Patents

Literature

53results about How to "No crushing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

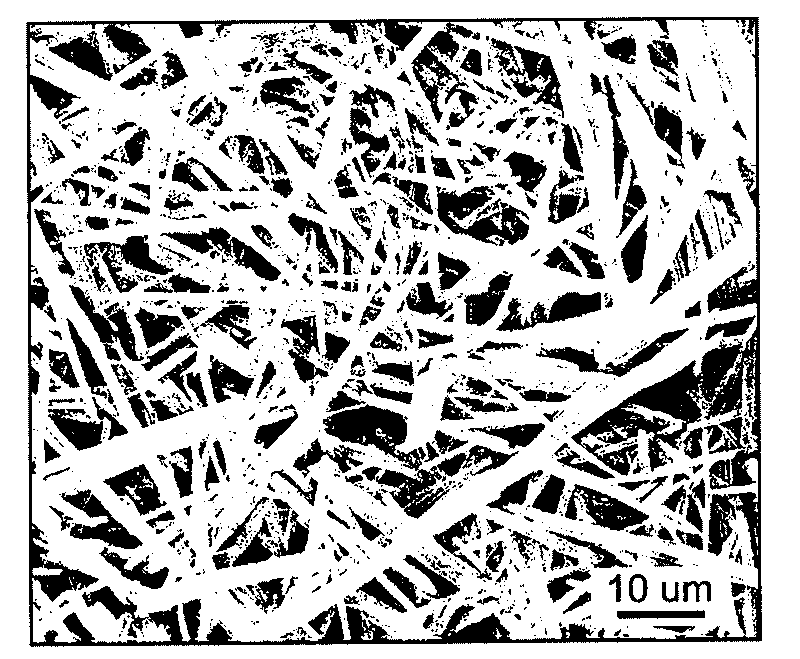

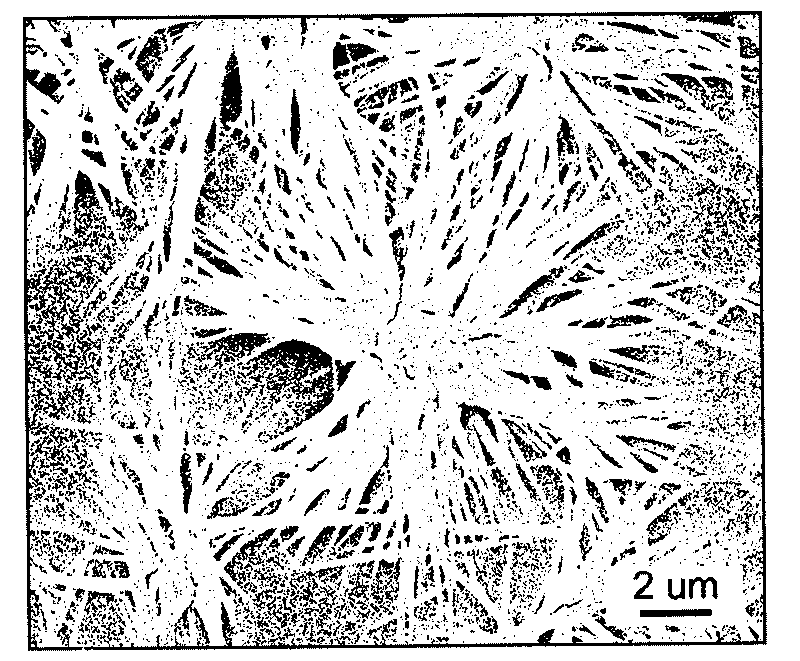

Silicon-containing composite material and its preparation method and application

ActiveCN101210119ASimple processReduce energy consumptionPigment treatment with macromolecular organic compoundsState of artLithium

The invention provides a siliceous composite material, comprising silicon particles and a clad wrapped on the surface of silicon particles, wherein, the clad is conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as the clad; the polymer does not need to be transformed further into 'hard carbon', and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is ensured to have high reversible capacity and good cycle performance. Therefore, the invention can be taken as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Silicon-containing composite material and its preparation method and application

ActiveCN101210112ASimple processReduce energy consumptionCell electrodesPigment treatment with macromolecular organic compoundsLithiumConductive polymer

The invention provides a siliceous composite material, comprising silicon particles, graphite particles and conducting polymer, wherein, the conducting polymer is wrapped on the surface of the graphite particles; at least part of the silicon particles is adhered to the surface of the conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as a clad material; the polymer does not need to be transformed further into 'hard carbon' and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is guaranteed to have high reversible capacity and good cycle performance. Therefore, the invention can be used as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Preparation method of hydroxy methionine salt and compound

The invention provides a preparation method of hydroxy methionine salt and a compound, comprising the following steps: a. feeding metal hydroxide or basic metal oxide or amphoteric metal oxide and 2-hydroxy-4-methylthiobutyricacid into a closed and corrosion resistant reaction kettle to react for 0.5-12h according to a stoichiometric ratio, taking the low-boiling polar organic solvent or the mixed solvent thereof with water as the reaction medium, stirring, separating the target product, washing and drying to obtain the products; and b. recycling the reaction medium. The preparation method of the invention has short route, no consumption of acid or alkali reagent, low cost, easily-controllable product quality, environmental friendliness and the like, thus being applicable to large-scale industrial production.

Owner:李宁 +1

Method for producing bioorganic fertilizer from pig manure

InactiveCN101565331AReduce nutrient lossShorten the ripening timeBio-organic fraction processingClimate change adaptationNitrogenOrganic fertilizer

The invention discloses a method for producing a bioorganic fertilizer from pig manure, which comprises that: fresh pig manure of which the water content is about 65 percent is mixed with sawdust in proper proportion to make the ratio of carbon to nitrogen be between 16 and 25; the mixture is evenly stirred with geotrichum or Bacillus stearothermophilus zymophyte; composting fermentation is carried out; and the heap is turned regularly, when the temperature of the materials is reduced to the ambient temperature, and the materials are baked or dried by air and crushed to become the finished product of the bioorganic fertilizer. The bioorganic fertilizer has the nutrient content of 7 percent and the organic content of over 50 percent.

