Large double-channel sealing valve not prone to deformation

A sealing valve, double-channel technology, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of large diameter, several times or even ten times higher, incomplete specifications, etc., to achieve high structural strength and ensure the area , good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

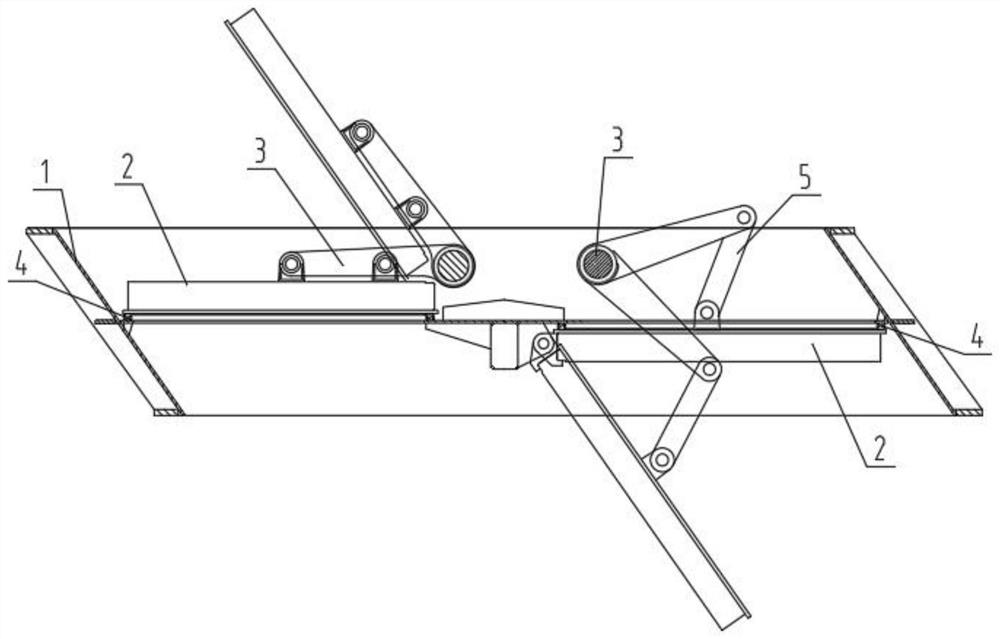

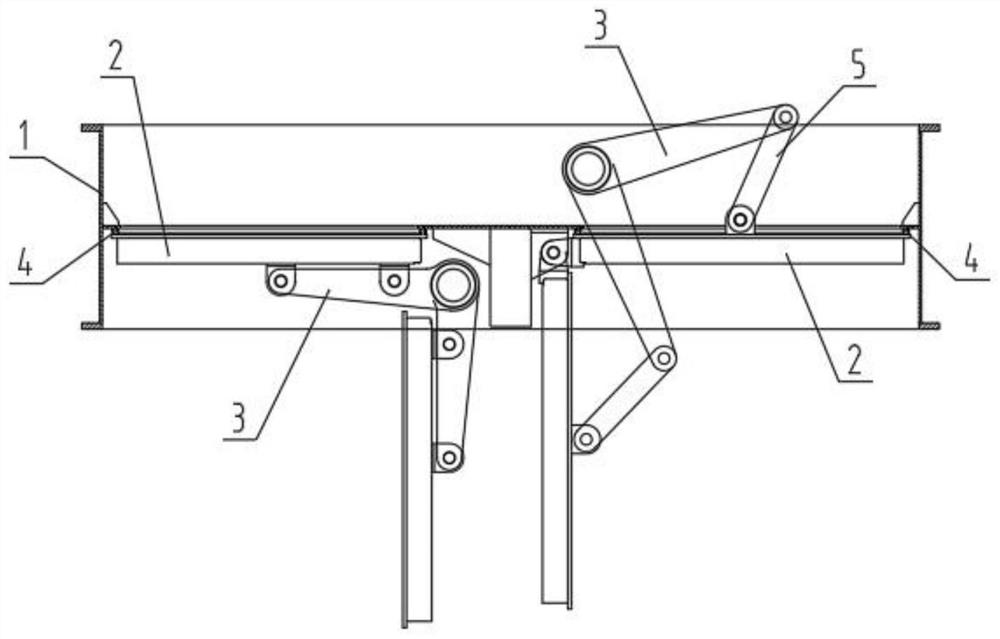

[0016] See Figure 1-2 , A large dual-channel sealing valve, including the sealing valve body 1, both sides of one end of the sealing valve main body 1, and the valve body plate 2 is provided with a rotary shaft member 3, and the shaft member is attached. 3 consist of the drive shaft, the bearing housing, the bearing, the driving arm, and one end of the rotation shaft member 3 is provided with a rotating link 5, and the side wall of the valve body plate 2 is fixedly connected to the seal 4, and the passage of the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com