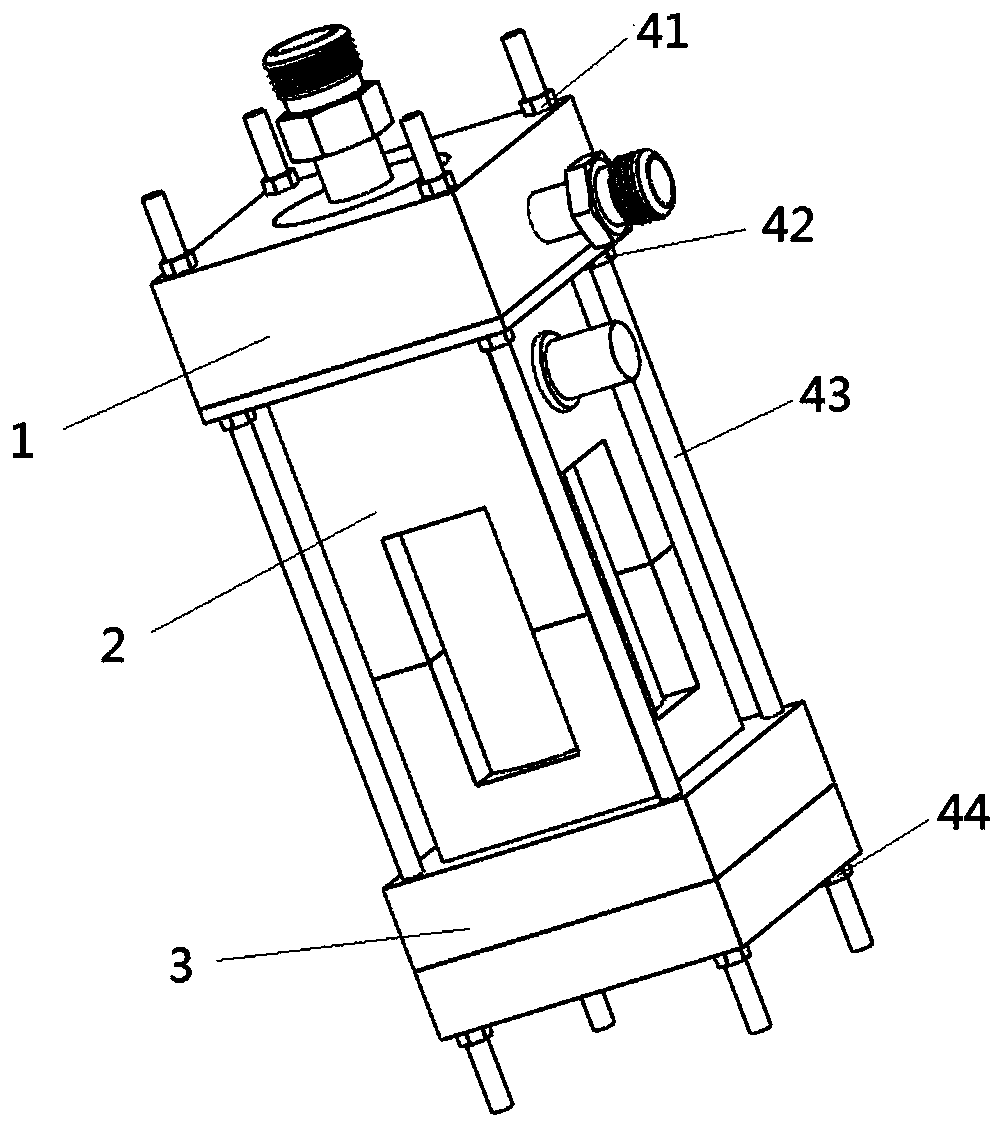

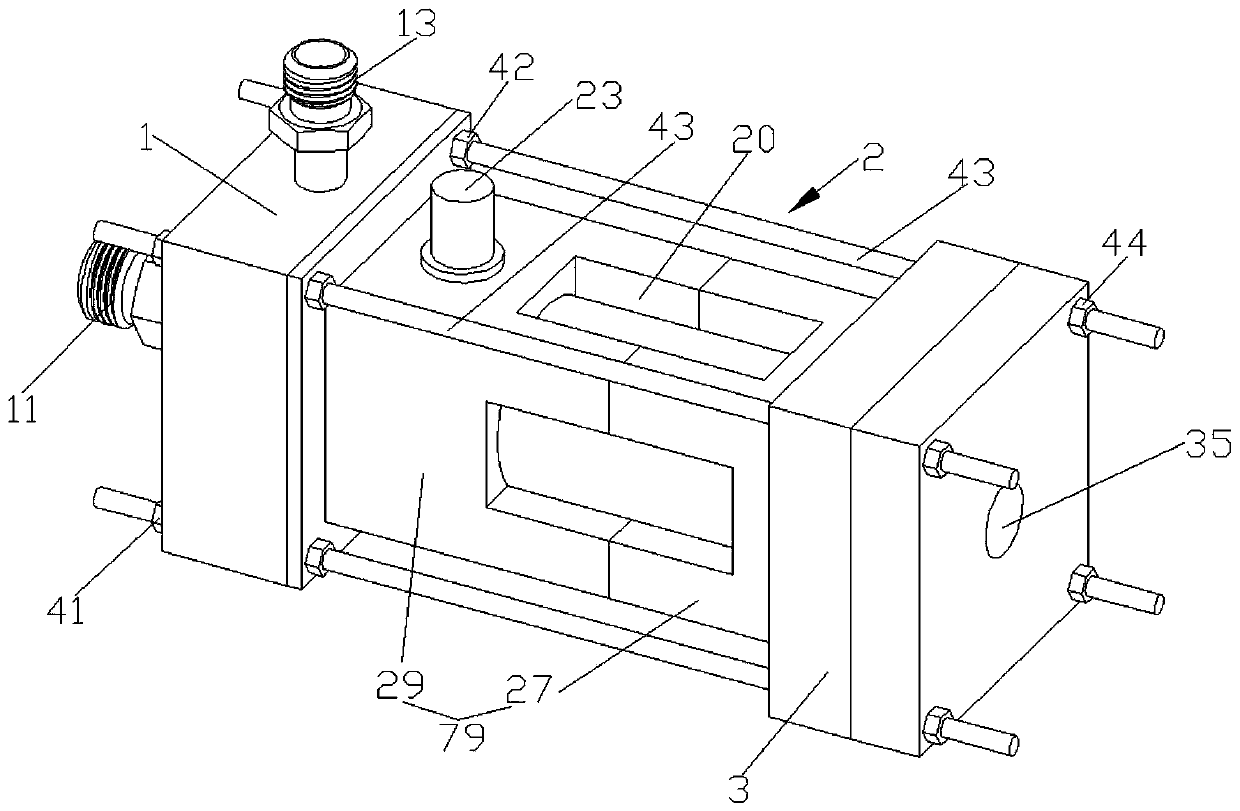

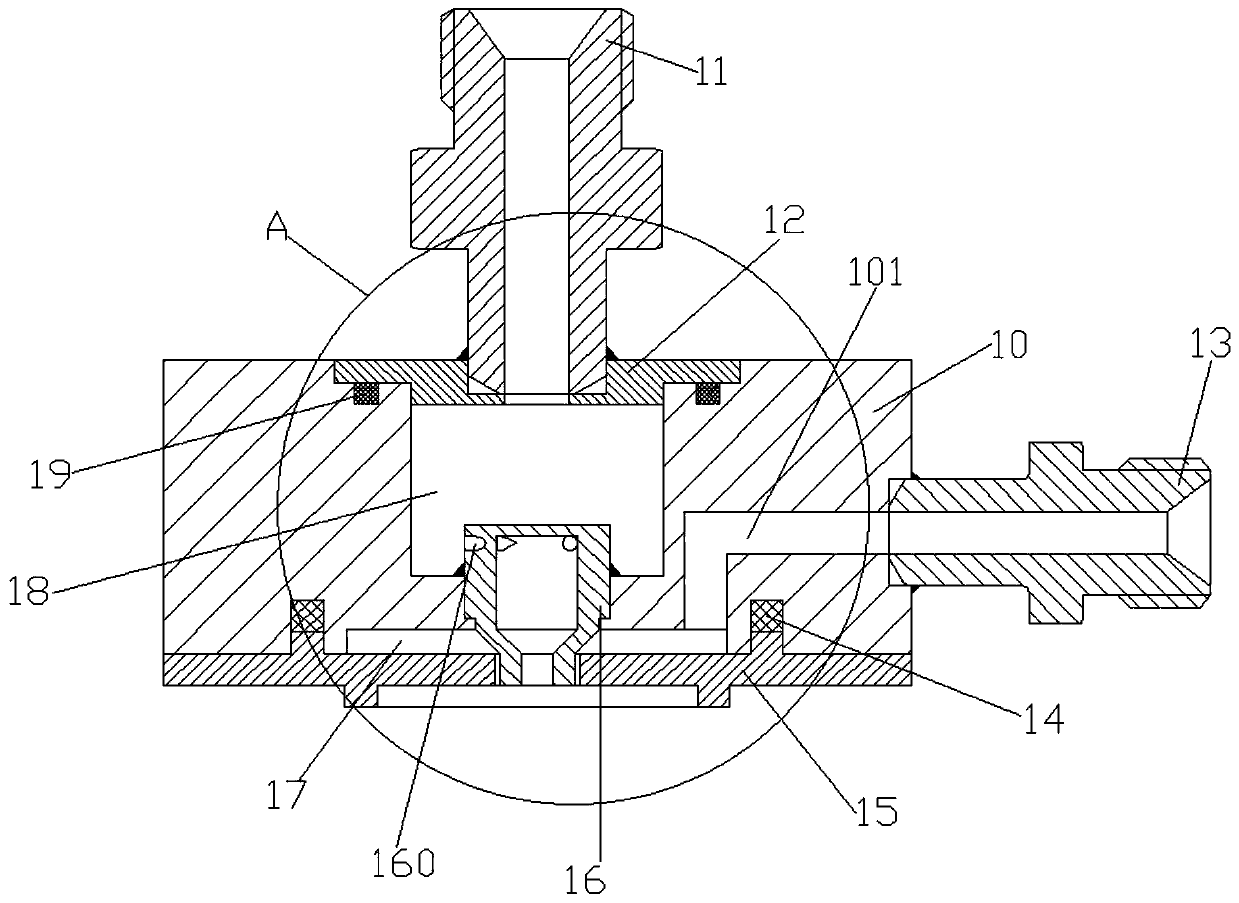

[0053] Embodiments of the present invention provide a small gas generator, such as Figure 1-9 shown, see figure 1 , the gas generator includes from top to bottom: an injector assembly 1, a combustion chamber assembly 2, and a nozzle assembly 3. The injector assembly 1 is arranged at the head of the gas generator, and the nozzle assembly 3 is arranged at the At the tail of the generator, the injector assembly 1 and the nozzle assembly 3 fix the combustion chamber assembly 2 in the middle through the screw 43; the injector assembly 1 and the nozzle assembly 3 of the embodiment of the invention A screw rod 43 of the same size is connected to fix the combustion chamber assembly 2 between the injector assembly 1 and the nozzle assembly 3 . The upper and lower ends of the screw rod 43 cooperate with the first nut 41 and the second nut 44 respectively to apply a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com