Owner:ANHUI AGRICULTURAL UNIVERSITY

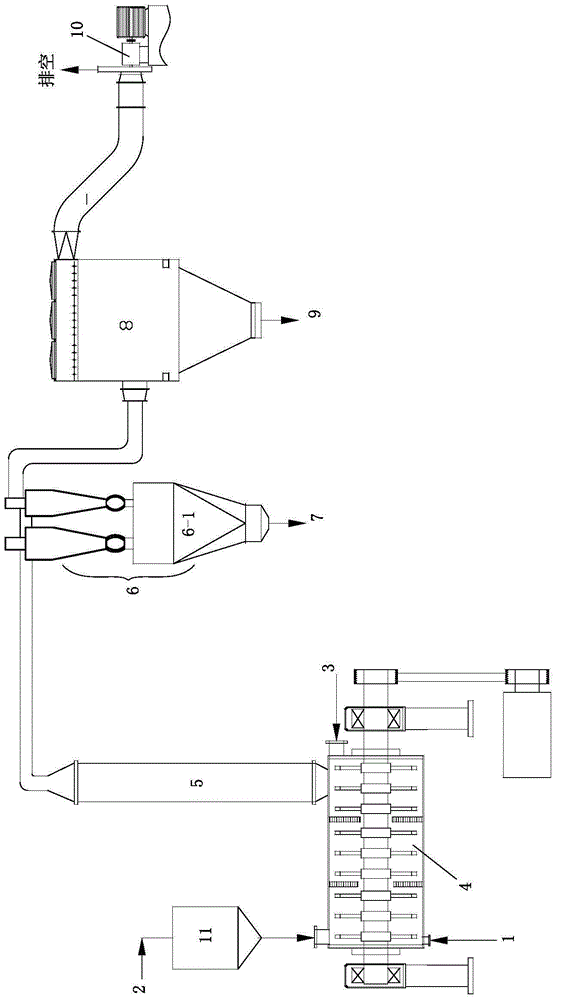

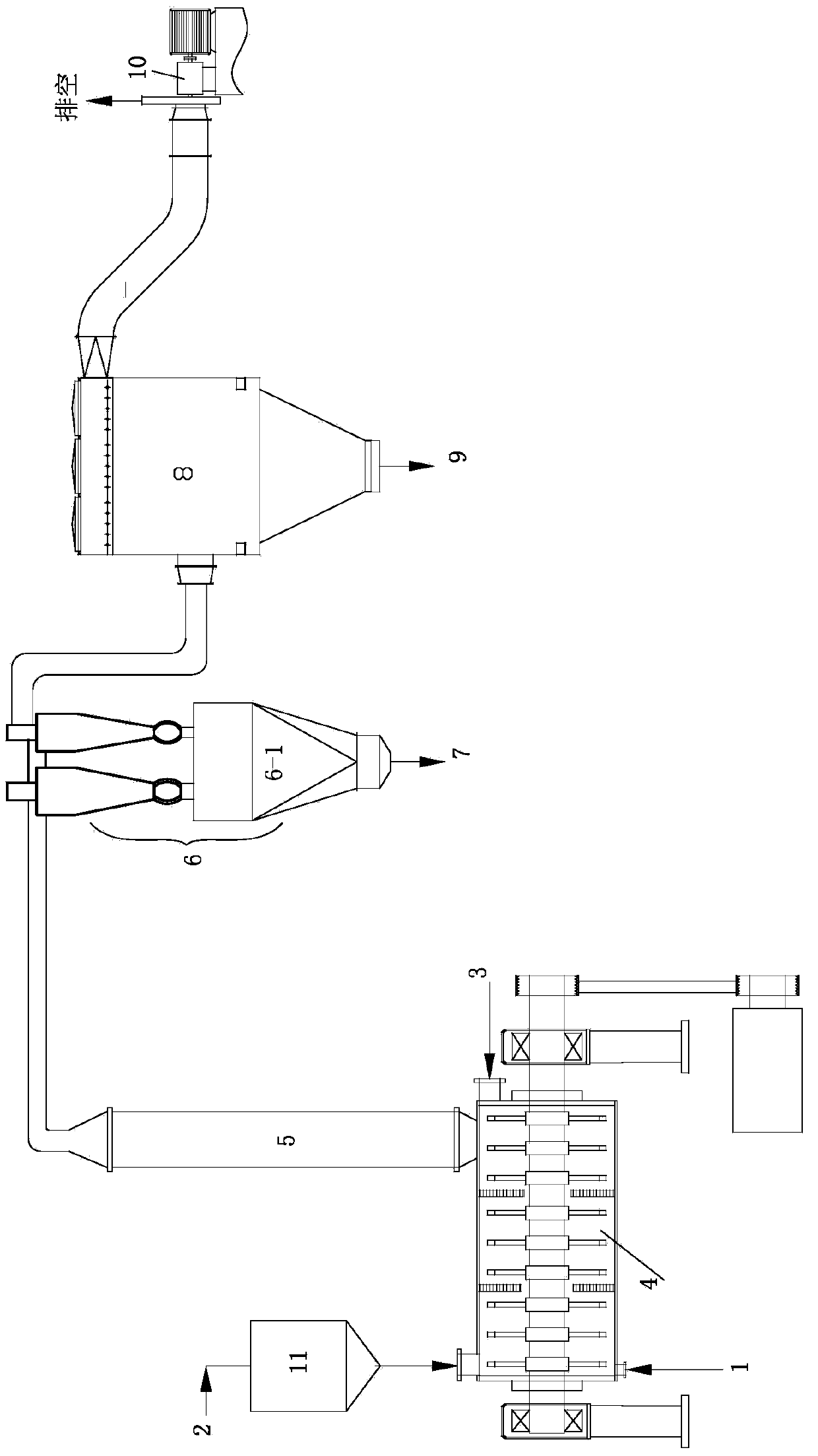

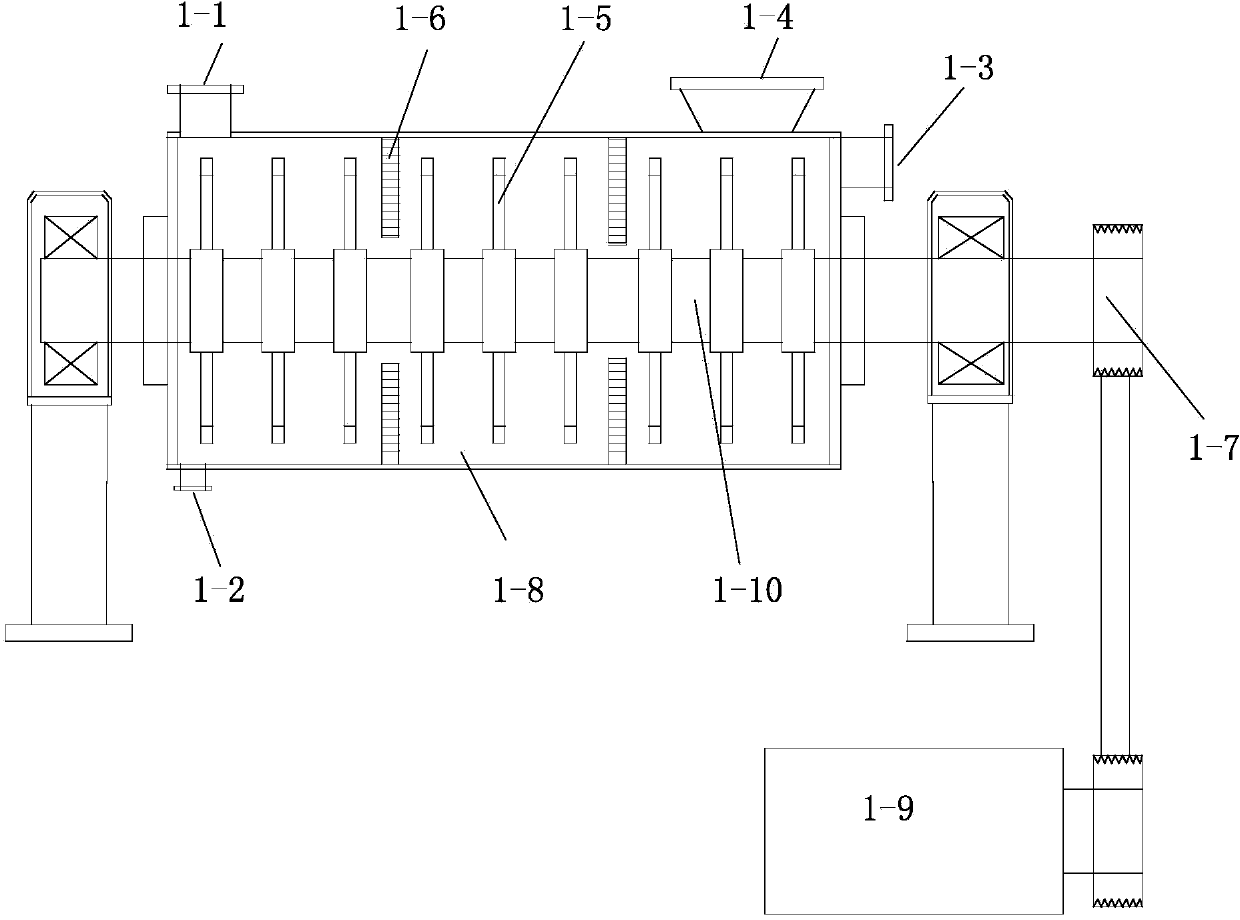

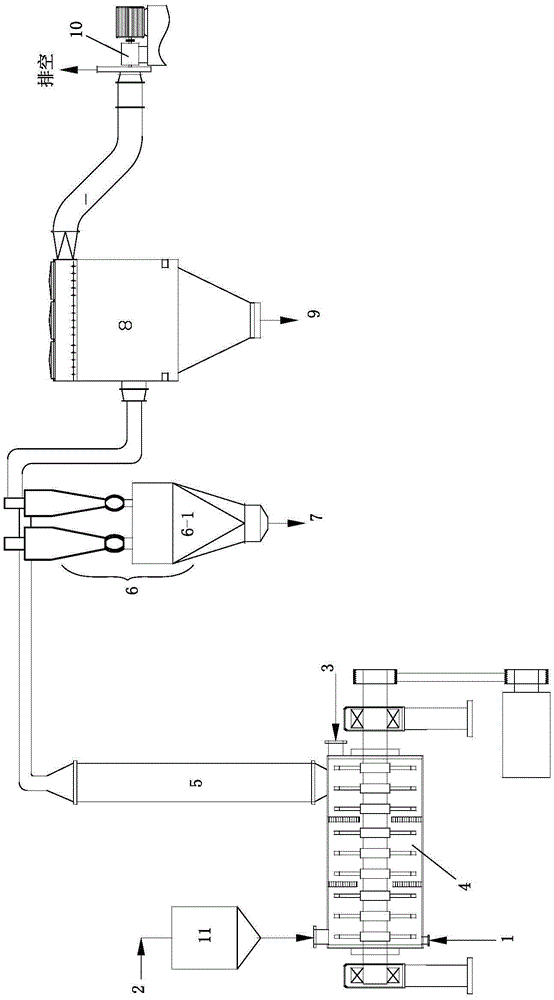

Process and device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles

ActiveCN103820253AImprove low temperature solubilityImprove energy utilizationSurface-active detergent compositionsDetergent powders/flakes/sheetsChemistryAirflow

The invention relates to a process and a device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles. A process flow is simple, and the provided preparation device is simple in structure. According to the technical scheme, the process for continuously preparing the powdery MES particles comprises the following steps of (1) causing a powdery mixture of a neutralizer, a wrapper and a stabilizer and fatty acid methyl ester acid ester to enter a high-shear reactor according to a certain proportion; (2) forming MES particles, and causing the MES particles to enter a flash dryer; (3) keeping the obtained MES particles at certain granularity; (4) causing mixed airflow discharged from an outlet of the flash dryer to enter a cyclone separator for separation; (5) obtaining a finished product. The device for continuously preparing the powdery MES particles comprises the high-shear reactor, the flash dryer, the cyclone separator, a bag-type dust collector and an induced draft fan, which are sequentially communicated, wherein the high-shear reactor is provided with an acid ester inlet, a powder inlet, an air inlet and a material outlet communicated with the flash dryer respectively.

Owner:ZANYU TECH GRP CO LTD +1

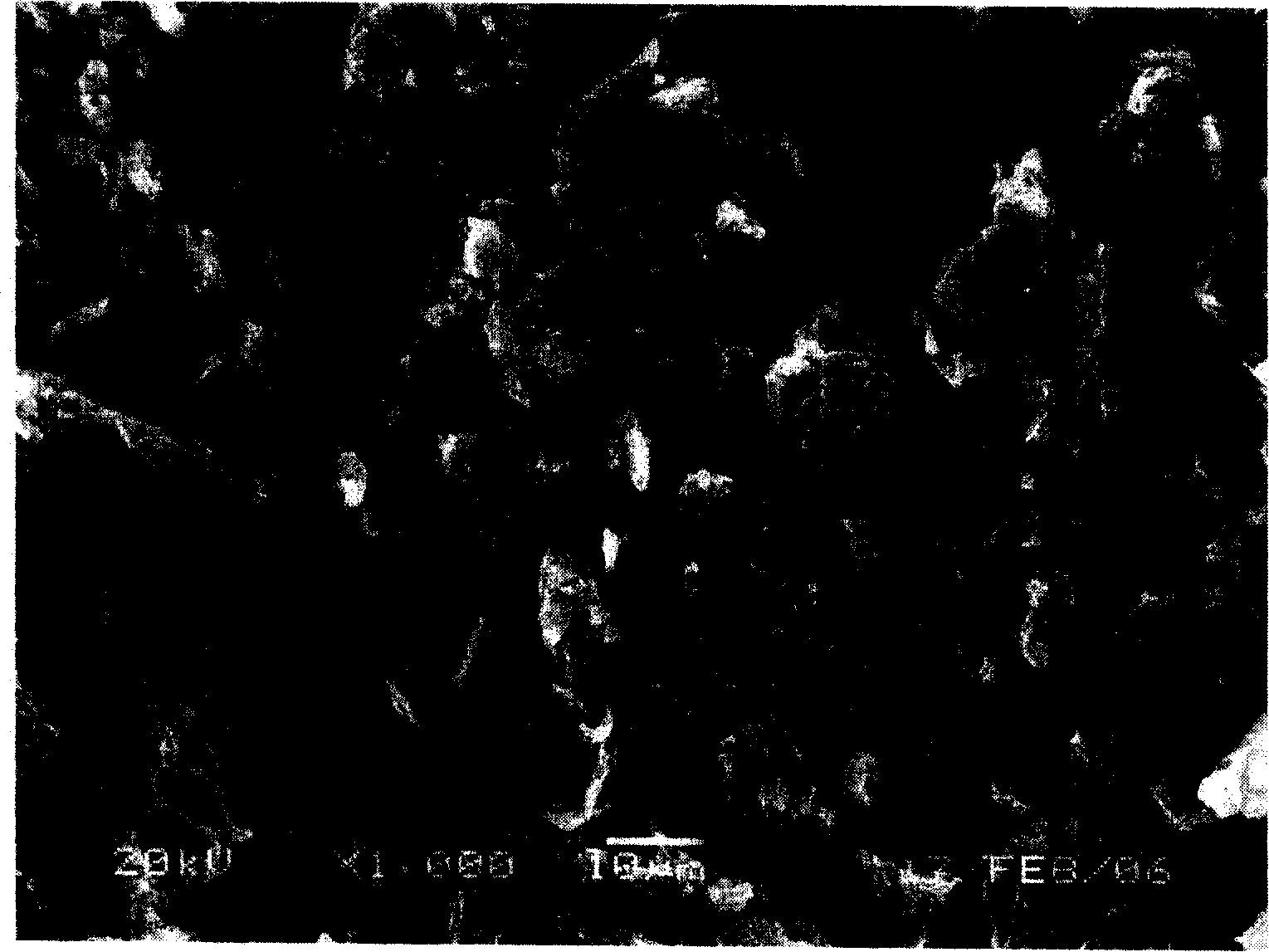

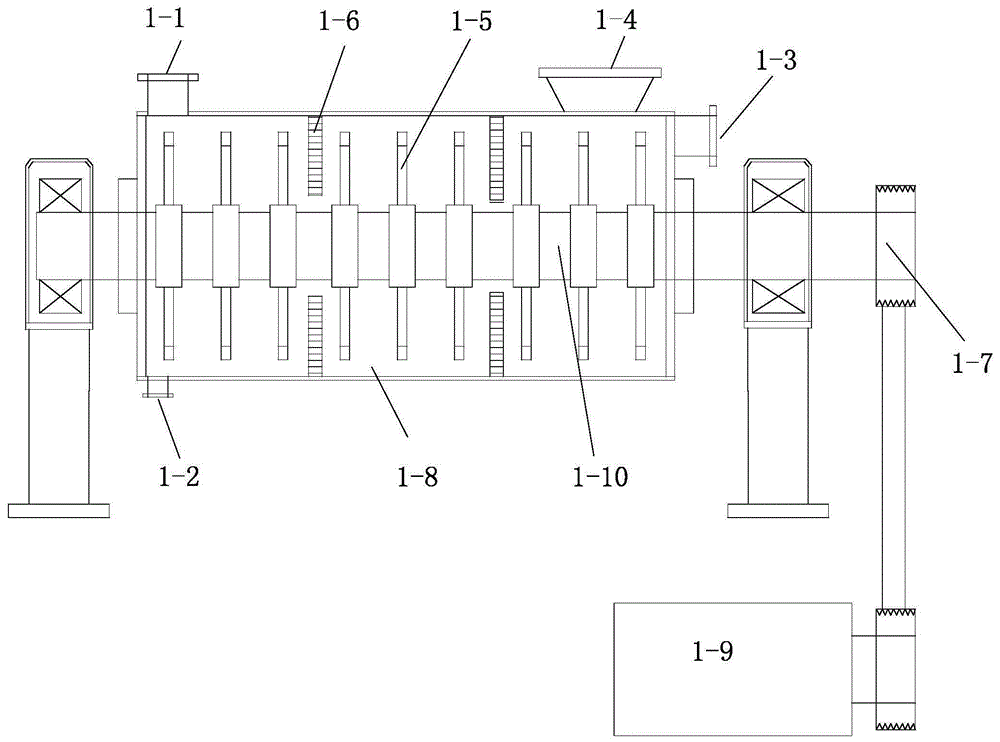

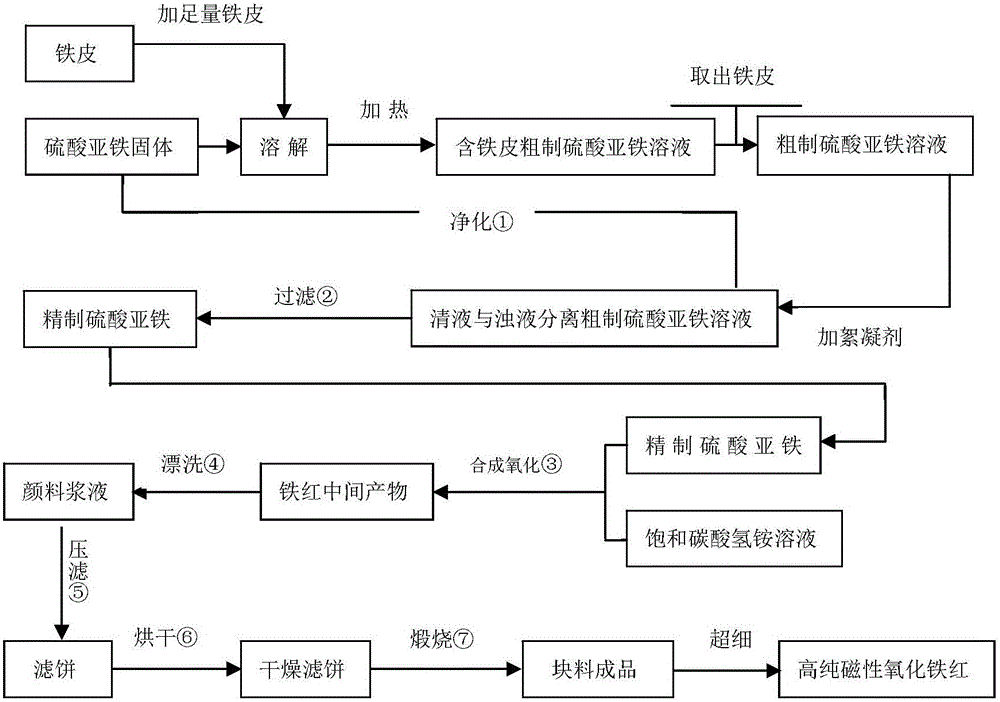

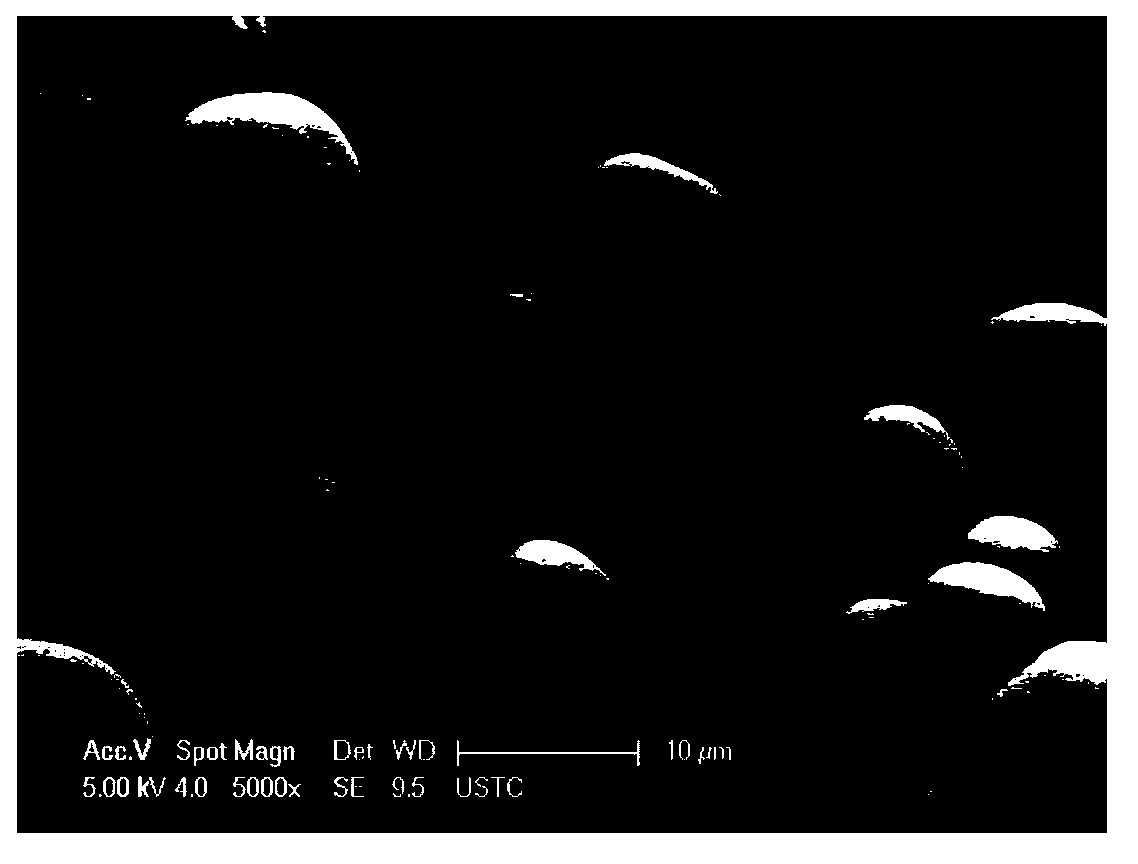

Method for preparing high-purity gamma-Fe2O3 iron oxide red pigment

InactiveCN105110382AEasy to filter washNo crushing requiredFerric oxidesSulfateFerric hydroxide oxide

