Non-rising stem gate valve

A dark stem gate valve and valve stem technology, used in sliding valves, valve details, valve devices, etc., can solve the problems of uneven thickness of rubber layer, uneven thickness of rubber coating, and high operating torque, and achieve uniform valve disc thickness. The effect of accurate lagging and low operating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

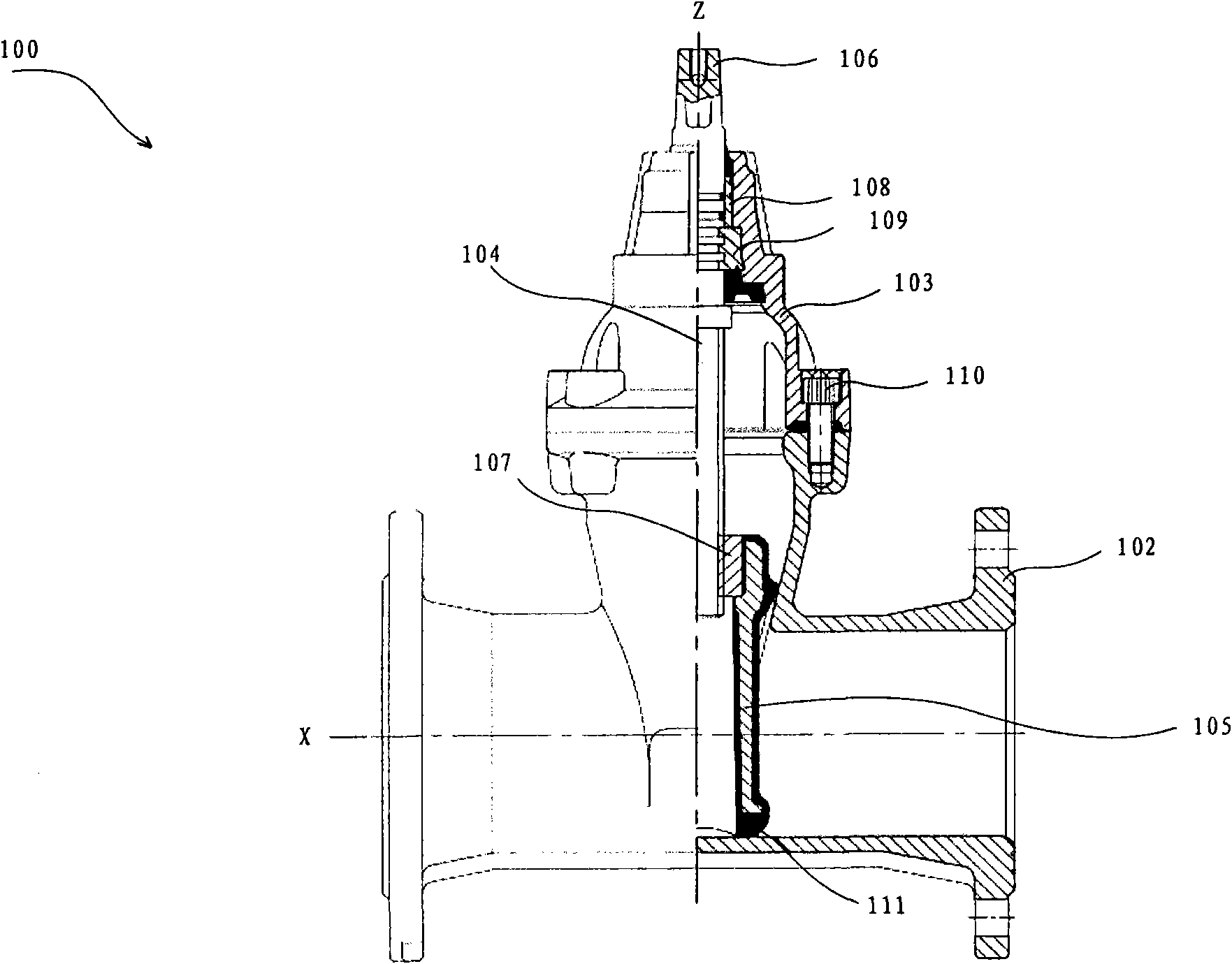

[0040] The specific implementation of the gate valve according to the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that although the features of the present invention are mainly described below in conjunction with an elastic-sealed concealed stem gate valve, the features of the present invention are also applicable to rising stem gate valves or metal-sealed gate valves unless otherwise specified.

