X-shaped electric fixture for cam

A cam and electric technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of limited movement range, only two-point reciprocation, slow response time, etc., to increase reliability, simplify control, and quickly The effect of opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

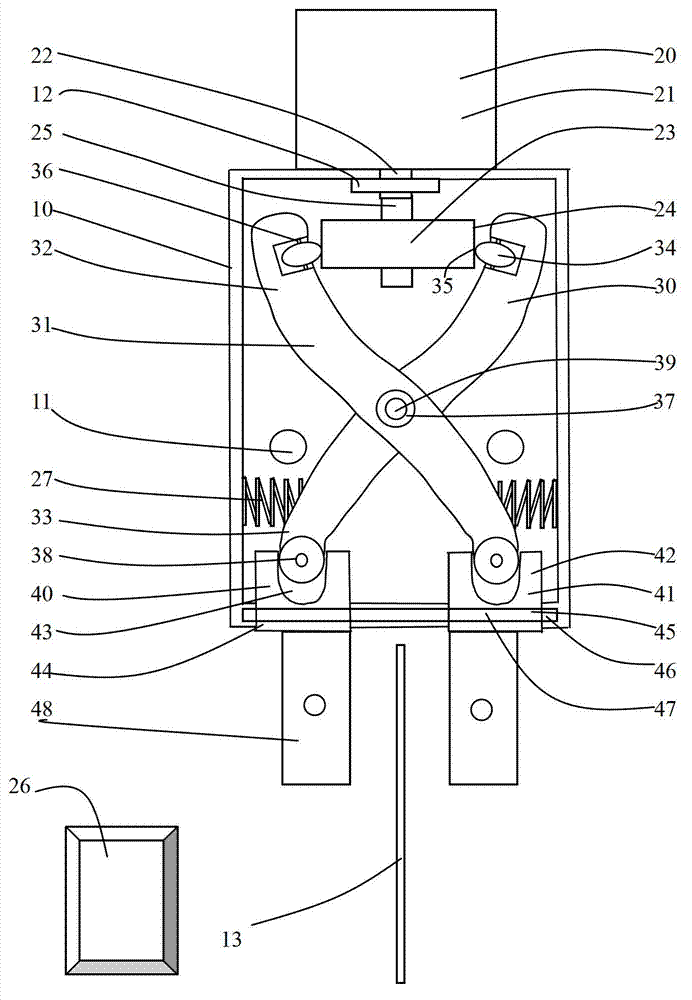

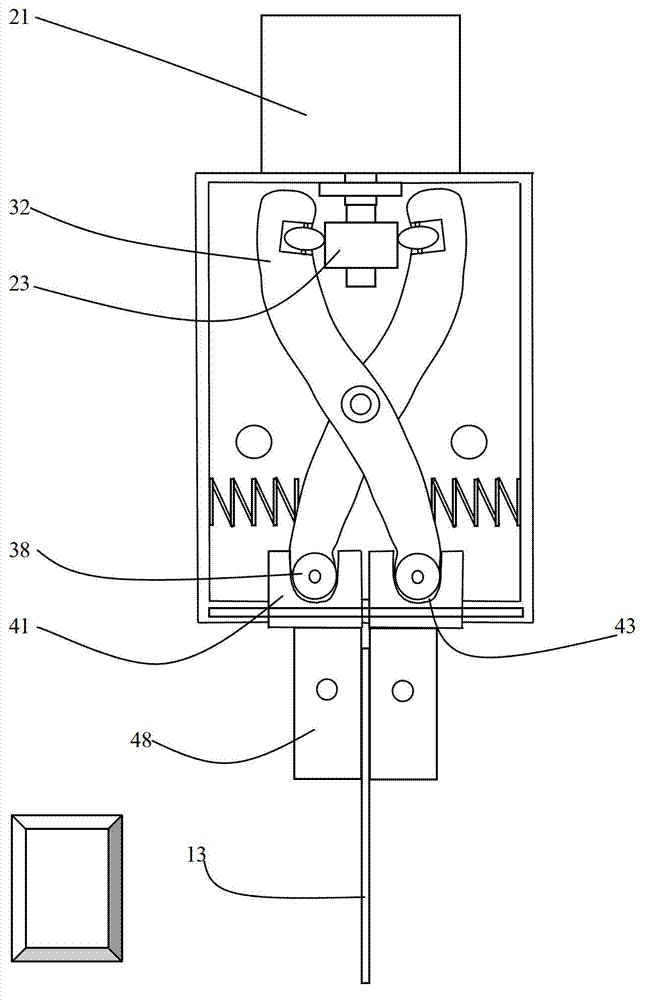

[0023] For the sake of illustration, we define the direction connecting the rotating motor and the cross column as the longitudinal direction, the direction 90 degrees to the longitudinal direction as the horizontal direction, the end close to the rotating motor as the upper end, and the end far from the driver as the lower end, and the cross column as the The center of the inside, and the sides of the inside are the outside. The housing of the embodiment has a cover, and the cover is not shown in the accompanying drawings. The wiring connections of the embodiments are not shown in the accompanying drawings.

[0024] In the following, an example of the X-type cam electric clamp provided by the present invention will be specifically described according to the accompanying drawings.

[0025] Refer to attached figure 1 , with figure 1 It is a schematic front view of the extended state of the clamping jaws of the X-type cam electric gripper of the rotary motor. In the figure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com