The invention relates to a method for preparing high-purity gamma-Fe2O3 iron oxide red pigment. The method includes the following steps: firstly, dissolving the ferrous sulfate solid in water, controlling the obtained solution to be at a certain temperature, adding a certain amount of a flocculating agent, and keeping at a certain temperature; after a certain time, filtering to obtain a refined ferrous sulfate solution; adding saturated ammonium bicarbonate solution into the refined ferrous sulfate solution for synthesizing iron carbonate and iron hydroxide precipitate with high magnetic properties under the conditions of a certain temperature and a pH value. According to the invention, the method is low in cost and simple and convenient to operate; the obtained product is high in stability and suitable for industrial production.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Polyamide microspheres and preparation method thereof

The invention belongs to the technical field of polymer materials, and discloses polyamide microspheres and a preparation method thereof. The polyamide microspheres are prepared from a polymer A, a lactam monomer B, a catalyst, a cocatalyst or / and a solvent, wherein the weight ratio of the polymer A to the lactam monomer B is 5:95 to 40:60, and the catalyst accounts for 0.2-5wt% of the total weight of the polymer A and the lactam monomer B; the cocatalyst accounts for 0.2-10wt% of the total weight of the polymer A and the lactam monomer B; and the solvent accounts for 50-500wt% of the total weight of the polymer A and the lactam monomer B. The invention also discloses the preparation method of the microspheres. According to the preparation method disclosed by the invention, any anionic polymerization initiator is not additionally added, the good solubility of the lactam monomer and the reaction characteristic of anionic ring-opening polymerization are used for preparing the polyamide microspheres through a one-step method, the process time is shortened, and the preparation method is more efficient and faster.

Owner:ホーフェイジーニアスアドバンストマテリアルカンパニーリミテッド

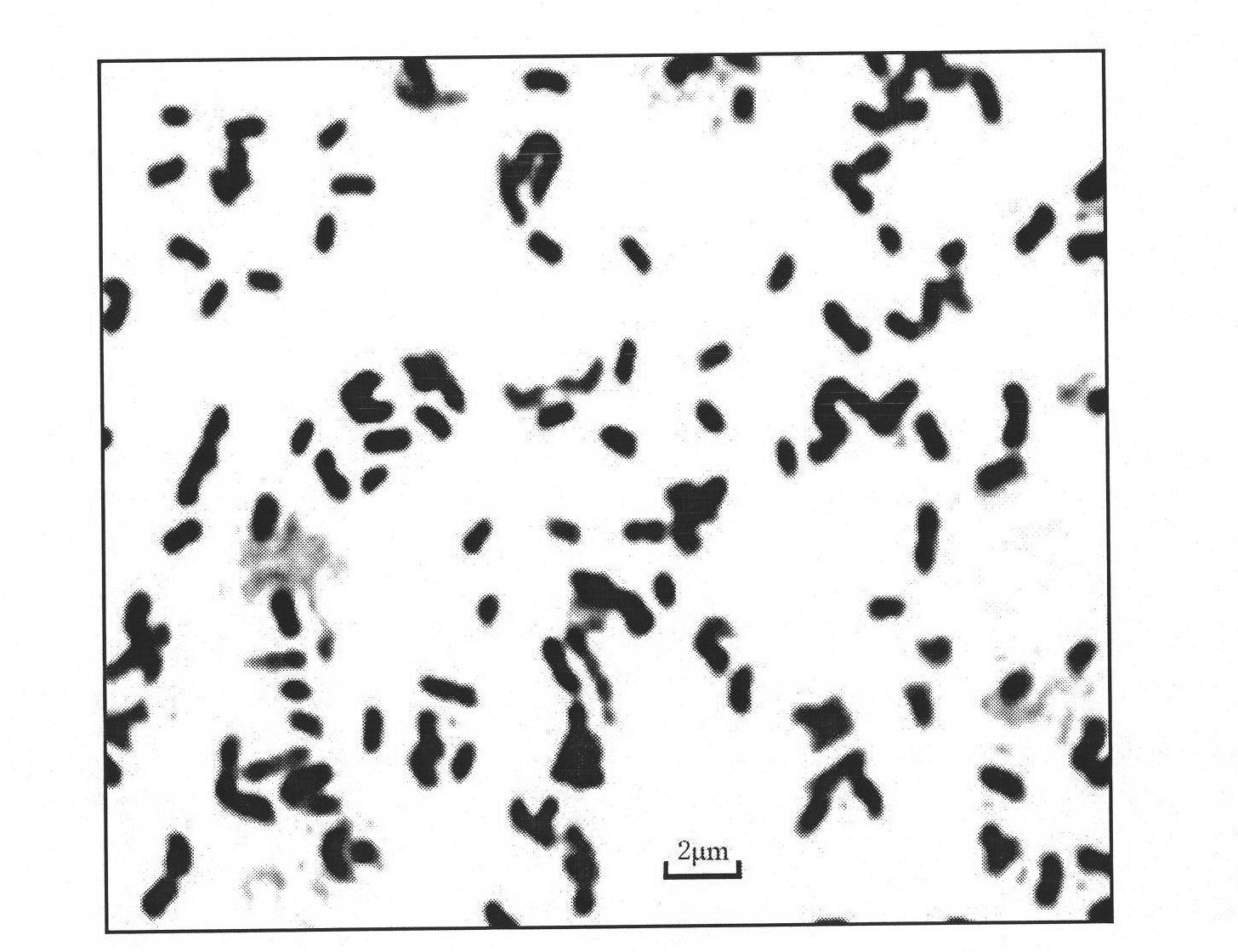

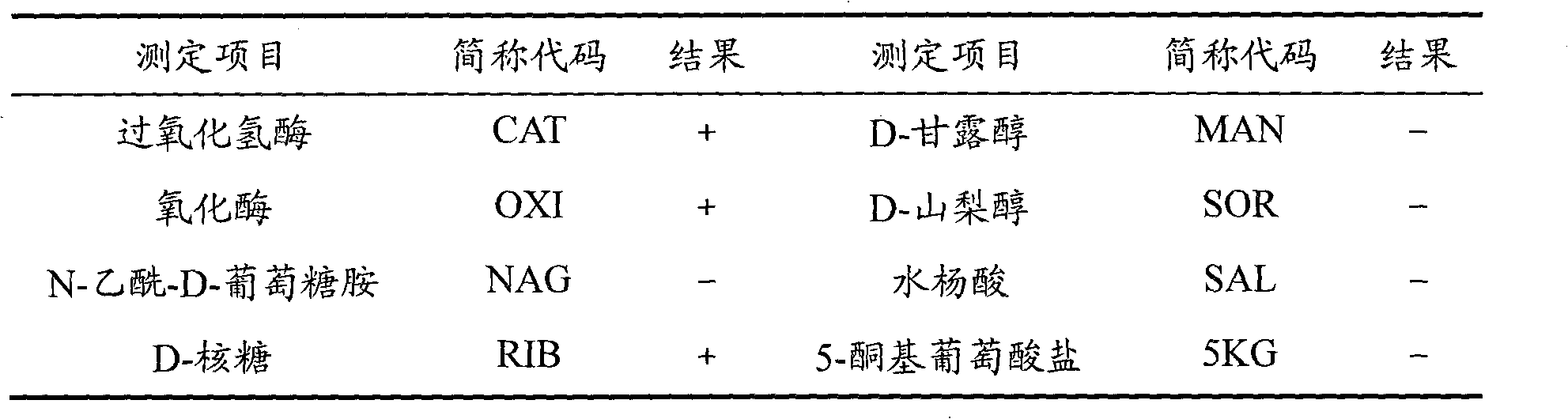

Roseobactersp.zjut and application thereof in preparation of agaro-oligosaccharide

The invention provides a novel agarase generating strain (roseobactersp.zjut) and application thereof in the preparation of agaro-oligosaccharide. The roseobactersp.zjut is preserved in the China Center for Type Culture Collection, the collection number is CCTCC No. M 209292, and the preservation date is December 3, 2009. The roseobactersp.zjut and the application thereof in the preparation of the agaro-oligosaccharide have the advantages that: (1) the roseobactersp.zjut of the invention has low requirements on nutrition and can be easily cultured; (2) agarase generated by the roseobactersp.zjut is an extracellular enzyme, separation and purification are convenient, and cell breakage is not required; (3) the roseobactersp.zjut has high agarase generating activity, and the activity of crude agarase liquid which is not separated and purified can reach 215.8U / ml under optimized conditions; (4) the agarase generated by the roseobactersp.zjut degrades agar under mild reaction conditions, and the reaction time is short; and (5) the agarase in the invention has high stability and basically has no enzyme activity loss (inactivation efficiency is less than or equal to 5 percent) after being stored in a refrigerator for 7 days at the temperature of less than 4 DEG C.

