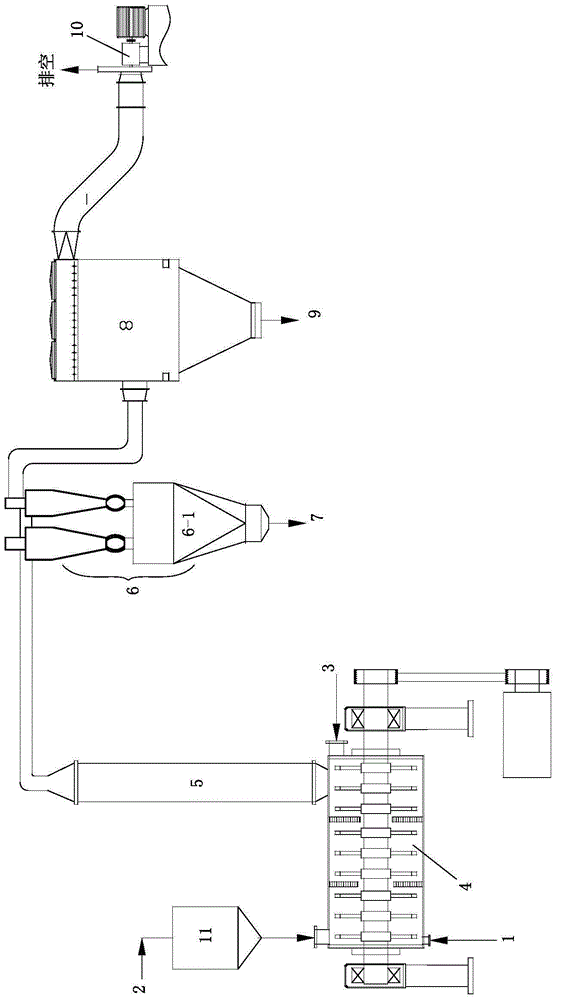

Process and device for continuously preparing powdery MES (fatty acid methyl ester sulfonate) particles

A technology for preparing devices and particles, which is applied in the preparation of detergents for liquid components, chemical instruments and methods, detergent powders/flakes/sheets, etc. It can solve the problems of poor solubility of MES particles at low temperature, complex process procedures, and low production efficiency. problems, to achieve the effect of improving low-temperature solubility, simple device structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

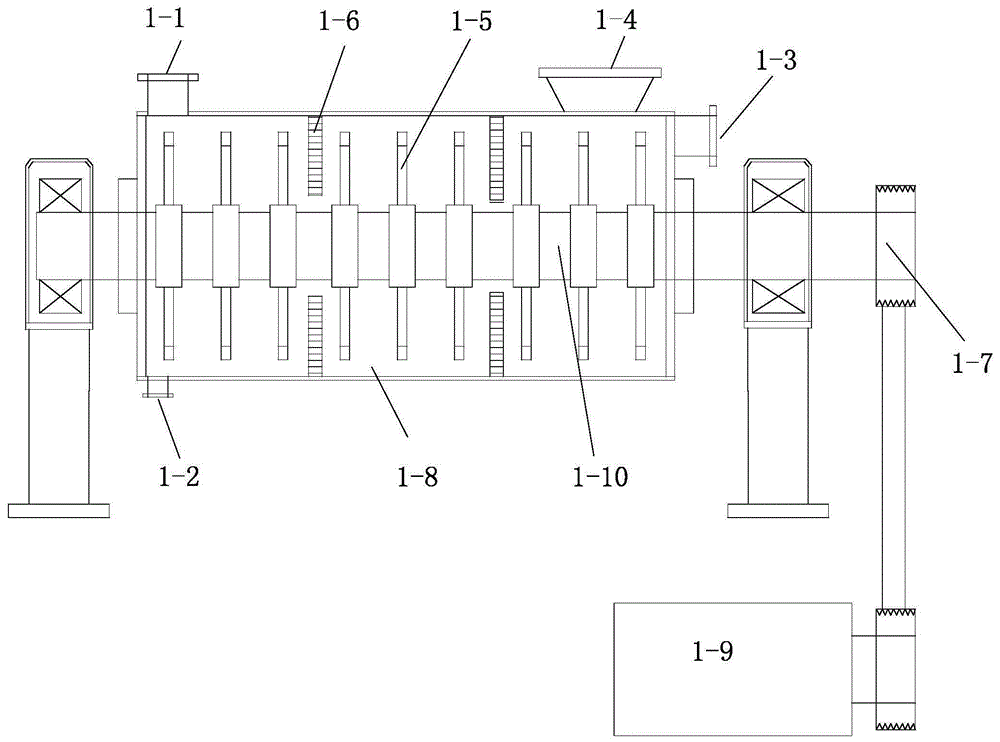

[0050] 1. 1t / h MES particle production line

[0051] Sodium carbonate, 4A zeolite, citric acid (weight ratio 7:9:1) enter the high-shear reactor at a flow rate of 700kg / h and fatty acid methyl ester at a flow rate of 300kg / h, and neutralize and granulate in it; The high-shear reactor is a reactor with a volume of 10L. The average residence time of the material is 10s, and the temperature is raised to 55°C after neutralization. In addition to neutralization to produce moisture; adjust the air pressure to control the particle size of the MES particles;

[0052] The final MES particle indicators are as follows:

[0053] indicators

[0054] 2. 1t / h MES particle production line

[0055] Sodium bicarbonate, sodium sulfate and sodium citrate (weight ratio 2:5:1) enter the high-shear reactor at a flow rate of 650kg / h, and fatty acid methyl ester esters at a flow rate of 350kg / h, where they are neutralized and produced The high-shear reactor uses a reactor with a volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com