Method for manufacturing building template by using waste circuit board

A technology for waste circuit boards and building templates, which is applied to the on-site preparation of building components, construction, building construction, etc., can solve the problems of increasing crushing equipment, increasing production processes and production costs, and reducing consumption and production costs. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

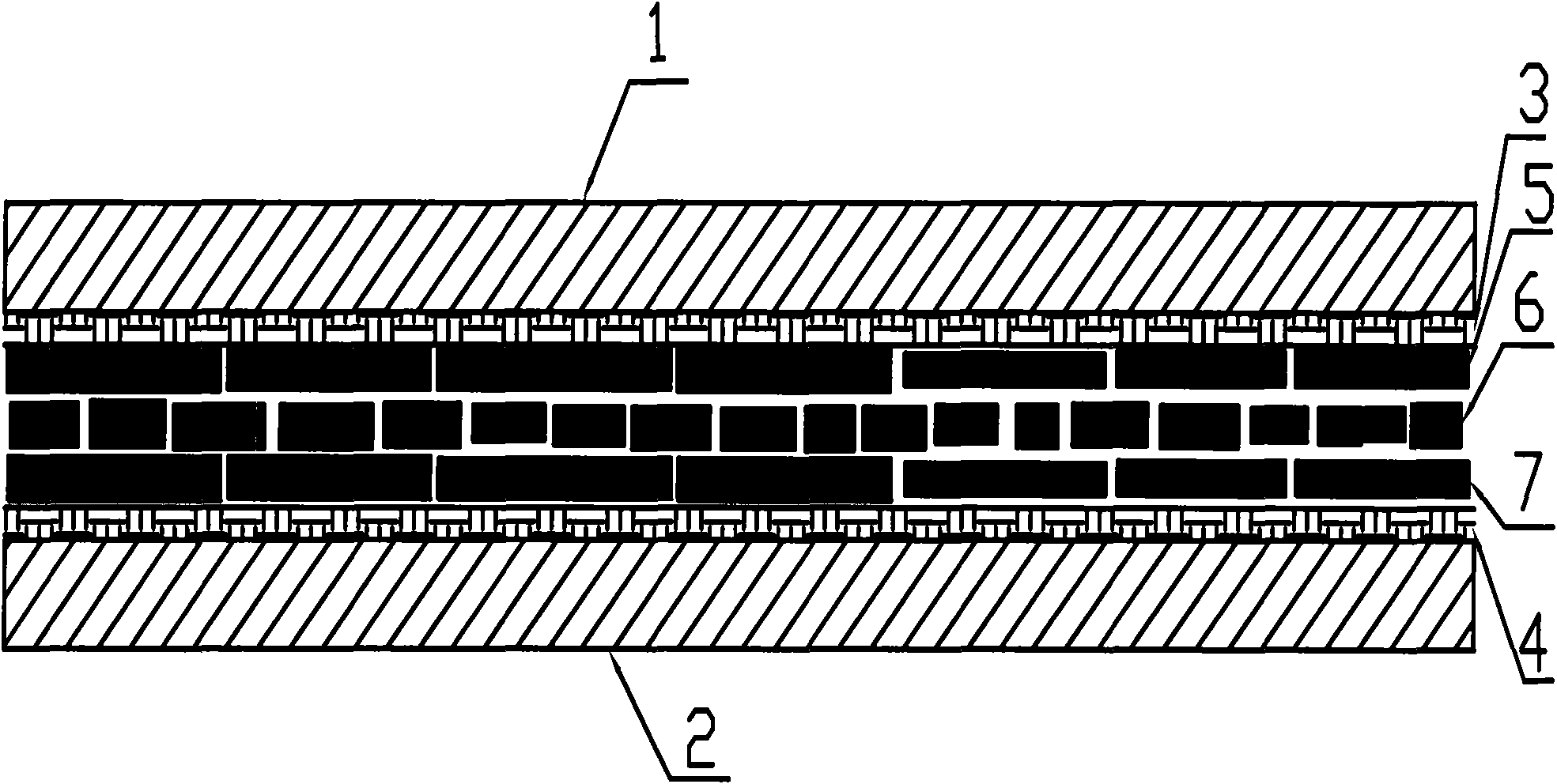

[0014] Refer to attached figure 1 , with figure 1 A schematic diagram of the principle of an embodiment of a method for making building templates provided by the present invention is described: After brushing the release agent on the lower plane plate 2, the lower glass fiber cloth 4 is spread on it, and on the glass fiber cloth 4 Brush FRP glue on top, then splice and place waste circuit boards 7 in the horizontal direction on top, brush the FRP glue and then splice and place waste circuit boards in the longitudinal direction 6, after brushing FRP glue, splice and place waste circuit boards in the horizontal direction Plate 5, cover the waste circuit board 5 with glass fiber cloth 3 on it, brush glass fiber reinforced plastic glue on the glass fiber cloth 3, then press the upper plane plate 1 that has been coated with a release agent, and take it out after curing. Architectural template.

[0015] The above-mentioned embodiments illustrate the present invention, but do not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com