Owner:ZHEJIANG UNIV OF TECH

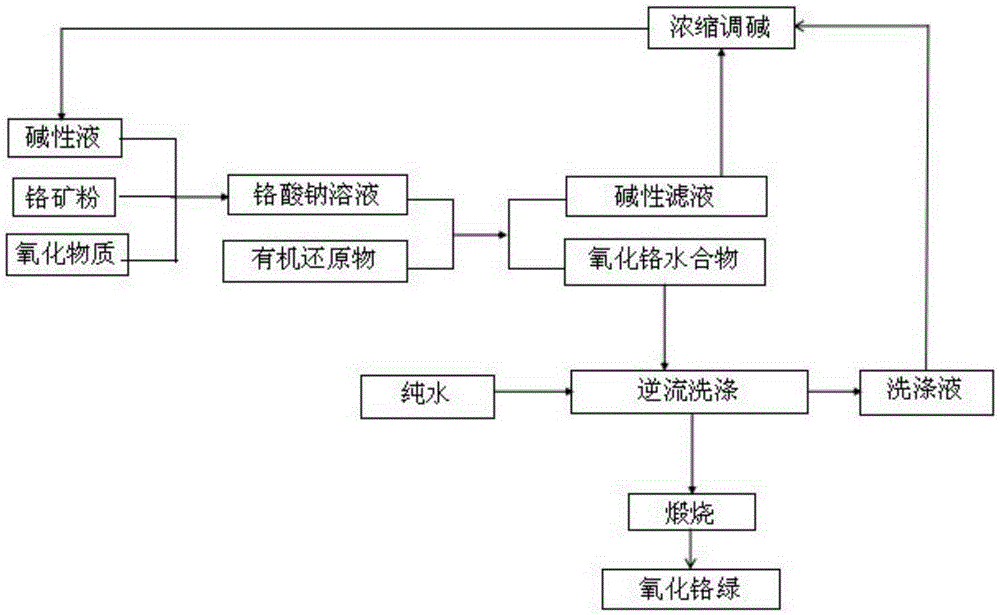

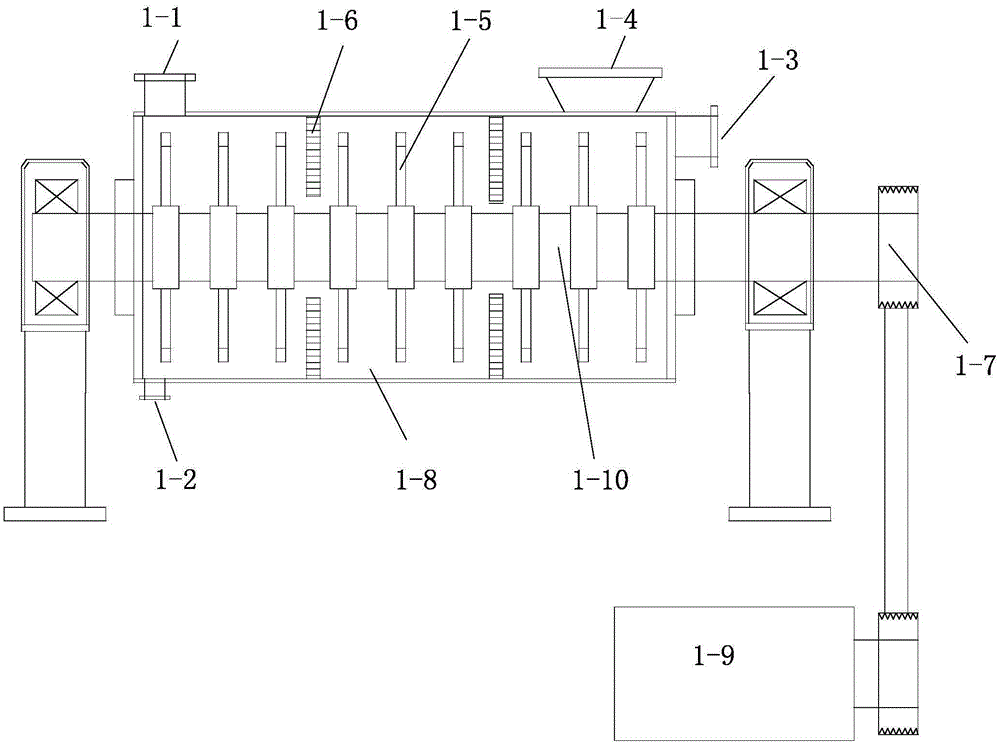

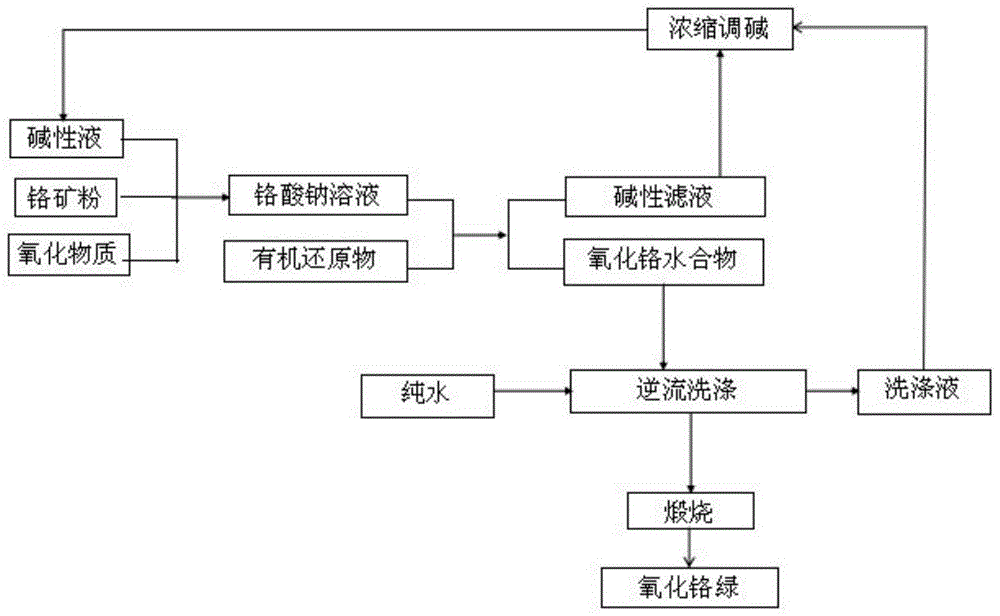

Method for producing chromium oxide green through sodium circulation

ActiveCN105366724ASimple processLow costChromium trioxideEnvironmental resistanceReducing substances

The invention discloses a method for producing chromium oxide green through sodium circulation. The method comprises the following steps: adding powdery chromite ores or ferrochromium powder into an alkali solution and introducing oxidation materials for reaction, and separating to obtain a sodium chromate alkali solution after full reaction; adding organic reducing substances into the sodium chromate alkali solution, after hydrothermal reaction, filtering and separating to obtain chromic oxide hydrate and alkali filter liquor; performing countercurrent washing on the chromic oxide hydrate and recycling the washing liquid; calcining the chromic oxide hydrate after washing in a high temperature furnace to obtain chromium oxide green; concentrating and performing alkali modulation on the alkali filter liquor and the washing liquid, and further returning the alkali filter liquor and the washing liquid after concentration and alkali modulation, so as to serve as the alkali solution to realize cyclic utilization of sodium resource in the technological process. Compared with the conventional preparation process of chromium oxide green, the method for producing chromium oxide green, provided by the invention, has the advantages that the production technical process is short, the operation is simple, and the prepared chromium oxide green is high in quality; besides, cyclic utilization of sodium resources in the production technology process is realized, and zero emission of the three wastes is also realized, so that the method is an environment-friendly and clean novel method for producing chromium oxide green.

Owner:绵阳市安剑皮革化工有限公司

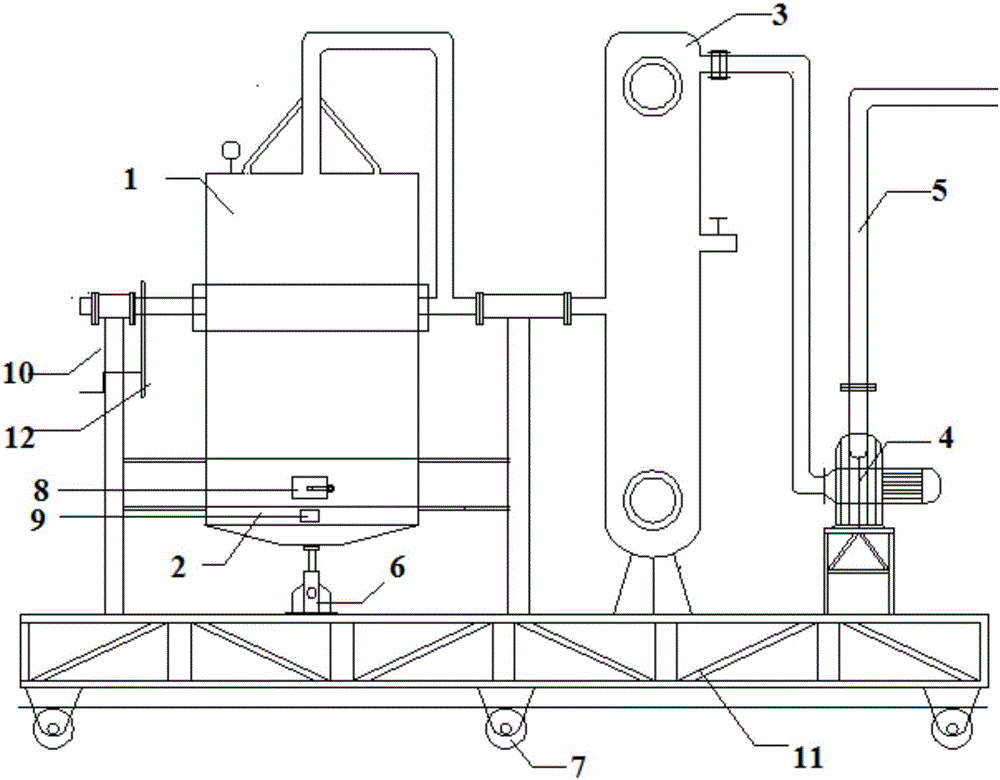

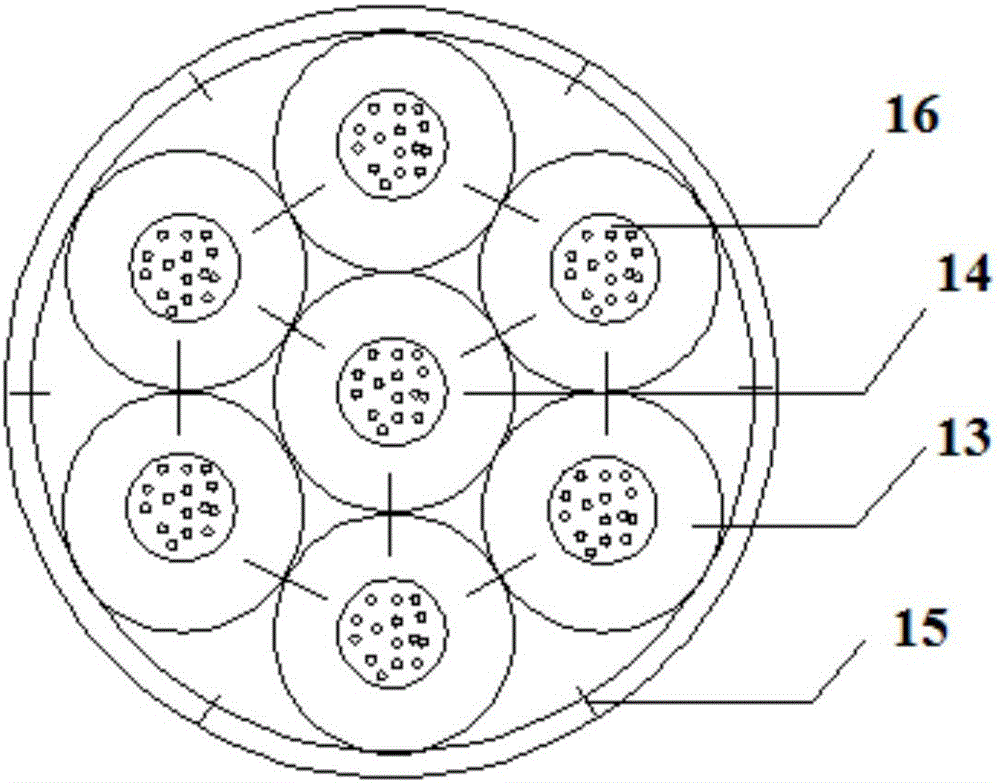

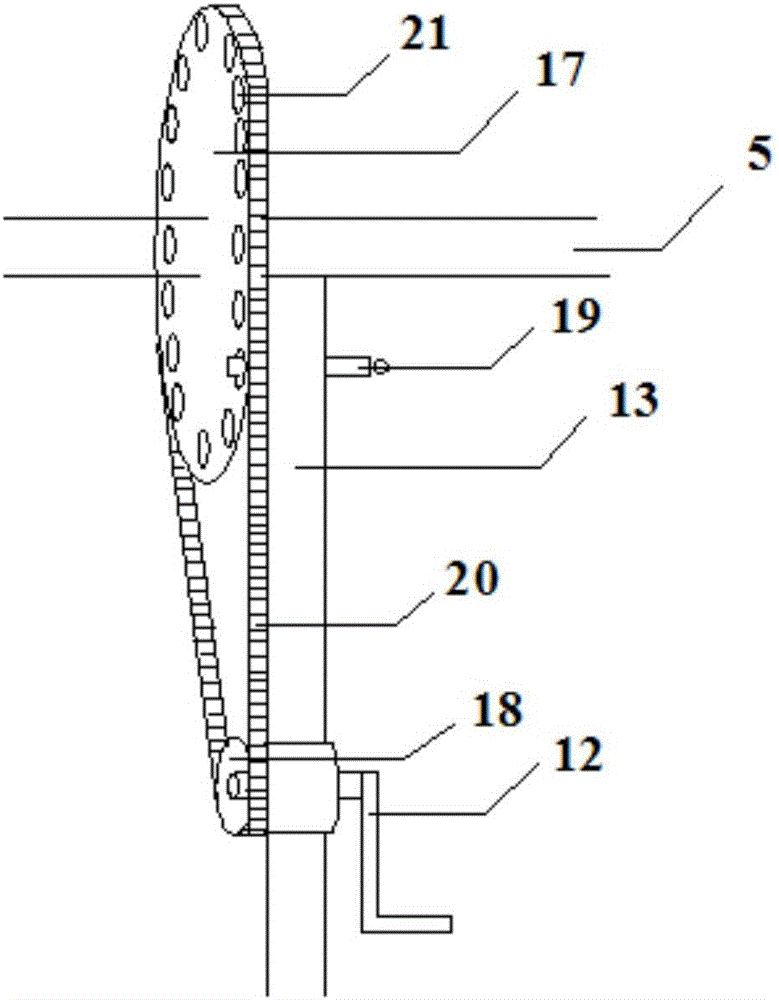

Low-consumption environment-friendly biochar production equipment

ActiveCN106010599ANo crushing requiredSave energyCombination devicesGas treatmentCombustion chamberCombustible gas

The invention relates to low-consumption environment-friendly biochar production equipment, which consists of a pedestal, a carbonization furnace, a gas purification device, a draught fan, an exhaust pipeline, a thermometer, a carbonization chamber support, a combustion chamber fixation bracket and a rotary handle. The carbonization furnace is composed of a carbonization chamber and a combustion chamber. The combustion chamber bottom is fixed on the pedestal through the combustion chamber bracket. The upper part of the carbonization chamber is movably fixed on a cross beam, and the carbonization chamber can turn freely and rotate around the cross beam. A set of gear linkage system is fixed on a steel pipe at the front end of the carbonization chamber support to adjust the inclination angle of the carbonization chamber. The carbonization chamber, the exhaust gas purification device and the draught fan are communicated through the exhaust pipeline. The carbonization chamber is internally provided with several independent pyrolysis chambers. While saving energy and protecting the environment, the equipment provided by the invention also can rapidly and effectively pyrolyze biomass into biochar, and utilizes the combustible gas generated by biomass pyrolysis to heat itself.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Process and device for continuously preparing powdery washing powder particles

ActiveCN103773618ASuitable for granulationReduce energy consumptionNon-ionic surface-active compoundsDetergent mixture composition preparationCyclonic separationBaghouse

The invention relates to a process and a device for continuously preparing powdery washing powder particles. The process provided by the invention is simple in adopted equipment and high in production efficiency. The provided preparation device is simple in structure. The technical scheme is as follows: the process comprises the following steps: (1) a powdery mixture of a neutralizing agent and a wrapping agent and organic-material acid ester enter a high-shearing reactor according to a certain proportion; (2) the formed washing powder particles are output and then enter a flashing dryer; (3) certain particle size is maintained for the obtained washing powder particles; (4) mixed gas flow from an outlet of the flashing dryer enters a cyclone separator for separation; and (5) a finished product is obtained. The device comprises the high-shearing reactor, the flashing dryer, the cyclone separator, a cloth-bag dust remover and an induced draft fan which are communicated in sequence; and the high-shearing reactor is provided with an acid-ester inlet, a powder inlet, an air inlet and a material outlet communicated with the flashing dryer.

Owner:ZANYU TECH GRP CO LTD +1

Preparation method of poly (acrylic acid-vinyl acetate)-polyvinyl alcohol interpenetrating network super absorbent resin

InactiveCN103937139AImprove water absorptionImprove salt tolerancePotassium persulfatePolymer science

The invention relates to a preparation method of poly (acrylic acid-vinyl acetate)-polyvinyl alcohol interpenetrating network super absorbent resin. The preparation method is characterized by comprising the following steps: 1) dissolving acrylic acid solution, vinyl acetate, polyvinyl alcohol solution, cross-linking agent, namely N, N-methylene-bis-acrylamide and initiator, namely potassium persulfate in distilled water, then adding into an oil phase comprising cyclohexane and dispersant, stirring for about 15-30min, then heating to 50-90 DEG C under the protection of nitrogen, stirring and reacting for 2.0h, wherein the reaction temperature is 50-90 DEG C; 2) filtering after the end of reaction, washing with methanol three times, and washing with ethanol once; 3) soaking the obtained product in anhydrous ethanol for 6.0h, and performing suction filtration and vacuum drying so as to obtain white granular resin. An interpenetrating network polymer with anions and non-ions is formed through an interpenetrating network technology, and the interpenetrating network polymer has better salt resistance and water absorption.

