Sealing mechanism for tower tube sleeving type anti-corrosion device

A sealing mechanism and anti-corrosion technology, applied in the installation/support of wind turbine configuration, engine, mechanical equipment, etc., can solve problems such as corrosion, corrosion of upper and lower clamp body towers, etc., to achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

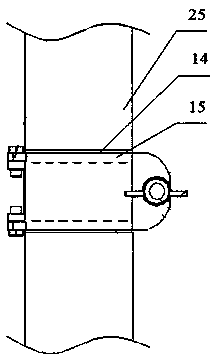

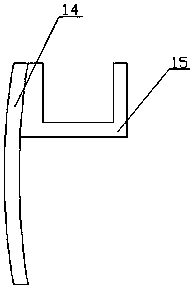

[0011] Such as figure 1 , figure 2 It shows an embodiment of a sealing mechanism of the present invention for a tower jacket anti-corrosion device. The anti-corrosion device includes a shell mechanism, and the shell mechanism includes an upper clamp body 1 and a lower clamp body 2. The upper clamp body The body 1 and the lower hoop body 2 are oppositely arranged to form a cavity into which the tower tube 25 is embedded, including sealing strips placed on both sides of the upper and lower hoop bodies, and the sealing strips include sealing strips placed on the inner end surfaces of the upper and lower hoop bodies. The sealing part a14 and the sealing part b15 placed at the end of the sealing part a14, the sealing part a14 is an arc-shaped structure, the sealing part b15 is a U-shaped structure, and the side edges of the upper and lower clamp bodies are embedded into the sealing part b15 set up.

[0012] The setting of the sealing mechanism of the present invention enables a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com