Planet pin roller spiral device, manufacturing method and forced seal ball valve

A planetary roller and screw device technology, applied in the direction of valve devices, cocks including cutting devices, engine components, etc., can solve the problem of affecting bearing capacity and working stability, increasing valve opening and closing operating torque, and reducing thread working life, etc. problems, to achieve the effect of improving operational reliability and working life, reducing friction and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

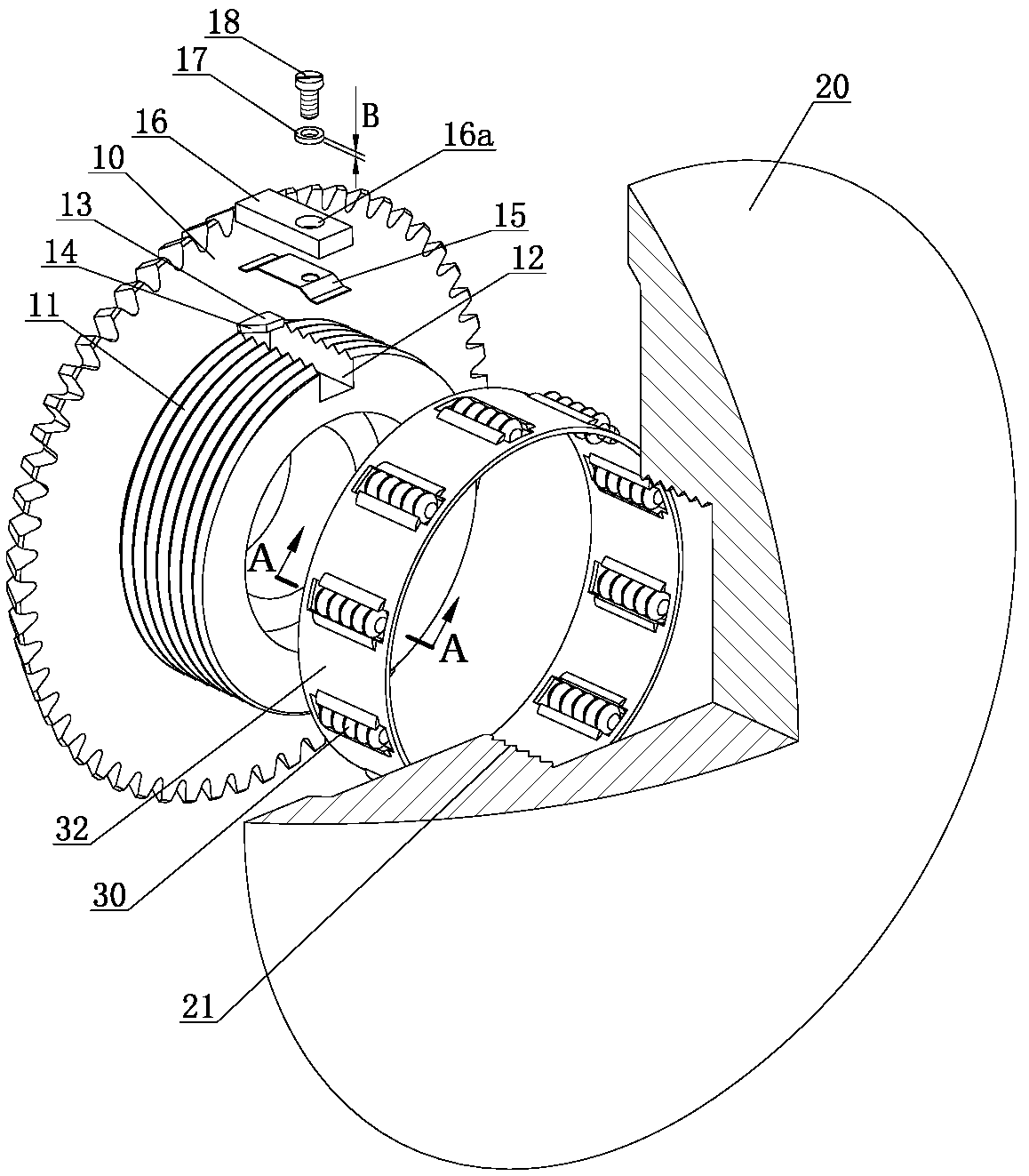

[0044] Such as Figure 7 , Figure 8 , a planetary roller screw top pressure forced sealing ball valve. It includes a valve seat 41, a valve ball and a valve stem 42. The valve ball includes a valve ball body 43 and a valve disc 20. The valve ball body is provided with a screw drive wheel 10 that drives the valve disc to lift and retract. The screw drive wheel passes through the planetary The roller screw unit drives the disc. In this embodiment, discs are provided at both the inlet end and the outlet end of the ball valve. The valve stem drives a sealed driving gear to rotate, and at the same time, the valve ball body is driven to rotate by the torsion spring. When the valve ball body rotates to the closed position, the valve stem drives the valve stem gear 44 to continue to rotate, and the valve stem gear drives the screw drive wheel to rotate. The valve clack is pushed out and pressed against the valve seat to realize the sealing and closing of the forced sealing ball va...

Embodiment 2

[0067] Such as Figure 9 , a planetary roller screw top pressure forced sealing ball valve. This embodiment is a structural replacement of the first embodiment.