Owner:NORTHWEST UNIV(CN)

Method for producing culture material of edible fungi by utilizing cellulosic ethanol factory waste material

InactiveCN102161603ARaw materials are easy to getReduce manufacturing costBio-organic fraction processingClimate change adaptationFiberPhosphoric acid

The invention relates to a method for producing a culture material of edible fungi by utilizing a cellulosic ethanol factory waste material. In the method, the cellulosic ethanol factory waste material is adopted and mainly comprises a waste material generated in the crushing process of straw raw materials and fermentation waste distiller. The culture material is prepared from the following raw materials: 62 to 65 percent of crushed waste material, 27 to 30 percent of fermentation waste distiller, 2 to 3 percent of bran, 0.8 to 1.2 percent of calcium superphosphate, 1.8 to 2.5 percent of quicklime, and 1 percent of gypsum powder. The edible fungi such as Agaricus bisporus, brown spore mushrooms, mushrooms and the like produced by utilizing the cellulosic ethanol factory waste material has good mouthfeel, high protein content, and low content of heavy metals and pesticides, and meets the standard of pollution-free edible fungi.

Owner:河南天冠纤维乙醇有限公司

Preparation method of n-propionic acid chromium

InactiveCN107814697ANo crushing requiredHigh purityOrganic compound preparationCarboxylic acid salt preparationPropanoic acidCrystallization

A kind of preparation method of chromium n-propionate of the present invention, this method comprises the following steps: (1) salt-forming reaction step: put n-propionic acid, chromium oxide, initiator, water in the reactor, stir, heating reaction makes carbon dioxide overflow, Generate chromium n-propionate; (2) Drying step: Dry the granular product obtained by crystallization separation in a drying sieve with upper and lower air permeability. The obtained product is sieved to obtain the product. In the production process of the present invention, chromium oxide and an initiator are used to ensure that granular products are obtained, which is beneficial to drying, does not need to be pulverized, and avoids dust. At the same time, the present invention has the characteristics of simple realization and convenient operation, which saves investment in production equipment and improves production efficiency. Productivity.

Owner:TIANJIN CHEM REAGENT RES INST

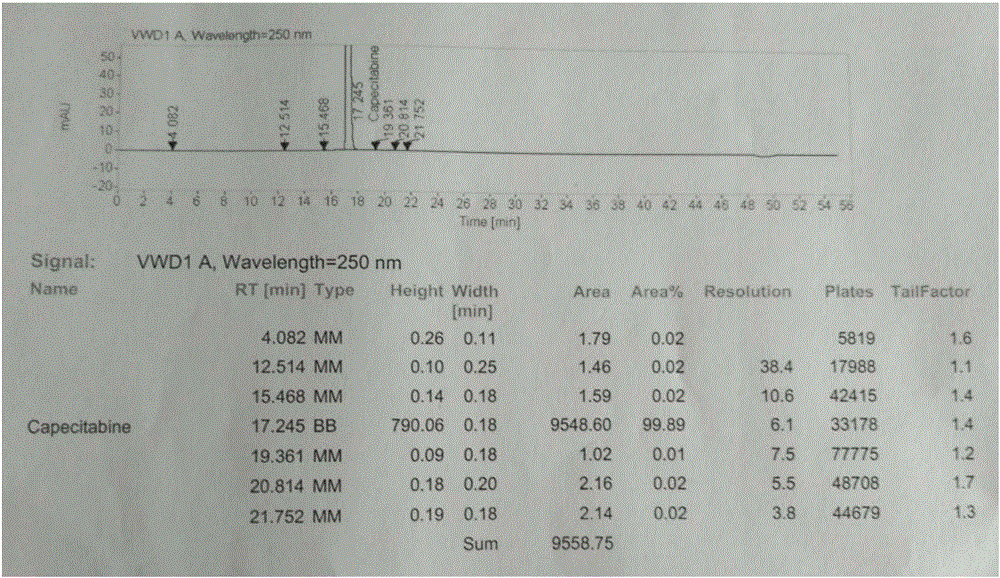

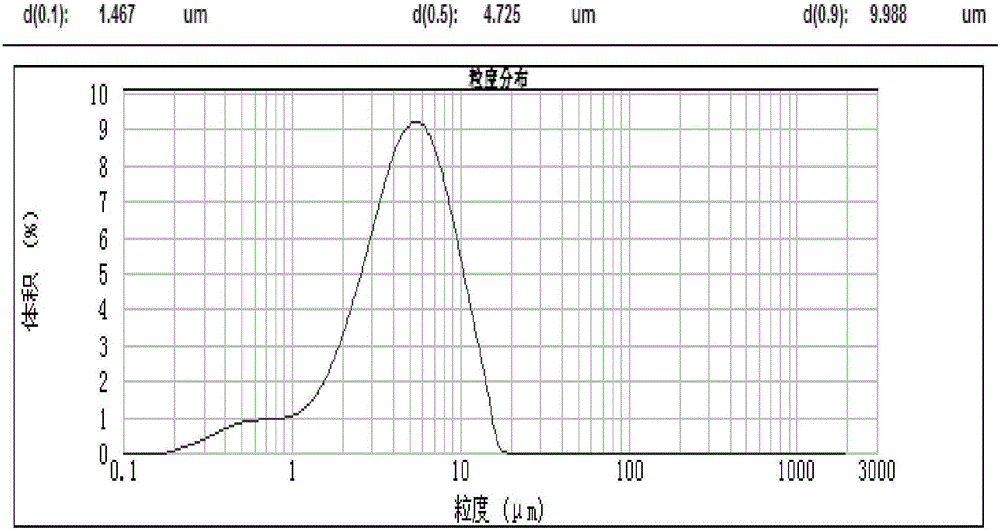

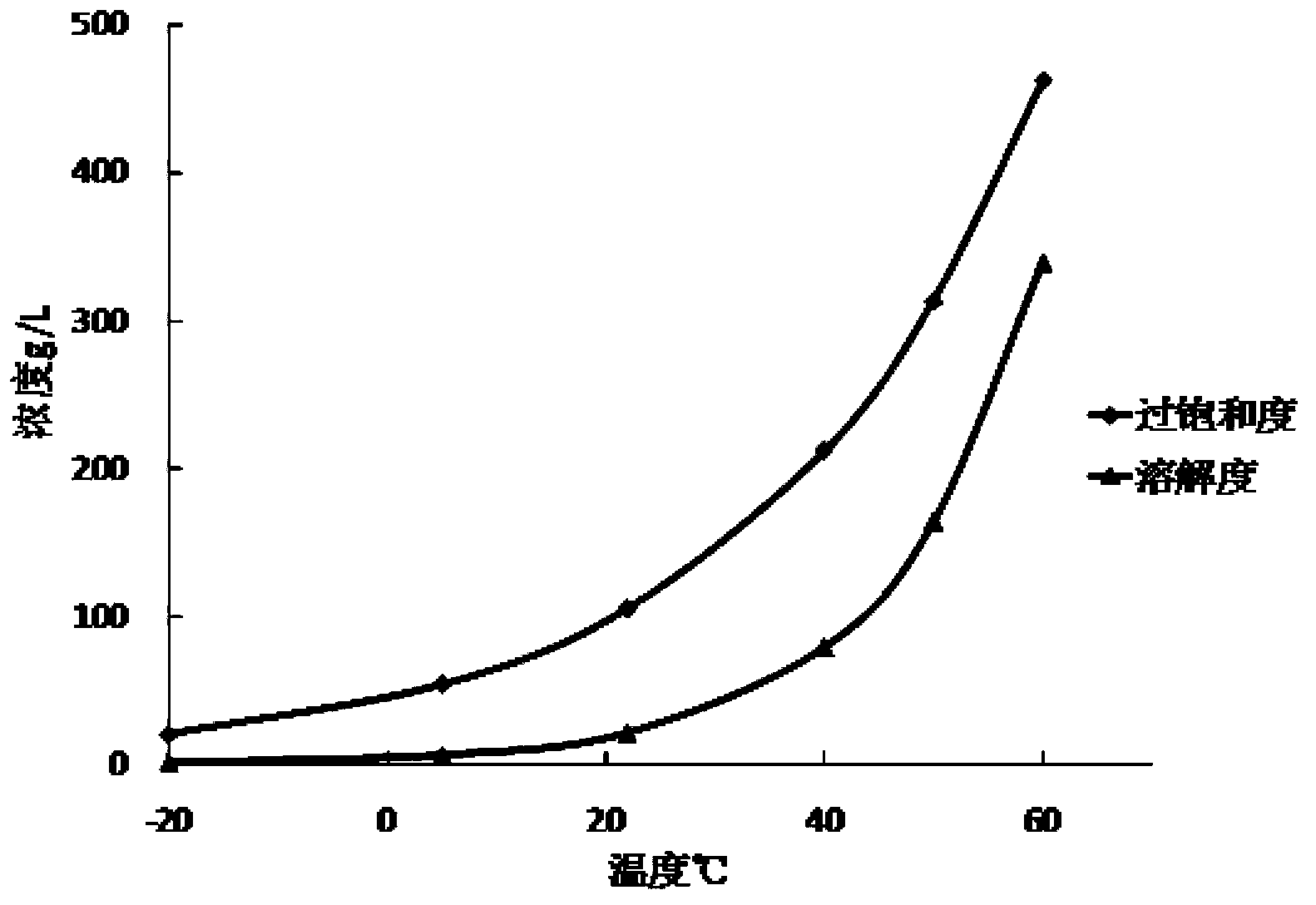

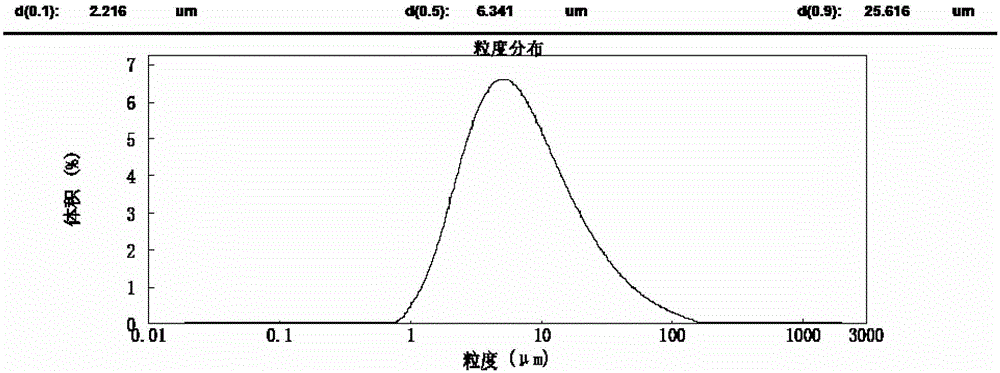

A method of preparing micro-powder-type capecitabine

ActiveCN106496294AEasy to operateImprove stabilitySugar derivativesOrganic chemistry methodsChemistryTetrahydrofuran

The invention discloses a method of preparing micro-powder-type capecitabine. The method includes the steps of adding a capecitabine crude product to tetrahydrofuran to dissolve the capecitabine crude product, and under stirring, adding an ether solvent, performing temperature-maintained crystallization, and reducing the temperature, suction-filtering the solution and drying the solution to obtain the micro-powder-type capecitabine. Particle size of the product is d (0.1) <= 2 [mu]m, d (0.5) <= 5 [mu]m and d (0.9) <= 12 [mu]m. The method has simple operations and high stability and is beneficial to industrial modeled production.

Owner:山东安信制药有限公司

Preparation method for zinc citrate

InactiveCN105218357AHigh purityKeep dryCarboxylic acid salt preparationSpontaneous combustionSulfate

The invention relates to a preparation method for zinc citrate. The preparation method comprises the following steps: (1) a salt forming reaction step: adding citric acid, zinc oxide, an initiator and water in a molar ratio of 1 to 15 to (0.5-0.6) to (0.02-0.05) into a reaction kettle to obtain a mixture, heating the mixture to 70-80 DEG C while stirring, reacting the mixture for 5-7 hours for releasing carbon dioxide, thereby obtaining zinc citrate; and (2) a drying step: centrifugally separating the zinc citrate obtained in the step (1) to obtain granular zinc citrate, putting the granular zinc citrate into a drying sieve to dry in a drying oven, and sieving the granular zinc citrate after drying the granular zinc citrate, thereby obtaining a finished product zinc citrate. According to the preparation method, citric acid is used to replace sodium citrate and zinc oxide is used to replace zinc sulfate; the obtained product is zinc citrate which is single, high in purity, granular and easy to dry after being separated, so that spontaneous combustion risks are relieved; and the obtained product does not need to crush, so that much dust is avoided.

Owner:TIANJIN CHEM REAGENT RES INST

Method for preparing zinc gluconate

InactiveCN105294425AHigh purityKeep dryCarboxylic acid salt preparationSulfate zincSpontaneous combustion

The invention relates to a method for preparing zinc gluconate. The method comprises the following steps of (1) conducting a salt-forming reaction step, namely putting gluconic acid, zinc oxide, initiator and water into a reaction kettle, conducting stirring and a heating reaction to spill out carbon dioxide and generate zinc gluconate; and (2) conducting a drying step, namely drying the granular product which is obtained by separation in a drying screen which is ventilated from top to bottom, and screening the obtained product to obtain the zinc gluconate. According to the preparation method, in the material charging step, the gluconic acid is used to replace sodium gluconate, and zinc oxide is used to replace zinc sulfate, so that only zinc gluconate is obtained. The single granular product zinc gluconate has high purity, can be easily dried after being separated, so that the risk of spontaneous combustion is cleared, the prepared product is not needed to be ground, and massive dust can be avoided.

