A process and device for continuously preparing powdery AES particles

A particle and powder technology, which is applied in the field of manufacturing process of ethoxylated sodium alkyl sulfate particles, can solve the problem of large washing waste water, inability to use sodium ethoxylated alkyl sulfate for drying and powdering, and difficult to apply powder and other problems, to achieve the effect of uniform and controllable material particle size, to avoid the easy separation of the coating agent, and to improve the low temperature solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

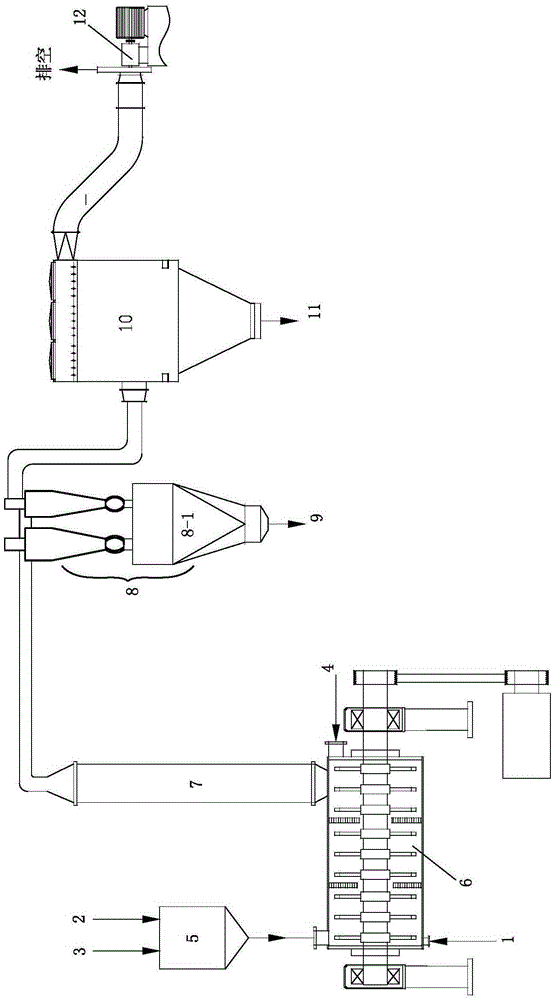

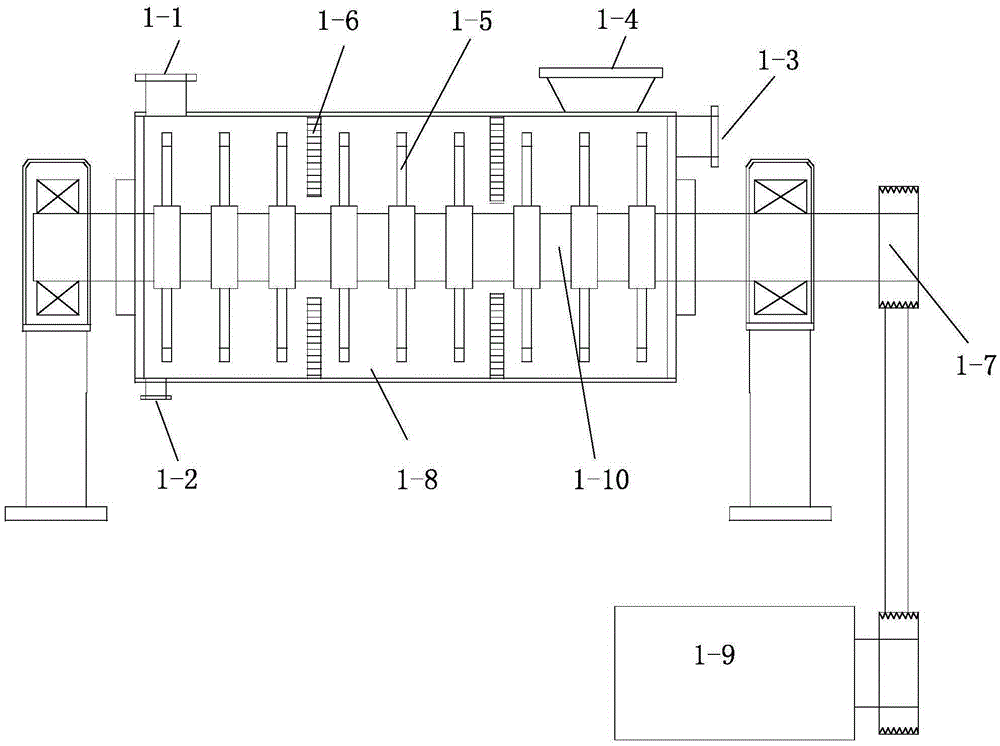

Method used

Image

Examples

Embodiment 1

[0048] 1. 1t / hAES particle production line

[0049] Sodium carbonate and 4A zeolite (weight ratio 2:5) enter the high-shear reactor at a flow rate of 700kg / h, and AEO ester at a flow rate of 300kg / h, and neutralize and granulate in it; the volume of the high-shear reactor is selected 10L reactor, the average residence time of the material is 10s, and the neutralization temperature is raised to 55°C; after that, the material is output and then enters the flash dryer, and the induced draft fan is turned on at the same time to rapidly cool down the material in the flash dryer and remove the moisture generated by neutralization; adjust Air pressure controls the particle size of the AES particles;

[0050] The resulting AES particle indicators are as follows:

[0051] indicators

result

30.6

Bulk density, g / ml

0.66

Particle size D90, μm

380

[0052] 2. 1t / hAES particle production line

[0053] Sodium carbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com