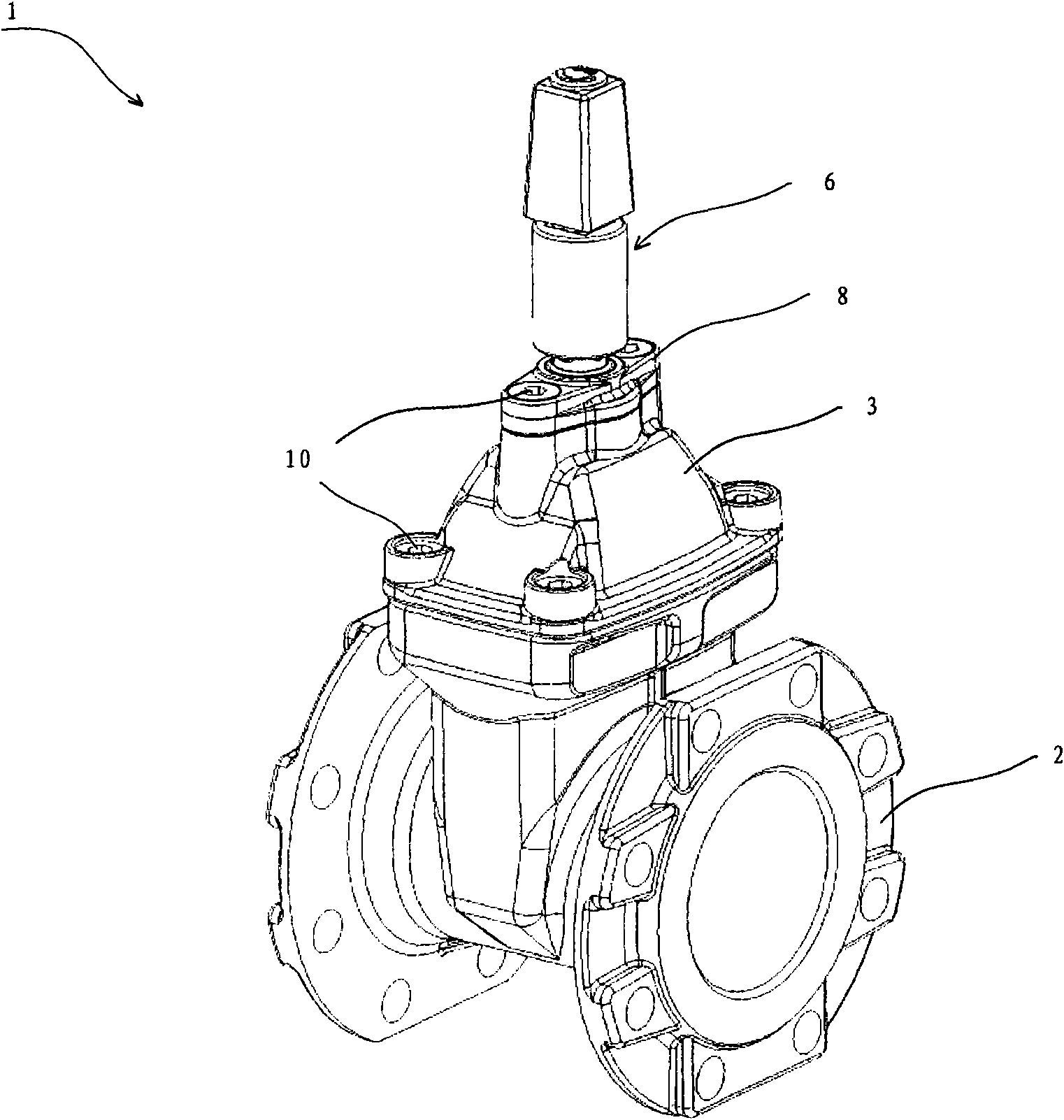

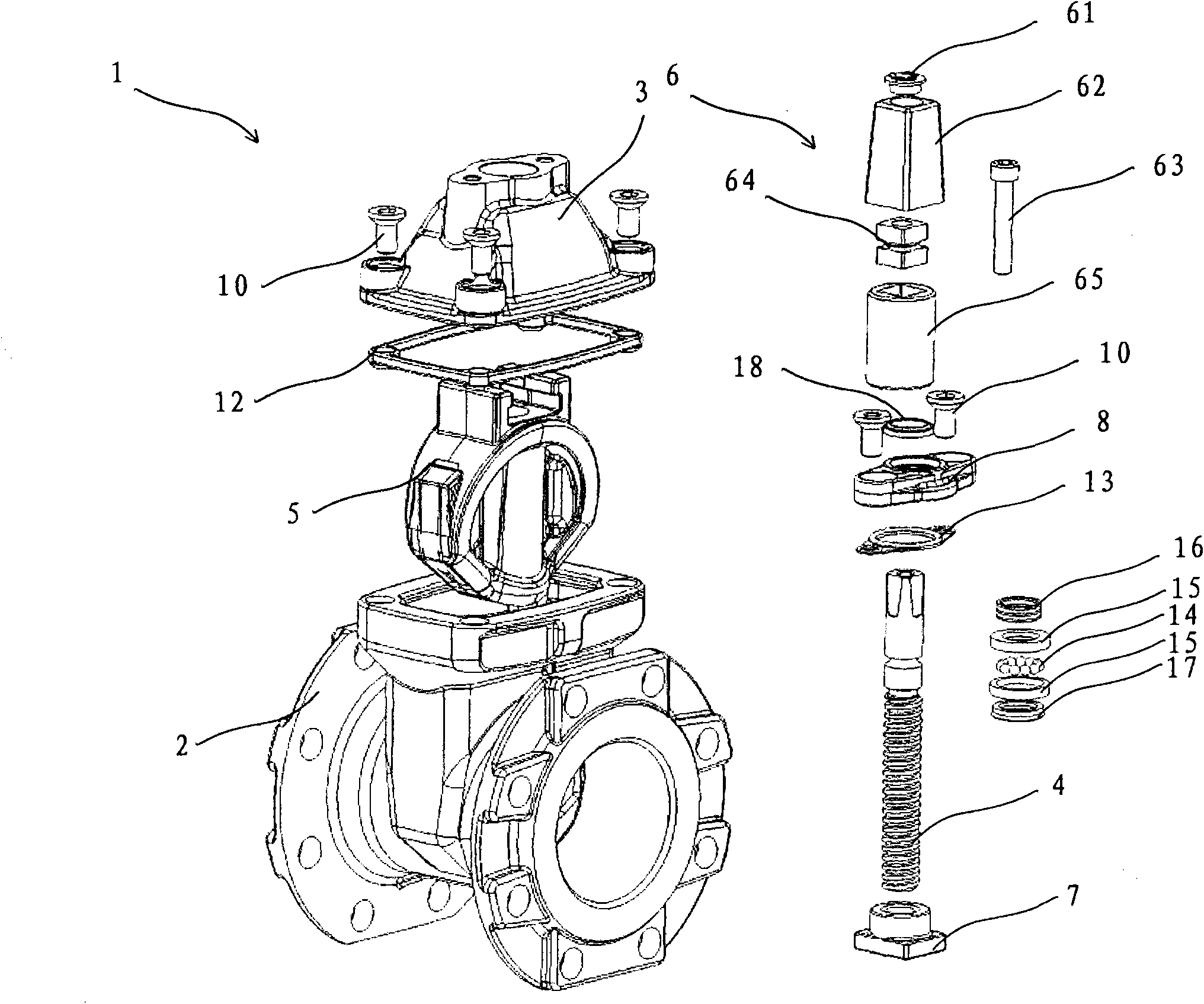

[0041] Such as Figure 2-4As shown, the gate valve 1 according to the present invention includes a valve body 2, a valve cover 3 connected to the valve body 2 by connecting screws 10, a shaft cover 8 connected to the valve cover 3 by connecting screws 10, a valve stem 4, and a valve disc Nut 7, disc 5 and transmission device 6.

[0042] The valve rod 4 is relatively rotatably supported in the inner hole of the valve cover 3 through the rolling bearing 14 and the corresponding bushing 15, so that the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com