Owner:TIANJIN CHEM REAGENT RES INST

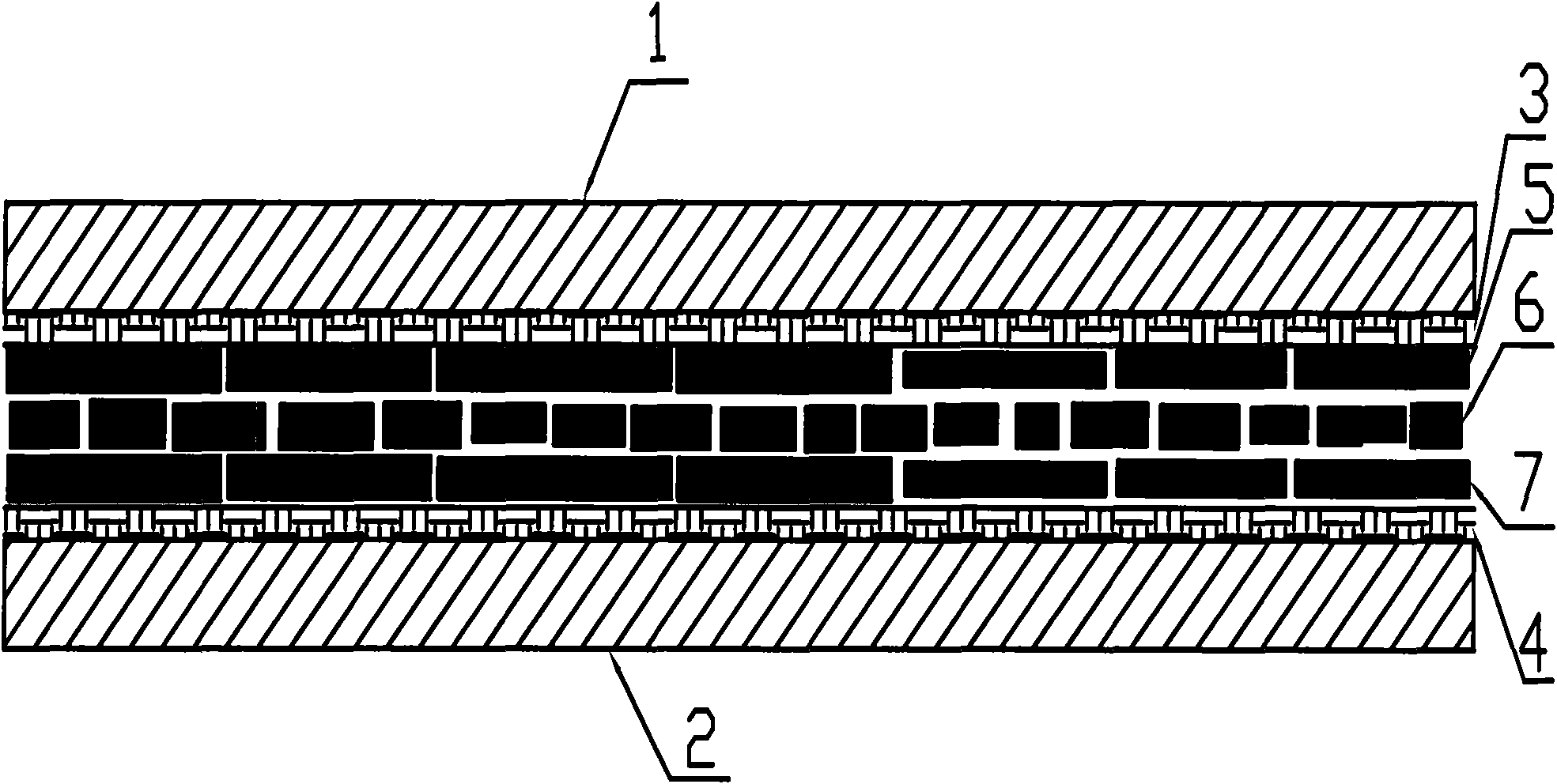

Method for manufacturing building template by using waste circuit board

InactiveCN101607461ASimple production processNo crushing requiredLamination ancillary operationsLaminationGlass fiberArchitectural engineering

The invention discloses a method for manufacturing a building template by using a waste circuit board, aims to overcome the defects of the prior art, and provides the method for manufacturing the building template by the waste circuit board, which can directly use the waste circuit board and has simple process, low cost and easy implementation. The method comprises the following steps: splicing the waste circuit boards according to the thickness and the size of the building template, painting resin adhesive on the waste circuit boards while splicing; spreading glass fiber cloth on two sides to coat the spliced board inside, and painting the resin adhesive on glass fiber; and curing the manufactured template in a mould to produce the building template. The method can be used for utilizing the waste circuit boards.

Owner:SHANGHAI QIMOU ENERGY SOURCE TECH DEV

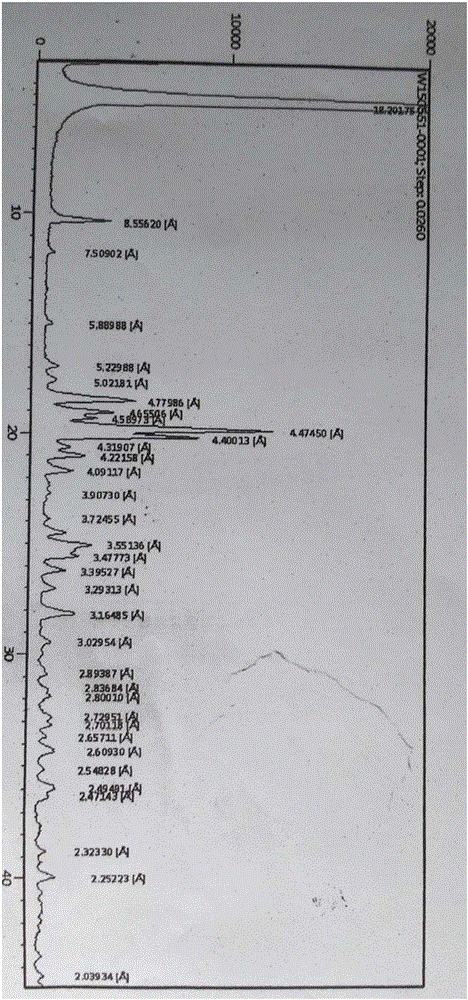

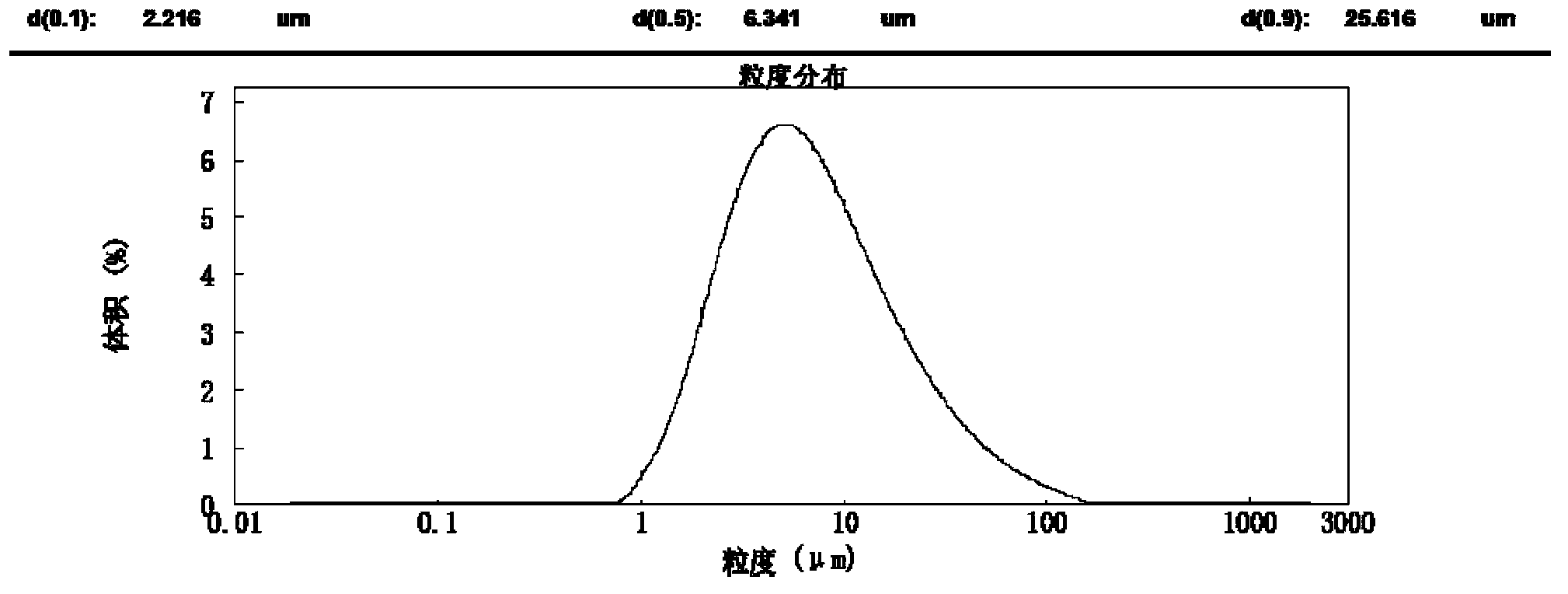

Preparation method of micro-powder capecitabine

ActiveCN103509072AUniform particle sizeHigh dissolution rateSugar derivativesSugar derivatives preparationAcetic acidFiltration

The invention relates to a preparation method of micro powder capecitabine, the method is as follows: adding a capecitabine crude product into ethyl acetate, dissolving by heating, cooling to a condition that capecitabine reaches a saturation state in the ethyl acetate, adding capecitabine seed crystal, and obtaining the micro powder capecitabine by thermal insulation crystallization, cooling, filtration and drying. The micro powder capecitabine prepared by the method is high in purity and uniform in particle size, does not generate static electricity, does not agglomerate, good in fluidity, easy for scale production, can well ensure the quality homogeneity of a preparation, and makes clinical medication safer.