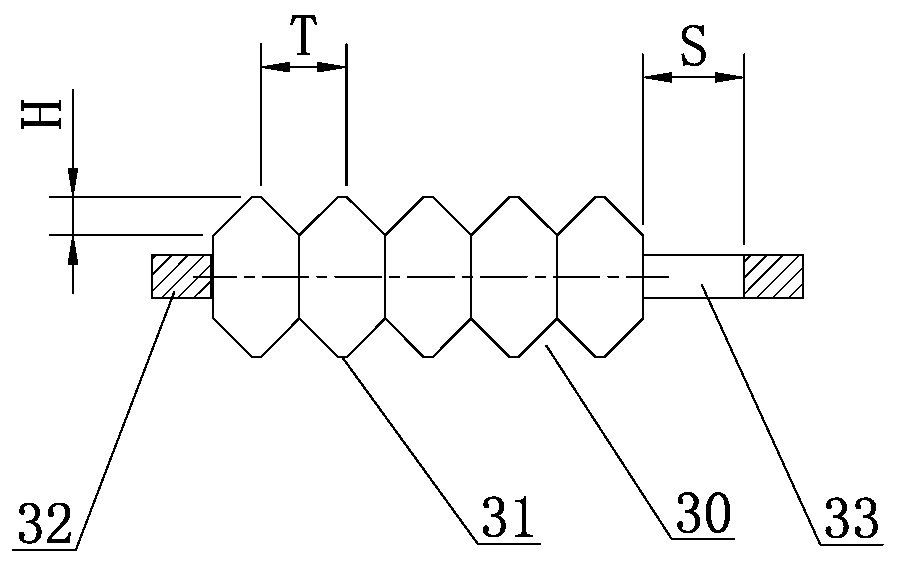

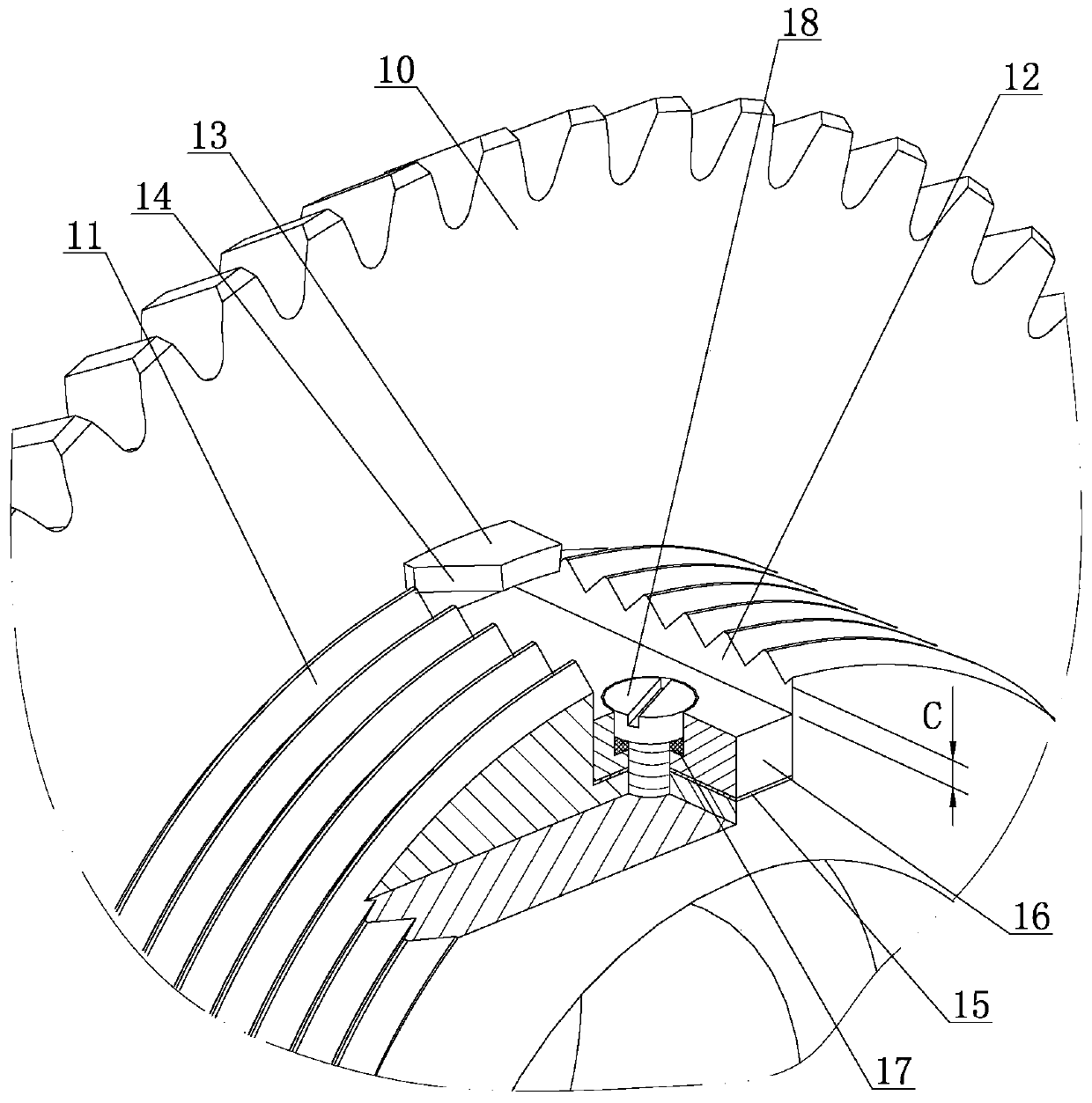

[0068] In this embodiment, the screw drive wheel 10a is provided with a screw hole, and the valve disc 20a is provided with a stud; the pitch of the stud and the screw hole is the same, and a plurality of planetary rollers 30 are arranged between the stud and the screw hole, and the planetary rollers The column is arranged between the stud and the screw hole through the cage 32, a threaded track changing groove 22 is arranged axially on the stud of the valve disc, and a top protrusion is arranged at the end of the threaded track changing groove.

[0069] The bottom surface of the threaded rail change groove is provided with a spring sheet 15, on which a flattening block 16 is arranged, the flattening block is provided with a counterbore, and a hot-melt gasket and a fastening screw 18 are arranged in the counterbore,...

Embodiment 3

[0071] A planetary roller screw top pressure forced sealing ball valve. This embodiment is a structural extension of Embodiment 1 or Embodiment 2.

[0072] In this embodiment, the stud component is provided with multiple turns of concentric studs, and the screw hole component is provided with multiple turns of concentric screw holes corresponding to the studs. By adopting the structure of this embodiment, the large-diameter forced sealing ball valve can be better adapted to the application of high-pressure pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com