Spring Balanced Plug Valve

A spring-balanced, plug valve technology, applied in the field of plug valves, can solve the problems of customer satisfaction, poor sealing performance, unsatisfactory plug valves, etc., to avoid stuck, reduce operating torque, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

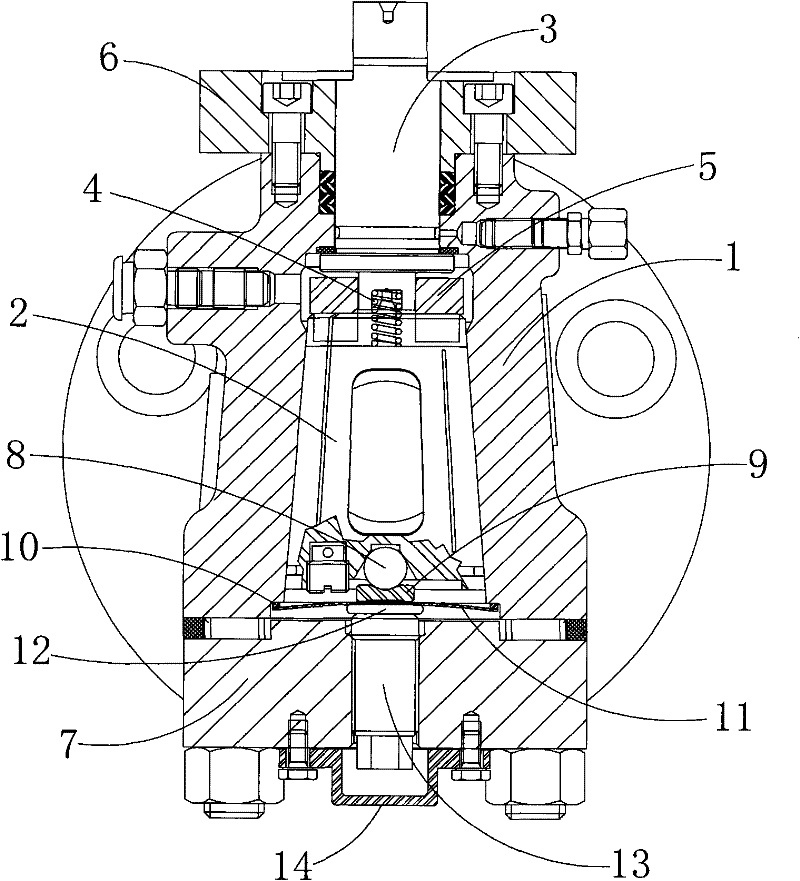

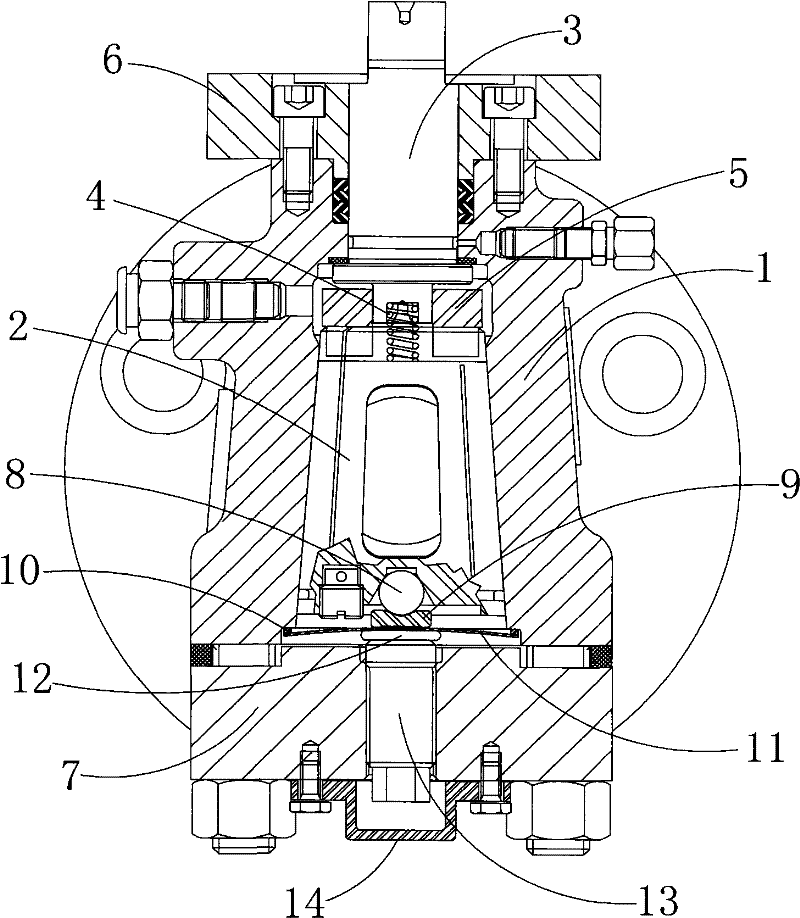

[0024] Embodiment: a spring balanced plug valve, including a valve body 1, a plug 2 and a valve stem 3, the plug is an inverted tapered valve plug, the plug is located in the inner cavity of the valve body, and the valve stem Drive the cock to rotate, an elastic member 4 is provided between the valve stem and the cock, the upper end of the elastic member elastically touches the lower end of the valve stem, the lower end of the elastic member elastically touches the upper end of the cock, and the elastic member is in a compressed state.

[0025] Since there is an elastic piece between the valve stem and the cock, since the elastic piece is in a compressed state, the upward force of the elastic piece acts on the valve stem, the downward force acts on the cock, and the upward force of the elastic piece pushes the valve stem to The valve body makes the step surface of the valve stem in close contact with the thrust pad, thereby playing a good upper sealing effect; the downward for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com