Metal hard seal ball valve

A hard-sealed, metal technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as poor sealing performance, poor temperature resistance, and inability to meet the requirements of sealing and high temperature, etc. Achieve low operating torque and enhanced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

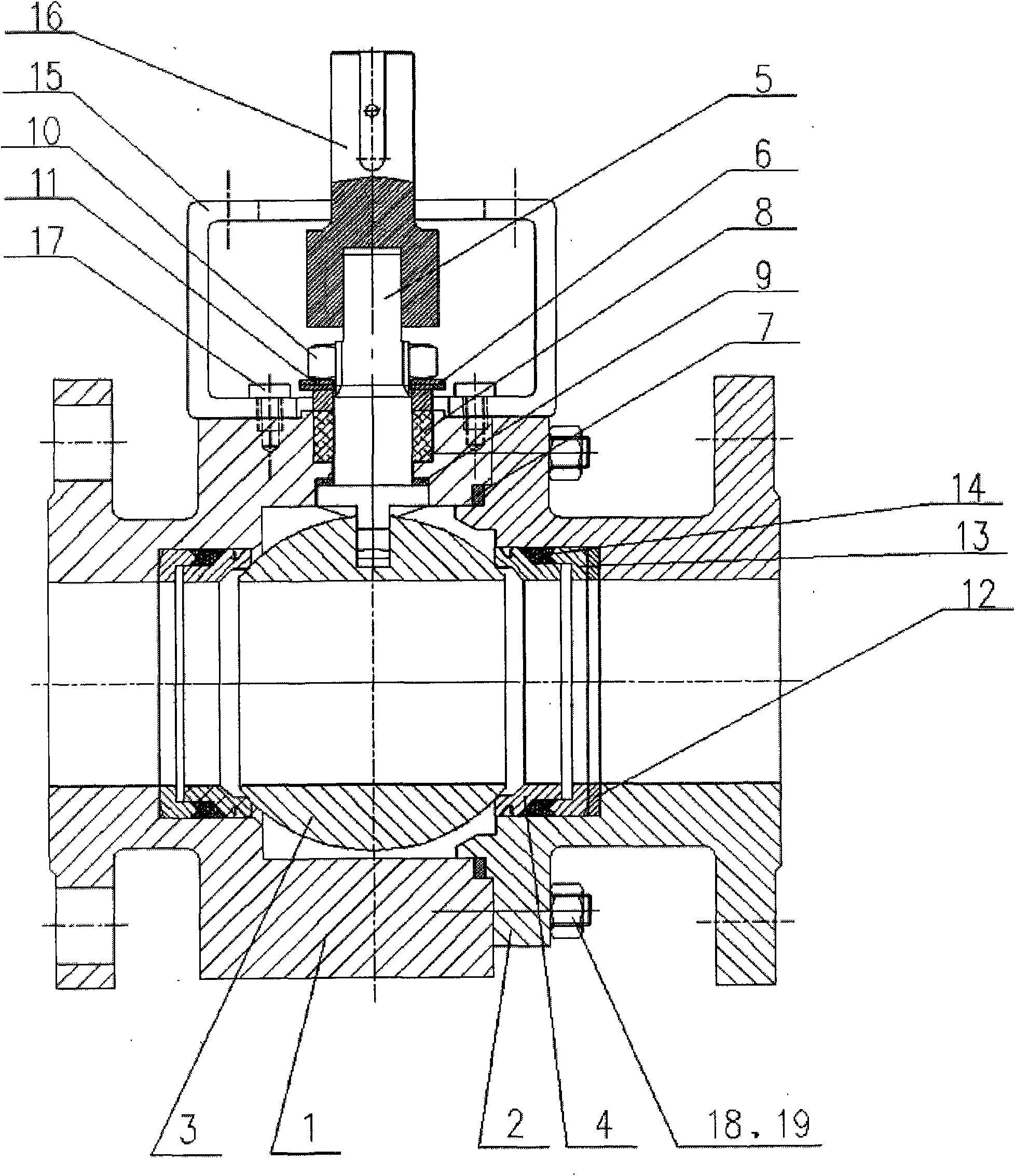

[0014] figure 1 It is a structural schematic diagram of the present invention.

[0015] Such as figure 1 Shown: a metal hard-sealed ball valve, including valve body 1, valve cover 2, valve ball 3, valve seat 4, valve stem 5, bracket 15 and driving device (not shown in the figure), valve body 1 and valve cover 2 The studs 18 and nuts b19 at both ends are fixedly connected to form a cavity, and the winding pad a7 is used to form a seal. The valve ball 3 with a through hole is located in the cavity, and the two sides of the valve ball 3 are respectively provided with valve seats 4. The valve seat 4 is made of metal material, between the valve body 1 and the valve seat 4, the valve cover 2 and the valve seat 4, a gasket 14, a pressure ring 13 and a butterfly spring b12 are arranged in sequence to form an effective seal, and the valve The upper end of the ball 3 is connected to one end of the valve stem 5, and the middle part of the valve stem 5 is fixedly connected to the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com