Owner:QILU PHARMA HAINAN +1

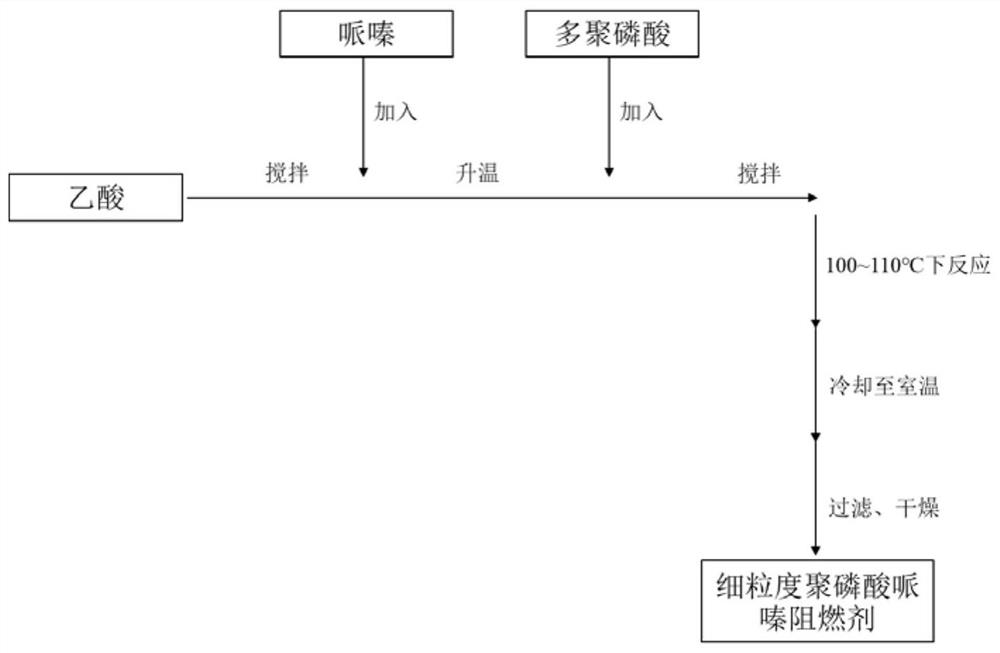

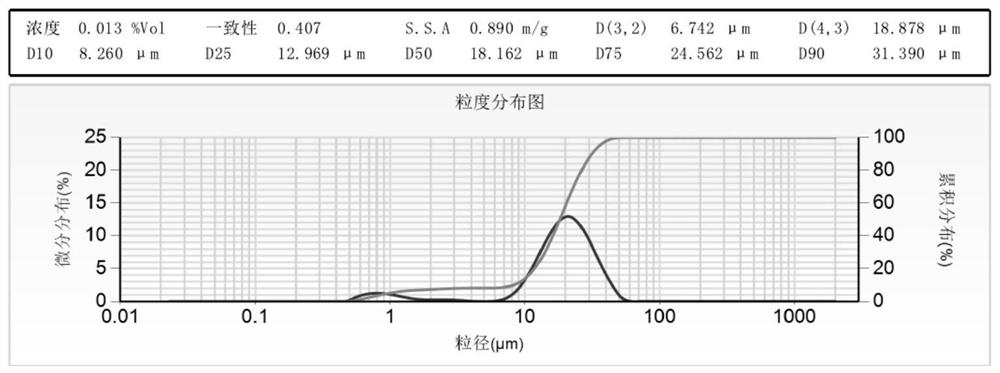

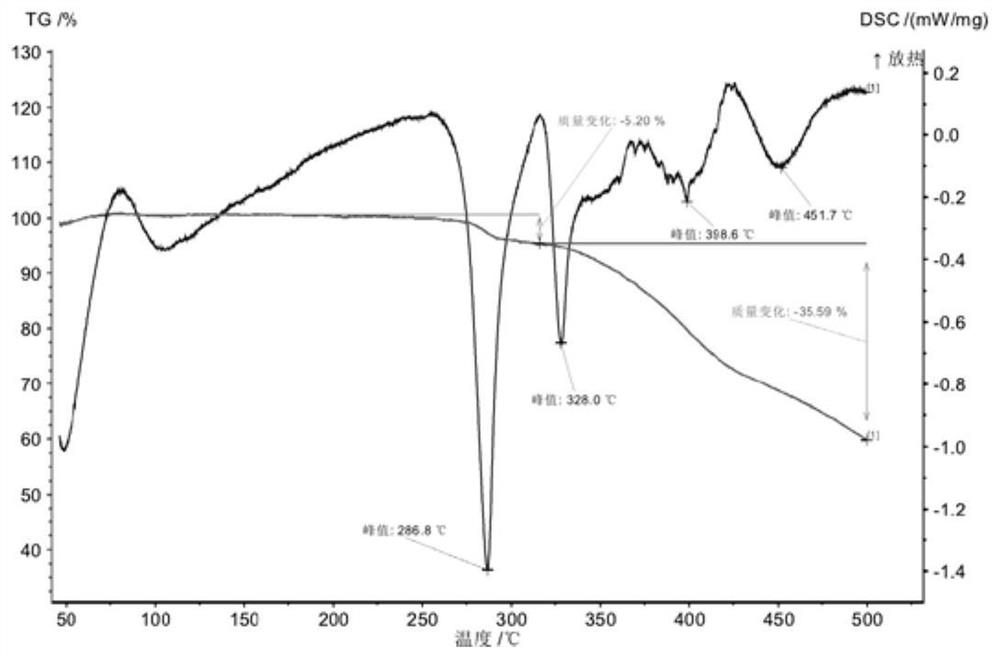

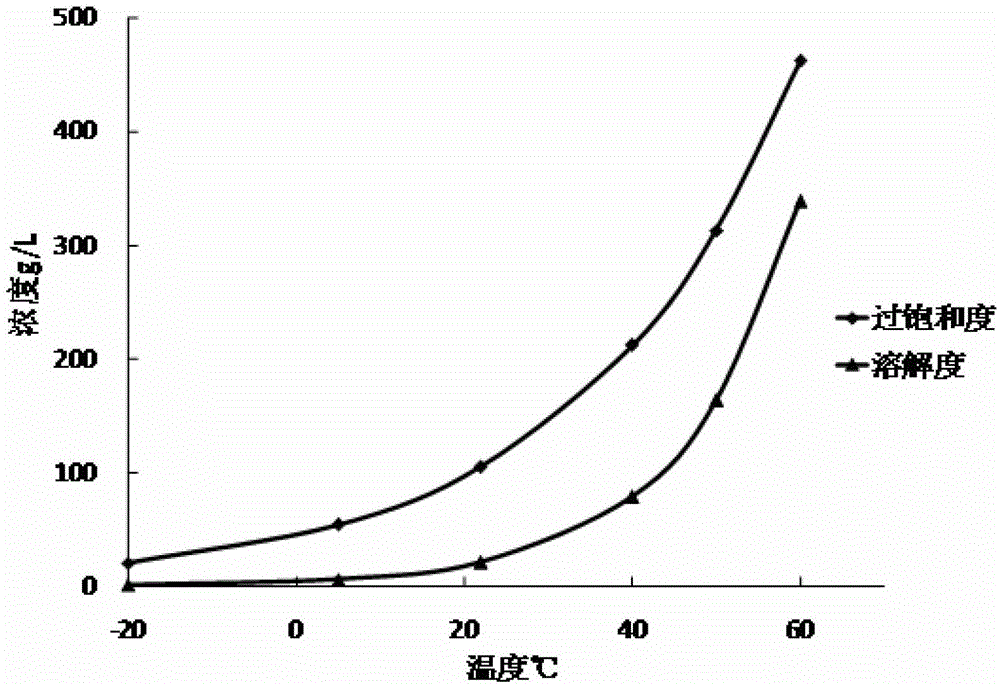

Fine-grained polypiperazine phosphate flame retardant as well as preparation method and application thereof

The invention discloses a fine-grained polypiperazine phosphate flame retardant. The particle size D50 of the fine-grained polypiperazine phosphate flame retardant is less than 20 [mu]m. The inventionalso discloses a preparation method of the fine-grained polypiperazine phosphate flame retardant. The preparation method comprises the following steps: adding acetic acid into a reaction device, adding piperazine under stirring, heating; adding polyphosphoric acid, stirring, reacting at 100-110 DEG C; cooling to the room temperature, filtering, and drying to obtain the fine-grained polypiperazinephosphate flame retardant. The method can be used for directly preparing the polypiperazine phosphate flame retardant with a small particle size, the product can be used without a crushing procedureafter being dried, and the acetic acid filtrate obtained by filtering after reaction can be directly used for the next reaction without treatment.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH +1

A kind of preparation method of micropowder capecitabine

ActiveCN103509072BUniform particle sizeNo crushing requiredSugar derivativesSugar derivatives preparationAcetic acidGranularity

Owner:QILU PHARMA HAINAN +1

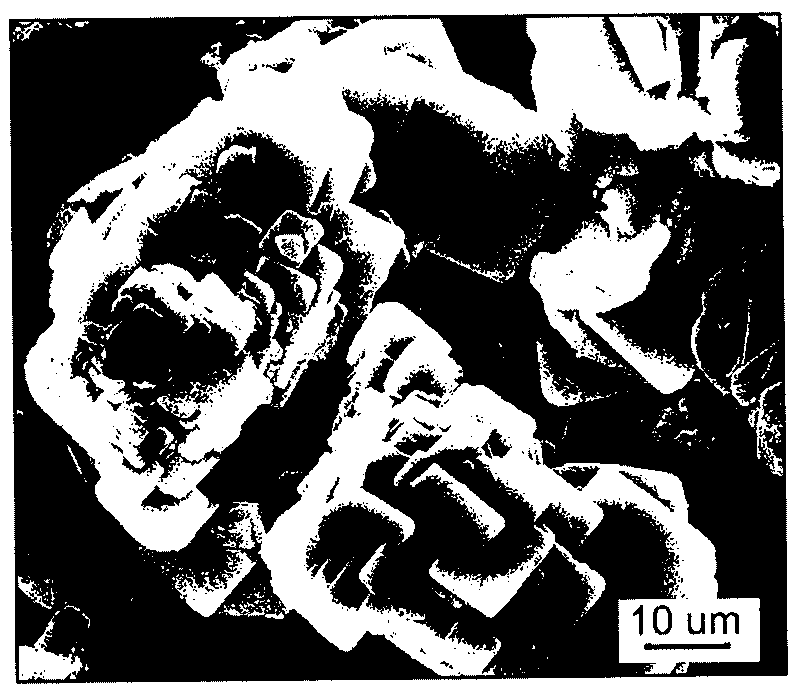

Preparation method of chromium phosphate

InactiveCN103274382ANo crushing requiredHigh purityPhosphorus compoundsPhosphoric acidChromium phosphate

The invention discloses a preparation method of chromium phosphate. The preparation method comprises the following steps of: (1), adding phosphoric acid, chromium oxide, an initiator and water to a reaction kettle, stirring and heating up, so that carbon dioxide is overflowed to generate chromium phosphate; (2), crystallizing and separating the chromium phosphate generated in the step (1) to obtain a granular product, and placing the product in a drying sieve which is ventilate from top to bottom for drying and sieving to obtain the product. According to the preparation method of the chromium phosphate, byproducts are not generated in the reaction, the generated chromium phosphate is high in purity and granular, the separated product is easy to dry, the use of drying equipment is reduced, the production cost is lowered, the obtained crystallized product is unnecessary to crush, and most dust is avoided. Besides, the preparation method of the chromium phosphate is convenient to operate, simple and easy to implement and capable of improving production efficiency, and conveniently realizes industrial production.

Owner:TIANJIN CHEM REAGENT RES INST

Silicon-containing composite material and its preparation method and application

ActiveCN101210119BSimple processReduce energy consumptionPigment treatment with macromolecular organic compoundsState of artLithium

The invention provides a siliceous composite material, comprising silicon particles and a clad wrapped on the surface of silicon particles, wherein, the clad is conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as the clad; the polymer does not need to be transformed further into 'hard carbon', and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is ensured to have high reversible capacity and good cycle performance. Therefore, the invention can be taken as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Silicon-containing composite material and its preparation method and application

ActiveCN101210112BSimple processReduce energy consumptionCell electrodesPigment treatment with macromolecular organic compoundsLithiumConductive polymer

The invention provides a siliceous composite material, comprising silicon particles, graphite particles and conducting polymer, wherein, the conducting polymer is wrapped on the surface of the graphite particles; at least part of the silicon particles is adhered to the surface of the conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as a clad material; the polymer does not need to be transformed further into 'hard carbon' and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is guaranteed to have high reversible capacityand good cycle performance. Therefore, the invention can be used as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Preparation method of chromium stearate

InactiveCN107814703ANo crushing requiredHigh purityOrganic compound preparationCarboxylic acid salt preparationParticulatesStearic acid

The present invention relates to a kind of preparation method of chromium stearate, this method comprises the following steps: (1) salt-forming reaction step, stearic acid, chromium oxide, initiator, water are put into reactor, stir, heating reaction, make carbon dioxide overflow , to generate chromium stearate; (2) drying step, the granular product obtained by crystallization separation is dried in the upper and lower air-permeable drying sieves. The obtained product is sieved to obtain the product. The granular product obtained by the preparation method of the chromium stearate is easy to dry, reduces protection and equipment, saves equipment investment, and reduces operating costs.

Owner:TIANJIN CHEM REAGENT RES INST

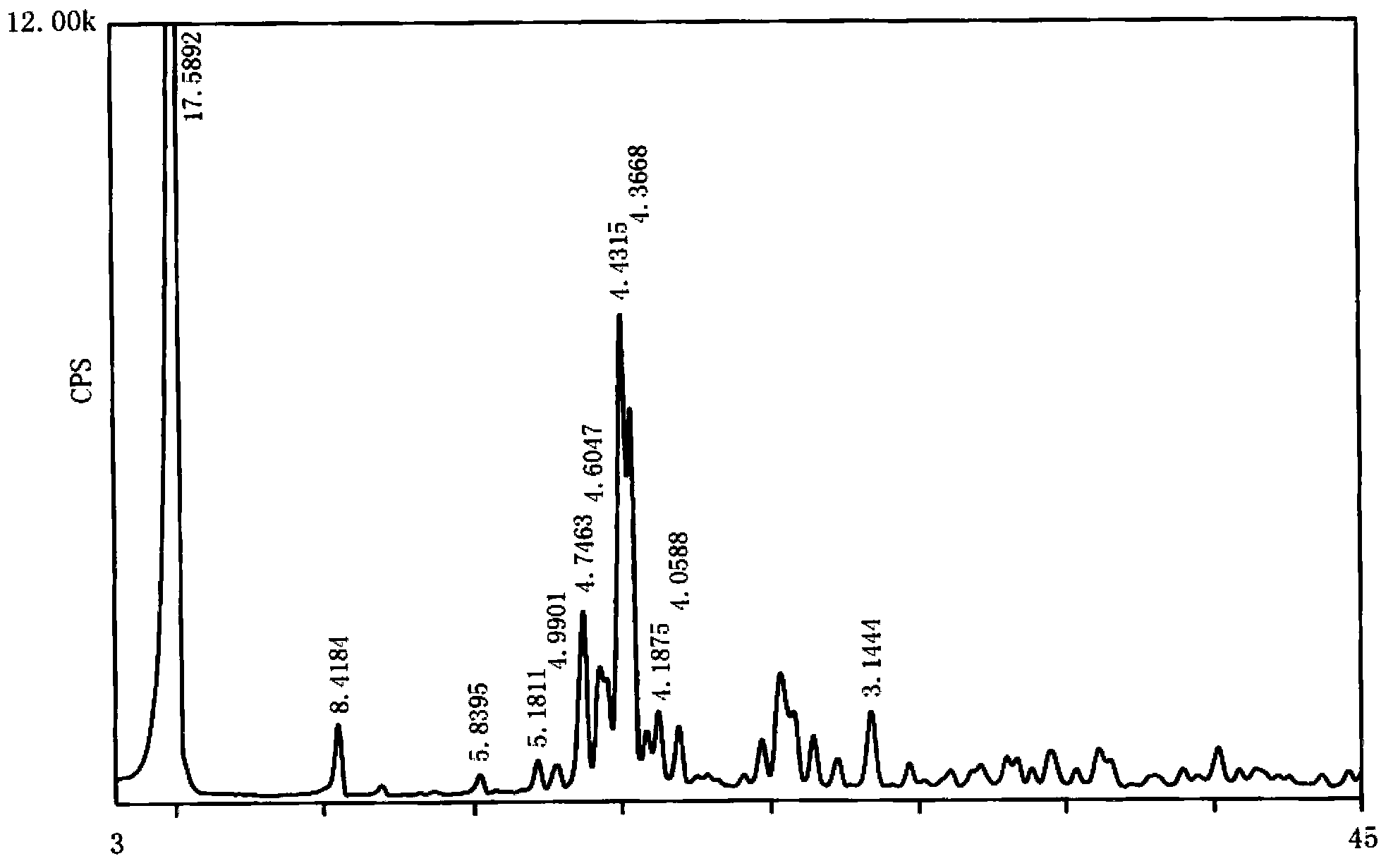

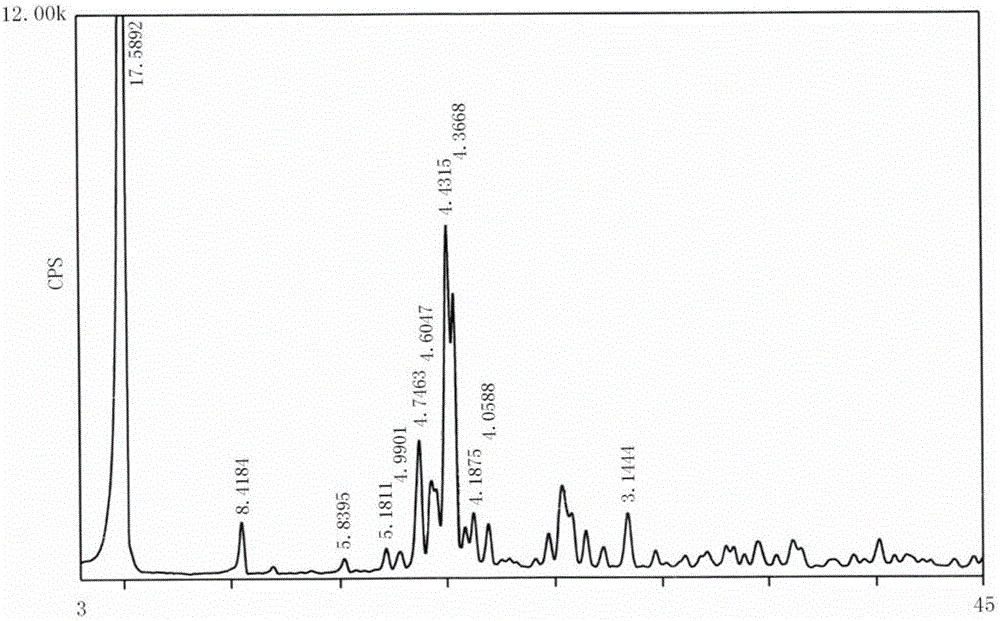

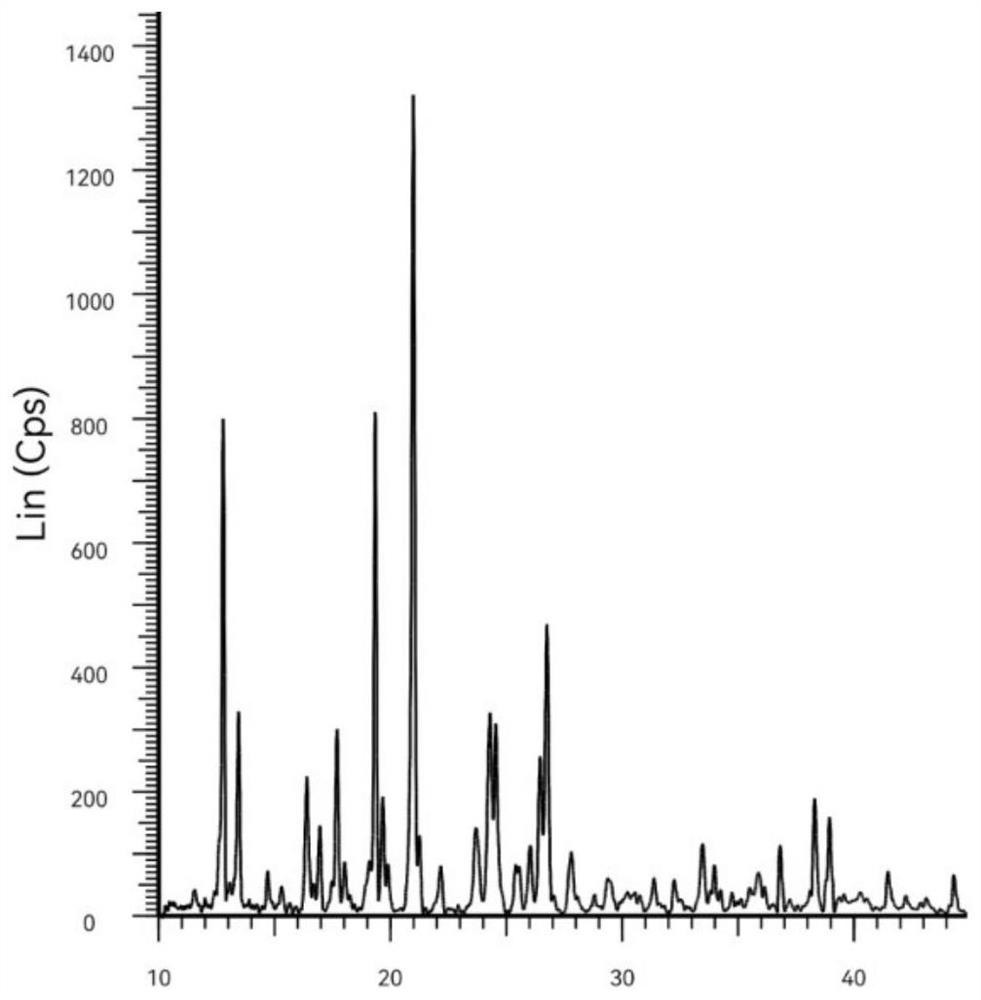

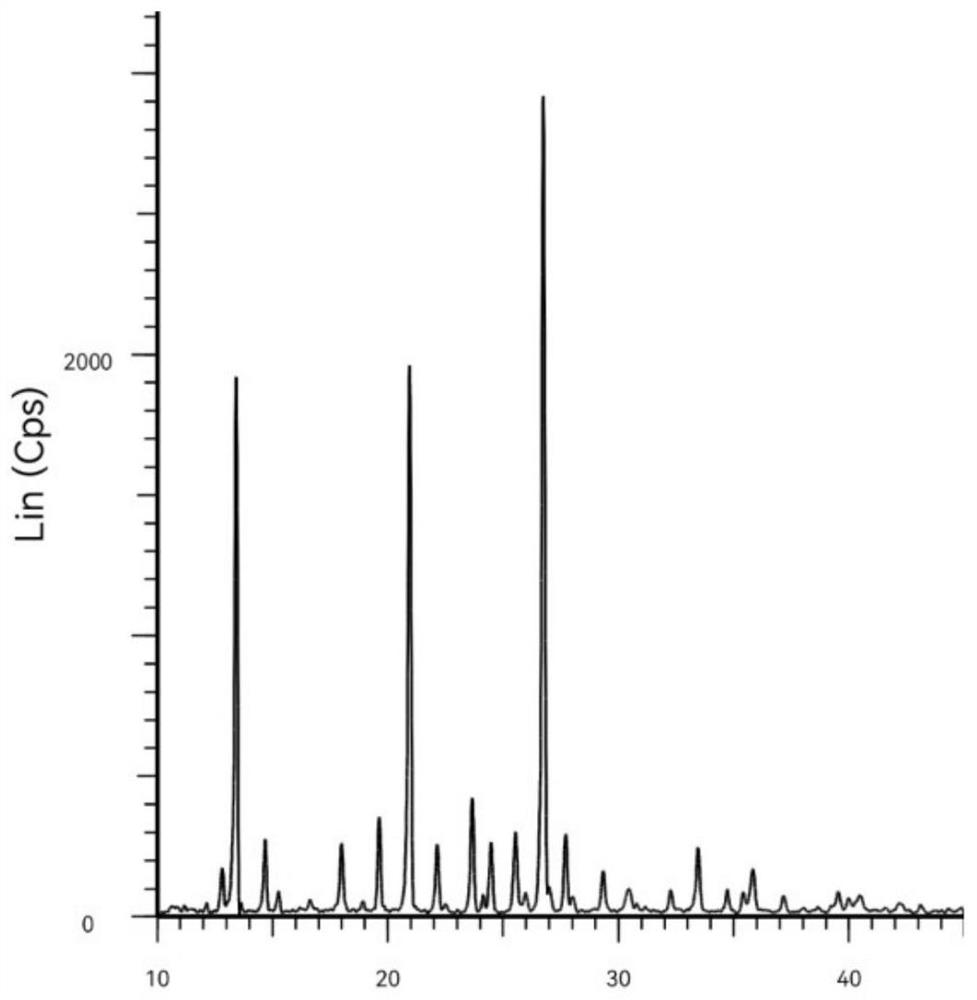

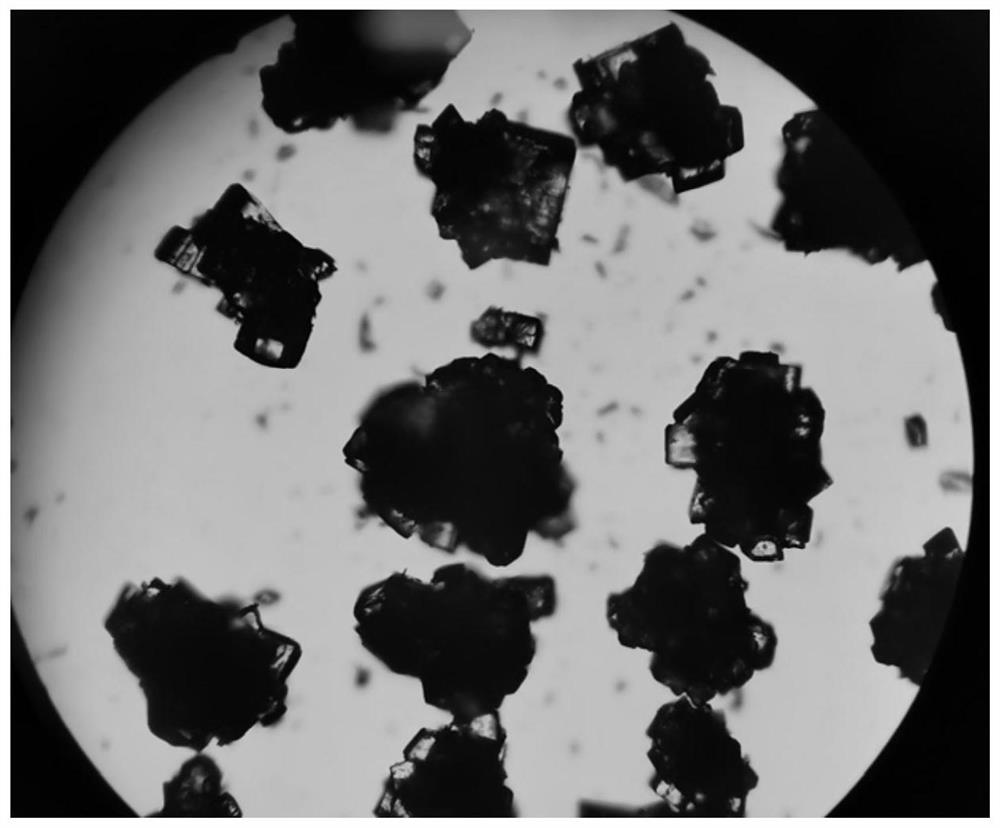

Cefixime side chain acid crystal form and preparation method thereof

PendingCN114315756AGood stabilityUniform primary particle size distributionOrganic chemistrySide chainAqueous solution

The invention belongs to the technical field of medicine crystallization, and particularly relates to a cefixime side chain acid crystal form and a preparation method thereof. The method comprises the following steps: dissolving cefixime side chain acid in a methanol aqueous solution, ultrasonically dissolving, and filtering; cooling the obtained filtrate in a jacketed kettle, crystallizing and growing the crystal while stirring, increasing the stirring speed to continue growing the crystal, and filtering; and washing and drying the obtained filter cake to obtain the cefixime side chain acid crystal form B. The HPLC (high performance liquid chromatography) content of the crystal form B of the side chain acid of the sporicloxime reaches 99.80% or above, and the crystal form B can be stored at room temperature for 6 months, has good stability and is very beneficial to storage of medicines; no aggregation phenomenon exists among crystals, and the main particle size distribution is uniform; according to the preparation method of the crystal form B of the cefixime side chain acid, the single-pass molar yield in the crystallization process is 85% or above, the technological operation is simple, and the preparation method is suitable for industrial production.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Preparing method for Reso octanoic acid manganese

InactiveCN106518661ASingle productHigh purityOrganic compound preparationCarboxylic acid salt preparationCarbon dioxideSieve

The invention relates to a preparing method for Reso octanoic acid manganese. The method comprises the steps of 1, salt forming reaction, wherein Reso octanoic acid, manganese sulfate, an initiator and water are put into a reactor, stirring is performed, and the reaction is heated to make carbon dioxide overflow and generate granular Reso octanoic acid manganese; 2, stoving, wherein the granular product obtained by crystalization and separation is put in an up-down ventilated drying sieve, stoving is performed, and the obtained product passes through the sieve to obtain the product. According to the preparing method for Reso octanoic acid manganese, the obtained granular product is easy to dry, reduces protection and devices, saves the equipment investment, and reduces the operation cost.

Owner:TIANJIN CHEM REAGENT RES INST

Method for preparing chrome resorcin-ate

InactiveCN105198736ANo crushing requiredHigh purityCarboxylic acid salt preparationSulfateReaction step

The invention relates to a method for preparing chrome resorcin-ate. The method includes the following steps of 1, the salt forming reaction step, wherein resorcin acid, chromic oxide, initiators and water are put into a reaction kettle in the molar ratio of 1:15:0.65-0.825:0.2-0.5, the mixture is heated to 70 DEG C to 80 DEG C while stirring, reacting is carried out for 5 h to 7 h to enable carbon dioxide to overflow, and the chrome resorcin-ate is obtained; 2, the drying step, wherein the chrome resorcin-ate crystals obtained in the step 1 are centrifugally separated to obtain granular chrome resorcin-ate, the granular chrome resorcin-ate is placed into a drying sieve to be dried in a drying box, sieving is carried out after drying, and the finished chrome resorcin-ate is obtained. According to the method, during material putting, sodium resorcin-ate is replaced by the resorcin acid, chromium sulfate is replaced by the chromic oxide, and the obtained product is only the chrome resorcin-ate; the product is single, high in purity, granular and easy to dry after being separated, the obtained crystal product does not need to be smashed, and a large amount of dust is avoided.

Owner:TIANJIN CHEM REAGENT RES INST

A process and device for continuously preparing powdery mes particles

ActiveCN103820253BReduce moisture contentPromote decompositionSurface-active detergent compositionsDetergent powders/flakes/sheetsCycloneBaghouse

The invention relates to a process and a device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles. A process flow is simple, and the provided preparation device is simple in structure. According to the technical scheme, the process for continuously preparing the powdery MES particles comprises the following steps of (1) causing a powdery mixture of a neutralizer, a wrapper and a stabilizer and fatty acid methyl ester acid ester to enter a high-shear reactor according to a certain proportion; (2) forming MES particles, and causing the MES particles to enter a flash dryer; (3) keeping the obtained MES particles at certain granularity; (4) causing mixed airflow discharged from an outlet of the flash dryer to enter a cyclone separator for separation; (5) obtaining a finished product. The device for continuously preparing the powdery MES particles comprises the high-shear reactor, the flash dryer, the cyclone separator, a bag-type dust collector and an induced draft fan, which are sequentially communicated, wherein the high-shear reactor is provided with an acid ester inlet, a powder inlet, an air inlet and a material outlet communicated with the flash dryer respectively.

Owner:ZANYU TECH GRP CO LTD +1

A kind of method for producing chromium oxide green by sodium cycle

The invention discloses a method for producing chromium oxide green through sodium circulation. The method comprises the following steps: adding powdery chromite ores or ferrochromium powder into an alkali solution and introducing oxidation materials for reaction, and separating to obtain a sodium chromate alkali solution after full reaction; adding organic reducing substances into the sodium chromate alkali solution, after hydrothermal reaction, filtering and separating to obtain chromic oxide hydrate and alkali filter liquor; performing countercurrent washing on the chromic oxide hydrate and recycling the washing liquid; calcining the chromic oxide hydrate after washing in a high temperature furnace to obtain chromium oxide green; concentrating and performing alkali modulation on the alkali filter liquor and the washing liquid, and further returning the alkali filter liquor and the washing liquid after concentration and alkali modulation, so as to serve as the alkali solution to realize cyclic utilization of sodium resource in the technological process. Compared with the conventional preparation process of chromium oxide green, the method for producing chromium oxide green, provided by the invention, has the advantages that the production technical process is short, the operation is simple, and the prepared chromium oxide green is high in quality; besides, cyclic utilization of sodium resources in the production technology process is realized, and zero emission of the three wastes is also realized, so that the method is an environment-friendly and clean novel method for producing chromium oxide green.

Owner:绵阳市安剑皮革化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com